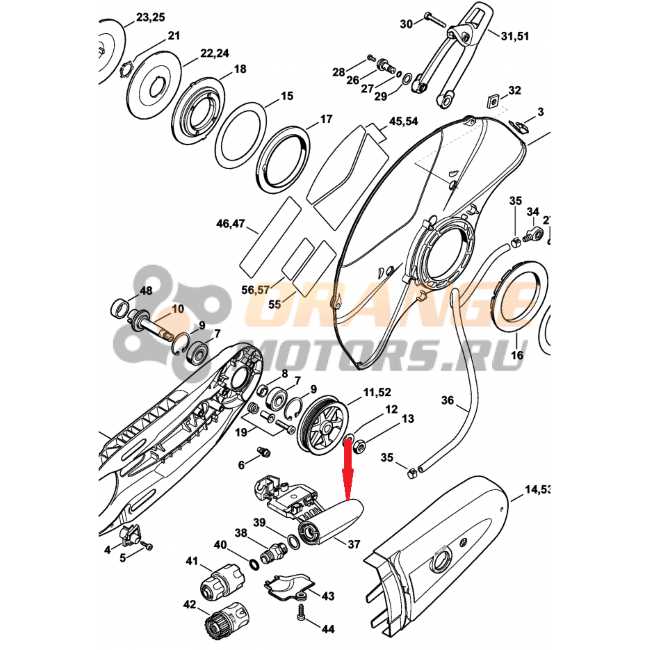

Stihl TS480i Parts Breakdown and Diagram Overview

In any complex equipment, every individual component plays a crucial role in ensuring smooth operation and overall efficiency. The structure and functionality of these elements are meticulously designed to work together, creating a well-coordinated system. Proper knowledge of each piece is essential for maintaining and repairing the equipment, ensuring its longevity and peak performance.

Examining core mechanisms is not just about knowing where each piece fits, but also understanding how they interact with one another. This knowledge can greatly assist in troubleshooting and maintaining the system over time. When equipped with this understanding, users can confidently approach repairs and adjustments, ensuring the equipment remains reliable and effective.

Overview of Key Components

This section provides a concise look at the main elements that form the foundation of the machine’s functionality. Understanding how these components work together is essential for optimal performance and maintenance.

Engine System

The core power source ensures smooth operation and drives all mechanical parts. It includes several smaller units that work in harmony to convert energy and ensure reliable function.

- Combustion chamber

- Cooling elements

- Fuel delivery system

Drive Mechanism

This system transfers power from the engine to the working parts, allowing the machine to perform its tasks effectively. Its durability and alignment are crucial for efficiency.

- Cl

Understanding the Engine Assembly

The engine system plays a crucial role in ensuring smooth operation and optimal performance. Proper knowledge of its components and their functionality is essential for maintaining efficiency and addressing any potential issues. In this section, we will explore the key elements involved in the engine assembly and how they contribute to the overall mechanism.

Core Components Overview

The main components of the engine include various mechanical and electrical parts that work in harmony. Each element, from the cylinder to the ignition system, has a specific function that ensures the smooth running of the machine. Understanding these parts is vital for troubleshooting and maintenance.

Key Functional Sections

The engine assembly is typically divided into several important sections. These sections include fuel intake, combustion chamber, and exhaust systems. Each section must be well-maintained for the machine

Fuel System Breakdown and Function

The fuel system plays a critical role in the proper operation of any machinery powered by internal combustion engines. It is responsible for delivering the right amount of fuel to the engine, ensuring smooth and efficient performance. Understanding the components involved in this system and how they interact can help prevent malfunctions and maintain optimal performance over time.

Key Components

The fuel system consists of various interconnected parts, each designed to handle specific functions. These components work together to transport fuel from the tank to the engine while maintaining the appropriate pressure and flow. Below is a breakdown of the main elements:

Component Function How the Ignition System Works The ignition system is crucial for powering internal combustion engines. Its role is to generate the necessary spark to ignite the air-fuel mixture, allowing the engine to run smoothly. Understanding the operation of this mechanism helps in diagnosing issues and ensuring efficient performance.

Ignition Coil: The ignition coil plays a vital role in converting low voltage from the battery into the high voltage required to create a spark. This electrical boost allows the spark plug to fire at the right moment, igniting the mixture in the combustion chamber.

Spark Plug: The spark plug is responsible for delivering the electric spark that starts the combustion process. It is placed within the engine’s

Air Filtration System Components

The air filtration system is designed to maintain the efficient operation of machines by ensuring that only clean air enters critical components. This system plays a crucial role in preventing contaminants from causing damage or reducing performance.

Primary Filter Unit

The primary filter is responsible for capturing larger particles, such as dust and debris. It serves as the first line of defense, keeping the air cleaner for subsequent filtration stages.

- Made of durable materials to withstand harsh environments

- Easy to remove and clean or replace when necessary

Secondary Filter Element

The secondary filter offers finer filtration, trapping smaller particles that may pass through the

Cutting Arm and Blade Parts

The cutting mechanism of a power tool is essential for its performance and efficiency. This section explores the various components that contribute to the functionality of the cutting arm and blade assembly, ensuring optimal operation and longevity.

Understanding the key elements involved in this system can enhance maintenance practices and improve overall user experience. Below are the main components that make up the cutting arm and blade assembly:

- Cutting Arm: This is the main structure that supports the blade and allows for movement during operation.

- Blade Holder: A crucial element that secures the cutting tool in place, enabling effective cutting.

- Blade: The sharp edge responsible for cutting through materials; available in various sizes and types for different applications.

- Adjustment Mechanism: Allows the user to modify the blade position for precision cutting.

- Protective Guard: A safety feature that shields the user from debris and potential injuries during operation.

Regular inspection and maintenance of these components are vital for ensuring safe and efficient operation. Proper care can significantly extend the lifespan of the cutting arm and blade assembly.

Drive Belt Mechanism Explained

The drive belt mechanism plays a crucial role in the functionality of various equipment, providing the necessary power transmission between components. This system ensures that energy is efficiently transferred from the engine to the tools, allowing for optimal performance during operation. Understanding the intricacies of this mechanism is essential for proper maintenance and troubleshooting.

Components of the Drive Belt System

The primary elements of the drive belt system include the belt itself, pulleys, and tensioners. The belt, typically made of durable materials, wraps around pulleys that rotate in unison with the engine. Tensioners maintain the correct tightness of the belt, preventing slippage and ensuring consistent power delivery. Each component must function harmoniously to achieve peak efficiency.

Importance of Regular Maintenance

To ensure the longevity and efficiency of the drive belt mechanism, regular inspections and maintenance are essential. Checking for signs of wear, such as cracks or fraying in the belt, as well as ensuring that pulleys are aligned, can prevent unexpected failures. Proper care of this system enhances the overall performance of the equipment and minimizes the risk of costly repairs.

Recoil Starter and Its Role

The recoil starter is a vital component in many outdoor power tools, serving as the primary mechanism for initiating engine operation. This device is designed to provide an efficient and reliable method for starting the engine, allowing users to quickly engage their equipment without complex procedures.

When the operator pulls the starter cord, it engages a series of mechanisms that spin the engine’s flywheel. This action creates the necessary conditions for the engine to ignite and begin functioning. The design of the recoil starter ensures that the user can easily start the engine with minimal effort, making it an essential feature for effective tool performance.

Component Description Starter Cord A strong, flexible rope that the user pulls to engage the starting mechanism. Spring A coiled element that helps retract the starter cord after the pull, returning it to its original position. Starter Handle The part that the user grips to pull the starter cord. Engagement Mechanism Components that connect the starter cord to the engine flywheel, enabling engine rotation. Regular maintenance of the recoil starter is essential for ensuring optimal performance. Over time, components may wear or become damaged, leading to difficulties in starting the engine. Checking the condition of the starter cord and other parts can prevent issues and extend the lifespan of the equipment.

Maintenance of Cooling System

Proper upkeep of the cooling mechanism is crucial for ensuring optimal performance and longevity of any power tool. Regular checks and maintenance can prevent overheating and prolong the life of the engine. A well-functioning cooling system dissipates heat effectively, allowing for efficient operation during extended use.

Inspection of Cooling Components

Regularly examining the components of the cooling system is essential. Look for any signs of wear or damage, such as cracks in hoses or blockages in vents. Clean any debris that may have accumulated in the cooling fins or around the engine. Ensuring that air can flow freely through these areas will enhance the cooling efficiency.

Fluid Levels and Quality

Maintaining the appropriate fluid levels in the cooling system is vital. Check the coolant level regularly and refill as necessary with the recommended type of fluid. Additionally, monitor the condition of the coolant; if it appears dirty or discolored, it may need to be replaced. Regularly changing the coolant can help prevent corrosion and ensure efficient heat transfer.

Handle and Control Components

The handle and control components are essential elements of any cutting equipment, significantly influencing user experience and operational efficiency. These parts ensure safe and comfortable handling while enabling precise control over the tool’s functions. Understanding their structure and functionality can help users maintain their equipment effectively and enhance overall performance.

Key Features

- Ergonomic Design: Facilitates comfortable grip and reduces fatigue during extended use.

- Control Levers: Allow for easy activation and adjustment of cutting functions.

- Safety Mechanisms: Prevent accidental start-up and ensure safe operation.

Maintenance Tips

- Regularly inspect handles for signs of wear or damage.

- Keep control levers clean and free of debris to ensure smooth operation.

- Lubricate moving parts as recommended by the manufacturer.

Common Wear Parts and Replacements

In the operation of any high-performance equipment, certain components experience regular wear and may require timely replacement to ensure optimal functionality. Identifying these essential components can prevent unexpected failures and enhance the lifespan of the machine. Below is a breakdown of frequently replaced elements that users should monitor closely.

Key Components to Monitor

- Cutting Blade: This is a crucial part that can dull over time, affecting performance and precision.

- Air Filter: A clean air filter is vital for maintaining engine efficiency; regular inspections are recommended.

- Fuel Filter: Ensures clean fuel delivery; a clogged filter can hinder operation.

- Spark Plug: Essential for ignition; replacing it can improve starting and overall performance.

- Drive Belts: These can wear out due to friction, affecting power transfer; check for signs of damage.

Replacement Recommendations

- Regular