Comprehensive Guide to John Deere 5065E Parts Diagram

The complexity of agricultural machinery often requires a thorough understanding of its various elements. Each piece plays a crucial role in ensuring optimal performance and efficiency, making it essential for operators and technicians alike to familiarize themselves with the inner workings of these machines.

Understanding the layout of components not only aids in maintenance but also enhances troubleshooting capabilities. A well-organized visual representation of these elements can serve as a valuable resource for anyone involved in the operation or repair of heavy equipment.

In this exploration, we will delve into the intricate network of machinery parts, revealing their ultimate functions and interrelations. By doing so, we aim to equip readers with the knowledge necessary to tackle any challenges that may arise during their usage.

Understanding John Deere 5065E Parts

Comprehending the various components of a tractor is essential for efficient maintenance and repair. Each element plays a crucial role in the overall functionality of the machine, ensuring optimal performance and longevity. Familiarity with these components enables operators to identify issues quickly and implement effective solutions.

Key Components Overview

The core structure of a tractor includes several vital systems, such as the engine, transmission, and hydraulic mechanisms. Recognizing how these systems interact enhances the ability to troubleshoot and perform routine inspections. A well-rounded understanding of these critical elements empowers users to maintain their machinery more effectively.

Maintenance and Replacement Tips

Overview of John Deere 5065E Model

This section provides an insight into a robust agricultural machine known for its reliability and efficiency. Designed to cater to various farming tasks, this model combines power with user-friendly features, making it a preferred choice for many operators.

Key Features

- Powerful engine for enhanced performance

- Ergonomic controls for ease of use

- Versatile attachments for diverse applications

- Durable construction for longevity

Applications

- Field cultivation and tilling

- Hauling materials and implements

- Landscaping and maintenance tasks

- Livestock farm management

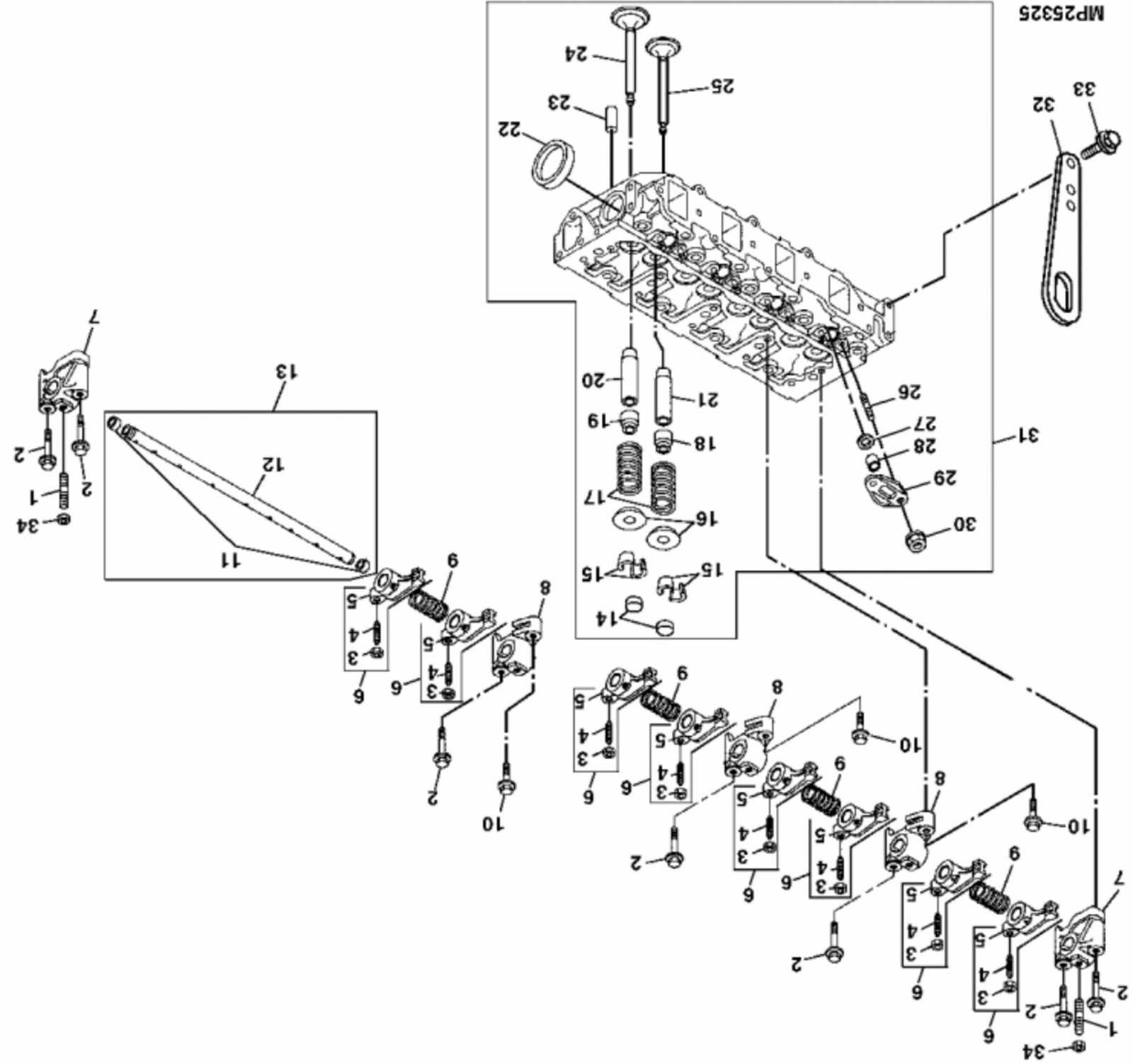

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide clear and organized information, helping users identify individual elements and their interconnections. This clarity enhances understanding and efficiency, ensuring that maintenance tasks are performed correctly.

Benefits of Visual Guides

- Improved Clarity: Visual aids break down complex assemblies into manageable parts.

- Efficiency: Quick identification of components saves time during repairs.

- Accurate Replacements: Ensures that the correct parts are sourced for replacements.

Enhanced Learning and Training

- Visual materials facilitate easier training for new technicians.

- They provide a reference point for understanding machinery functionality.

- Encourage a hands-on approach to learning about specific components.

Key Components of the 5065E Tractor

This section highlights the essential elements that contribute to the functionality and efficiency of the agricultural machine. Understanding these key components is crucial for effective operation and maintenance, ensuring optimal performance in various farming tasks.

Powertrain and Engine

The powertrain is at the heart of this machine, providing the necessary torque and horsepower for demanding applications. The engine is designed for reliability and efficiency, enabling seamless operation across diverse terrains. Proper maintenance of these components is vital for longevity and performance.

Hydraulic System

The hydraulic system plays a significant role in enhancing the versatility of the equipment. It facilitates the operation of various attachments and implements, allowing for increased productivity in the field. Understanding its components and functions is essential for troubleshooting and ensuring smooth operation.

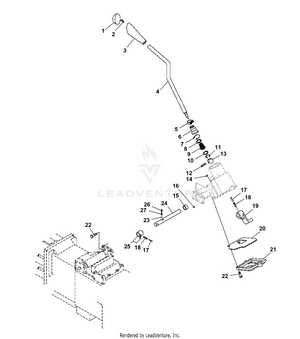

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide crucial information about the arrangement and relationships between various elements, ensuring accurate assembly and troubleshooting.

Key Elements to Identify

- Labels: Each component is typically labeled for easy identification.

- Connections: Look for lines or arrows indicating how parts interact.

- Legend: Refer to the legend for explanations of symbols used in the illustration.

Steps to Analyze the Illustration

- Start with the overview to grasp the general layout.

- Identify the specific sections relevant to your task.

- Cross-reference with the parts list for accurate ordering.

Common Replacement Parts for 5065E

Maintenance is crucial for ensuring the longevity and efficiency of any machinery. Certain components are frequently replaced due to wear and tear, impacting overall performance. Understanding these elements can aid in timely repairs and enhance operational reliability.

- Fuel filters – essential for maintaining clean fuel flow.

- Air filters – crucial for preventing contaminants from entering the engine.

- Oil filters – help in keeping the engine oil clean and functioning effectively.

- Batteries – ensure reliable starting and electrical power.

- Tires – important for traction and mobility on various terrains.

- Belts – necessary for the operation of various engine components.

- Hydraulic hoses – vital for maintaining fluid power and function.

Regular inspections and timely replacements of these essential components can significantly enhance the machine’s performance and lifespan.

Maintenance Tips for 5065E Owners

Proper upkeep is essential for enhancing the longevity and efficiency of your machinery. Regular checks and timely interventions can prevent major breakdowns and ensure smooth operation. Here are some key practices to keep in mind.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil and filter to ensure optimal lubrication. |

| Air Filter Inspection | Every 50 hours | Clean or replace to maintain proper airflow and engine performance. |

| Coolant Level Check | Weekly | Ensure coolant is at the recommended level to prevent overheating. |

| Tire Pressure Check | Monthly | Inspect and adjust tire pressure for better traction and fuel efficiency. |

| Battery Maintenance | Every season | Check terminals for corrosion and ensure a secure connection. |

Following these tips will ultimately lead to better performance and reduce repair costs over time.

Where to Find Authentic Parts

Locating genuine components for your equipment is crucial for maintaining optimal performance and longevity. Authentic replacements ensure compatibility and reliability, safeguarding your investment over time. Understanding where to source these elements can significantly impact the functionality of your machinery.

Official Dealerships

One of the most reliable sources for authentic components is through authorized dealerships. These establishments provide not only original items but also expert advice on installation and maintenance. Visiting a dealership can often lead to additional resources such as service plans and warranties.

Online Retailers

Reputable online platforms offer a wide range of genuine replacements, often at competitive prices. Look for websites that specialize in agricultural machinery and have a solid reputation for quality and customer service. Always check reviews and confirm the authenticity of the items before purchasing.

Comparing OEM and Aftermarket Parts

When it comes to machinery maintenance and repair, the choice between original components and alternative options can significantly impact performance and longevity. Understanding the differences between these two categories can help owners make informed decisions that align with their needs and budgets.

Original equipment manufacturer (OEM) components are produced by the same company that manufactured the machinery. These parts are typically designed to meet the exact specifications required for optimal operation. On the other hand, aftermarket components are produced by third-party manufacturers and may vary in quality, price, and compatibility.

Advantages of OEM Components

- Exact fit and compatibility with existing systems

- Assured quality and performance standards

- Warranty protection and support from the original manufacturer

Advantages of Aftermarket Components

- Potential cost savings compared to original offerings

- Wider variety of options and features

- Availability from multiple suppliers

Considerations When Choosing

- Assess the importance of quality and reliability for your specific application.

- Evaluate budget constraints and the potential for savings.

- Research the reputation of aftermarket suppliers for quality and support.

Ultimately, the decision between these two types of components should be based on individual needs, balancing cost-effectiveness with performance requirements to ensure machinery remains in peak condition.

Tractor Parts Troubleshooting Guide

This guide provides essential insights for diagnosing common issues encountered in agricultural machinery. Understanding how various components interact is crucial for maintaining optimal performance and preventing costly repairs. By following a systematic approach, you can effectively identify malfunctions and determine appropriate solutions.

Identifying Common Issues

Begin by observing the symptoms displayed by your equipment. Unusual noises, diminished power, or inconsistent operation can signal underlying problems. Pay attention to fluid leaks, excessive vibrations, or warning indicators on the control panel. Documenting these observations will aid in pinpointing the source of the trouble.

Troubleshooting Steps

Once issues are noted, proceed with a structured examination of relevant components. Start with basic checks such as fluid levels, battery condition, and connection integrity. Inspecting belts, filters, and electrical systems can often reveal wear or blockages that need addressing. If problems persist, refer to technical manuals for detailed instructions on specific assemblies.

Regular maintenance and timely diagnostics are key to extending the lifespan of your machinery. By staying proactive and informed, you can ensure that your equipment operates efficiently and reliably.

Resources for 5065E Repair Manuals

This section provides essential references for those seeking maintenance and repair guidance for their agricultural machinery. Accessing reliable resources can significantly enhance the efficiency of repair tasks and ensure longevity of equipment.

Online Resources

- Manufacturer’s Official Website

- Online Forums and Communities

- DIY Repair Video Channels

Printed Manuals

- Service Manuals Available at Local Dealers

- Specialty Bookstores with Technical Literature

- Library Resources with Repair Guides

Impact of Regular Maintenance on Longevity

Consistent upkeep is essential for enhancing the lifespan of machinery and equipment. By adhering to a structured maintenance schedule, owners can prevent costly repairs and ensure optimal performance. Regular attention not only safeguards against unexpected breakdowns but also promotes efficiency, making operations smoother and more reliable.

Benefits of Regular Upkeep

- Prevention of Major Issues: Routine inspections can identify potential problems before they escalate.

- Enhanced Performance: Regular care ensures that all components function at their best.

- Cost Savings: Investing in maintenance can lead to significant savings by avoiding extensive repairs.

- Safety Assurance: Well-maintained equipment reduces the risk of accidents and enhances safety for operators.

Key Maintenance Practices

- Conduct regular inspections to assess the condition of vital components.

- Follow the manufacturer’s guidelines for lubrication and fluid replacement.

- Keep the machinery clean to prevent dirt and debris from causing wear and tear.

- Address minor repairs promptly to avoid more significant issues down the line.

In summary, prioritizing maintenance is a proactive approach that greatly contributes to the durability and reliability of equipment. Through dedicated efforts, owners can extend the useful life of their assets and enhance overall operational success.

Customer Reviews and Experiences

This section explores the insights and feedback from users regarding their experiences with equipment components. The perspectives shared here highlight the importance of reliability and quality in enhancing performance.

Many users have praised the durability and efficiency of their machinery, noting how essential quality parts contribute to overall productivity. One customer mentioned that after upgrading specific components, they noticed a significant improvement in operation, which directly affected their workflow.

Conversely, some have encountered challenges, such as sourcing compatible elements. One review pointed out the difficulty in finding accurate resources for maintenance, which emphasized the need for detailed guides and diagrams.

Overall, the shared experiences reflect a common desire for high-quality equipment and support, ultimately enhancing the operational success of users.