Massey Ferguson 165 Steering Parts Diagram Explained

In the realm of agricultural machinery, effective maneuverability is paramount for optimal performance and productivity. A thorough comprehension of the various elements that contribute to the directional functionality of these machines is essential for any operator or technician. This section delves into the intricate mechanisms that enable precise navigation, ensuring that every task is executed with ease.

Key components play a crucial role in facilitating smooth handling and responsiveness. By familiarizing oneself with these vital elements, users can enhance their understanding of how their equipment operates and identify potential issues before they escalate. Furthermore, a well-maintained system not only improves efficiency but also extends the lifespan of the machinery.

Additionally, visual representations serve as invaluable tools for those seeking to grasp the complexities of these systems. Diagrams can illuminate the relationships between different components, providing clarity on assembly and disassembly processes. With this knowledge, operators can confidently undertake repairs and maintenance, ensuring their equipment remains in peak condition.

Overview of the Iconic Tractor

This section provides a comprehensive insight into a renowned agricultural machine celebrated for its durability and efficiency. Its robust design and functionality have made it a preferred choice among farmers and enthusiasts alike.

Features and Specifications

The vehicle boasts a powerful engine and a user-friendly interface, making it ideal for various farming tasks. With its reliable performance, it can easily handle both light and heavy-duty operations, ensuring productivity in the field.

Maintenance and Parts

Regular upkeep is crucial to maximize the lifespan of this equipment. Accessing quality components and understanding their arrangement is essential for effective maintenance. Proper care ensures that the machine continues to perform at its ultimate capacity.

Importance of Steering Mechanism

The control system that enables precise navigation and maneuverability is crucial for the effective operation of any vehicle. Its design and functionality directly influence not only the performance of the machine but also the safety of its operator and surroundings.

Efficiency in handling and direction is vital, particularly in agricultural equipment where navigating various terrains is common. A well-designed control system allows for smooth adjustments, ensuring that operators can make quick decisions and execute them accurately.

Moreover, durability and maintenance play significant roles in the longevity of the vehicle. High-quality components reduce wear and tear, minimizing downtime and enhancing productivity. Regular inspection and care of the mechanism are essential to uphold operational standards.

Additionally, the ergonomics of the control system contribute to the comfort of the operator. A well-placed and responsive mechanism reduces fatigue, enabling longer working hours without compromising efficiency. This is especially important in demanding environments where precision is paramount.

In conclusion, the significance of a reliable control system cannot be overstated. It is a fundamental aspect that ensures optimal functionality, safety, and comfort, ultimately contributing to the overall success of agricultural and industrial operations.

Key Components of Steering System

The functionality of any maneuvering apparatus relies on its essential elements, which ensure precision and control during operation. Understanding these crucial components provides insight into how the system achieves responsiveness and stability.

| Component | Description |

|---|---|

| Wheel Assembly | Consists of the tires and rims that facilitate movement and support weight. |

| Linkage Mechanism | A series of rods and joints that connect the operator’s input to the wheels, translating movement. |

| Control Column | The input device used by the operator to direct the apparatus, influencing the direction of travel. |

| Hydraulic System | Uses fluid pressure to enhance the ease of turning and maintain control during operation. |

| Pivot Points | These are crucial joints that allow for rotational movement, enabling effective directional changes. |

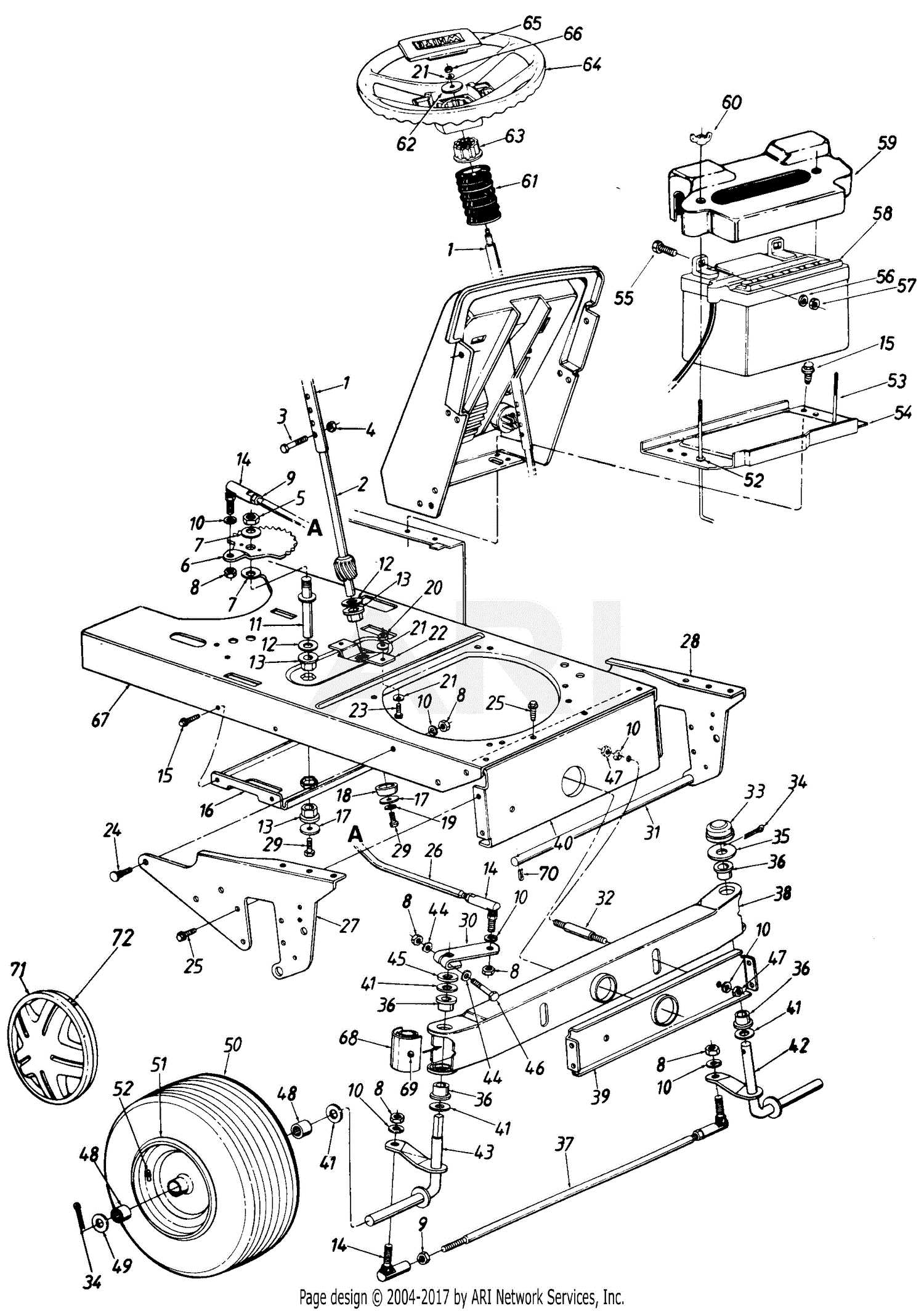

Understanding the Parts Diagram

A visual representation of components is essential for comprehending the mechanics of any machine. These illustrations provide a clear overview of how various elements interact, making it easier to identify and address issues. By studying these schematics, users can gain insights into assembly, maintenance, and troubleshooting processes.

Each section of the illustration highlights specific items, allowing for a systematic approach to repairs. Familiarity with the layout enhances one’s ability to locate necessary components swiftly, minimizing downtime during operations. Furthermore, understanding the relationships between different parts can lead to improved performance and longevity of the equipment.

For anyone involved in the upkeep or operation of machinery, being able to interpret these representations is a valuable skill. It not only empowers users to carry out repairs confidently but also fosters a deeper appreciation for the engineering behind the equipment.

Common Issues with Steering Parts

In the realm of agricultural machinery, maintaining control and maneuverability is vital for efficient operation. Various components contribute to the steering mechanism’s functionality, and several common problems can arise over time. Understanding these issues helps in timely diagnosis and repairs, ensuring the equipment remains operational and safe.

Frequent Problems Encountered

Several challenges may affect the maneuvering system. Here are some of the most frequently observed issues:

| Issue | Description |

|---|---|

| Excessive Play | Worn-out connections can lead to a loose feel, impacting precision during navigation. |

| Fluid Leaks | Hydraulic systems may develop leaks, causing a drop in pressure and responsiveness. |

| Misalignment | Improper adjustment can cause uneven wear and affect the ability to turn smoothly. |

| Noisy Operation | Strange sounds during use may indicate failing components or lack of lubrication. |

Maintenance Recommendations

Regular inspection and maintenance are key to preventing and addressing these issues. Keeping components clean, ensuring proper lubrication, and replacing worn parts can significantly enhance performance and longevity.

How to Identify Faulty Components

Diagnosing malfunctioning elements in machinery requires a systematic approach to ensure effective troubleshooting. Understanding the signs of wear and tear, as well as unusual behavior, can help in pinpointing the components that may need attention. This guide outlines essential steps for recognizing defective parts that could impact performance.

Visual Inspection: Start with a thorough visual examination of the equipment. Look for signs of damage, such as cracks, corrosion, or abnormal wear. Pay close attention to connections and joints, as these areas often show early signs of failure.

Performance Assessment: Evaluate the functionality of the machine. Unusual noises, erratic movements, or inconsistent responses can indicate underlying issues. Document any specific behaviors that deviate from normal operation.

Fluid Analysis: If applicable, check the quality of fluids within the system. Contaminated or degraded fluids can lead to component malfunction. Regularly testing for impurities can help in early detection of problems.

Measurement Tools: Utilize appropriate measuring instruments to assess critical parameters such as pressure, temperature, and alignment. Discrepancies from standard values can signal the need for further inspection or replacement.

Consulting Manuals: Reference the equipment’s manual for specific troubleshooting procedures. These documents often provide valuable insights into common issues and detailed diagrams that can assist in identifying faulty components.

Professional Evaluation: If uncertainty persists, consider seeking the expertise of a qualified technician. Their experience can facilitate accurate diagnostics and recommend necessary repairs or replacements.

Maintenance Tips for Steering System

Regular upkeep of the directional control mechanism is essential for ensuring optimal performance and safety. By adhering to a few simple guidelines, operators can extend the life of the components and enhance the overall functionality of the machinery.

One of the primary aspects to focus on is the lubrication of moving elements. Proper lubrication minimizes friction and wear, preventing premature damage. Always use the recommended types of lubricants, and ensure that they are applied at the right intervals.

Another critical factor is the inspection of linkages and joints for any signs of wear or damage. Timely detection of issues such as cracks, rust, or excessive play can prevent further complications. Regular checks can help identify necessary replacements before they lead to larger problems.

Maintaining fluid levels in hydraulic systems is equally important. Ensure that fluids are clean and free of contaminants, as this can greatly affect the performance of the control system. Replace fluids as recommended by the manufacturer to maintain efficiency.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Lubrication | Every 50 hours | Use manufacturer-recommended lubricant |

| Visual Inspection | Weekly | Look for wear, cracks, or rust |

| Fluid Check | Every 100 hours | Replace contaminated fluids |

| Component Replacement | As needed | Monitor for performance issues |

By following these maintenance tips, operators can ensure that the directional control system remains reliable and efficient, contributing to a safer working environment and reducing downtime.

Replacing Steering Parts: A Guide

Maintaining optimal control and maneuverability of your machinery is crucial for efficiency. When components wear out or fail, timely replacement becomes necessary to ensure smooth operation. This guide outlines the essential steps for successfully replacing the critical elements of the directional system.

| Step | Description |

|---|---|

| 1 | Assess the condition of the components to identify what needs replacement. |

| 2 | Gather necessary tools and new components for the job. |

| 3 | Carefully remove the old components, ensuring to note their arrangement. |

| 4 | Install the new components, following the original configuration. |

| 5 | Test the assembly to ensure proper functionality before returning to operation. |

Tools Required for Repairs

Effective maintenance and repair of agricultural machinery necessitate a range of specialized tools. These instruments are essential for disassembling components, making precise adjustments, and ensuring that all systems operate smoothly. Having the right equipment at hand not only simplifies the repair process but also enhances safety and efficiency.

Below is a table outlining some of the essential tools you may need for carrying out repairs effectively:

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws in various components. |

| Pliers | Useful for gripping, twisting, and cutting wires and small parts. |

| Jack | Allows for lifting heavy machinery for easier access during repairs. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Diagnostic Tools | Helps in identifying faults and assessing the condition of various systems. |

Equipping yourself with these tools will facilitate more effective and safer repair processes, ultimately prolonging the lifespan of your equipment.

Where to Find Replacement Parts

Finding suitable components for your machinery can be a daunting task. However, there are several reliable avenues to explore when searching for high-quality replacements that ensure optimal performance and longevity of your equipment.

Online Retailers are among the most convenient options. Numerous websites specialize in agricultural machinery, offering a vast selection of items. Be sure to check user reviews and ratings to gauge the reliability of the seller.

Local Dealers often have the advantage of immediate availability. Establishing a relationship with a trusted dealer can lead to personalized service and potentially better pricing on essential components.

Salvage Yards can be a hidden gem for those seeking affordable alternatives. Many yards stock older models and may have the exact parts you need at a fraction of the price.

Online Marketplaces also present a viable option. Platforms that facilitate peer-to-peer sales can yield surprising finds, but always ensure to verify the condition and compatibility of the items before purchase.

Finally, Manufacturer Websites can provide valuable information regarding recommended suppliers and official replacement components, ensuring you receive authentic parts tailored for your specific machinery.

Upgrading Your Steering System

Enhancing your vehicle’s guidance apparatus can significantly improve maneuverability and responsiveness. By incorporating advanced components and modern technologies, you can achieve a smoother and more controlled driving experience. This process not only elevates performance but also contributes to overall safety.

Benefits of Modernization

Upgrading can lead to enhanced precision and reduced effort in handling. Newer elements may offer greater durability, resulting in less maintenance and extended lifespan. Moreover, improved functionality can also provide a more enjoyable ride.

Key Considerations

Before initiating upgrades, assess compatibility with existing systems. Research various options available on the market to ensure you select the ultimate enhancements for your requirements. Prioritizing quality will lead to optimal performance and longevity.