Comprehensive Guide to Ryobi 2700 PSI Pressure Washer Parts Diagram

When it comes to maintaining outdoor equipment, familiarity with the inner workings of your cleaning apparatus can greatly enhance its efficiency and longevity. Each element of these powerful machines plays a crucial role in delivering optimal performance, and understanding how they interact is essential for effective operation and troubleshooting.

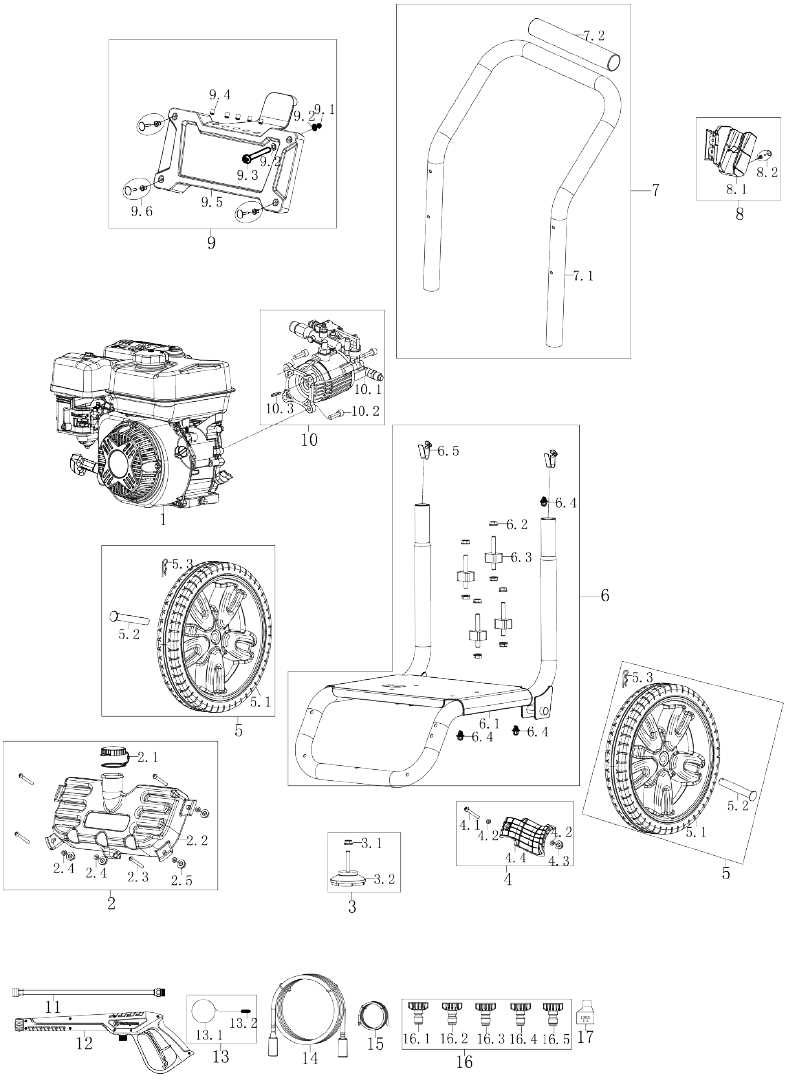

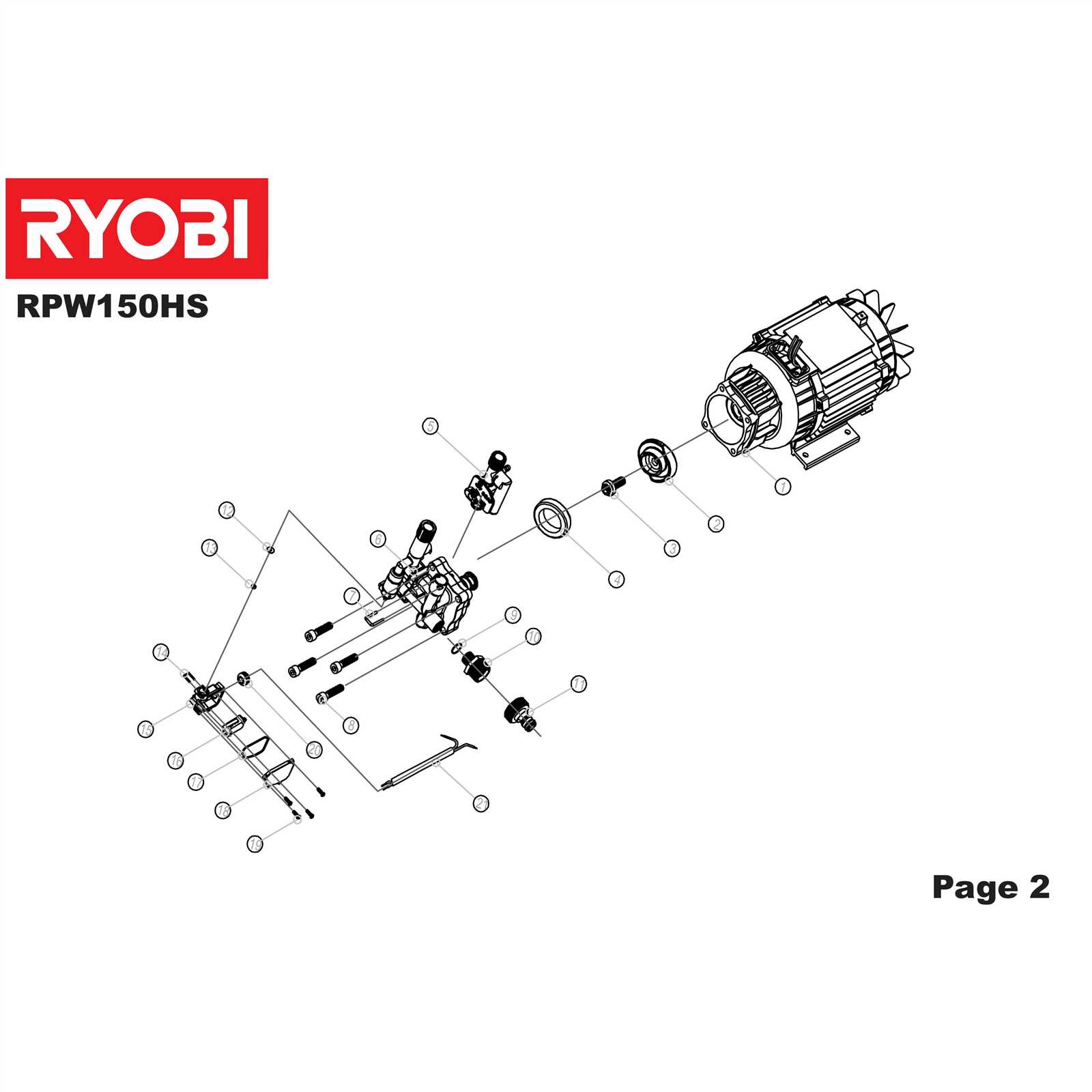

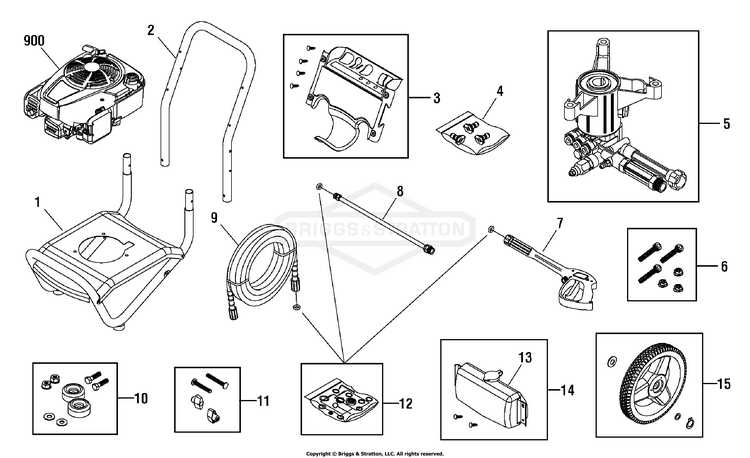

Detailed schematics offer valuable insights into the specific elements that comprise these machines, allowing users to identify potential issues and streamline maintenance efforts. A clear overview of the various components enables owners to recognize wear and tear, ensuring that every aspect of their cleaning device functions smoothly.

In this guide, we will explore the intricate relationships between the essential components, equipping you with the knowledge needed to enhance your device’s reliability and performance. Whether you’re a seasoned user or a newcomer to the world of high-efficiency cleaning, understanding these details can transform your maintenance routine.

Understanding Ryobi Pressure Washers

High-performance cleaning devices are essential for tackling tough outdoor tasks. These machines combine power and efficiency, enabling users to restore surfaces and maintain their surroundings with ease. Familiarity with the components and functionalities of these cleaning systems can significantly enhance user experience and effectiveness.

Key Components of Cleaning Devices

Every high-pressure cleaning unit consists of several crucial elements that contribute to its overall performance. Understanding these components can help users troubleshoot issues and optimize their usage.

| Component | Function |

|---|---|

| Motor | Powers the pump and generates the required pressure for effective cleaning. |

| Pump | Pressurizes water and ensures a consistent flow, enhancing cleaning efficiency. |

| Nozzle | Adjusts the spray pattern, allowing for versatile cleaning options. |

| Hose | Connects the unit to the water source and delivers pressurized water to the nozzle. |

Benefits of Using High-Performance Cleaning Equipment

Investing in a reliable cleaning device offers numerous advantages. Users can tackle various tasks, from washing vehicles to cleaning patios, with remarkable efficiency. Additionally, these units often require minimal maintenance, making them a practical choice for homeowners and professionals alike.

Importance of Maintenance for Longevity

Regular upkeep is crucial for extending the lifespan of any machinery. By investing time and effort into consistent care, users can ensure optimal performance and prevent premature failures. This proactive approach not only enhances efficiency but also safeguards against costly repairs and replacements.

One of the primary benefits of routine maintenance is the identification of potential issues before they escalate. Small problems, if left unchecked, can lead to significant malfunctions that disrupt operation. Regular inspections allow users to detect wear and tear, enabling timely interventions that can save both time and resources.

Additionally, proper maintenance contributes to maintaining the overall efficiency of the equipment. Clean components and well-lubricated parts function better, which translates to reduced energy consumption and improved performance. This efficiency not only benefits the user but also supports environmentally friendly practices.

Moreover, maintaining equipment can enhance safety for users. Well-maintained machines are less likely to malfunction unexpectedly, reducing the risk of accidents. Ensuring that all parts are in optimal condition creates a safer working environment, which is essential for both personal and professional settings.

In conclusion, the significance of regular maintenance cannot be overstated. By prioritizing upkeep, users can enjoy enhanced performance, increased safety, and a longer lifespan for their equipment. Taking these steps ensures a reliable and efficient operation, ultimately leading to greater satisfaction and reduced long-term costs.

Common Parts of Ryobi Pressure Washers

Understanding the essential components of a cleaning machine is crucial for maintenance and effective usage. Familiarity with these elements can enhance performance and prolong the lifespan of the equipment.

- Motor: The heart of the machine, responsible for generating power.

- Pump: Converts the motor’s energy into high-pressure fluid, crucial for effective cleaning.

- Nozzle: Directs the flow of water, allowing for various spray patterns to tackle different cleaning tasks.

- Hose: Connects the machine to the water source, ensuring a steady supply.

- Trigger Handle: Controls the release of water, providing user convenience and safety.

- Wheels: Facilitate mobility, making it easier to maneuver the equipment during use.

- Filter: Prevents debris from entering the system, protecting internal components.

Each of these components plays a vital role in the overall functionality and efficiency of the device, making regular inspection and maintenance essential for optimal performance.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair equipment. These visuals serve as a guide, helping users identify individual components and their respective functions. By mastering the art of reading these graphics, you can ensure proper assembly and troubleshooting, ultimately enhancing the longevity of your tools.

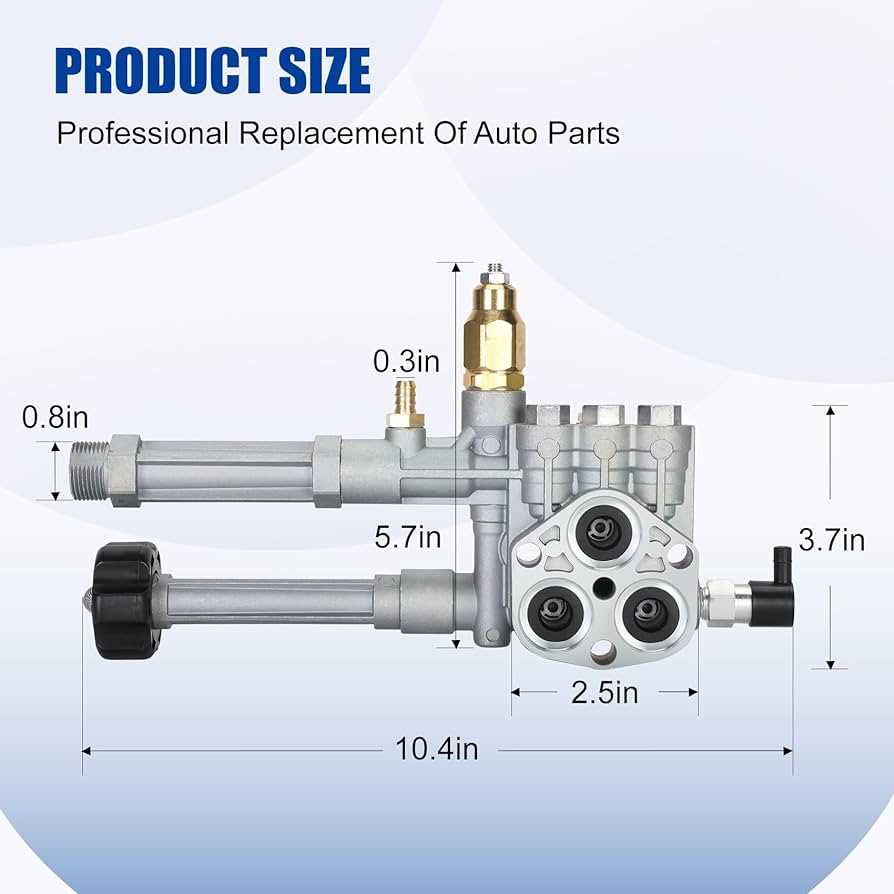

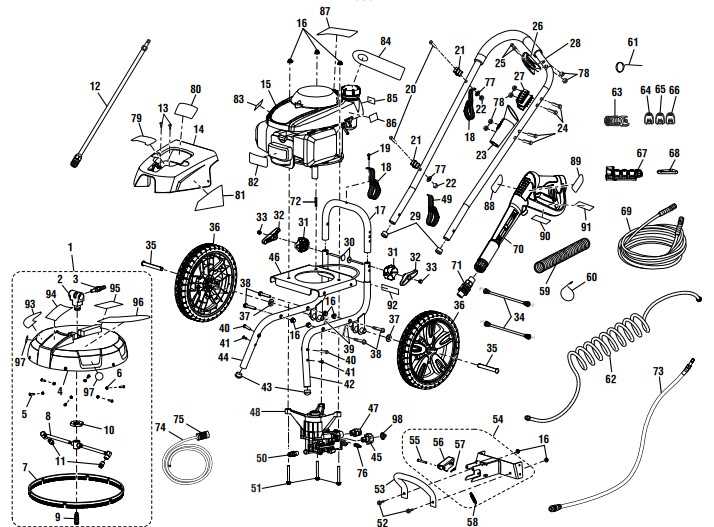

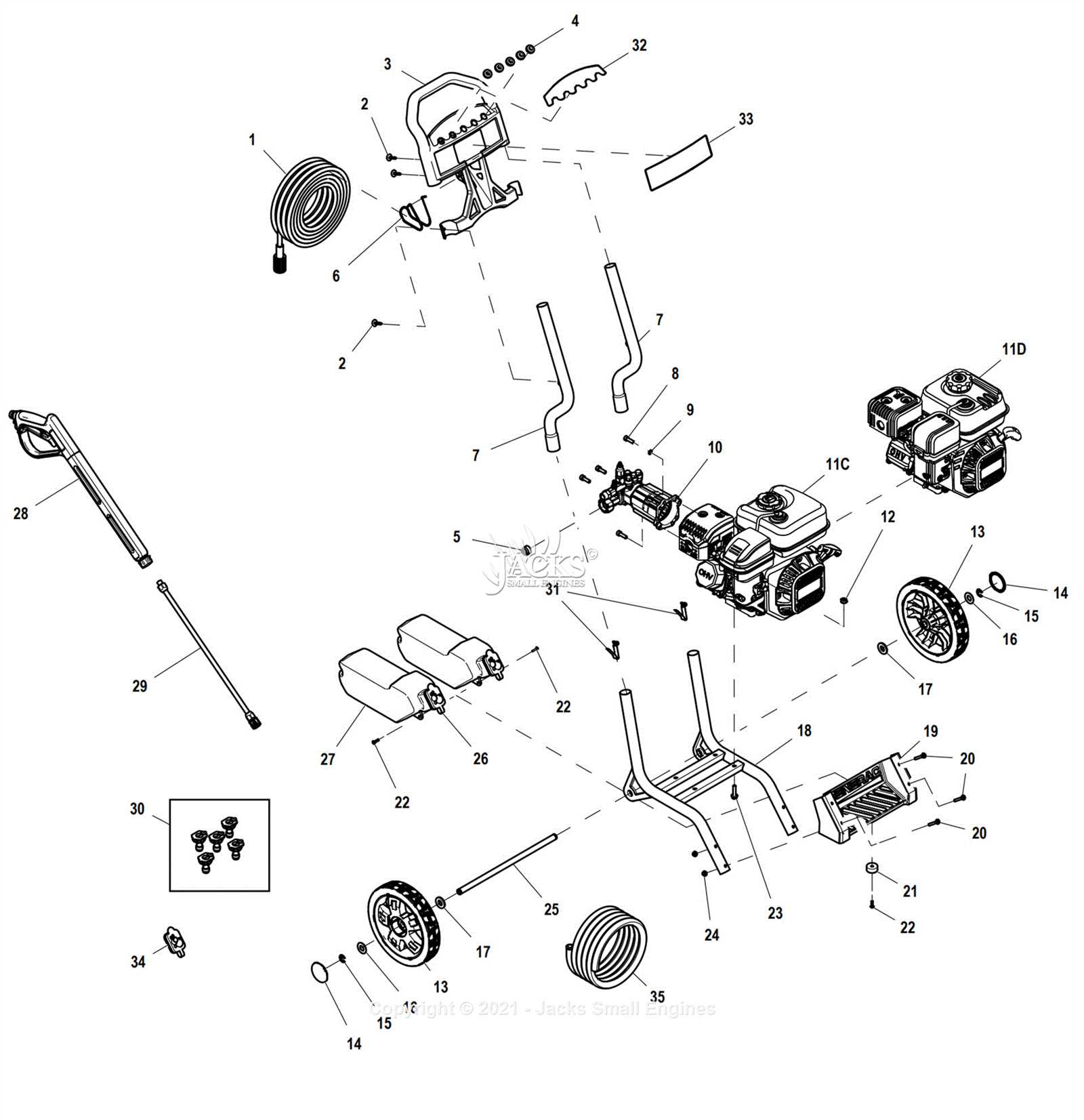

To start, familiarize yourself with the overall layout of the illustration. Components are usually labeled with unique numbers or letters that correspond to a parts list. Pay close attention to the orientation and positioning, as this can indicate how pieces fit together. Understanding the relationships between various elements can provide insight into assembly order and potential issues that may arise during repairs.

Next, examine any accompanying annotations or notes. These details often highlight important information, such as torque specifications or maintenance intervals. Don’t overlook these insights, as they can significantly influence the effectiveness of your repairs. Additionally, being aware of any optional components or accessories can broaden your understanding of what may be required for upgrades or replacements.

Lastly, practice makes perfect. The more you engage with these visuals, the better you’ll become at interpreting them. Whether you’re working on a small device or a larger machine, proficiency in reading these illustrations will empower you to tackle maintenance tasks with confidence.

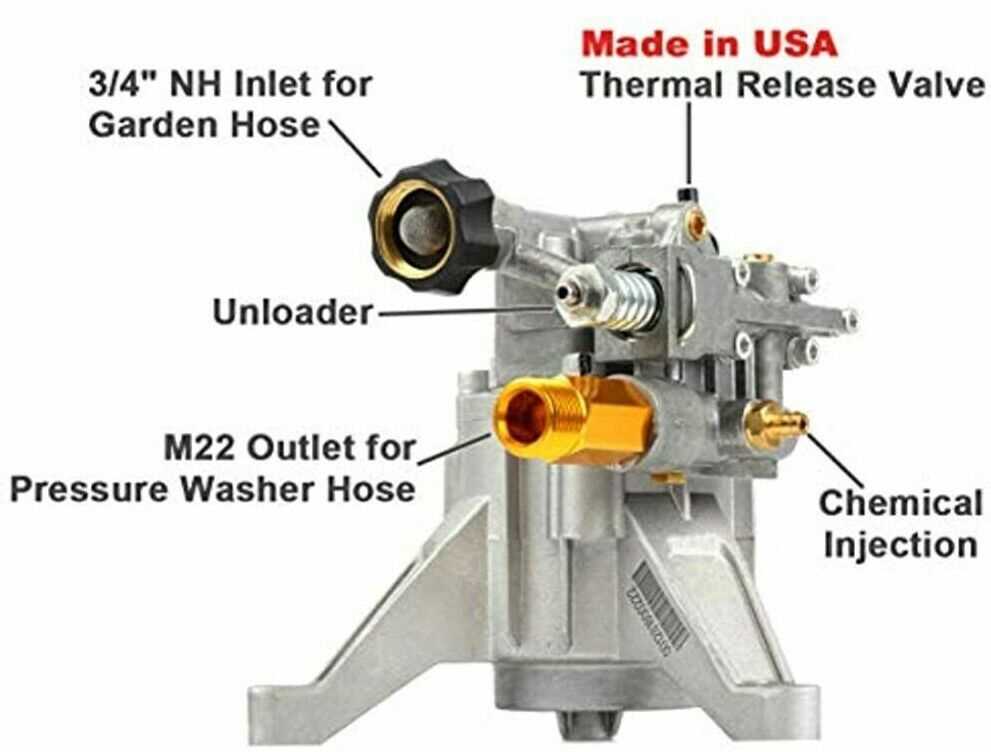

Identifying Essential Components

Understanding the key elements of a cleaning machine is crucial for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance, and recognizing these components can enhance the user experience. This section aims to highlight the main features that contribute to the functionality and efficiency of the equipment.

Motor: The heart of the device, responsible for powering the entire system. A reliable motor ensures consistent energy supply for high performance.

Pump: This component is essential for generating the force necessary to propel the cleaning solution. The pump’s efficiency directly impacts the cleaning effectiveness.

Hose: A vital link between the machine and the cleaning surface, the hose transports water and cleaning agents. Quality hoses reduce the risk of leaks and enhance maneuverability.

Nozzle: The nozzle determines the spray pattern and pressure of the output. Different nozzles allow for various cleaning tasks, from gentle rinsing to intense scrubbing.

Trigger: This control mechanism allows users to regulate the flow of water. An ergonomic design improves user comfort and control during operation.

By familiarizing oneself with these critical components, users can ensure their equipment remains in optimal condition, leading to effective and efficient cleaning outcomes.

Replacement Parts: Where to Buy

Finding quality components for your cleaning equipment is essential for maintaining its performance and longevity. Whether you need specific items for repairs or upgrades, knowing where to source them can save you time and money. Various options are available, each offering unique advantages depending on your needs.

Online Retailers

Shopping online provides a wide selection of components, often at competitive prices. Major platforms specialize in home improvement and outdoor equipment, allowing you to compare options easily.

| Website | Features |

|---|---|

| Amazon | Vast selection, user reviews, fast shipping |

| eBay | New and used items, potential for lower prices |

| Home Depot | In-store pickup, reliable customer service |

Local Stores

Visiting nearby retailers can also be beneficial. Local hardware stores often stock essential components and provide personalized assistance. Additionally, you can check availability immediately, ensuring you get the items you need without waiting for shipping.

Tips for Troubleshooting Issues

When dealing with a cleaning machine that isn’t functioning as expected, it’s essential to identify and resolve potential problems efficiently. By following a systematic approach, users can often diagnose issues and restore performance without professional assistance. Here are some helpful tips to consider.

Common Problems and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Low water flow | Clogged filter or hose | Inspect and clean filters; check for kinks in hoses. |

| Inconsistent pressure | Faulty nozzle or unclean components | Replace or clean nozzles; ensure all parts are free of debris. |

| Engine won’t start | Empty fuel tank or spark plug issues | Refill fuel and check spark plug for wear; replace if necessary. |

| Excessive noise | Loose components or worn parts | Tighten loose screws and replace worn components. |

Maintenance Tips

Regular upkeep can prevent many common issues. Always ensure that your equipment is clean and stored properly after use. Seasonal maintenance checks can also extend the life of your machine and enhance its efficiency.

Safety Precautions During Repairs

When conducting maintenance or repairs on machinery, adhering to safety protocols is essential to prevent accidents and injuries. Proper preparation and awareness can significantly reduce the risks associated with handling equipment and components. This section outlines crucial safety measures to follow during such activities.

Personal Protective Equipment

Using the right personal protective equipment (PPE) is vital. Ensure that you are equipped with the following items:

| Equipment | Purpose |

|---|---|

| Safety goggles | Protect eyes from debris and chemicals. |

| Gloves | Prevent cuts and chemical exposure. |

| Ear protection | Reduce noise levels to protect hearing. |

| Sturdy footwear | Protect feet from falling objects. |

Workspace Organization

A well-organized workspace minimizes hazards. Ensure the area is free of clutter and potential trip hazards. Keep tools and components in designated places to avoid confusion and ensure efficiency. Adequate lighting is also crucial for clear visibility during repairs.

Benefits of OEM Parts vs. Aftermarket

When it comes to maintaining equipment, the choice between original manufacturer components and third-party alternatives can significantly impact performance and longevity. Each option presents unique advantages, making it essential for users to understand the differences in order to make informed decisions.

Advantages of OEM Components

- Quality Assurance: Original parts are designed specifically for the equipment, ensuring a perfect fit and reliable performance.

- Manufacturer Support: OEM components often come with warranties and customer support, providing peace of mind.

- Compatibility: These components are engineered to work seamlessly with the machine, minimizing the risk of malfunctions.

- Longevity: Generally, OEM options are made from higher quality materials, leading to longer-lasting performance.

Benefits of Aftermarket Options

- Cost-Effectiveness: Aftermarket items tend to be more affordable, making them an attractive choice for budget-conscious consumers.

- Variety: There is often a wider range of aftermarket products available, allowing for customization and different performance levels.

- Accessibility: These options may be easier to find in various retail outlets, enhancing convenience for users.

- Innovation: Some aftermarket manufacturers incorporate advancements that may not yet be available in OEM items.

Step-by-Step Repair Guide

This section provides a detailed approach to troubleshoot and fix common issues related to your cleaning device. By following the steps outlined below, you can effectively identify problems and restore functionality without needing extensive experience.

-

Identify the Issue:

- Observe any unusual sounds or vibrations.

- Check for leaks or inconsistent performance.

- Take note of error codes or warning lights if available.

-

Gather Tools and Supplies:

- Wrenches and screwdrivers of various sizes.

- Replacement components as needed.

- Lubricants and cleaning solutions.

-

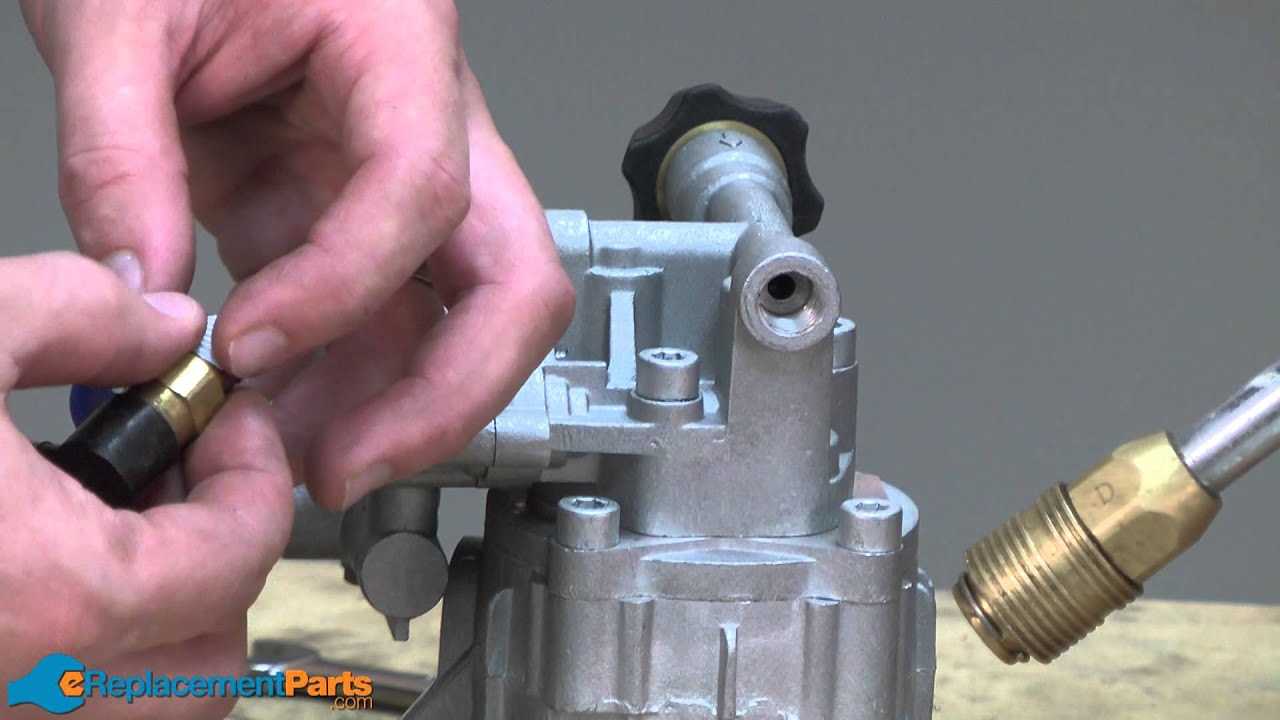

Disassemble the Unit:

- Ensure the device is powered off and unplugged.

- Carefully remove outer covers to access internal components.

- Organize screws and parts to avoid confusion during reassembly.

-

Inspect Components:

- Look for signs of wear or damage.

- Check seals and gaskets for leaks.

- Test electrical connections for corrosion or disconnections.

-

Replace or Repair Parts:

- Substitute any broken or worn-out components with new ones.

- Clean any parts that show signs of grime or buildup.

- Apply lubricants where necessary to ensure smooth operation.

-

Reassemble the Unit:

- Carefully put back all components in reverse order of disassembly.

- Tighten screws securely but avoid over-tightening.

- Ensure all parts are correctly aligned and seated.

-

Test Functionality:

- Plug in and power on the device.

- Run a short cycle to check for proper operation.

- Monitor for any issues that may arise during testing.

By following these systematic steps, you can effectively address common malfunctions and maintain the longevity of your cleaning device.

Upgrading Your Pressure Washer Parts

Enhancing the components of your cleaning device can significantly improve its performance and longevity. Whether you’re looking to boost efficiency, reduce maintenance needs, or achieve better cleaning results, upgrading specific elements can make a substantial difference. Understanding which components to replace or enhance will help you achieve optimal functionality and satisfaction.

Here are some common upgrades to consider:

| Component | Benefits | Considerations |

|---|---|---|

| High-Quality Nozzles | Improved cleaning versatility and precision. | Choose the right type for your specific tasks. |

| Enhanced Hoses | Increased durability and flexibility, reducing kinks. | Ensure compatibility with your equipment’s specifications. |

| Powerful Motors | Boosted cleaning capabilities and speed. | Check for compatibility with existing system. |

| Upgraded Pumps | Higher efficiency and longer lifespan. | Installation may require professional assistance. |

Investing in these upgrades not only enhances the functionality of your equipment but also contributes to a more enjoyable and effective cleaning experience. Always research and select components that suit your cleaning needs and ensure compatibility with your existing setup.

Understanding Pressure Washer Specifications

When selecting a cleaning machine for various tasks, it’s essential to grasp the specifications that define its capabilities and performance. These details provide insight into how effectively the equipment can handle specific jobs, ensuring you choose the right model for your needs.

Key Specifications to Consider

- Power Rating: This measurement indicates the strength of the motor or engine, influencing the cleaning force.

- Water Flow Rate: Expressed in gallons per minute (GPM), this determines how much water the machine can deliver, affecting efficiency and coverage.

- Cleaning Units: A combination of power and flow, calculated as PSI multiplied by GPM, offers a comprehensive view of the machine’s effectiveness.

- Weight: The overall weight can impact portability and ease of use, particularly in larger models.

Importance of Specifications

Understanding these specifications helps in making informed choices. By assessing the required cleaning tasks, you can match the specifications of various models to ensure optimal performance. For example, higher flow rates may be necessary for extensive surfaces, while greater power ratings are suitable for tougher stains.

In summary, being aware of these fundamental specifications enables users to select equipment tailored to their specific cleaning challenges, enhancing both efficiency and satisfaction with the chosen solution.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionality in high-pressure cleaning devices. Understanding these elements is essential for effective maintenance and troubleshooting.

What should I consider when selecting components?

When choosing replacements, consider factors such as compatibility, durability, and the specific requirements of your cleaning equipment. Always refer to the manufacturer’s recommendations to ensure optimal performance.

How can I identify the right component for my equipment?

You can identify the correct component by consulting the user manual or examining the existing parts for model numbers and specifications. If you’re uncertain, reaching out to a customer support service can provide clarity.

Regular maintenance of your equipment not only extends its lifespan but also enhances its cleaning efficiency. Always use quality components to ensure the best results.