Understanding the Stihl FS 280 Parts Diagram for Optimal Maintenance

Every outdoor equipment enthusiast knows that familiarity with the essential elements of their machine can significantly enhance performance and longevity. In this section, we will explore the intricate relationships between various components and their functions. Gaining insight into these aspects is crucial for optimal maintenance and troubleshooting.

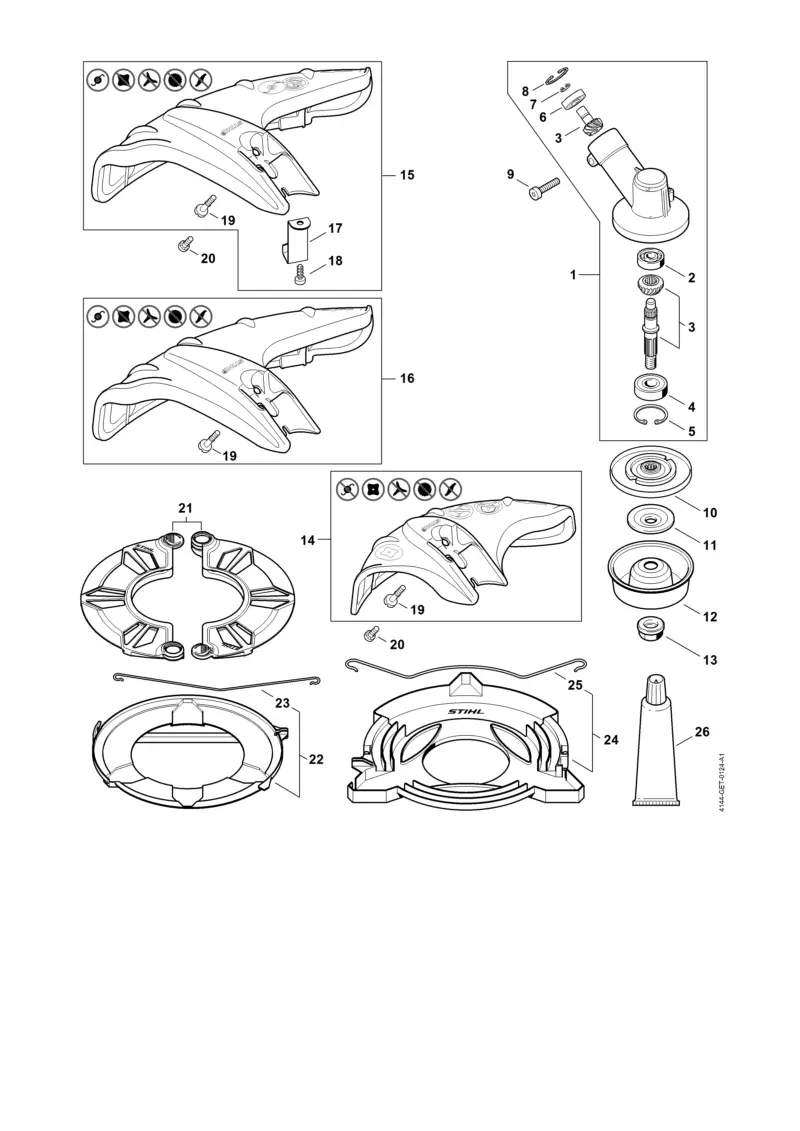

Visual aids play a vital role in grasping the layout and arrangement of the machinery’s inner workings. By examining detailed representations, users can easily identify each component, ensuring they are well-prepared for any repairs or replacements that may arise. This understanding ultimately leads to improved efficiency and a more satisfying user experience.

Whether you are a seasoned professional or a weekend warrior, knowing the layout of your equipment can save time and prevent costly errors. As we delve deeper into this topic, you’ll find valuable insights that will aid you in mastering the nuances of your tool’s structure.

Understanding Stihl FS 280 Overview

This section provides a comprehensive look at a popular model known for its reliability and performance in the realm of outdoor power equipment. Designed for various landscaping tasks, this machine is a go-to choice for both professionals and hobbyists alike. Its robust build and user-friendly features make it an essential tool for maintaining lawns and gardens efficiently.

Key Features

- Powerful engine for enhanced performance

- Lightweight design for ease of use

- Adjustable handles for comfort during operation

- Versatile attachments for different tasks

Applications

- Trimming grass and weeds in tight spaces

- Maintaining large areas of land

- Clearing brush and overgrowth

- Creating landscape designs and edging

Key Components of FS 280

Understanding the essential elements of this equipment is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficient operation, contributing to overall functionality and longevity.

Engine Assembly

The engine assembly serves as the powerhouse of the machine. It transforms fuel into mechanical energy, driving the cutting tools effectively. Regular inspection of this unit is necessary to maintain peak efficiency.

Cutting Head

The cutting head is designed for precision and effectiveness. It houses the cutting lines or blades, which are pivotal for achieving the desired results. Ensuring this part is in good condition is key to achieving ultimate performance.

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations serve as a crucial tool for users, providing clarity on how each element fits together.

These illustrations facilitate:

- Identification: Quickly recognize individual components and their functions.

- Assembly: Simplify the reassembly process after repairs or replacements.

- Diagnosis: Aid in troubleshooting issues by illustrating potential problem areas.

- Ordering: Ensure accurate procurement of replacements by clearly showing what is needed.

Ultimately, utilizing these visual aids enhances efficiency and prolongs the life of the equipment.

Common Issues with Stihl FS 280

Garden maintenance tools often encounter various challenges that can hinder their performance. Understanding these common problems can help users maintain their equipment effectively and ensure longevity. Below are some frequent issues that owners may face with their grass trimming devices.

Starting Difficulties: One of the most prevalent issues is trouble starting the machine. This can be attributed to fuel-related problems, such as stale fuel or improper mixing of oil and gasoline. Additionally, a clogged air filter or a malfunctioning spark plug can prevent the engine from igniting properly.

Excessive Vibration: If the tool vibrates excessively during operation, it may indicate a problem with the cutting attachment or an imbalance in the engine components. This can lead to operator discomfort and potential safety hazards.

Power Loss: Users might notice a significant drop in power during use, which can stem from a dirty air filter, a faulty fuel line, or issues with the ignition system. Regular maintenance checks can help identify these problems early on.

Overheating: Overheating can occur if the engine is running too lean or if there is inadequate lubrication. This not only affects performance but can also lead to severe damage if not addressed promptly.

Worn Cutting Head: The cutting head may wear out over time, leading to ineffective trimming. Regular inspection and replacement of this part can enhance performance and ensure clean cuts.

Identifying Replacement Parts

Understanding how to recognize components for your outdoor equipment is essential for maintaining its performance and longevity. This section will guide you through the process of locating the necessary elements to ensure your machinery operates smoothly. By familiarizing yourself with the various elements and their functions, you can effectively manage repairs and replacements.

Common Components and Their Functions

Each machine comprises several key elements that contribute to its overall functionality. Familiarity with these components allows you to pinpoint issues more accurately. For instance, the cutting head, drive shaft, and air filter each play a critical role in the performance of your equipment. Regular inspection of these parts can help identify wear and tear early, preventing further damage.

Finding the Right Components

Once you recognize the specific elements, the next step is sourcing the correct replacements. Check your owner’s manual for specifications and compatibility. Online resources and forums can also provide valuable insights and recommendations from other users. Additionally, local dealers may offer genuine alternatives to ensure reliability and optimal performance. Choosing high-quality replacements will ultimately enhance the efficiency of your equipment and extend its operational life.

How to Use the Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will provide insights on navigating the schematic to enhance your experience with your equipment.

First, familiarize yourself with the layout and symbols used in the illustration. Each part is labeled clearly, making it easier to identify individual elements and their functions.

Next, refer to the legend or key if available, as it provides crucial information regarding the various components. This can help you pinpoint specific items you may need to replace or inspect.

Finally, use the visual tool as a reference while disassembling or reassembling your equipment. By following the schematic methodically, you can ensure everything is in its rightful place, reducing the risk of errors during the process.

With practice, navigating these illustrations will become second nature, leading to improved efficiency and longevity of your tools.

Maintenance Tips for FS 280

Regular upkeep is essential for ensuring the longevity and performance of your outdoor power tool. Proper maintenance not only enhances efficiency but also prevents potential breakdowns. By adhering to a systematic care routine, you can keep your equipment operating smoothly and effectively.

Routine Inspection

Conduct frequent checks of all components to identify any signs of wear or damage. Pay particular attention to the cutting attachment and air filter. A clean air filter is crucial for optimal engine performance, while a dull cutting head can hinder productivity. Replace worn-out parts promptly to avoid further complications.

Fuel and Lubrication

Always use the recommended fuel mixture for your machine. This ensures that the engine runs efficiently and reduces the risk of damage. Additionally, keep all moving parts well-lubricated to minimize friction. Regularly check the oil level and replace it as needed, maintaining the right balance for a smooth operation. Proper fuel and lubrication practices can significantly extend the lifespan of your tool.

Where to Find Parts Diagrams

Locating visual schematics for outdoor equipment can significantly enhance maintenance and repair efforts. Understanding the layout and components of a machine is crucial for ensuring its optimal performance and longevity. Whether you are a professional technician or a DIY enthusiast, having access to detailed illustrations can streamline the troubleshooting process.

One reliable source for these visuals is the manufacturer’s official website, where you can often find comprehensive manuals and resources tailored to specific models. Additionally, authorized dealers frequently provide online access to such resources, ensuring you receive accurate information. Various online forums and communities dedicated to outdoor equipment are also excellent places to seek out shared diagrams, tips, and advice from experienced users.

Moreover, third-party websites and repair service platforms may offer extensive databases featuring schematics for a wide range of machinery. Utilizing search engines with specific queries can yield valuable results, leading you to informative sites that specialize in repair and maintenance. Always ensure that the resources you consult are credible to avoid any discrepancies that may arise from inaccurate information.

Buying Genuine Stihl Parts

When it comes to maintaining outdoor equipment, selecting authentic components is crucial for ensuring longevity and performance. Quality pieces contribute to the overall efficiency and reliability of your machine, providing peace of mind during operation.

Counterfeit items may seem attractive due to their lower cost, but they often lead to greater expenses over time. Here are some advantages of opting for genuine components:

| Benefit | Description |

|---|---|

| Quality Assurance | Authentic parts undergo rigorous testing for durability and performance. |

| Perfect Fit | Designed specifically for your machine, ensuring seamless integration. |

| Warranty Protection | Using genuine components often helps maintain your warranty coverage. |

| Enhanced Performance | Original parts are engineered to optimize the function of your equipment. |

Investing in real components ultimately leads to a better user experience and a longer lifespan for your equipment.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for ensuring efficiency and precision. A well-equipped toolkit not only facilitates smoother repairs but also enhances safety during the process. Below are some of the crucial instruments that can help you effectively address various issues.

Firstly, a set of screwdrivers in different sizes is vital for loosening or tightening screws. Additionally, pliers and wrenches are indispensable for gripping and turning components that may be stubborn or difficult to access. A socket set can further enhance your ability to handle nuts and bolts with ease.

Moreover, a reliable utility knife is useful for cutting through materials such as cords or straps. For electrical repairs, having a multimeter can aid in diagnosing issues by measuring voltage and current. Don’t forget a sturdy pair of gloves to protect your hands and safety goggles to shield your eyes from debris.

Finally, keeping a clean workspace with a magnetic tray or parts organizer can prevent loss of small items, making the entire repair process more efficient. With these tools at your disposal, you’ll be well-prepared to tackle any maintenance challenges that arise.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also ensure that the equipment remains in optimal condition.

Firstly, always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. This gear acts as a barrier against potential hazards, such as sharp edges or flying debris.

Secondly, work in a well-ventilated area to avoid inhaling harmful fumes or dust. Adequate airflow minimizes the risk of respiratory issues during repairs.

Additionally, keep your workspace organized and free of clutter. A tidy environment reduces the chances of tripping or misplacing tools, allowing for a smoother repair process.

Lastly, ensure that all power sources are disconnected before starting any maintenance work. This step is vital to avoid accidental starts that could lead to serious injuries.

Enhancing Performance with Upgrades

Improving the efficiency and effectiveness of your outdoor equipment can significantly elevate your work experience. By focusing on strategic enhancements, users can achieve not only better performance but also increased durability and reliability. Upgrades often allow for a smoother operation and can lead to time savings in various tasks.

Powerful engine modifications can lead to heightened output and speed, while optimized cutting tools ensure cleaner and more precise results. Additionally, investing in quality components may reduce wear and extend the lifespan of your machine, providing ultimate value.

Exploring ergonomic accessories can also enhance comfort, allowing for extended use without fatigue. Overall, thoughtful upgrades can transform your equipment into a more formidable ally in any outdoor endeavor.