Comprehensive Guide to John Deere 4100 Parts Diagram

In the realm of machinery, a comprehensive grasp of individual components is essential for optimal functionality and maintenance. Each element plays a pivotal role, contributing to the overall performance and efficiency of the equipment. By exploring the intricate relationships among these parts, users can enhance their operational knowledge and troubleshooting skills.

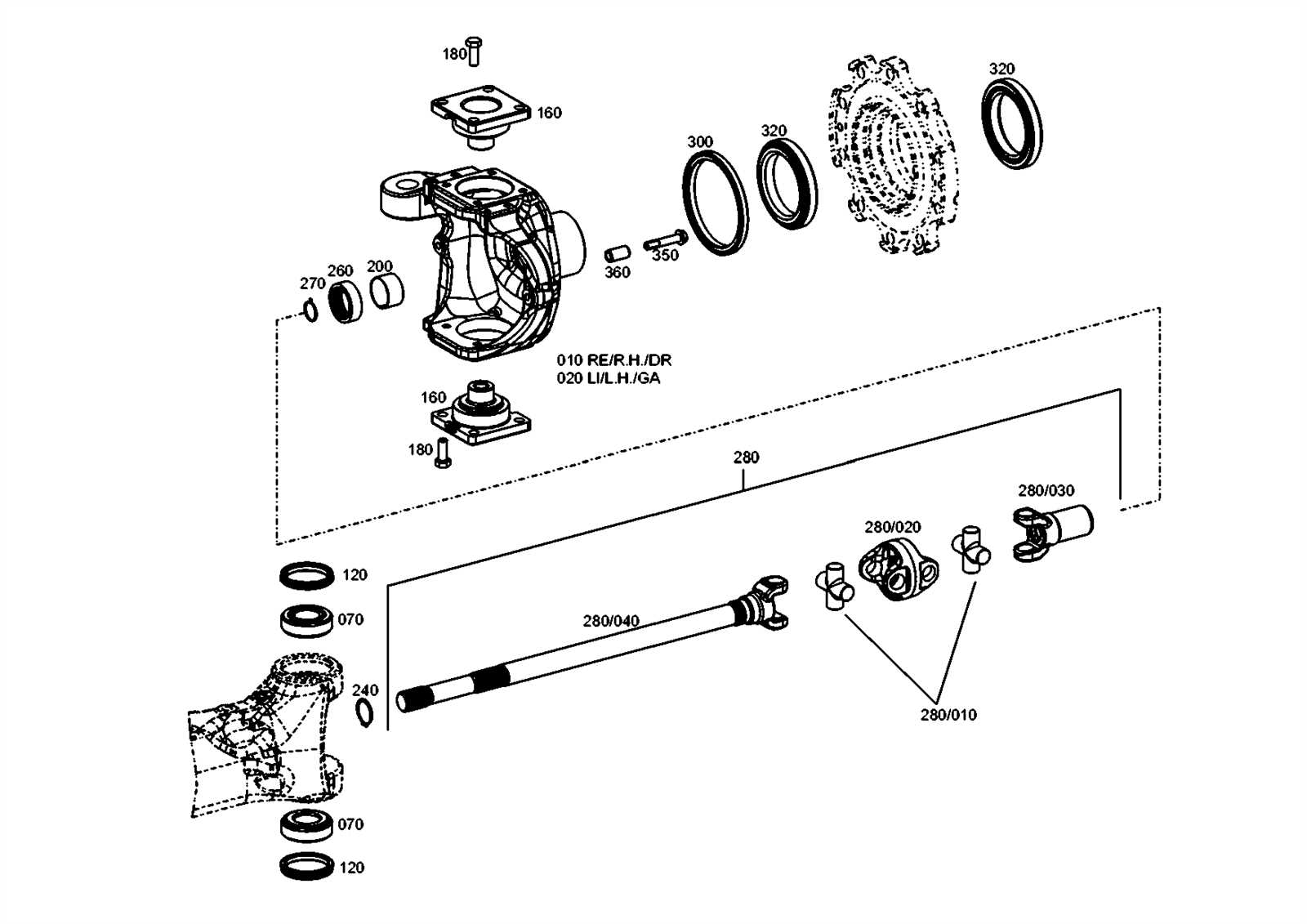

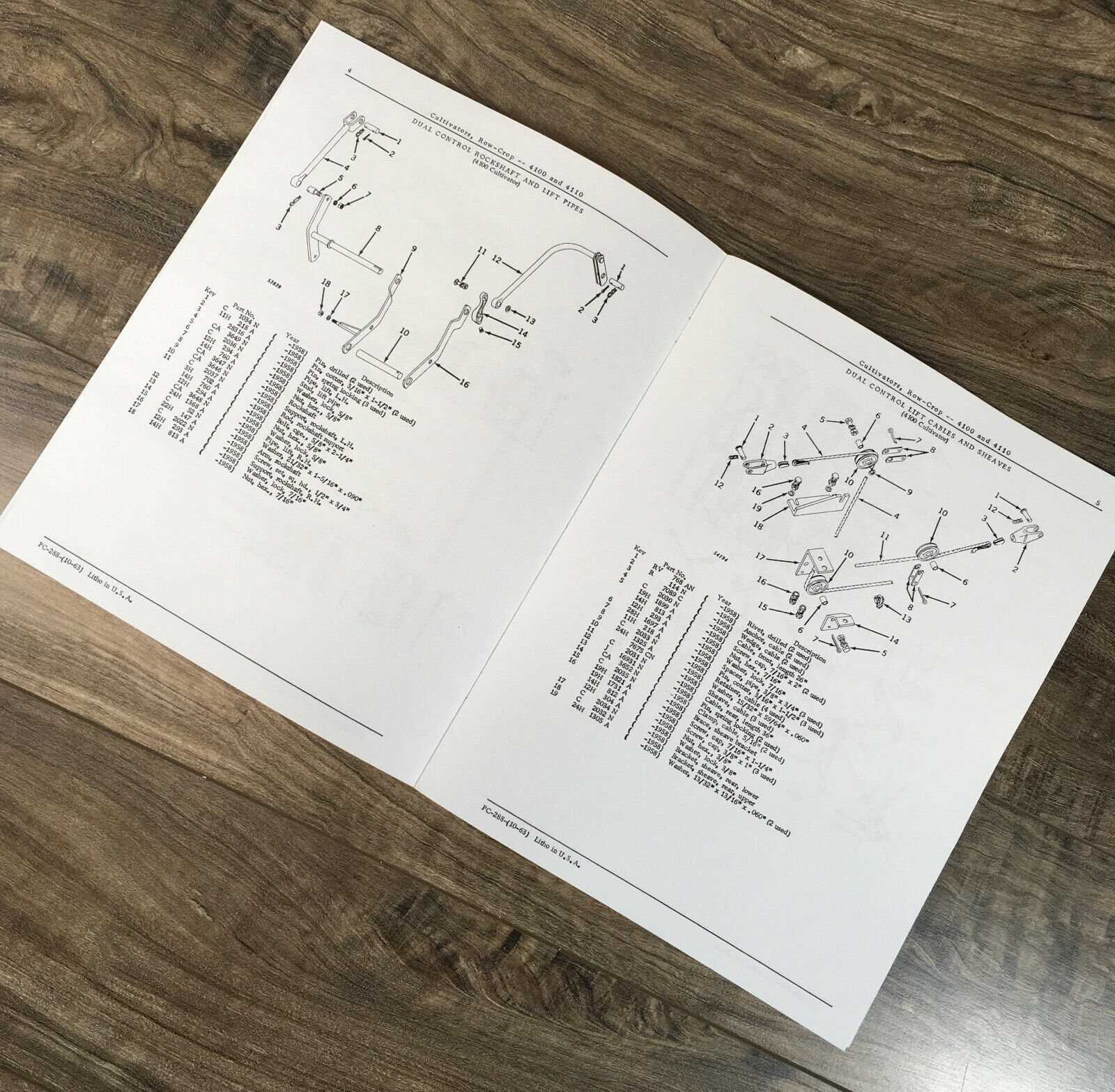

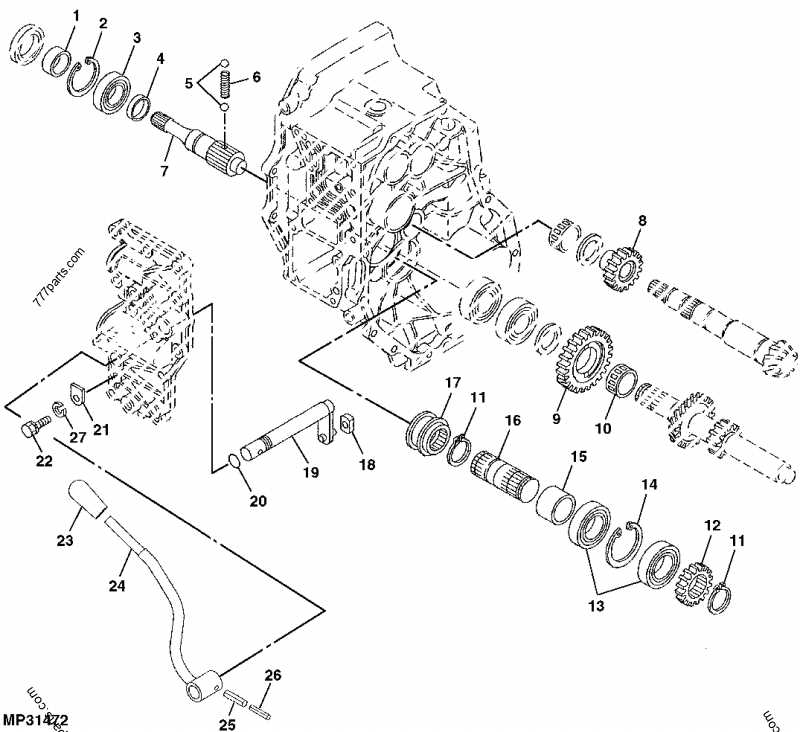

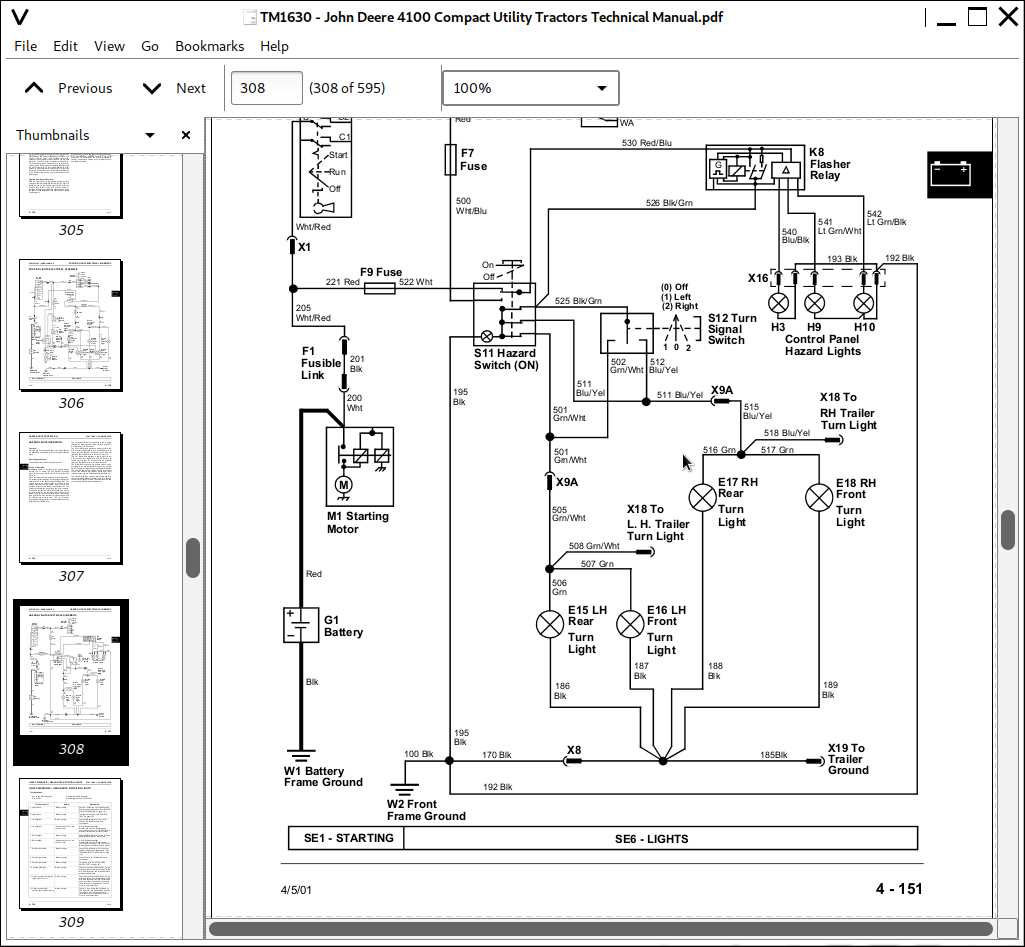

Accessing visual representations of these components allows for a deeper insight into their arrangement and interconnectivity. Such illustrations serve as valuable resources for both seasoned operators and newcomers alike, guiding them through the complexities of machinery. The ultimate goal is to ensure seamless operation and longevity of the equipment.

Whether for repairs or upgrades, understanding how each piece fits into the larger assembly empowers users to make informed decisions. This knowledge not only facilitates maintenance but also promotes a culture of proactive care and operational excellence.

Understanding John Deere 4100 Overview

This section provides a comprehensive look at a compact utility machine designed for versatility and efficiency in various tasks. With its robust design and reliable performance, this equipment caters to both agricultural and landscaping needs. It combines functionality with user-friendly features, making it suitable for a range of users, from hobbyists to professionals.

The machine is equipped with a powerful engine and a variety of attachments, enabling it to tackle different challenges effectively. Its compact size allows for easy maneuverability in tight spaces, while still offering substantial power for heavy-duty operations. Understanding its core components and features is essential for optimal usage and maintenance.

Importance of Parts Diagrams

Understanding the structure and components of machinery is essential for efficient maintenance and repair. Visual representations of individual elements play a crucial role in ensuring that users can quickly identify and access the necessary components for their equipment. This clarity facilitates smoother operations and reduces the likelihood of errors during servicing.

Enhanced Understanding

Diagrams provide a clear visual reference that enhances comprehension of complex assemblies. Key benefits include:

- Clear identification of individual elements

- Insight into the relationship between components

- Facilitation of troubleshooting processes

Efficient Maintenance

Utilizing visual aids simplifies the maintenance process, making it more effective. Important aspects include:

- Streamlined identification of needed replacements

- Reduced downtime during repairs

- Improved accuracy in reassembly

Overall, these visual tools serve as indispensable resources for anyone involved in the upkeep of machinery, fostering better practices and enhancing operational longevity.

Key Components of the 4100 Model

Understanding the essential elements of this compact utility vehicle is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance and durability, contributing to the overall functionality of the machine.

The engine serves as the powerhouse, delivering the necessary torque and horsepower for various tasks. Complementing the engine, the transmission system ensures smooth power transfer to the wheels, allowing for seamless movement across diverse terrains.

The hydraulic system is another critical feature, enabling the use of attachments and enhancing versatility. Additionally, the chassis design provides stability and support, ensuring that the vehicle can handle heavy loads without compromising safety.

Finally, the operator’s controls and dashboard facilitate ease of use, allowing for intuitive operation and monitoring of the vehicle’s status. Together, these components create a cohesive unit, capable of tackling a wide range of agricultural and landscaping tasks.

How to Interpret the Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations provide a clear view of how parts interact within a system, making it easier to identify issues and plan service tasks.

Here are some key steps to help you navigate the illustration effectively:

- Familiarize Yourself with the Legend: Most diagrams include a legend or key that explains the symbols used. Take time to understand these symbols to avoid confusion.

- Identify Major Components: Start by locating the primary elements in the illustration. This will give you a sense of the overall structure and flow of the system.

- Trace Connections: Follow the lines that connect different components. This will help you understand how each part interacts and where potential issues may arise.

- Pay Attention to Annotations: Look for notes or labels that provide additional context. These often contain crucial information regarding part specifications or maintenance tips.

By applying these steps, you can enhance your understanding of the representation, leading to more effective troubleshooting and repair processes.

Common Parts and Their Functions

This section explores essential components found in agricultural machinery, detailing their roles and significance in overall functionality. Understanding these elements helps in maintenance and ensures optimal performance during operation.

| Component | Function |

|---|---|

| Engine | Generates power for various tasks and operations. |

| Transmission | Transfers power from the engine to the wheels or attachments. |

| Hydraulic System | Facilitates lifting and movement of heavy loads through fluid pressure. |

| Chassis | Provides structural support and stability for the entire machine. |

| Electrical System | Powers lighting, starting mechanisms, and electronic controls. |

Where to Find Replacement Parts

Locating high-quality components for your machinery can significantly enhance performance and longevity. Whether you are a professional or a DIY enthusiast, knowing where to search for reliable substitutes is essential.

Online Retailers: Numerous e-commerce platforms specialize in equipment components. They often provide detailed descriptions and customer reviews to assist in your selection.

Local Dealerships: Authorized sellers can be invaluable resources for authentic replacements. They frequently offer expert advice and support tailored to your specific model.

Salvage Yards: Consider visiting local salvage yards where you might find used components at a fraction of the cost. This option is particularly appealing for older models.

Community Forums: Engaging with online communities can provide insights and recommendations. Experienced users often share their sources for hard-to-find components.

Manufacturer Websites: Checking the official websites of manufacturers can yield information about recommended vendors and authorized service centers, ensuring you receive quality products.

Exploring these avenues can ultimately lead to successful and efficient repairs, keeping your machinery running smoothly.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent attention and care. By following specific maintenance practices, you can significantly enhance the lifespan and performance of your equipment. Implementing a routine schedule and adhering to best practices can prevent costly repairs and downtime.

Regular Inspections

Conducting frequent assessments helps identify potential issues before they escalate. Look for wear and tear, fluid leaks, and any unusual noises. Keeping a checklist can aid in systematic evaluations.

Lubrication and Cleaning

Proper lubrication is essential for minimizing friction and preventing component damage. Additionally, regular cleaning prevents debris buildup, ensuring optimal functionality and efficiency.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Change | Every 100 hours | Use recommended fluids |

| Filter Replacement | Every 200 hours | Check for clogs |

| Inspection | Monthly | Document findings |

Comparing with Other John Deere Models

When evaluating different machinery options within the same brand, it is essential to consider how specific models stack up against each other. Each machine offers unique features, performance capabilities, and design elements that cater to various needs. This comparison helps users determine the most suitable equipment for their tasks, ensuring they make an informed decision.

Performance and Capability

Several models in this lineup showcase varied horsepower and torque, influencing their effectiveness for different applications. For instance, some machines are engineered for heavy-duty tasks, while others prioritize efficiency and maneuverability. Understanding these differences can aid users in selecting the right tool for their requirements.

Design and Usability

The layout and user interface of different models can significantly affect operational ease. Certain units come equipped with advanced controls and ergonomic designs, enhancing comfort and reducing fatigue during extended use. Evaluating these aspects allows potential buyers to choose a model that aligns with their preferences and working conditions.

Benefits of Using Genuine Parts

Choosing authentic components for machinery ensures optimal performance and longevity. These high-quality items are designed specifically for the equipment, minimizing the risk of malfunctions and enhancing overall reliability.

Enhanced Performance

Utilizing original components guarantees that your machinery operates at its best. Authenticity leads to better fit and function, allowing systems to work seamlessly together, which ultimately translates to improved efficiency and productivity.

Long-Term Savings

While genuine items may have a higher upfront cost, they often result in significant savings over time. Reduced maintenance and lower risk of breakdowns mean fewer repairs and less downtime, leading to greater overall value.

Identifying Part Numbers Easily

Understanding the unique identifiers for components is crucial for maintaining and repairing machinery. Familiarity with these codes allows users to streamline the procurement process, ensuring that the correct items are sourced without confusion.

Here are some key strategies to effectively identify these numbers:

| Method | Description |

|---|---|

| Manufacturer Manuals | Referencing the official documentation can provide accurate codes and specifications for each item. |

| Online Resources | Utilizing reliable websites dedicated to machinery can help locate necessary identifiers quickly. |

| Community Forums | Engaging with fellow users can uncover insights and shared experiences regarding specific codes. |

| Visual Inspection | Examining the components directly often reveals marked identifiers that are essential for ordering replacements. |

Tips for Ordering Online

Making purchases through the internet can be a convenient and efficient way to find the components you need. However, to ensure a smooth experience and receive the correct items, it’s important to follow certain guidelines when placing your orders.

- Research the Supplier: Verify the reputation of the online store. Look for reviews and ratings from other customers to ensure reliability.

- Know Your Specifications: Gather detailed information about the items you need, including model numbers and compatibility, to avoid mistakes.

- Compare Prices: Check multiple websites to find the best deals. This can save you money and provide a better understanding of the market.

- Read Descriptions Carefully: Take time to read product descriptions thoroughly to ensure they meet your requirements.

- Check Return Policies: Familiarize yourself with the return and exchange policies in case the item does not meet your expectations.

- Look for Discounts: Search for promotional codes or seasonal sales to maximize your savings.

By adhering to these tips, you can enhance your online shopping experience and ensure you receive the right items efficiently.

DIY Repair vs. Professional Help

When it comes to fixing machinery, enthusiasts often face the choice between tackling repairs themselves or seeking the expertise of a specialist. This decision hinges on factors like skill level, available resources, and the complexity of the issue. Understanding the pros and cons of each approach can lead to more informed choices and ultimately successful outcomes.

Advantages of DIY Repair

Engaging in self-repair can foster a sense of accomplishment and save money. With access to manuals and online resources, many individuals find they can address minor issues effectively. Additionally, hands-on experience enhances knowledge and can build confidence for future projects.

Benefits of Professional Assistance

On the other hand, enlisting a professional ensures that repairs are performed efficiently and correctly. Experts possess the necessary tools and experience to diagnose and resolve problems that may be beyond the scope of an amateur. This can prevent potential damage and save time, making it a worthwhile investment for more complex situations.

Resources for Further Research

Exploring relevant materials can significantly enhance your understanding of machinery and its components. This section offers valuable references that can assist in deepening your knowledge and guiding your inquiries.

Online Forums and Communities

Engaging with online forums allows enthusiasts and professionals to share insights and troubleshoot issues collaboratively. Websites dedicated to agricultural machinery often have sections where users can discuss experiences and exchange information about various models.

Manufacturer’s Manuals and Documentation

Official manuals provide comprehensive details about machinery specifications, maintenance, and operational guidelines. Accessing these documents can offer ultimate clarity and assistance in your research, ensuring you have the most accurate information at hand.