Comprehensive Guide to Craftsman LT1500 Parts Diagram

In the world of outdoor machinery, maintaining optimal performance often hinges on a clear understanding of how each element functions and fits together. When tackling repairs or upgrades, having access to an organized representation of the various components can make all the difference. This section delves into the intricate assembly of a specific model, providing valuable insights for enthusiasts and professionals alike.

Identifying individual elements within your equipment not only simplifies maintenance tasks but also enhances the overall efficiency of the machine. By familiarizing yourself with the arrangement and interaction of key components, you equip yourself with the knowledge to troubleshoot effectively and make informed decisions about replacements or enhancements.

In the following segments, we will explore the intricate details of this machinery’s structure. Understanding these relationships allows you to navigate challenges with confidence and ensures that your outdoor tools remain in peak condition, ready to tackle any lawn care task.

Understanding the Craftsman LT1500

This section aims to provide a comprehensive overview of a popular lawn tractor model, focusing on its features, functionality, and maintenance needs. By exploring its design and capabilities, users can gain insight into how to optimize its performance and longevity.

Key Features

One of the standout characteristics of this model is its robust engine, which delivers reliable power for a variety of lawn care tasks. Additionally, the ergonomic design ensures user comfort during operation, making it ideal for prolonged use. Versatile attachments enhance its functionality, allowing for year-round application beyond just mowing.

Maintenance Considerations

Regular upkeep is essential to maintain efficiency and prevent potential issues. Routine checks of the engine, belts, and blades will ensure smooth operation. Utilizing a detailed reference for components can greatly assist owners in identifying parts that may need replacement, ultimately prolonging the life of the machine.

Overview of LT1500 Features

This section delves into the distinctive characteristics and functionalities of a popular lawn care machine, highlighting its advantages for users seeking efficiency and reliability in their gardening tasks.

One of the standout aspects of this model includes its robust engine, designed to provide ample power for various yard maintenance activities. This ensures users can tackle even the toughest jobs without any hassle.

Key features include:

- Efficient Cutting System: The advanced blade technology promotes a clean and even cut, enhancing the overall appearance of your lawn.

- Ergonomic Design: The machine’s structure is tailored for user comfort, reducing fatigue during extended operation.

- Easy Maneuverability: With responsive steering and a compact frame, navigating tight spaces becomes effortless.

- Durable Build: Constructed with high-quality materials, it promises longevity and resilience against the elements.

- Versatile Attachments: Compatible with various accessories, allowing users to expand its functionality for different tasks.

In summary, this lawn care equipment combines power, comfort, and adaptability, making it an excellent choice for maintaining any outdoor space effectively.

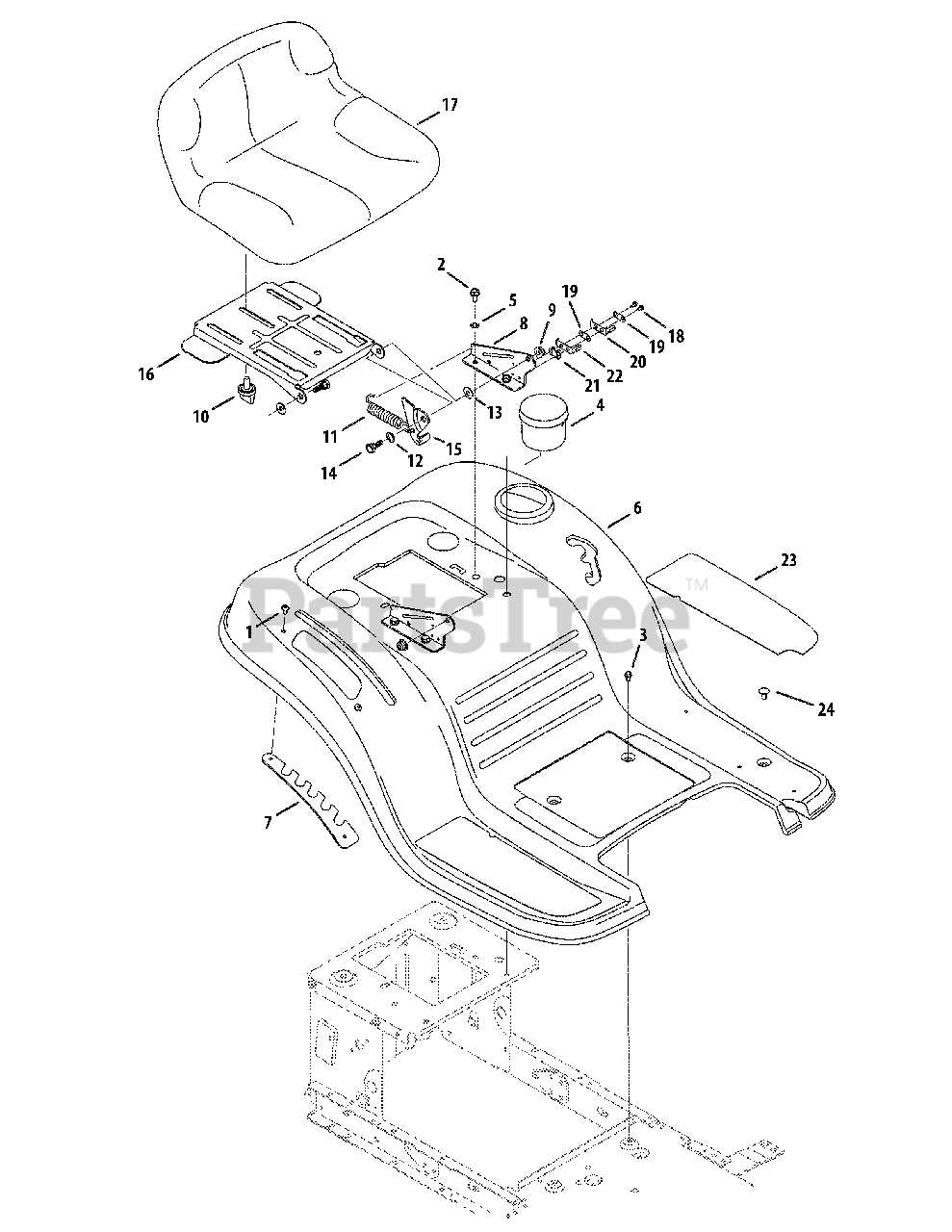

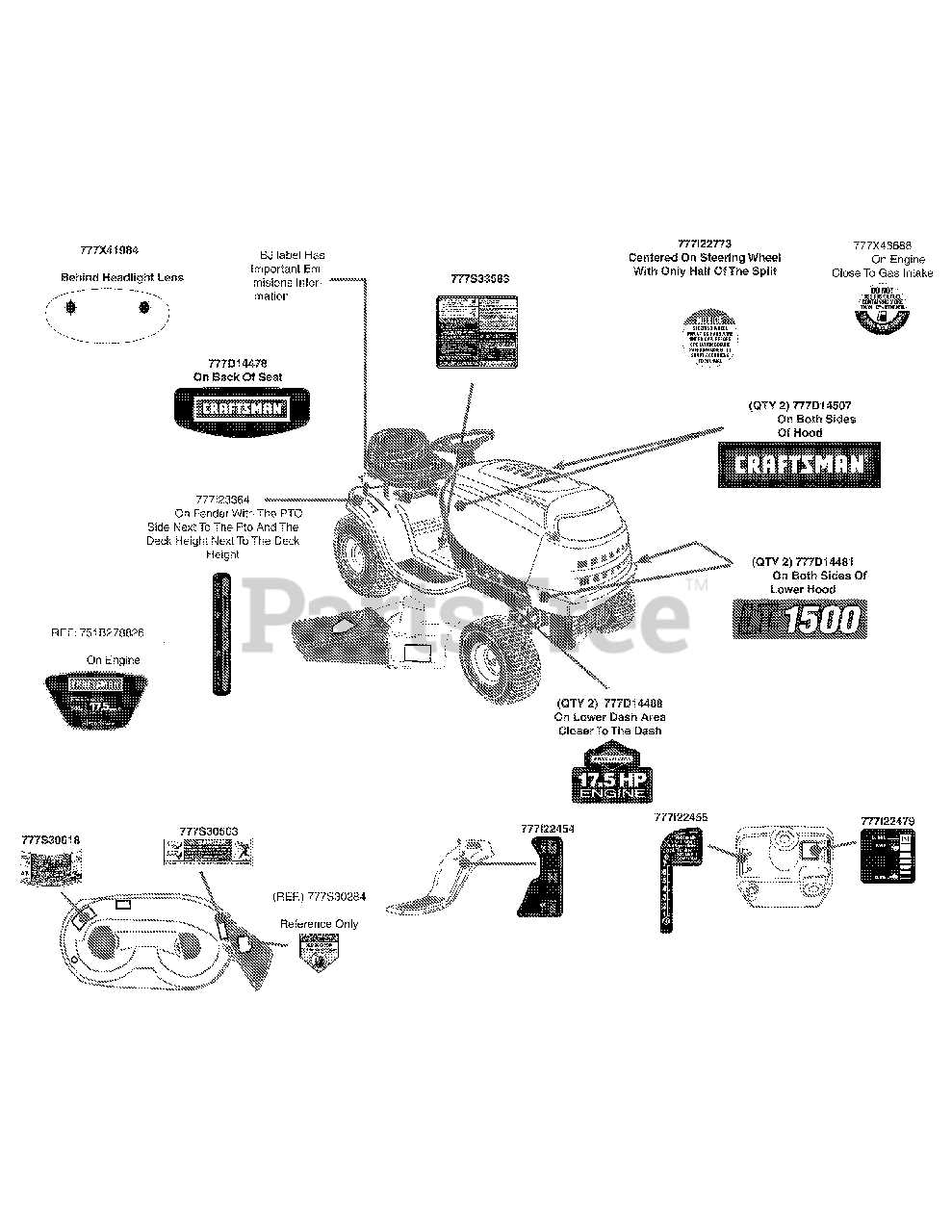

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations serve as valuable tools for users, enabling them to identify and address issues more efficiently.

- Facilitates quick troubleshooting.

- Enhances comprehension of assembly and disassembly processes.

- Reduces the risk of errors during repairs.

- Helps in sourcing appropriate replacements.

Moreover, having a clear visual reference can ultimately improve the longevity and performance of equipment, ensuring that it operates smoothly for years to come.

Key Components of the LT1500

Understanding the essential elements of a lawn tractor is crucial for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance, contributing to the overall efficiency and reliability of the machine. Familiarity with these components allows users to troubleshoot issues and undertake necessary repairs more confidently.

At the heart of the tractor lies the engine, which provides the power needed for various tasks, from mowing to hauling. Coupled with the transmission system, it facilitates smooth movement and control. The cutting deck is another vital component, designed to deliver a clean and even cut, significantly impacting the quality of the lawn’s appearance.

Additionally, the steering mechanism ensures maneuverability, allowing users to navigate tight spaces with ease. The wheels and tires are engineered for stability and traction, essential for navigating different terrains. Lastly, the electrical system, including the battery and ignition components, is critical for starting the engine and powering accessories.

Where to Find Parts Diagrams

Locating visual representations of components for various machinery can be essential for maintenance and repairs. These illustrations provide a clear overview of each piece and its relation to others, facilitating easier identification and troubleshooting.

Here are some reliable sources to consider when searching for these valuable resources:

- Manufacturer’s Website: Many companies host detailed catalogs on their official sites, offering downloadable illustrations and specifications.

- Online Retailers: Websites that specialize in selling equipment often provide access to component visuals alongside product listings.

- Forums and Community Groups: Enthusiast forums and social media groups can be treasure troves of shared knowledge and resources, including links to useful visuals.

- Repair Manuals: Printed or digital repair manuals frequently contain detailed sketches and can be purchased or found in libraries.

Utilizing these resources can significantly enhance your ability to perform repairs effectively and efficiently.

Common Issues and Solutions

In the world of outdoor machinery, users often encounter a range of challenges that can impede performance and efficiency. Identifying these frequent problems is the first step toward effective troubleshooting and restoration. Below are some typical concerns along with practical solutions to enhance operation and longevity.

One common issue is engine starting difficulties, often caused by fuel problems or ignition failures. Ensuring that fresh fuel is used and checking the spark plug can often resolve this problem. Regular maintenance of these components is crucial for smooth operation.

Another frequent challenge is uneven cutting performance. This can stem from dull blades or improper deck height settings. Sharpening the blades and adjusting the cutting height can significantly improve results.

Furthermore, if the equipment is experiencing excessive vibration, it may indicate misalignment or worn-out parts. Inspecting the belt and other moving components for wear can help mitigate this issue.

Lastly, issues with the electrical system, such as dead batteries or faulty connections, can hinder functionality. Regularly checking battery health and cleaning connections can prevent these setbacks.

How to Use a Parts Diagram

A visual representation of components can be an invaluable tool when attempting to understand the assembly and functioning of machinery. These illustrations help users identify each element, making repairs and maintenance tasks more manageable and efficient.

Understanding the Layout

Typically, these visuals are organized in a way that groups related items together. Familiarizing yourself with the layout is crucial to quickly locate the parts you need.

Finding Replacement Components

Once you have a grasp of the arrangement, you can easily pinpoint the specific elements that require attention or replacement. Here’s a simple guide to help you navigate:

| Step | Description |

|---|---|

| 1 | Identify the section related to your issue. |

| 2 | Match the part numbers to ensure accuracy. |

| 3 | Note any additional components that may need replacement. |

Identifying Parts by Model Number

Understanding the specific identifiers associated with machinery is crucial for effective maintenance and repair. Each model features unique numbers that enable users to locate the correct components swiftly. By familiarizing oneself with these identifiers, one can ensure optimal performance and longevity of the equipment.

| Identifier Type | Description |

|---|---|

| Model Number | A unique code that denotes the specific version of the equipment. |

| Serial Number | A distinct number assigned to each individual unit for tracking and warranty purposes. |

| Part Number | A specific code that identifies each component within the model, facilitating replacement. |

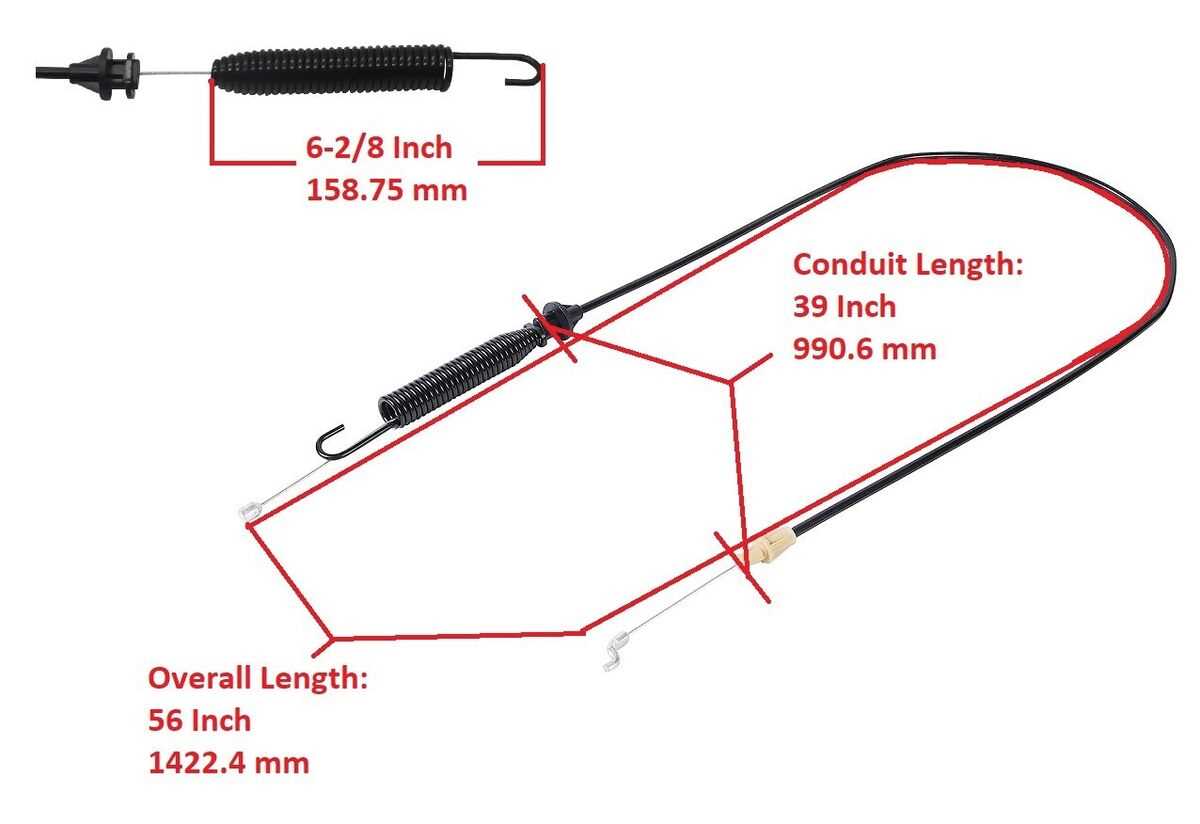

Replacement Parts: What You Need

When it comes to maintaining and repairing your equipment, knowing the essential components and their replacements is crucial. Understanding which elements require attention can significantly enhance the longevity and performance of your machinery.

Here’s a guide to help you identify the key components that may need replacement over time:

- Belts: Over time, belts can wear out due to constant tension and friction. Regularly inspect them for cracks or fraying.

- Blades: Dull or damaged blades can hinder performance. Ensure they are sharpened or replaced as needed.

- Batteries: If your equipment relies on a battery, check its condition. A weak battery can lead to unreliable operation.

- Filters: Air and fuel filters should be changed periodically to ensure optimal performance and efficiency.

- Wheels: Inspect wheels for damage or wear. Replacing them can improve mobility and safety.

By keeping an eye on these components and replacing them when necessary, you can ensure that your machinery runs smoothly and effectively for years to come.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular care and attention. Proper maintenance not only enhances performance but also prevents costly repairs in the long run. By adhering to a few essential practices, you can significantly improve the durability and efficiency of your machinery.

1. Regular Cleaning: Keep the surfaces and components free from dirt and debris. Use a soft brush or cloth to remove any buildup, especially in hard-to-reach areas. This simple step can prevent rust and corrosion.

2. Fluid Checks: Periodically inspect oil and fuel levels. Maintaining the appropriate levels is crucial for optimal operation. Replace old fluids with fresh ones according to the manufacturer’s recommendations.

3. Inspection of Belts and Cables: Examine belts for signs of wear or fraying. Ensure that all cables are securely connected and in good condition. Addressing minor issues promptly can prevent more significant failures.

4. Sharpening Blades: If applicable, regularly sharpen cutting tools to ensure efficiency and reduce strain on the engine. Dull blades can lead to increased wear and energy consumption.

5. Seasonal Tune-Ups: Perform a thorough checkup at the start of each season. This can include changing filters, inspecting tires, and adjusting settings as necessary. A proactive approach will keep your equipment running smoothly.

By implementing these maintenance strategies, you can maximize the life and performance of your machinery, ensuring it remains reliable for years to come.

Online Resources for Craftsman Parts

Accessing quality components for your machinery can significantly enhance its performance and longevity. Fortunately, the internet offers a wealth of resources for locating essential items, ensuring that repairs and maintenance are straightforward and efficient. With various online platforms available, users can find detailed information and a range of products tailored to their specific needs.

Manufacturer Websites

Many manufacturers maintain official websites where users can find a comprehensive catalog of available components. These sites often feature searchable databases, allowing individuals to enter their model numbers to locate precise items quickly. Additionally, they may provide manuals, installation guides, and troubleshooting tips, which are invaluable for both novice and experienced users alike.

Online Marketplaces

Various online marketplaces serve as excellent alternatives for sourcing components. These platforms connect buyers with multiple sellers, offering a variety of options and price points. User reviews and ratings can guide purchasing decisions, ensuring that customers receive reliable products. Furthermore, many of these sites feature user-friendly interfaces, making it easy to navigate and compare different offerings.

Customer Support and Assistance Options

Accessing reliable support can significantly enhance your experience when working with mechanical products. Whether you need troubleshooting help or guidance on maintenance, there are several resources available to ensure you receive the assistance you require.

Contact Methods

- Phone Support: Reach out to dedicated representatives for immediate assistance.

- Email Inquiries: Send detailed questions for thorough responses.

- Online Chat: Engage with support agents in real-time for quick solutions.

Additional Resources

- Official Website: Explore FAQs and helpful articles that cover common issues.

- User Manuals: Access documentation for comprehensive instructions and guidelines.

- Community Forums: Connect with fellow users to share experiences and solutions.