Comprehensive Guide to John Deere GT245 Parts Diagram

Maintaining a lawn tractor requires a solid understanding of its intricate systems. Each element plays a crucial role in ensuring smooth operation and optimal performance. By familiarizing yourself with the various components, you can enhance the longevity of your machine and tackle any issues that may arise with confidence.

In this section, we will explore the essential parts of a specific model, highlighting their functions and interconnections. This knowledge not only aids in effective troubleshooting but also empowers you to perform routine maintenance tasks independently. Whether you’re a seasoned technician or a DIY enthusiast, grasping the layout of your tractor’s assembly can significantly improve your repair skills.

We’ll provide a comprehensive overview of the main elements, illustrating their arrangement and relationship to one another. Understanding these connections will help you make informed decisions when it comes to repairs or upgrades. With the right insights, you can ensure that your lawn tractor continues to operate efficiently for years to come.

Understanding the GT245 Model

The GT245 represents a significant advancement in the realm of lawn care and maintenance machinery. Designed for efficiency and ease of use, this model showcases a blend of power and versatility, catering to a variety of landscaping tasks. Its construction emphasizes durability, ensuring it can withstand rigorous use while delivering consistent performance.

Key Features

Among the notable characteristics of this model are its user-friendly controls and robust engine. These elements combine to enhance the overall user experience, making it suitable for both residential and commercial applications.

Maintenance and Care

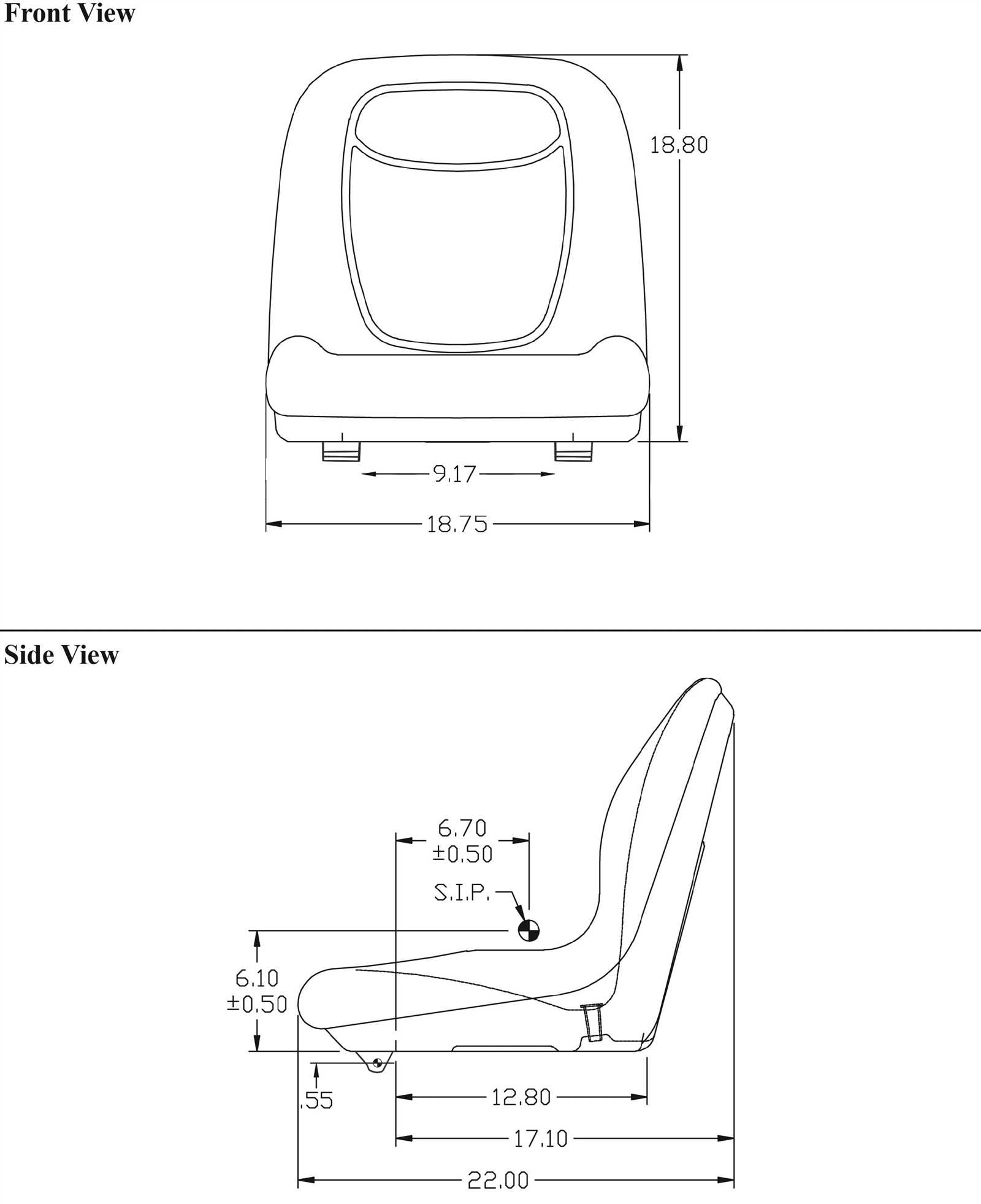

Proper upkeep is essential for longevity and optimal performance. Regular inspections and timely replacements of components can prevent common issues and extend the lifespan of the machine.

| Component | Recommended Maintenance |

|---|---|

| Engine Oil | Change every 50 hours of operation |

| Air Filter | Inspect and clean monthly |

| Blades | Sharpen or replace as needed |

| Belt | Check for wear every season |

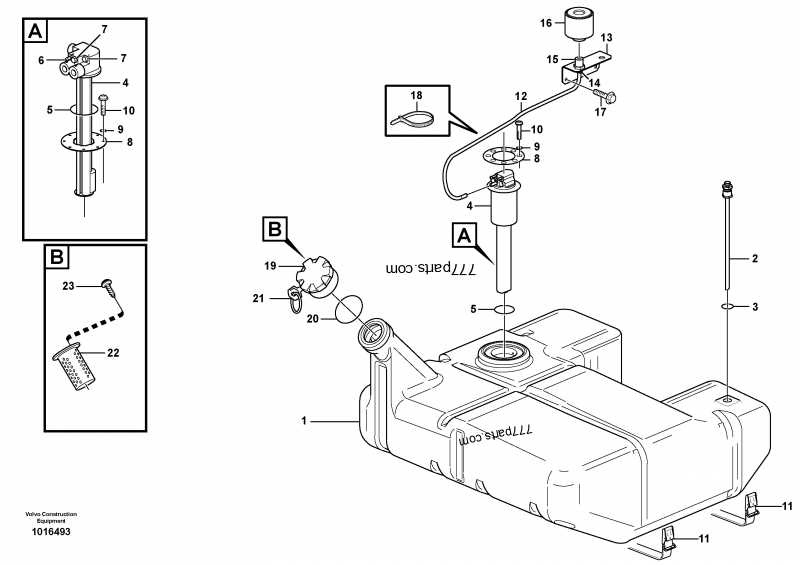

Importance of Parts Diagrams

Understanding the intricate assembly of machinery is crucial for effective maintenance and repair. Visual representations of components serve as essential tools for identifying, organizing, and managing the various elements of equipment. Such illustrations not only enhance clarity but also facilitate troubleshooting, ensuring that users can efficiently address issues that may arise.

Efficiency in repairs is greatly improved when a clear outline of the machine’s layout is available. Technicians can quickly locate specific items, minimizing downtime and expediting the restoration process. Moreover, these visuals support accurate reassembly, reducing the likelihood of errors that could compromise functionality.

In addition, educational value plays a significant role. For new operators or technicians, visual guides provide an intuitive way to grasp complex systems. This foundational knowledge can foster confidence and skill development, ultimately leading to better overall performance and safety in handling machinery.

Lastly, having a reliable reference can enhance resource management. When users are familiar with the various components, they can make informed decisions about procurement and inventory, ensuring that necessary supplies are readily available for maintenance tasks.

Common Issues with GT245

This section explores frequent challenges faced by users of this particular model. Understanding these common problems can help in troubleshooting and maintaining optimal performance.

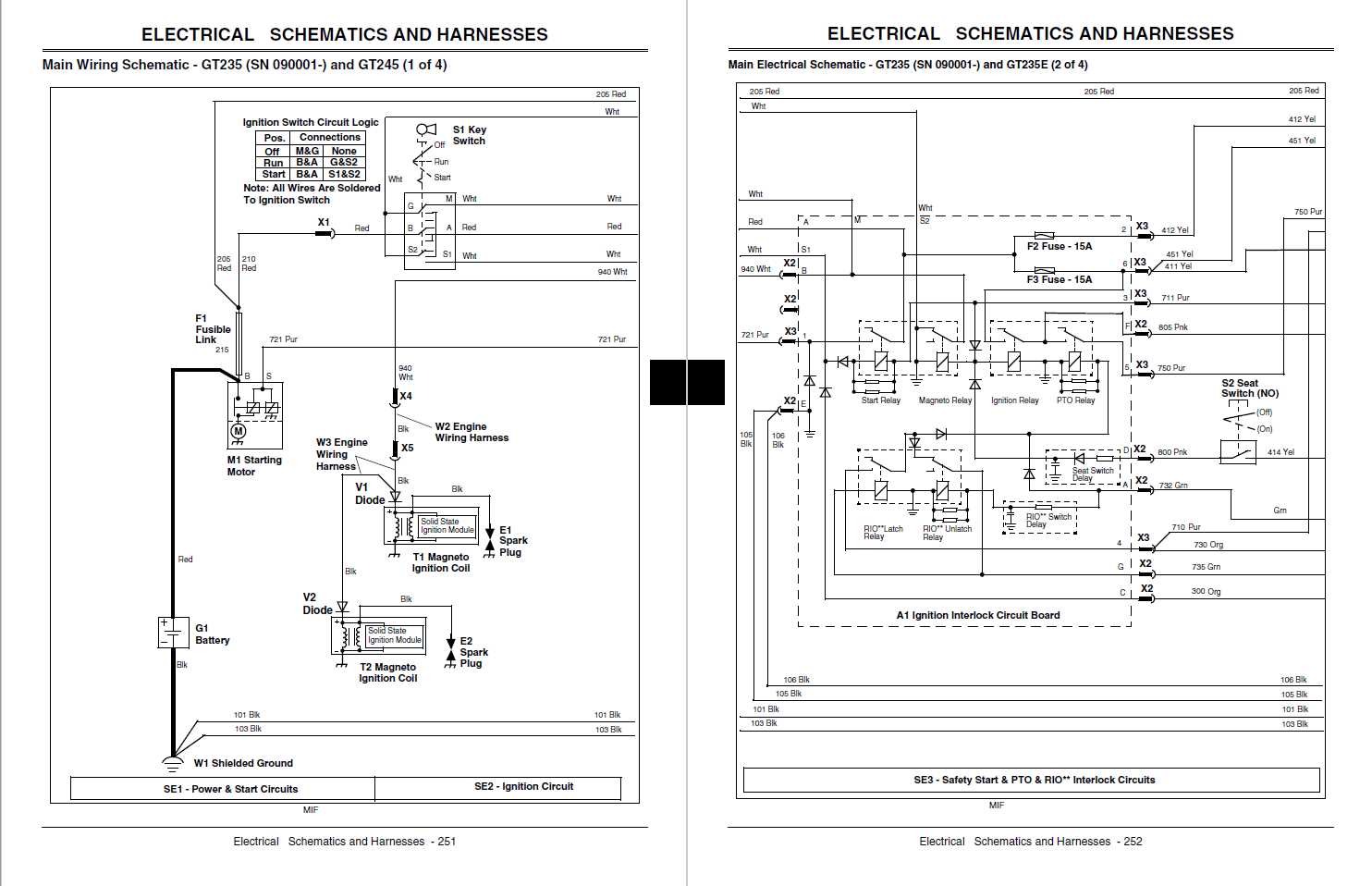

- Electrical Failures:

Many users report issues related to the electrical system, such as:

- Battery drainage

- Faulty ignition switch

- Wiring connections corroding

- Engine Performance:

Engine-related concerns can arise, including:

- Hard starting

- Overheating

- Unusual noises during operation

- Transmission Issues:

Problems with the drive system may occur, such as:

- Slipping gears

- Difficulty shifting

- Unresponsive movement

- Deck and Cutting Problems:

Maintaining a clean cut can be challenging due to:

- Blades becoming dull

- Uneven cutting

- Clogged discharge areas

- Fuel System Troubles:

Fuel-related issues can hinder performance, such as:

- Clogged fuel filters

- Inconsistent fuel supply

- Contaminated fuel

lessCopy code

How to Locate Replacement Parts

Finding the right components for machinery can be a challenging task, especially when ensuring compatibility and quality. This section outlines effective strategies for identifying suitable replacements, making the process more efficient and straightforward.

Utilizing Online Resources

The internet is a valuable tool for discovering various options. Numerous websites specialize in providing detailed catalogs and specifications for machinery components. Search for reputable online retailers or forums dedicated to equipment maintenance. User reviews and ratings can guide you toward reliable sources.

Consulting Manuals and Specifications

Referencing the original documentation can be immensely helpful. Manuals often include crucial information about dimensions, model numbers, and part compatibility. Ensure you have the correct version of the manual to avoid any confusion.

| Resource Type | Description |

|---|---|

| Manufacturer’s Website | Official site offering specifications and direct ordering options. |

| Online Retailers | Third-party vendors with a wide selection of components. |

| Forums and Communities | Discussion boards where users share advice and experiences. |

| Service Manuals | Comprehensive guides that include installation instructions and specifications. |

Exploring GT245 Maintenance Tips

Regular upkeep of your outdoor equipment ensures optimal performance and longevity. By implementing a few essential practices, you can enhance the efficiency of your machine and prevent potential issues. Proper care not only maintains functionality but also contributes to a smoother user experience.

Routine Inspections: Conducting frequent checks on your machinery is crucial. Look for any signs of wear and tear, loose components, or fluid leaks. Addressing minor issues early can prevent costly repairs down the line.

Fluid Maintenance: Keeping fluids at appropriate levels is vital for engine health. Regularly check and replace oil, coolant, and fuel as needed. Clean filters and ensure that all fluids are free from contaminants to maintain performance.

Cleaning: A clean machine operates more efficiently. Remove grass clippings, dirt, and debris from critical areas. Regular cleaning not only improves appearance but also prevents corrosion and build-up that can hinder performance.

Sharpening Blades: For cutting tools, maintaining sharp blades is essential. Dull blades can lead to poor cutting performance and increased strain on the engine. Regular sharpening ensures a clean cut and enhances the overall efficiency of the equipment.

Storage Practices: Proper storage during off-seasons can significantly extend the lifespan of your machinery. Keep the equipment in a dry, sheltered area and consider using protective covers to shield it from dust and moisture.

By following these maintenance tips, you can ensure that your outdoor equipment remains reliable and efficient for years to come. Consistent attention to detail will yield significant benefits in performance and durability.

Identifying Essential Components

Understanding the key elements of machinery is crucial for effective maintenance and repair. Each component plays a significant role in the overall functionality and performance, making it important to recognize and assess their conditions regularly.

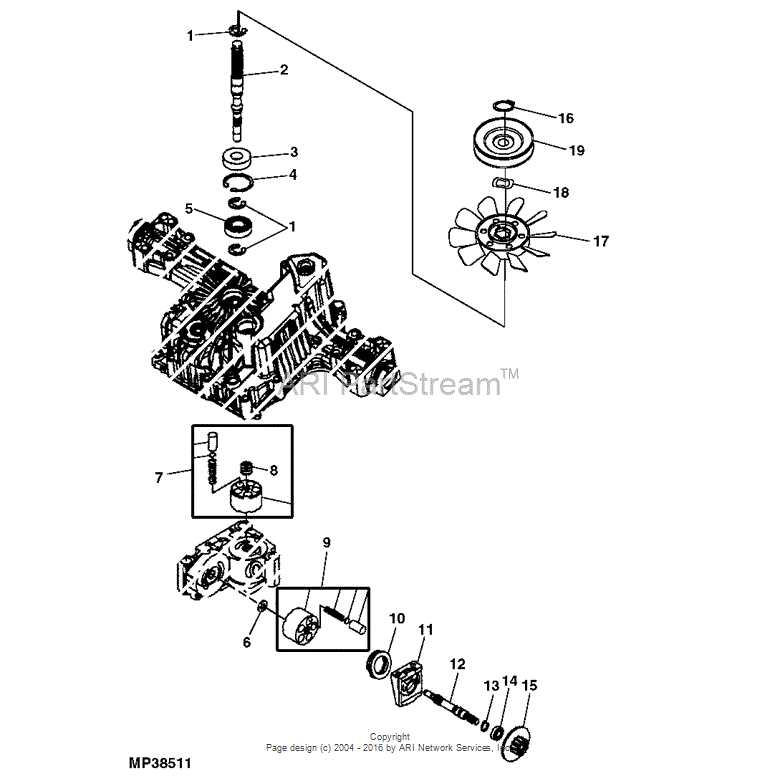

Engines serve as the heart of the equipment, providing the necessary power for operation. Regular checks for wear and tear can prevent major failures.

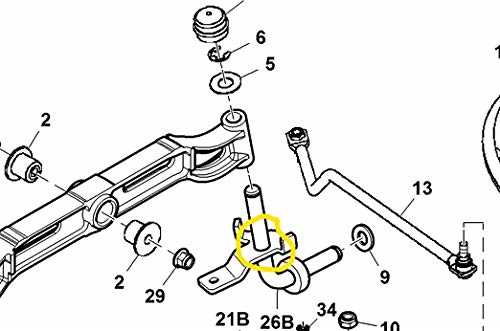

Transmission systems facilitate the transfer of power from the engine to the wheels, ensuring smooth movement. It’s vital to monitor fluid levels and inspect for leaks.

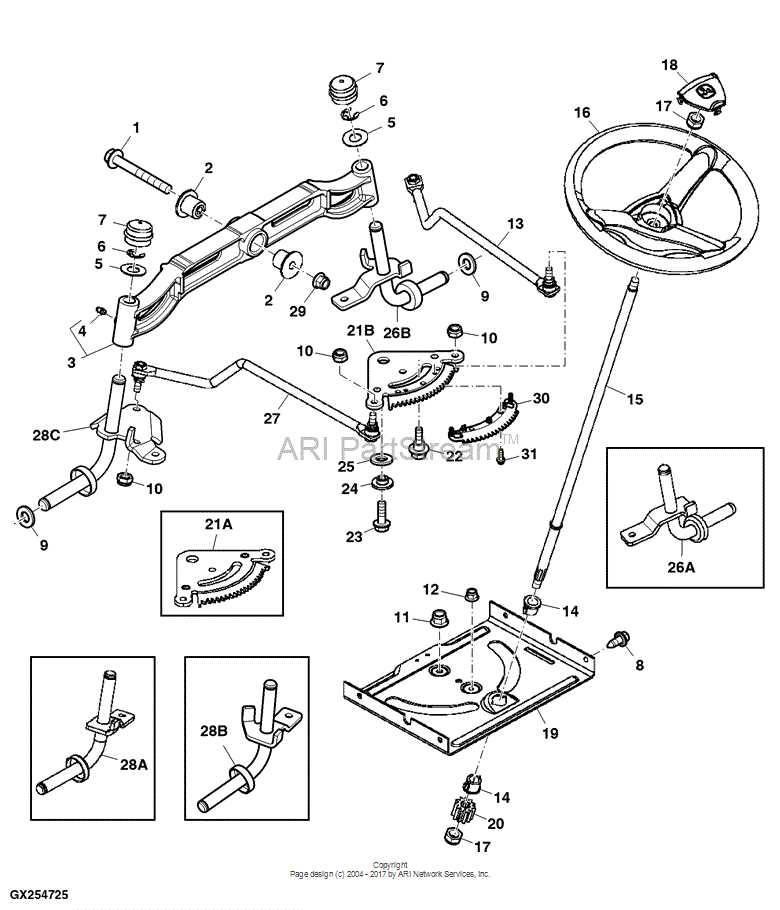

Electrical systems control various functions, from starting the engine to powering accessories. Keeping connections clean and secure is essential for reliability.

Hydraulic components are critical for lifting and maneuvering, providing the force needed for various tasks. Regular maintenance can extend their lifespan and enhance performance.

Finally, frames and chassis provide structural integrity and stability. Regular inspections help identify any cracks or corrosion that may compromise safety.

By familiarizing oneself with these essential elements, operators can ensure their machinery remains in optimal condition, leading to increased efficiency and reduced downtime.

Where to Buy John Deere Parts

Finding the right components for your machinery can be a crucial task, ensuring optimal performance and longevity. Fortunately, there are several avenues to explore when seeking high-quality replacements and accessories for your equipment.

Online Retailers

The internet offers a plethora of options for purchasing machinery components. Here are some popular choices:

- Manufacturer’s Website: Official sites often provide the most reliable selection, ensuring authenticity.

- Specialized Online Stores: Many websites focus exclusively on agricultural equipment and its needs.

- General Retailers: Major e-commerce platforms may also have a dedicated section for machinery components.

Local Dealers and Stores

For those who prefer in-person shopping, local dealers and supply stores are excellent resources:

- Authorized Dealers: These establishments specialize in specific brands and typically offer expert advice.

- Farm Supply Stores: Many of these shops carry a range of components suitable for various models.

- Salvage Yards: For budget-conscious buyers, second-hand parts can be a viable option.

Whichever route you choose, ensure that the components meet your quality standards and are compatible with your machinery.

Comparing OEM and Aftermarket Parts

When maintaining machinery, the choice between original components and alternatives often arises. This decision can significantly impact performance, reliability, and overall cost. Understanding the distinctions between these options is crucial for making an informed choice that suits both the equipment and the owner’s needs.

Original Equipment Manufacturer (OEM) components are produced by the same company that manufactured the machinery. These components are designed to meet the exact specifications and standards of the original design, ensuring optimal compatibility and performance. Users can typically expect consistent quality and reliability, as these parts undergo rigorous testing.

In contrast, aftermarket components are produced by third-party companies. While they can offer a more affordable option, the quality and compatibility can vary widely. Some aftermarket alternatives may provide excellent performance and durability, while others may fall short, leading to potential issues down the line. It is essential to research and choose reputable brands to mitigate risks.

Ultimately, the choice between these options hinges on factors such as budget, performance expectations, and personal preferences. Each type has its own set of advantages and drawbacks, making it essential to weigh them carefully before making a decision.

Reading the Parts Diagram Effectively

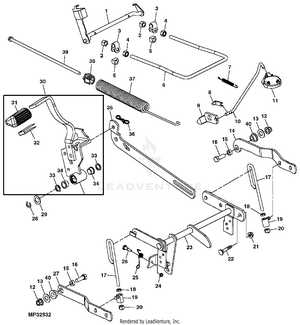

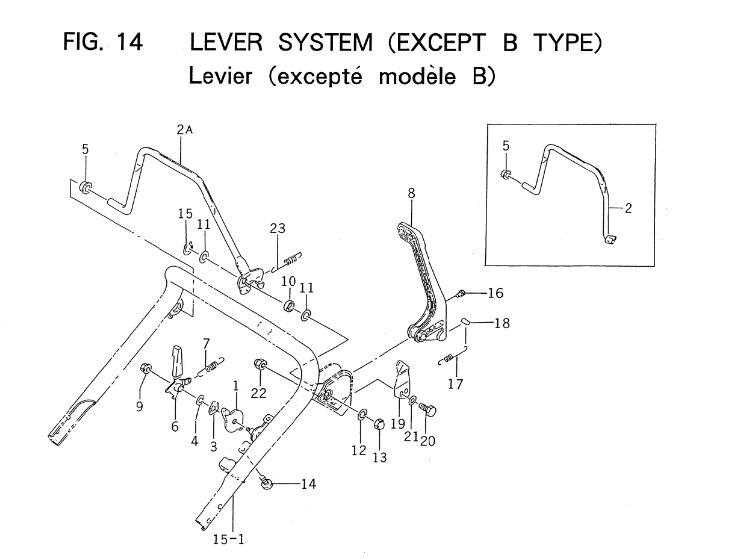

Understanding the layout of components is crucial for efficient maintenance and repairs. A well-structured illustration can provide clarity on how each element interacts, aiding in identification and troubleshooting. Grasping the key aspects of these visual aids can save time and enhance accuracy when working on machinery.

Here are some essential tips for interpreting these visuals:

| Tip | Description |

|---|---|

| Familiarize Yourself with the Legend | Start by reviewing any symbols or annotations provided. They often explain the various components and their corresponding codes. |

| Break Down the Sections | Divide the illustration into manageable parts. Focus on one section at a time to avoid feeling overwhelmed. |

| Cross-Reference with Manuals | Use technical manuals in conjunction with the visual guide. This can provide additional context and specifications. |

| Take Notes | Jot down important details as you study the illustration. This will help reinforce your understanding and serve as a quick reference. |

By applying these strategies, you can navigate complex visual representations with confidence, making your repair and maintenance tasks more efficient and effective.

DIY Repairs for GT245 Owners

For enthusiasts of lawn care equipment, understanding how to perform maintenance and minor repairs can enhance the longevity and efficiency of your machine. Whether it’s a simple tune-up or addressing specific issues, tackling these tasks yourself can save time and money while fostering a deeper connection with your equipment.

Essential Tools and Preparation

Before diving into any repairs, ensure you have the right tools at your disposal. A basic toolkit should include wrenches, screwdrivers, pliers, and a multimeter for electrical diagnostics. Additionally, having a clean workspace and proper safety gear is crucial to execute tasks safely and effectively.

Common Repairs and Maintenance Tips

Routine maintenance is vital. Start with checking the oil and changing it as necessary to ensure optimal performance. Blades should be sharpened regularly to maintain a clean cut, while air filters must be inspected and replaced to keep the engine running smoothly. If electrical issues arise, consulting the wiring schematics can help identify problems without the need for professional assistance.

By understanding these fundamental tasks, owners can confidently approach repairs and ensure their equipment remains in top shape for years to come.

Tools Needed for Maintenance

Proper upkeep of machinery requires a variety of essential implements to ensure optimal performance and longevity. Familiarity with these tools can simplify tasks and enhance efficiency during maintenance procedures.

Here are some key instruments you will need:

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening bolts and nuts.

- Screwdrivers: A set of flathead and Phillips screwdrivers is necessary for various fastening tasks.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, bending, and cutting wires.

- Grease Gun: This tool helps in lubricating moving parts, reducing friction and wear.

- Oil Filter Wrench: Designed to remove and install oil filters efficiently.

- Jack Stands: Essential for safely elevating and securing equipment during repairs.

- Multimeter: Used for checking electrical systems and diagnosing potential issues.

Having these tools readily available will facilitate routine inspections and repairs, contributing to the overall health of your equipment.

Maximizing the Lifespan of Your Mower

To ensure your cutting machine remains efficient and reliable for years to come, proper maintenance and care are essential. By following a few key practices, you can significantly enhance the longevity of your equipment while ensuring optimal performance throughout its lifespan.

Regular Maintenance Routines

Establishing a consistent maintenance schedule is crucial. Consider the following tasks:

- Check and change the oil regularly to keep the engine running smoothly.

- Sharpen the blades frequently to achieve a clean cut and reduce strain on the motor.

- Inspect and clean air filters to prevent debris buildup and ensure proper airflow.

- Examine belts and cables for wear and tear to avoid unexpected breakdowns.

Seasonal Preparations

Preparing your equipment for seasonal changes can also extend its lifespan. Here are some tips:

- Before winter, store your mower in a dry, sheltered area to protect it from the elements.

- Fuel stabilizers can prevent fuel degradation during off-seasons.

- In spring, inspect the battery and recharge if necessary to ensure reliability.

By implementing these practices, you can maintain your mower in peak condition, allowing you to enjoy a beautifully manicured lawn for many seasons ahead.