Understanding the BMW N55 Engine Parts Diagram

The intricate world of high-performance vehicles captivates enthusiasts and professionals alike. A deep exploration into the mechanical intricacies reveals how various elements work in harmony to achieve optimal functionality. Each component plays a crucial role in enhancing performance and ensuring reliability.

In this section, we will delve into the essential constituents that contribute to the dynamic operation of these powerful machines. By examining their relationships and functions, we aim to provide clarity and insight into how they collectively elevate driving experiences.

Ultimately, grasping the layout and significance of these integral elements empowers enthusiasts to make informed decisions regarding maintenance and upgrades. Whether for personal projects or professional repairs, understanding the framework is vital for anyone involved in automotive performance.

BMW N55 Engine Overview

This section provides a comprehensive look at a renowned power unit known for its performance and efficiency. Developed for various models, this unit showcases a combination of advanced technology and innovative design, catering to both everyday drivers and enthusiasts alike. Understanding its key components and functionality can enhance appreciation for its engineering excellence.

Key Features

The discussed power unit is characterized by a range of features that contribute to its dynamic capabilities. Turbocharging, direct fuel injection, and variable valve timing are some of the technologies employed to optimize power delivery and fuel efficiency.

Specifications

| Specification | Details |

|---|---|

| Cylinder Configuration | Inline 6 |

| Displacement | 3.0 liters |

| Power Output | 320 hp |

| Torque | 332 lb-ft |

| Turbocharger | Single Twin-scroll |

Overall, this power unit exemplifies a blend of performance and efficiency, making it a favorite among many drivers. Its innovative engineering continues to influence the design of future powertrains in the automotive industry.

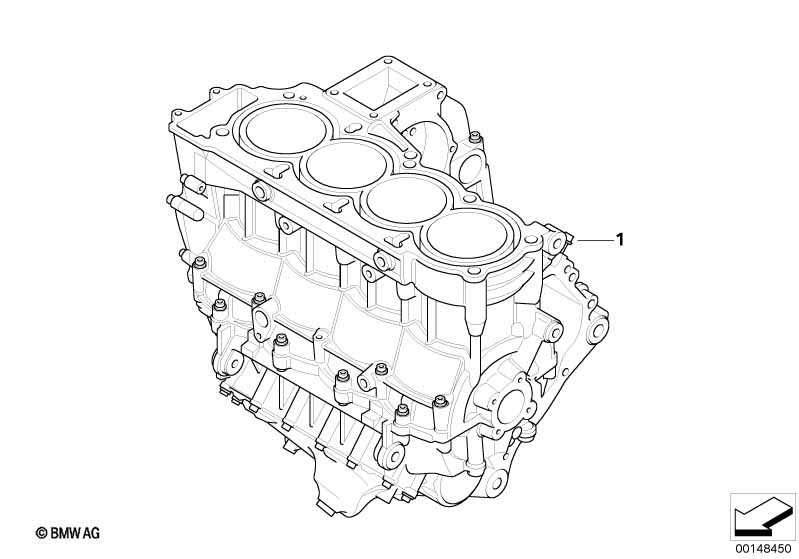

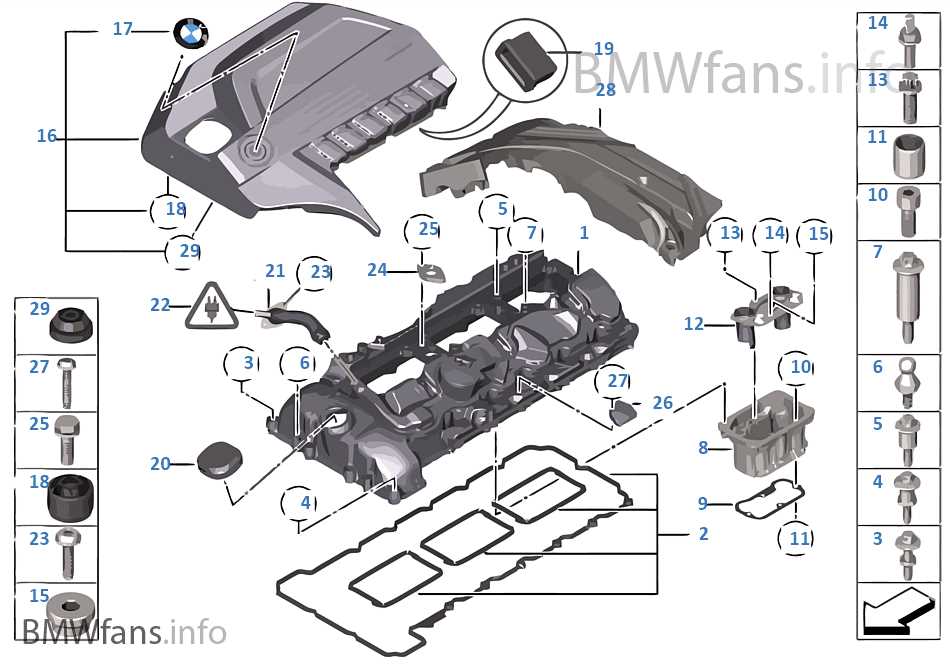

Key Components of N55 Engine

This section explores the essential elements that contribute to the overall performance and efficiency of a high-performance power unit. Understanding these crucial components provides insight into how they work together to deliver power and reliability.

The heart of this system includes the block, which houses critical mechanisms, while the cylinder head plays a vital role in airflow management. Additionally, the intake and exhaust systems are engineered for optimal performance, facilitating efficient gas exchange. The fuel delivery system ensures that the right amount of fuel reaches the combustion chamber, while the ignition system ignites the fuel-air mixture at the perfect moment for maximum output.

Furthermore, auxiliary components such as the cooling system and lubrication elements are designed to maintain ideal operating conditions, preventing overheating and reducing friction. Collectively, these integral parts ensure smooth operation and enhance the longevity of the entire assembly.

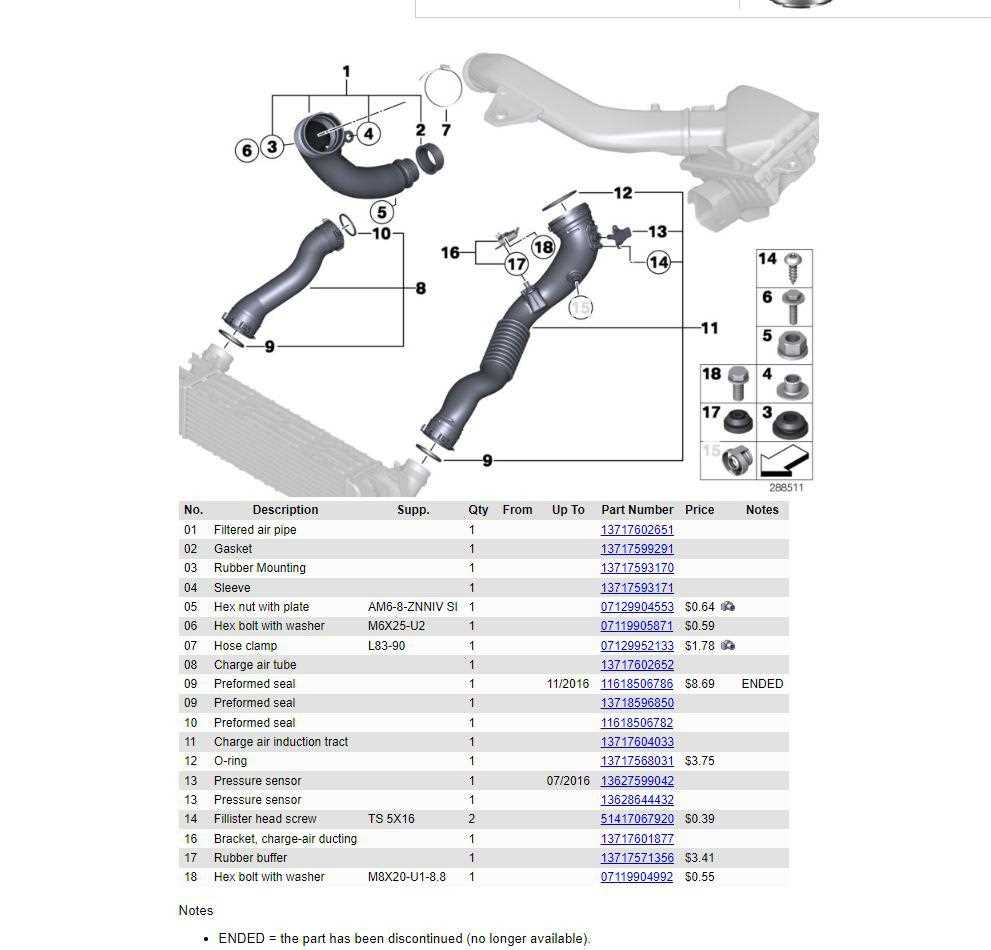

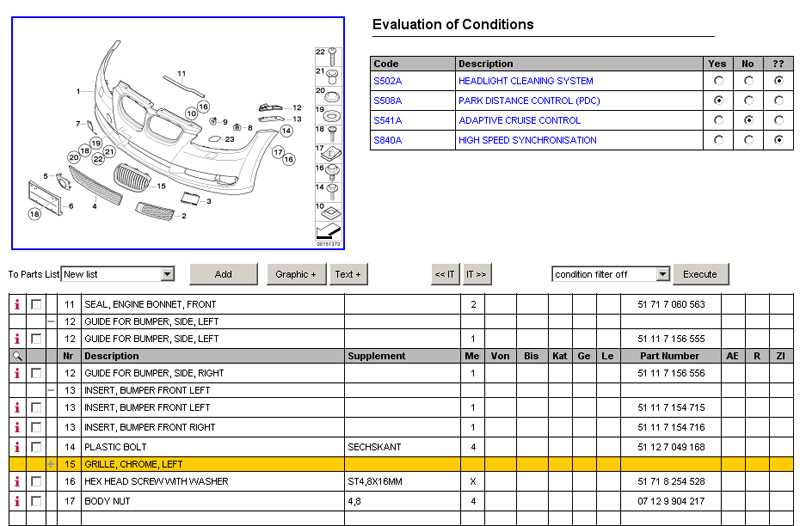

Understanding Engine Diagrams

Comprehending mechanical schematics is crucial for anyone involved in automotive maintenance or repair. These visual representations serve as valuable tools that convey complex relationships between components and systems.

- Visual clarity: Simplifies the understanding of intricate setups.

- Component identification: Helps pinpoint specific items and their functions.

- Troubleshooting aid: Assists in diagnosing issues by illustrating connections.

To fully appreciate these illustrations, one must consider various elements:

- Symbols: Each shape and line conveys distinct meanings.

- Orientation: Layout can indicate flow and interactions between elements.

- Labels: Proper tagging enhances clarity and understanding.

By delving into these aspects, individuals can enhance their knowledge and effectively apply it in practical situations. Mastery of these visual tools can lead to ultimate proficiency in vehicle care and optimization.

Importance of Proper Parts Identification

Accurate identification of components is crucial for the longevity and performance of any machinery. Without precise knowledge, one risks selecting incorrect items, leading to inefficiencies and potential damage.

Benefits of Correct Identification

- Enhances performance and reliability

- Reduces the risk of malfunctions

- Saves time and costs in repairs

Consequences of Misidentification

- Increased wear and tear on machinery

- Potential safety hazards

- Higher long-term expenses due to frequent replacements

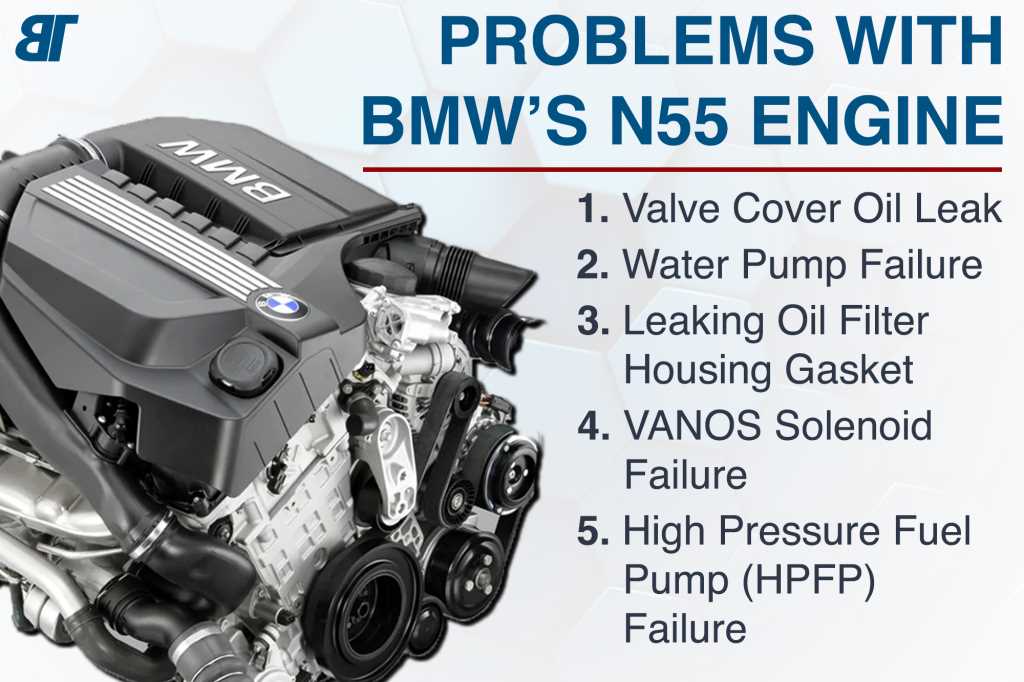

Common Issues with N55 Parts

Understanding the frequent challenges faced with components of this specific powertrain can enhance maintenance and longevity. Many enthusiasts and mechanics encounter similar problems that can impact performance and reliability.

Typical Problems

- Oil Leaks

- Overheating

- Fuel Delivery Issues

- Turbocharger Failures

Preventive Measures

- Regular Maintenance Checks

- Using Quality Fluids and Parts

- Monitoring Temperature Levels

- Addressing Warning Signs Promptly

Visualizing Engine Layouts

Understanding the configuration of complex machinery is essential for enthusiasts and professionals alike. By creating clear representations of these intricate systems, one can appreciate the arrangement and functionality of various components. Visual aids enhance comprehension, making it easier to identify parts and their interrelationships.

Utilizing diagrams allows for a more intuitive grasp of how individual elements fit together to achieve optimal performance. This approach not only aids in troubleshooting but also enhances the learning experience for those looking to deepen their knowledge. Whether for maintenance, repairs, or upgrades, a visual representation serves as a valuable reference.

Moreover, accurate illustrations can bridge the gap between theoretical knowledge and practical application. By visualizing the layout, individuals can more effectively plan modifications or repairs, ensuring that every component is considered. Strong understanding fosters confidence in working with advanced machinery.

Maintenance Tips for N55 Components

Regular upkeep of vital mechanical systems is essential for optimal performance and longevity. By understanding key elements and their functions, you can ensure that everything operates smoothly and efficiently, avoiding costly repairs and downtime.

Routine Inspections

Conducting frequent checks on critical assemblies helps identify wear and tear early. Look for signs of leaks, unusual noises, or irregular vibrations, which can indicate potential issues that require immediate attention.

Fluid Changes

Changing fluids at recommended intervals is crucial for maintaining performance. Regularly replacing lubricants and coolants not only ensures proper function but also prolongs the lifespan of various components, enhancing overall efficiency.

Aftermarket vs. OEM Parts

When it comes to vehicle maintenance and upgrades, the choice between original and alternative components plays a crucial role in performance and reliability. Each option has its own set of advantages and potential drawbacks, making it essential for owners to weigh their options carefully.

Original components, often referred to as factory-produced, are manufactured by the same company that made the vehicle. These items typically ensure a perfect fit and are designed to meet the strict specifications set by the manufacturer.

- Guaranteed compatibility with the vehicle.

- Often come with a warranty, providing peace of mind.

- Quality assurance through rigorous testing standards.

On the other hand, alternative components are produced by third-party companies and can vary significantly in quality and price. This category offers a wide range of choices, appealing to those seeking specific features or cost savings.

- Potential for lower costs, making repairs more affordable.

- Availability of specialized options not found in original components.

- Possibility of performance enhancements for enthusiasts.

Ultimately, the decision between these two types hinges on individual priorities such as budget, desired performance, and trust in product quality. Understanding the differences can lead to a more informed choice that aligns with the owner’s expectations and vehicle needs.

How to Read an Engine Diagram

Understanding a mechanical layout can enhance your comprehension of how a vehicle functions. These visual representations simplify complex structures, allowing enthusiasts and professionals alike to navigate the components with ease.

| Component | Description |

|---|---|

| Legend | A key that explains the symbols used throughout the visual representation. |

| Sections | Divisions within the layout that group related components, helping to organize information. |

| Lines and Arrows | Indicate connections and the flow of operation, essential for understanding interactions. |

| Labels | Text accompanying components that provide names and specific details. |

By focusing on these elements, you can effectively interpret any technical visual, leading to deeper insights into functionality and maintenance. This skill is ultimately invaluable for any automotive enthusiast.

Essential Tools for N55 Repairs

When undertaking repairs on a complex power unit, having the right instruments is crucial for efficiency and precision. This section outlines the must-have tools that facilitate successful maintenance and ensure optimal performance.

Basic Hand Tools

A set of quality hand tools, including wrenches, sockets, and screwdrivers, is foundational for any repair task. These instruments allow for easy access to various components and help in tightening or loosening bolts effectively.

Diagnostic Equipment

Advanced diagnostic tools are essential for identifying issues accurately. Utilizing scanners and multimeters can help delve into the intricacies of the system, ensuring that repairs are targeted and efficient.

Replacing N55 Engine Parts

When it comes to maintaining high-performance vehicles, the process of swapping out specific components is crucial for ensuring optimal functionality. Understanding which elements require replacement and how to approach the task can greatly enhance the longevity and efficiency of the machine.

Essential Steps for Replacement

- Identify the components that need attention.

- Gather the necessary tools and replacements.

- Follow manufacturer guidelines for safe removal and installation.

Common Components to Consider

- Turbocharger

- Fuel injectors

- Intercooler

- Valves

- Timing chain

Performance Upgrades for N55 Engine

Enhancing the capabilities of a turbocharged unit can significantly elevate driving experience and power output. By implementing various modifications, enthusiasts can unlock the full potential of their vehicle, leading to improved acceleration, responsiveness, and overall performance.

Turbocharger Enhancements

Upgrading the turbocharger is a pivotal step in boosting power levels. A larger or more efficient unit can increase airflow and reduce lag, providing an exhilarating surge of power at higher RPMs. Intercoolers also play a crucial role, as they help maintain optimal intake temperatures, ensuring maximum efficiency during high-performance driving.

Exhaust System Modifications

Revising the exhaust pathway allows for better airflow, reducing back pressure and enhancing sound. High-performance headers and cat-back systems are popular choices that improve both aesthetics and functionality. Tuning the vehicle’s software post-modification ensures that all upgrades work harmoniously, optimizing performance and longevity.

N55 Engine Specifications and Features

This section provides an overview of the key specifications and characteristics of a notable power unit renowned for its performance and efficiency. Designed to deliver an exceptional driving experience, this unit combines advanced technology with robust engineering to meet the demands of enthusiasts and everyday drivers alike.

Displacement: The power unit boasts a displacement of approximately 3.0 liters, contributing to its impressive power output while maintaining a balanced weight-to-performance ratio.

Configuration: Featuring a six-cylinder inline layout, this configuration enhances smoothness and minimizes vibrations, ensuring a refined operation.

Turbocharging: Equipped with a twin-scroll turbocharger, this unit maximizes airflow and minimizes lag, resulting in quick acceleration and responsive throttle response.

Power Output: With an output ranging around 320 horsepower, it provides ample power for spirited driving, while also being capable of efficient cruising.

Torque: Generating a torque figure of approximately 450 Nm, this power unit delivers strong pulling power across a broad RPM range, enhancing drivability.

Fuel Injection: Incorporating direct injection technology, it optimizes fuel delivery for improved efficiency and reduced emissions, aligning with modern environmental standards.

Cooling System: A sophisticated cooling system ensures optimal operating temperatures, promoting longevity and reliability even under demanding conditions.

Technology: The integration of advanced management systems allows for precise control of various parameters, further enhancing performance and fuel efficiency.