Exploring Stihl Parts Diagrams for Ultimate Maintenance and Repair

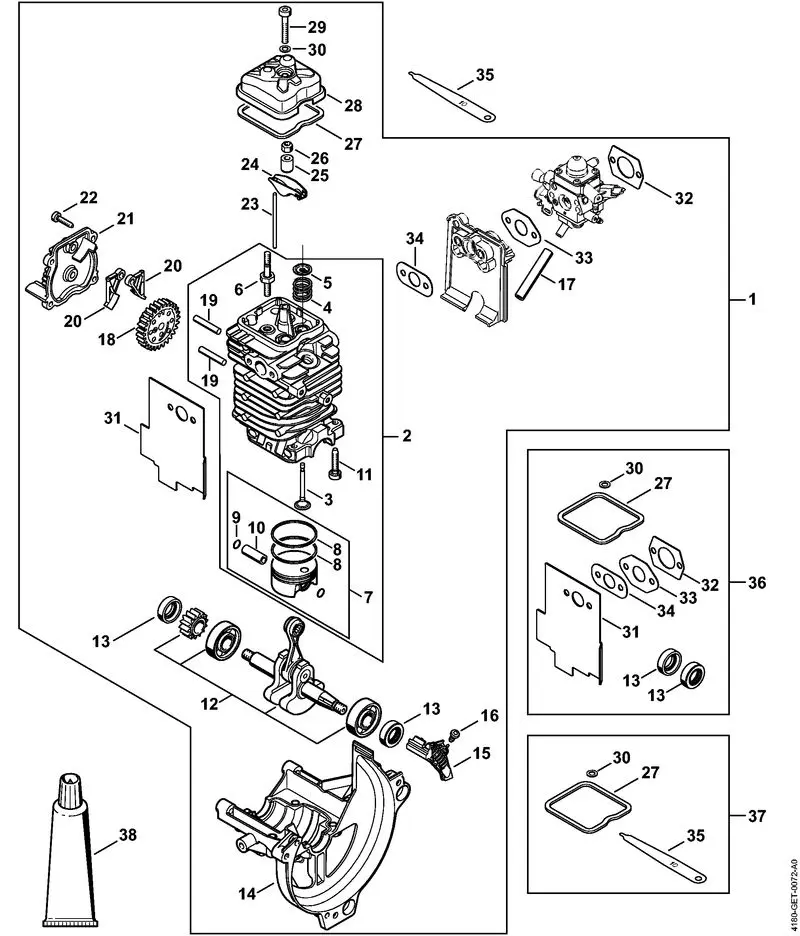

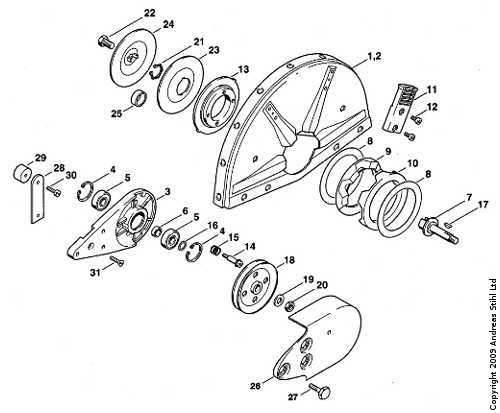

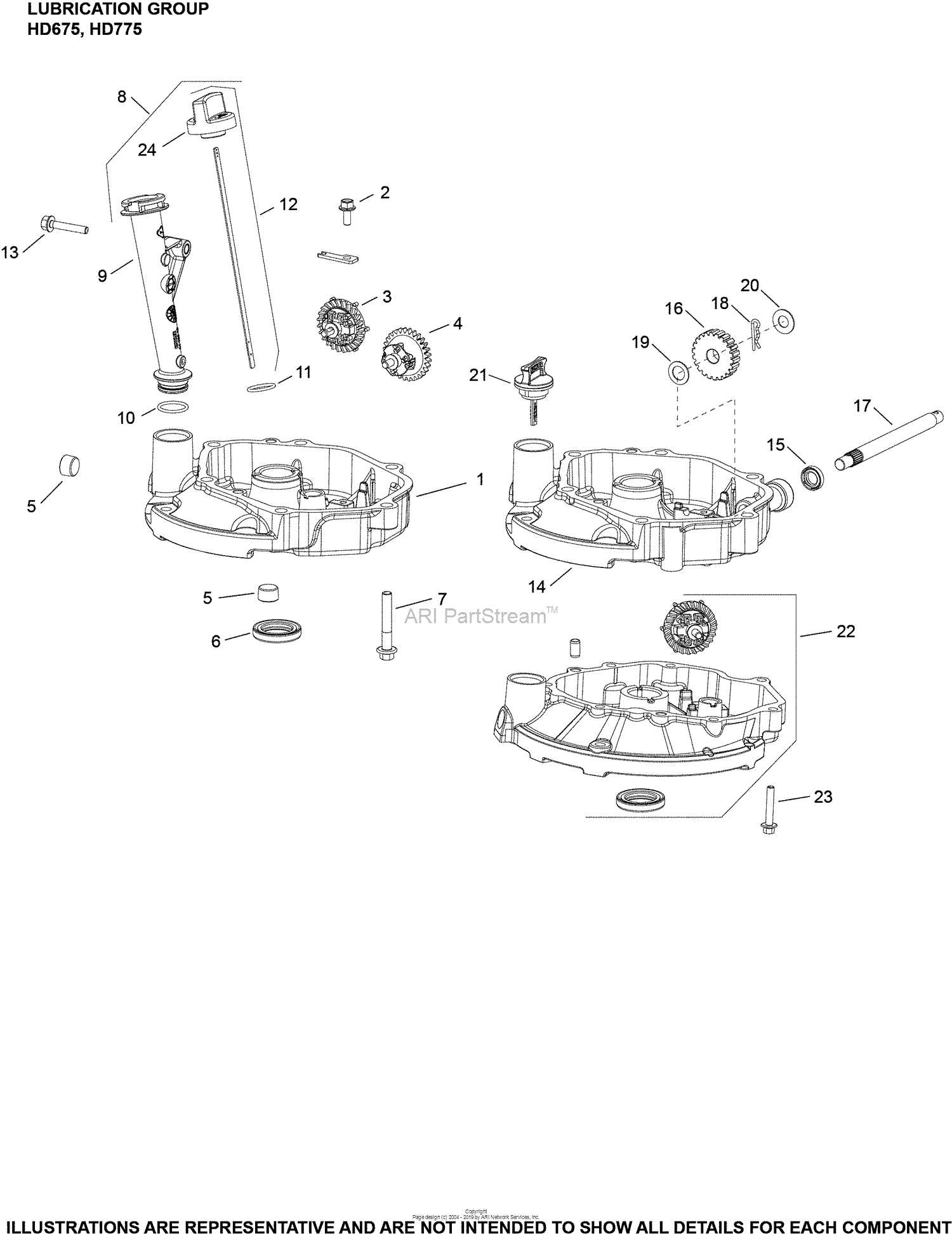

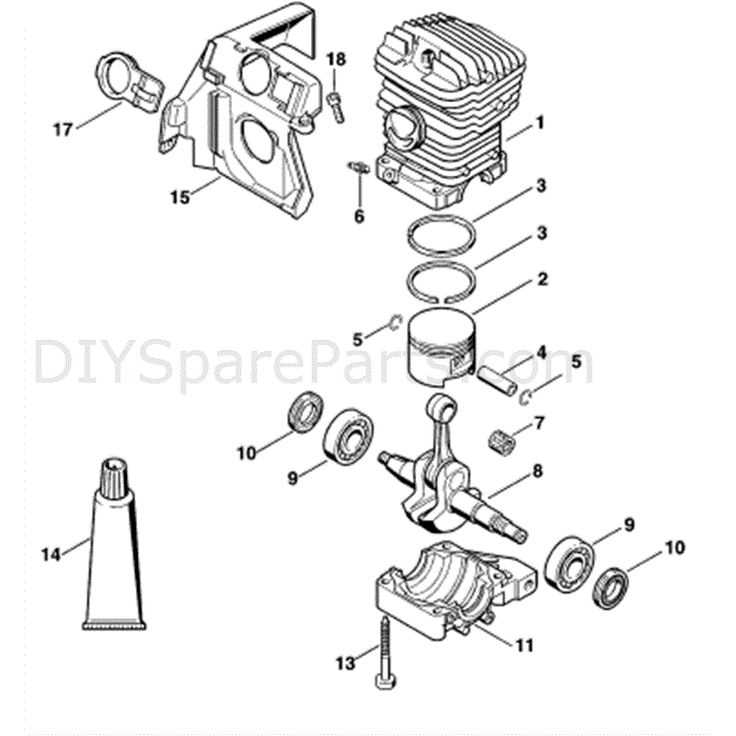

When it comes to maintaining and repairing outdoor machinery, having a clear visual reference can make all the difference. These instructional illustrations serve as invaluable tools for both seasoned technicians and enthusiastic DIYers. They break down complex structures into manageable components, simplifying the process of identification and replacement.

Each visual reference offers a detailed overview of the machine’s configuration, highlighting the various elements that contribute to its functionality. This clarity not only aids in understanding how different parts work together but also enhances the efficiency of repairs and maintenance. With a comprehensive view at hand, users can approach their projects with confidence, knowing they have the right information to guide them.

Moreover, these guides often include essential details about compatibility and specifications, ensuring that users can source the correct components for their specific models. This attention to detail is crucial in preventing potential issues during repairs and maximizing the longevity of the equipment. Embracing these resources ultimately empowers users to take control of their machinery, leading to smoother operations and improved performance.

Understanding Stihl Parts Diagrams

Gaining insight into assembly illustrations is essential for anyone involved in maintenance or repair of outdoor power equipment. These visual guides serve as invaluable tools, simplifying the process of identifying components and their relationships within a machine. By interpreting these representations accurately, users can ensure efficient troubleshooting and effective restoration of their devices.

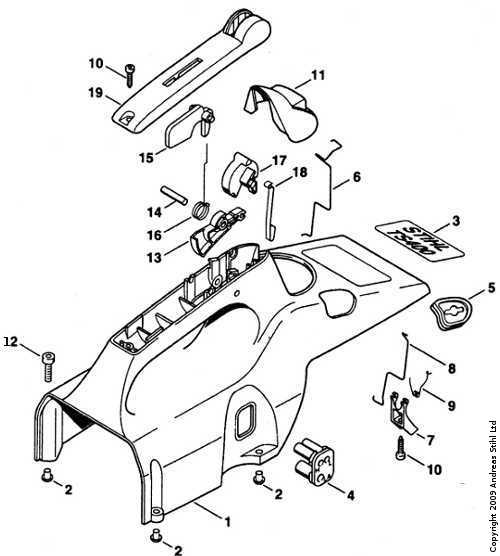

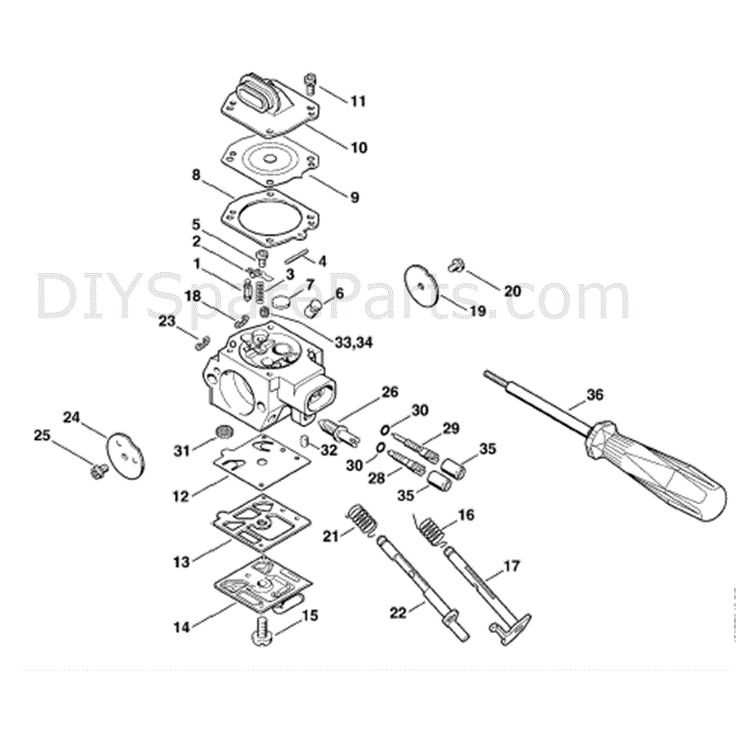

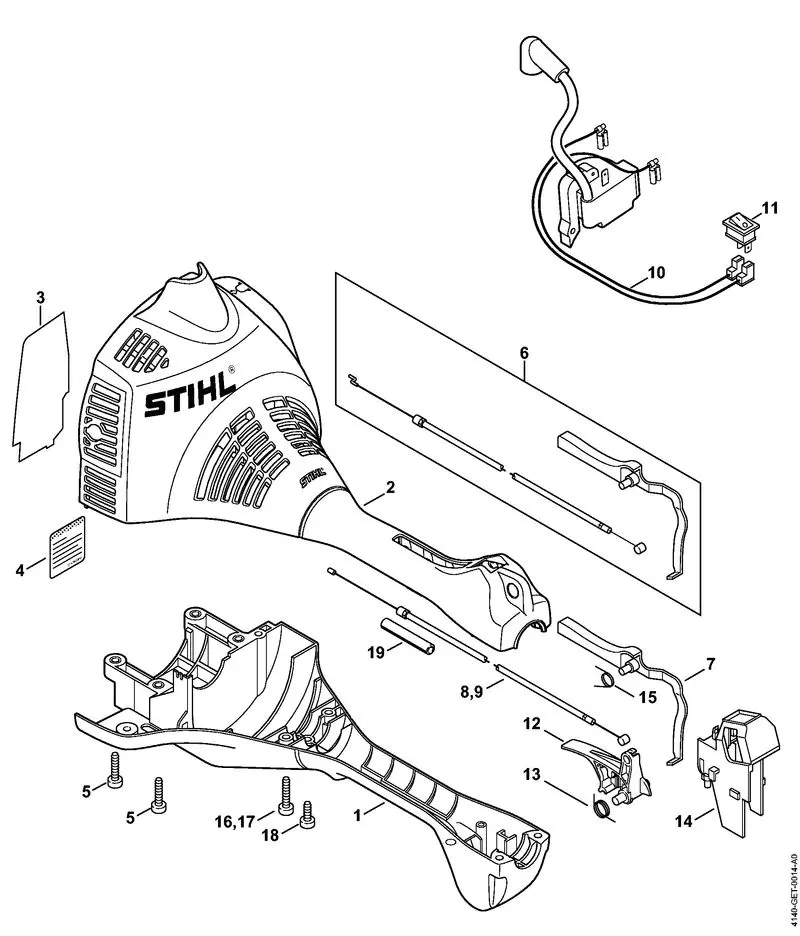

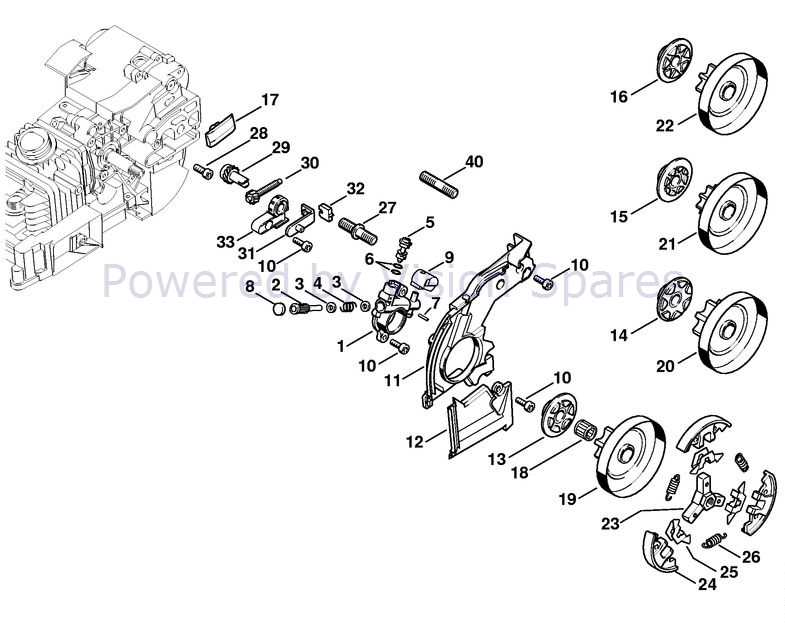

First and foremost, it’s important to recognize that these illustrations typically break down a machine into its individual elements. Each section showcases specific items, often labeled with unique identifiers. This allows for easier navigation when sourcing replacements or understanding how various pieces interact with one another.

Moreover, familiarizing oneself with common symbols and notations found in these visual guides can greatly enhance comprehension. Many illustrations employ standardized icons to denote functions, making it easier to discern the role of each component. As users become adept at reading these symbols, their confidence in handling repairs and maintenance tasks will undoubtedly grow.

Lastly, accessing and utilizing these resources can significantly reduce downtime and improve overall performance. Whether for routine upkeep or more extensive repairs, a clear understanding of these graphical aids can empower users to tackle challenges effectively, ensuring their equipment operates at peak efficiency.

Importance of Accurate Parts Identification

Ensuring the precise recognition of components is crucial in maintaining the efficiency and longevity of any machinery. Misidentifying elements can lead to operational failures, increased downtime, and potentially costly repairs. Therefore, having a clear understanding of each individual piece is vital for effective maintenance and overall performance.

Enhancing Efficiency

When components are accurately identified, it becomes easier to obtain the correct replacements or necessary adjustments. This streamlined process minimizes delays and helps in keeping operations running smoothly. Additionally, knowing the exact specifications of each part aids in troubleshooting, allowing for quicker resolutions to mechanical issues.

Cost-Effectiveness

Proper identification of individual elements can significantly reduce expenses. By ensuring that only the required components are replaced or serviced, one can avoid unnecessary expenditures associated with incorrect purchases or labor. Furthermore, this attention to detail can extend the life of machinery, resulting in long-term savings.

In summary, accurate identification of components is essential for optimal functionality and cost management. Investing time in understanding each piece not only enhances performance but also contributes to overall efficiency.

Common Stihl Tools and Their Schematics

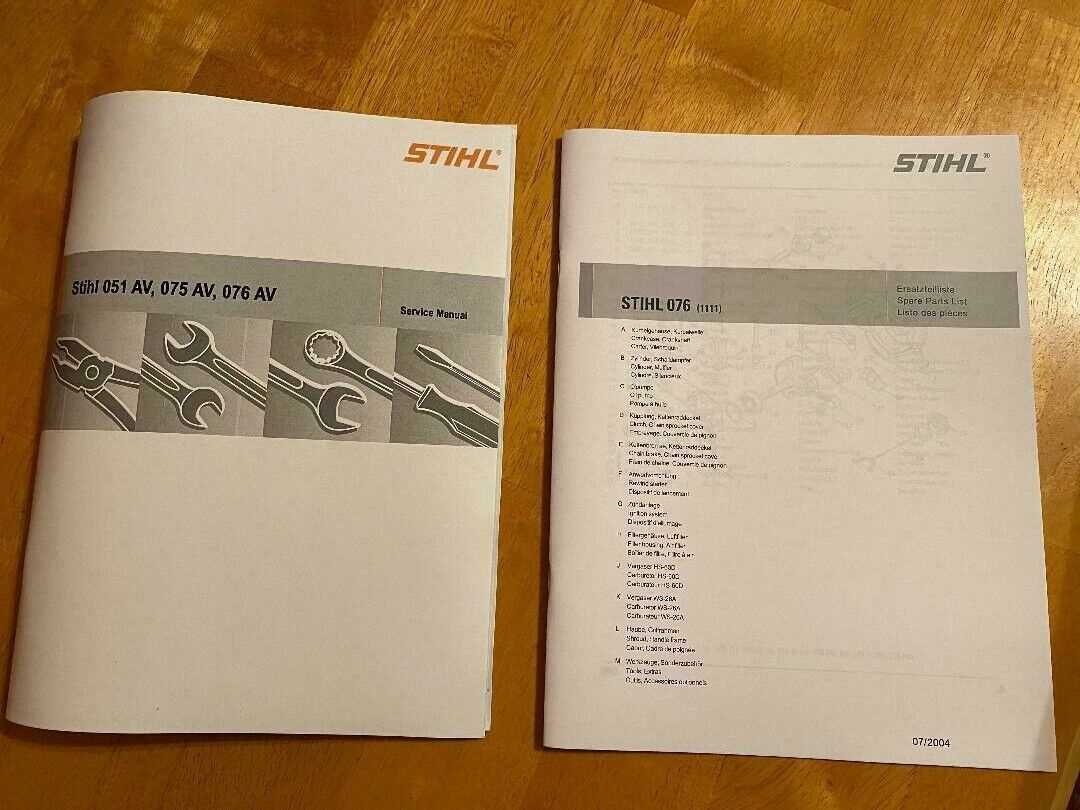

Understanding the layout and components of various tools is essential for efficient maintenance and repair. This section explores popular equipment used in landscaping and forestry, providing insights into their structure and functionality.

Chainsaws

Chainsaws are versatile machines designed for cutting wood. Key components include the engine, bar, chain, and safety features. Knowing how these elements interact can enhance performance and safety during use.

Trimmers

Trimmers are ideal for tidying up edges and hard-to-reach areas. They typically consist of a motor, spool, and cutting line. Familiarity with the schematic of these devices helps users troubleshoot issues and optimize their operation.

How to Read Parts Diagrams Effectively

Understanding technical illustrations is crucial for successful equipment maintenance and repair. These visuals provide a detailed representation of components, enabling users to identify and locate specific elements easily. Mastering this skill can significantly enhance your efficiency and accuracy in working with machinery.

Start by familiarizing yourself with the key symbols used in these illustrations. Different shapes often represent various types of components, and recognizing these can help you navigate the visual layout more effectively. Take note of any legends or keys that accompany the image, as they often provide essential information about each part’s function and specifications.

Next, break down the illustration into sections. Focus on one area at a time to avoid feeling overwhelmed. By concentrating on smaller portions, you can better understand how each element interacts with others. Additionally, cross-referencing with manuals or guides can provide further clarity and context, ensuring you grasp the overall assembly and disassembly processes.

Finally, practice makes perfect. The more you engage with these visual aids, the more proficient you’ll become in interpreting them. Consider working on actual equipment or using simulations to deepen your understanding. Embrace the challenge and approach each new illustration as an opportunity to expand your knowledge and skills.

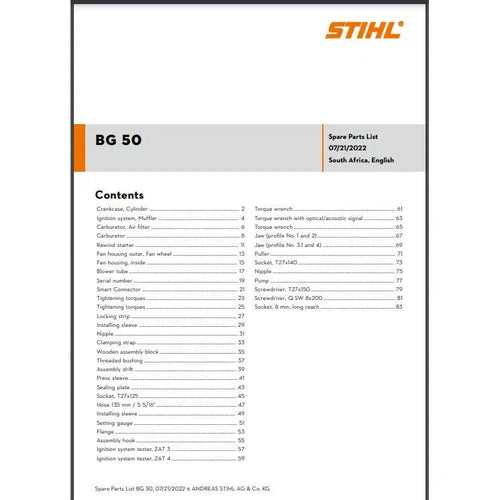

Finding Stihl Diagrams Online

Locating visual schematics for various outdoor power equipment can greatly enhance the repair and maintenance process. Online resources provide an efficient means to access these valuable illustrations, enabling users to identify components quickly and accurately. By utilizing specific search techniques and reputable websites, one can streamline the journey toward effective troubleshooting.

Here are some useful strategies for finding these illustrations online:

| Method | Description |

|---|---|

| Manufacturer’s Website | Visit the official site where you can often find manuals and visual guides for various models. |

| Online Retailers | Many online stores offer schematics alongside product listings, providing useful visuals. |

| Forums and Communities | Participate in discussion boards where enthusiasts share resources and diagrams. |

| YouTube Tutorials | Watch videos that often include detailed visuals and instructions related to specific equipment. |

By employing these methods, you can effectively navigate the vast online landscape to find the illustrations needed for successful repairs.

Identifying Replacement Parts Quickly

When it comes to maintaining your equipment, recognizing the necessary components swiftly can save both time and frustration. Understanding how to efficiently locate the correct elements for repairs or upgrades is essential for optimal performance. This process can significantly enhance your workflow, ensuring that you can tackle any task with confidence.

Begin by familiarizing yourself with the model number of your machine. This crucial identifier will lead you to specific information tailored to your device. Additionally, visual references can be invaluable. Utilizing clear illustrations and labels can help you pinpoint the exact pieces you need without confusion.

Consider creating a systematic approach. Organizing your reference materials–whether they are digital resources or printed manuals–will streamline the identification process. Having a designated area for this information allows for quick access during repairs, minimizing downtime and keeping your projects on track.

Finally, utilizing online communities and forums can provide insights from fellow users. These platforms often share experiences and advice, helping you navigate any uncertainties. By leveraging these resources, you can enhance your ability to identify the right components promptly and efficiently.

Comparing Different Stihl Models’ Diagrams

When exploring the intricacies of various models, it becomes essential to understand how components are organized and interact within each machine. Each design reflects unique engineering choices tailored to specific functionalities, making it crucial to delve into their respective layouts for effective maintenance and repairs.

Understanding Model Variations

Different models often showcase distinct arrangements and component types, reflecting their intended use. For example, a compact device may feature a simplified setup, while a heavy-duty variant could have a more complex assembly to accommodate additional features. Recognizing these differences enables users to make informed decisions regarding repairs or upgrades.

Benefits of Familiarization

Becoming acquainted with the layout of a specific model aids in troubleshooting and enhances the efficiency of maintenance tasks. By comparing these layouts, users can gain insights into the design philosophy behind each model, leading to improved operational understanding and performance optimization. Understanding these variations can also assist in identifying compatible components for repairs or enhancements.

Common Repairs Illustrated in Diagrams

Understanding the intricacies of maintenance and troubleshooting can greatly enhance the lifespan and efficiency of your tools. This section focuses on frequently encountered issues, providing visual representations to simplify the repair process. These illustrations serve as a valuable resource, guiding users through various tasks with clarity.

Identifying Fuel System Issues

Fuel delivery problems are common and can lead to performance failures. The visuals depict the components involved, helping to pinpoint blockages or leaks that may hinder operation.

Chain Maintenance and Replacement

Proper upkeep of the cutting chain is essential for optimal performance. Illustrated steps outline how to assess wear and replace the chain, ensuring safety and efficiency.

Air Filter Cleaning

A clean air filter is crucial for engine efficiency. The schematic representations show the steps needed to access and clean the filter, maintaining proper airflow and performance.

Electrical Component Troubleshooting

Issues with ignition or electrical systems can be daunting. Visual guides break down the diagnostic process, making it easier to trace and resolve electrical faults.

Using Diagrams for Maintenance Guidance

Visual representations serve as invaluable tools for ensuring effective upkeep of equipment. They provide a clear roadmap, allowing users to identify components and understand their functions easily. By following these illustrations, individuals can perform necessary tasks with confidence and accuracy.

Understanding how to interpret these visuals can significantly enhance maintenance practices. Users can pinpoint areas requiring attention and efficiently locate specific items, minimizing the risk of errors. This structured approach not only streamlines the process but also contributes to prolonging the lifespan of machinery.

Incorporating these resources into regular maintenance routines fosters a proactive mindset. By making use of visual guides, individuals are empowered to address issues promptly, ultimately ensuring optimal performance and reliability of their equipment.

Tips for Ordering Correct Parts

Ensuring you receive the right components for your equipment can significantly enhance its performance and longevity. To achieve this, it’s essential to follow a systematic approach when placing your orders.

Verify Model Information

Always double-check the model number and specifications of your machinery. This information is crucial for identifying compatible items and can prevent costly mistakes.

Consult Trusted Resources

Utilize reliable guides and documentation to assist you in your selection process. Expert advice and user manuals can provide invaluable insights, ensuring you make informed decisions when sourcing necessary replacements.

Understanding Diagram Symbols and Labels

Grasping the significance of various symbols and annotations within technical illustrations is essential for effective comprehension. These elements provide crucial insights, enabling users to identify components and their functions clearly.

Common Symbols

- Circles: Often indicate attachment points or joints.

- Arrows: Show the direction of movement or flow.

- Boxes: Represent specific parts or assemblies.

Labeling Conventions

- Numbers: Correspond to a parts list or key.

- Letters: Identify variations of a particular component.

- Color Codes: Indicate specific materials or functions.

Integrating Diagrams into Repair Workflow

Incorporating visual aids into the maintenance process significantly enhances efficiency and accuracy. By utilizing detailed illustrations, technicians can easily identify components and follow systematic procedures, minimizing the risk of errors. This approach streamlines the repair tasks, allowing for quicker diagnostics and effective resolutions.

Improving Communication

Clear visuals foster better communication among team members. When everyone has access to the same reference materials, it reduces misunderstandings and promotes collaborative problem-solving. This shared understanding accelerates the workflow and ensures that all parties are aligned with the repair objectives.

Training and Development

Visual aids also play a crucial role in training new personnel. By engaging with illustrative resources, trainees can grasp complex concepts more effectively, enhancing their learning curve. This foundation allows them to contribute confidently to the repair process, ultimately elevating the overall skill level of the team.

Resources for Stihl Parts Support

Accessing reliable resources for maintenance and repair components is crucial for ensuring the longevity and efficiency of outdoor equipment. A variety of tools and references are available to assist users in identifying and acquiring necessary elements for their machinery. These resources include official websites, user manuals, and community forums, each offering valuable insights and assistance.

Official Websites

Manufacturer websites are often the most reliable source for authentic components. They provide comprehensive catalogs, guides for identification, and purchasing options. Many sites also feature a support section where users can find troubleshooting tips and FAQs.

Community Forums

Engaging with fellow users on online forums can yield practical advice and shared experiences. These platforms allow individuals to ask questions, share insights, and gain recommendations for trusted suppliers or alternative solutions.

| Resource Type | Description |

|---|---|

| Manufacturer Website | Official source for genuine components and user manuals. |

| User Manual | Detailed guide containing assembly instructions and part identification. |

| Online Forums | Community-driven discussions for tips and problem-solving. |

| Retailers | Various vendors offering a wide range of components and accessories. |