Comprehensive Guide to Stihl 026 Parts Diagram

When it comes to maintaining and repairing power tools, having a clear visual representation of their internal structure is essential. This insight not only aids in the identification of individual elements but also enhances the overall comprehension of how these machines operate. By examining the intricate layout of a chainsaw, users can ensure optimal performance and longevity.

In this exploration, we will delve into the various elements that make up a particular model of a cutting tool, shedding light on their functions and interconnections. Understanding these components is crucial for anyone looking to troubleshoot issues or perform routine maintenance. Knowledge of the assembly’s design can empower users to take charge of their equipment’s upkeep.

Equipped with a thorough understanding of the essential components, operators can approach repairs with confidence. Whether it’s replacing a worn-out part or conducting a comprehensive inspection, familiarity with the layout will facilitate a smoother process. This knowledge not only streamlines repairs but also promotes a deeper appreciation for the machinery in use.

Understanding the Stihl 026 Chainsaw

The chainsaw in question is a robust tool, known for its reliability and efficiency in various cutting tasks. Designed for both professional and home use, it combines power and precision, making it an essential piece of equipment for anyone who regularly handles woodwork or forestry projects. Familiarity with its components can greatly enhance the user experience and maintenance efforts.

Key Features

- Powerful engine for high performance

- Lightweight design for ease of handling

- Ergonomic grip for comfort during prolonged use

- Durable construction for long-lasting reliability

Common Components

- Bar and chain: Essential for cutting through wood.

- Fuel system: Includes the tank and carburetor for optimal engine performance.

- Air filter: Keeps the engine clean by filtering out debris.

- Safety features: Designed to protect the user during operation.

Understanding these aspects will not only enhance operational effectiveness but also facilitate better maintenance and troubleshooting, ensuring that the equipment remains in peak condition for years to come.

Key Components of Stihl 026

The performance and efficiency of a chainsaw largely depend on its essential elements. Understanding these critical components can enhance maintenance practices and ensure optimal operation. Each part plays a unique role, contributing to the overall functionality and durability of the tool.

One of the primary elements is the engine, which provides the necessary power for cutting. The carburetor regulates the fuel-air mixture, ensuring smooth operation and performance under various conditions. Additionally, the ignition system is vital for starting the engine and maintaining consistent power delivery.

The cutting mechanism consists of a chain and guide bar, which work together to achieve precision in cutting tasks. The tensioning system allows for easy adjustments, ensuring the chain remains secure during operation. Furthermore, the brake system enhances safety by stopping the chain quickly in case of kickback.

Lastly, the body of the tool is designed for durability and comfort, featuring ergonomic grips that reduce fatigue during prolonged use. Regular inspection and understanding of these crucial components can significantly extend the lifespan of the equipment.

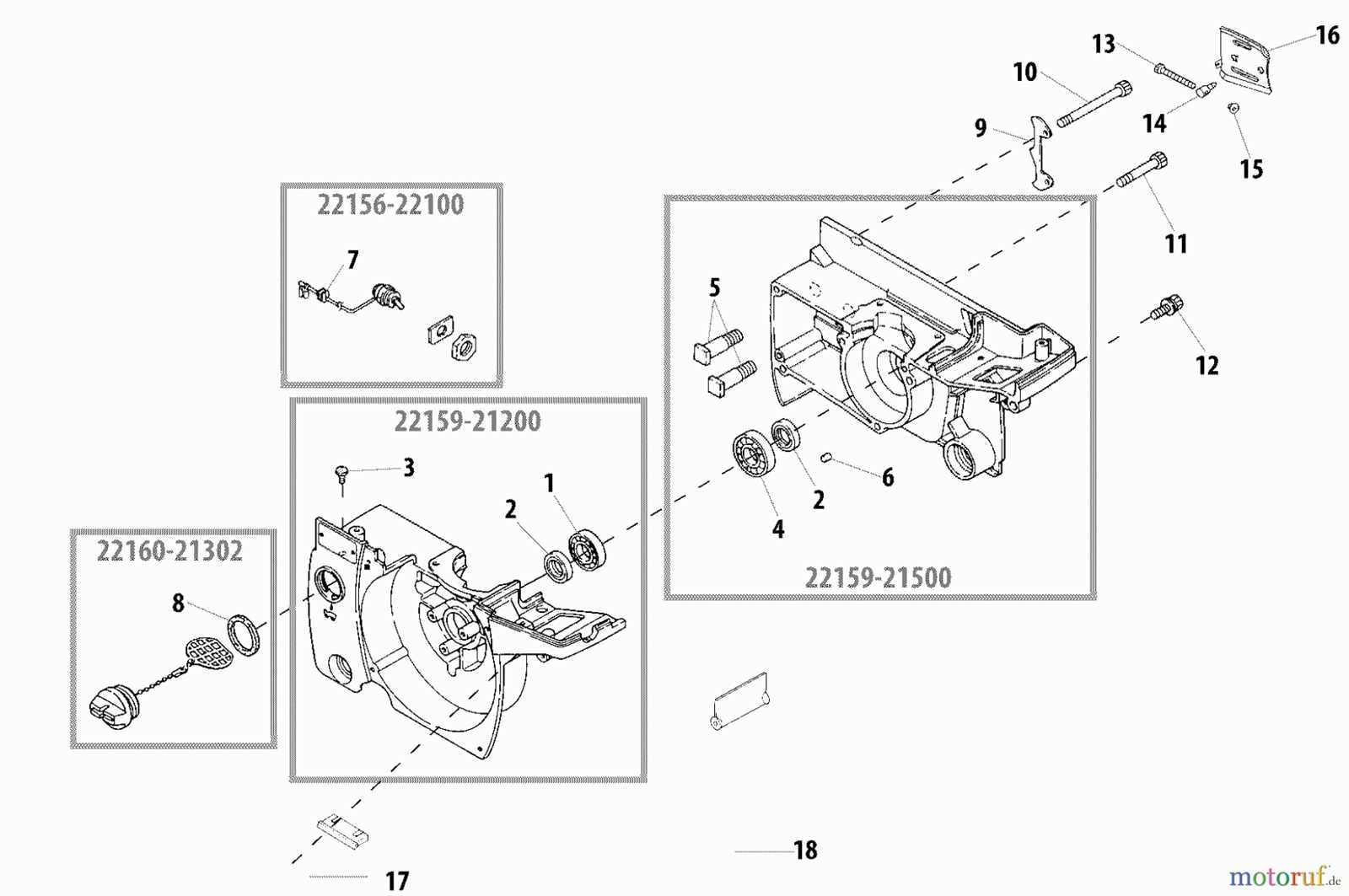

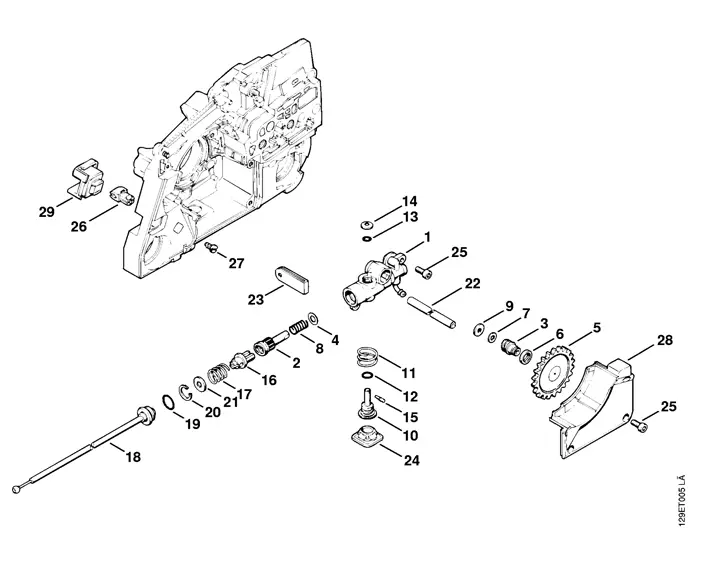

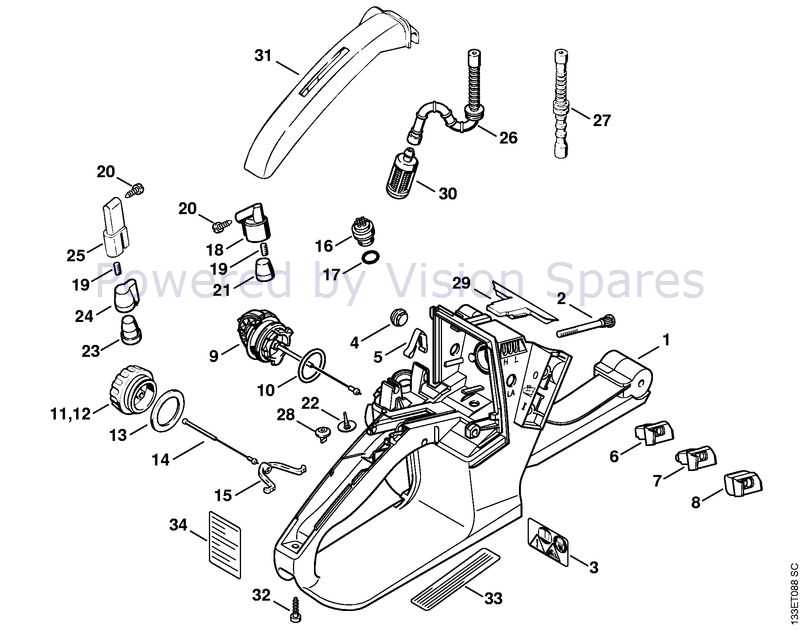

Importance of Parts Diagrams

Understanding the components of any mechanical device is crucial for effective maintenance and repair. Visual representations that outline individual elements and their relationships serve as valuable resources for technicians and hobbyists alike. These illustrations simplify complex systems, making it easier to identify and troubleshoot issues.

Enhanced Clarity and Efficiency

Detailed illustrations provide a clear view of each component’s location and function within the overall system. This clarity enhances efficiency during repairs, as users can quickly locate the necessary parts. Instead of guessing or relying on memory, having a visual guide ensures that the right pieces are addressed, minimizing the risk of errors.

Facilitating Knowledge Transfer

Diagrams are not just beneficial for experienced technicians; they also aid in the learning process for newcomers. By visually demonstrating how components fit together, these resources promote better understanding and retention of knowledge. Learning through visuals can significantly accelerate the proficiency of those who are less familiar with the equipment.

In summary, comprehensive visual representations are essential tools that improve maintenance practices and foster a deeper understanding of mechanical systems.

Common Issues with Stihl 026

When it comes to outdoor power equipment, certain challenges frequently arise that can affect performance and reliability. Understanding these common problems can help users maintain their machines more effectively and ensure optimal operation.

Fuel and Ignition Problems

One of the most prevalent issues involves the fuel system. Clogged filters and old fuel can lead to starting difficulties and uneven performance. Additionally, ignition malfunctions such as faulty spark plugs may prevent the engine from running smoothly, impacting overall efficiency.

Wear and Tear on Components

Over time, various parts may experience significant wear. Chain tensioners and guide bars can become damaged, leading to improper cutting action. Regular inspections and timely replacements are crucial in preventing more serious breakdowns.

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to identify and source necessary items for maintenance or repair. These illustrations serve as valuable resources, offering a clear depiction of each element’s location and relationship to others in a system. Familiarizing yourself with how to interpret these images will streamline your repair processes and ensure that you have the right pieces at hand.

Key Elements to Identify

When examining a visual layout, there are several crucial features to note:

| Element | Description |

|---|---|

| Reference Numbers | Often found next to each component, these numbers correspond to a list that details specifications and part names. |

| Connections | Lines and arrows may indicate how components are connected or interact with one another, providing insight into assembly. |

| Grouping | Parts may be grouped into sections that represent a specific function or area within the overall system, aiding in easier navigation. |

Tips for Effective Interpretation

To effectively decode these illustrations, consider the following strategies:

- Start by familiarizing yourself with the reference list, as it serves as a key to understanding the corresponding elements.

- Pay attention to the layout, noting how components are positioned relative to one another.

- Use a notepad to jot down any unfamiliar items and look them up for a better understanding of their functions.

Ordering Replacement Parts Easily

Finding the right components for your equipment can be a straightforward process with the right approach. Understanding how to navigate the various options available online and in-store will save you time and ensure you get the correct items needed for repairs or maintenance.

Start by identifying the specific components required for your machine. Referencing a reliable source or guide can help you pinpoint the exact pieces you need, eliminating guesswork. Once you have this information, you can move on to sourcing these items.

Utilize reputable retailers, whether online or in physical stores, that specialize in equipment supplies. Websites often provide detailed catalogs and search functions, making it easier to locate the necessary items. Don’t hesitate to read customer reviews to gauge the quality and reliability of the seller.

Consider contacting customer service if you’re uncertain about your selection. Knowledgeable representatives can assist you in confirming compatibility and provide recommendations for alternative solutions, if needed.

Lastly, keep track of your orders by saving confirmations and receipts. This will facilitate any potential returns or exchanges, ensuring that your experience is as seamless as possible. With these tips, you can efficiently acquire the components required to keep your equipment in top shape.

Maintenance Tips for Stihl 026

Regular upkeep is essential for ensuring the longevity and performance of your outdoor power equipment. Proper care not only enhances functionality but also prevents costly repairs and replacements down the line. Here are some valuable recommendations to keep your machine in top shape.

Routine Cleaning

Keeping your equipment clean is crucial for its efficiency. Here are some steps to follow:

- Wipe down the exterior with a damp cloth after each use.

- Remove any debris from the air filter and ensure it is free from blockages.

- Clean the fuel tank and inspect for any signs of contamination.

Regular Inspections

Conducting frequent inspections can help you identify potential issues before they escalate. Consider the following:

- Check the condition of the spark plug and replace it if worn.

- Inspect the chain and guide bar for wear and damage.

- Examine the fuel lines for cracks or leaks.

By following these maintenance tips, you can ensure that your equipment runs smoothly and reliably for years to come.

Identifying Genuine Stihl Parts

Ensuring the quality and reliability of equipment relies heavily on the authenticity of components used in its assembly. Recognizing authentic items is crucial for optimal performance and longevity. This section provides insights into distinguishing original components from replicas.

Key Characteristics of Authentic Components

- Brand Markings: Genuine items often feature distinctive logos or markings that signify their authenticity. Look for precise engravings and consistent branding.

- Quality of Materials: Original components are manufactured from high-grade materials, ensuring durability. Inspect for solid construction and resistance to wear.

- Packing and Labels: Authentic items usually come in branded packaging with clear labels. Examine for any signs of tampering or poor-quality printing.

Verification Methods

- Authorized Dealers: Purchase only from certified retailers who guarantee authenticity.

- Online Resources: Utilize official websites or trusted forums to confirm component specifications and verify against available options.

- Part Numbers: Cross-check the part number against manufacturer databases to ensure compatibility and authenticity.

By following these guidelines, users can confidently select components that enhance performance and extend the lifespan of their equipment.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for ensuring efficiency and effectiveness. A well-equipped toolkit allows you to address various issues, prolonging the life of your device and enhancing its performance.

Here’s a list of essential tools to consider for your repair tasks:

- Screwdrivers: Both flathead and Phillips types in various sizes are necessary for removing and tightening screws.

- Wrenches: A set of adjustable wrenches and socket wrenches will help you tackle nuts and bolts of different sizes.

- Pliers: Needle-nose and standard pliers can assist in gripping, twisting, and cutting wires or small components.

- Torque Wrench: This tool is essential for applying a specific torque to fasteners, ensuring they are securely tightened without damage.

- Hex Keys: Often referred to as Allen wrenches, these are crucial for working with hexagonal screws found in many mechanical assemblies.

In addition to the basic tools, you may also need:

- Replacement Parts: Ensure you have a stock of necessary components that may wear out or break during use.

- Cleaning Supplies: Brushes, cloths, and solvents help keep your tools and equipment clean and functional.

- Safety Gear: Gloves, goggles, and ear protection are important for ensuring personal safety during repairs.

Equipping yourself with these tools will not only facilitate smoother repair processes but also help you handle unexpected challenges that may arise along the way.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment efficiently. By following these detailed instructions, you can tackle common issues, ensuring optimal performance and longevity. Each step is designed to be clear and actionable, allowing you to confidently navigate the repair process.

Understanding the Basics

Before diving into the repair, familiarize yourself with the key components and their functions. Knowing how each part interacts can significantly streamline your efforts. Gather the necessary tools and materials to prepare for a successful repair experience.

Repair Procedure

Begin by assessing the specific problem. Disassemble the relevant sections carefully, noting the arrangement of each component. Clean any debris and inspect parts for wear or damage. Replace any faulty items with new ones that match the specifications. Finally, reassemble everything in reverse order, ensuring that all connections are secure.

Comparing Stihl 026 to Other Models

This section aims to highlight the distinctions and similarities between a specific chainsaw model and its competitors. By examining various features, performance metrics, and user experiences, we can provide valuable insights into how this tool stands in relation to others in the market. Such comparisons are essential for potential buyers who seek to make informed choices based on their specific needs.

Performance and Power

When evaluating the capabilities of this model against others, power output and efficiency are critical factors. While many models boast impressive engine specifications, this particular one offers a balance of torque and weight that enhances maneuverability. Users often note that its cutting speed and durability in tough conditions set it apart, making it a reliable choice for both professionals and enthusiasts.

User Experience and Features

In terms of user-friendliness, this model incorporates features that enhance operation, such as vibration reduction and ergonomic designs. Compared to rival chainsaws, the intuitive controls and easy maintenance further contribute to a more satisfying user experience. While some alternatives may excel in specific areas, the overall package offered here appeals to a wide audience, catering to various skill levels and preferences.

Expert Advice on Troubleshooting

When dealing with mechanical equipment, issues can arise unexpectedly, leading to frustration and downtime. Understanding the common problems and their solutions is essential for maintaining optimal performance. This section offers guidance on how to identify and resolve typical malfunctions effectively, ensuring smooth operation.

Common Issues and Solutions

| Problem | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine won’t start | Empty fuel tank, clogged filter, faulty spark plug | Refill fuel, clean or replace filter, check spark plug condition |

| Loss of power | Dirty air filter, dull blade, fuel line obstruction | Clean or replace air filter, sharpen or replace blade, inspect fuel line |

| Excessive vibration | Loose components, unbalanced cutting tool | Tighten all screws, ensure tool is balanced |

Best Practices for Maintenance

Regular upkeep is crucial to prevent issues from arising. Always refer to the manufacturer’s guidelines for servicing intervals. Cleaning components, checking fuel quality, and inspecting wear parts can greatly extend the life of your equipment and minimize the risk of breakdowns.

Resources for Stihl Enthusiasts

For those passionate about their outdoor equipment, having access to reliable sources of information is essential. Whether you’re looking to maintain, repair, or enhance your tools, there are numerous resources available to help you make informed decisions and keep your equipment running smoothly.

| Resource Type | Description | Link |

|---|---|---|

| Official Websites | Manufacturer websites often provide valuable information on specifications, accessories, and maintenance tips. | Visit Manufacturer |

| Online Forums | Join communities of enthusiasts to share experiences, ask questions, and exchange tips. | Join Forum |

| Repair Guides | Comprehensive guides are available online to assist with troubleshooting and repairs. | View Repair Guides |

| Video Tutorials | Platforms like YouTube offer numerous instructional videos for visual learners. | Watch Tutorials |

| Local Workshops | Participate in hands-on workshops to enhance your skills and knowledge. | Find Workshops |