Understanding the John Deere 6X4 Gator Parts Diagram

In the realm of outdoor machinery, comprehending the intricate elements that contribute to a vehicle’s performance is essential for both enthusiasts and professionals alike. This section delves into the various components that make up a specific model of utility vehicle, providing insights into their functionality and interconnectivity.

By familiarizing oneself with the essential elements, operators can enhance maintenance practices, ensuring longevity and optimal performance. The analysis of these components offers a comprehensive view, allowing for informed decisions when it comes to repairs or upgrades.

In this exploration, we will break down the structure of the vehicle, highlighting key sections and their respective roles. A thorough understanding of these mechanisms can empower users to tackle challenges effectively and maintain their equipment with confidence.

Understanding the John Deere 6×4 Gator

This section delves into a versatile utility vehicle that excels in various terrains, providing reliability and functionality for both recreational and work purposes. Known for its robust construction and efficient design, this model caters to the needs of operators in diverse environments, from farms to landscaping projects.

Features and Specifications

This vehicle is equipped with a powerful engine and a well-thought-out suspension system, enabling smooth rides across uneven surfaces. Its cargo capacity is impressive, allowing users to transport tools, supplies, and equipment effortlessly. Additionally, the layout promotes easy access to controls, enhancing user experience and efficiency.

Maintenance and Care

Key Features of the 6×4 Gator

The versatile utility vehicle stands out due to its remarkable design and functional capabilities. Engineered for efficiency, it caters to a variety of tasks, making it an essential asset in diverse environments.

Robust Build: Constructed with durability in mind, this model features a strong frame that withstands heavy loads and rough terrains. The rugged exterior ensures reliability in demanding conditions.

Powerful Engine: Equipped with a high-performance power unit, this vehicle offers impressive torque and acceleration. This feature allows users to tackle challenging jobs effortlessly.

Generous Cargo Space: The spacious cargo area is designed to accommodate a substantial amount of materials, making it ideal for transporting tools, equipment, or supplies across work sites.

All-Terrain Capability: With its advanced suspension system and large tires, this utility vehicle excels in navigating various landscapes, from muddy paths to rocky trails.

User-Friendly Controls: The intuitive control layout enhances ease of use, allowing operators of all skill levels to maneuver confidently and efficiently.

Versatile Accessories: A range of attachments and accessories are available, enabling customization to meet specific operational needs, from plowing snow to towing trailers.

Overall, this utility vehicle combines practicality with performance, making it a preferred choice for both professional and recreational use.

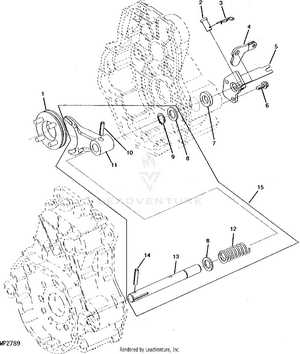

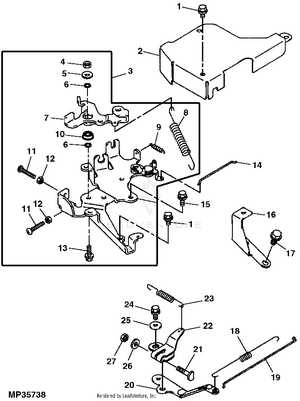

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repairs. Visual representations serve as crucial tools for technicians and owners, simplifying the identification of each element and its relationship to the whole system. This clarity not only enhances operational efficiency but also minimizes downtime during service activities.

Enhanced Troubleshooting

When issues arise, having a visual reference can significantly expedite the troubleshooting process. It allows users to quickly pinpoint problematic areas, facilitating faster diagnosis and resolution. By following the schematic, one can systematically check connections and parts, ensuring that no detail is overlooked.

Effective Communication

Visual aids foster better communication among team members and between technicians and customers. A well-structured representation makes it easier to explain complex issues, ensuring that everyone involved understands the situation clearly. This shared understanding can lead to more effective collaboration during repair and maintenance tasks.

| Benefit | Description |

|---|---|

| Speed | Quick identification of components for faster repairs. |

| Clarity | Clear visualization of parts and their functions. |

| Collaboration | Improved communication among team members. |

Identifying Essential Components

Understanding the crucial elements of a utility vehicle is vital for optimal performance and maintenance. By familiarizing oneself with these key components, operators can ensure their machinery runs smoothly and efficiently. This section highlights the primary parts that contribute to the functionality of these vehicles.

- Chassis: The foundational structure that supports all other components.

- Engine: The powerhouse that drives the vehicle, providing the necessary energy for movement.

- Transmission: Responsible for transferring power from the engine to the wheels, influencing speed and torque.

- Suspension System: Essential for maintaining stability and comfort during operation, absorbing shocks from uneven terrain.

- Braking System: A critical safety feature that allows for controlled stopping and handling.

Each of these elements plays a pivotal role in ensuring the utility vehicle operates effectively. Regular inspection and maintenance of these components can prevent costly repairs and extend the lifespan of the machine.

- Check the chassis for signs of wear or damage.

- Monitor engine performance for any irregularities.

- Inspect the transmission fluid levels and condition.

- Evaluate the suspension for any loose or worn parts.

- Test the braking system for responsiveness and reliability.

By prioritizing these areas, operators can enhance the vehicle’s performance and reliability in various working conditions.

Common Issues with Gator Parts

When operating utility vehicles, users often encounter a range of challenges related to their components. Understanding these common problems can help in maintaining optimal performance and prolonging the lifespan of the equipment. From wear and tear to occasional malfunctions, identifying issues early on is crucial for effective troubleshooting.

One frequent concern involves the electrical system, where connections may become loose or corroded, leading to performance hiccups. Additionally, issues with the fuel system can arise, often resulting from clogged filters or malfunctioning pumps. These problems can hinder the vehicle’s ability to start or run smoothly.

Another area of concern is the drivetrain, where components such as belts and axles may wear out over time, causing decreased efficiency and potential safety hazards. Regular inspections and timely replacements are essential to mitigate these risks. Furthermore, suspension issues can arise, often manifested through uneven tire wear or handling difficulties, which require attention to ensure a smooth ride.

By being aware of these common issues, operators can take proactive steps to address potential failures and maintain their vehicles in peak condition, ensuring reliable performance for various tasks.

Maintenance Tips for Longevity

Proper upkeep of your utility vehicle is essential to ensure it operates efficiently and lasts for many years. Regular maintenance not only enhances performance but also helps in preventing costly repairs down the line.

- Regular Cleaning: Keep the exterior and undercarriage free from dirt and debris. A clean vehicle is less prone to corrosion and wear.

- Fluid Checks: Regularly inspect and top off fluids such as oil, coolant, and brake fluid to maintain optimal functionality.

- Tire Maintenance: Check tire pressure and tread regularly. Proper inflation and good tread will enhance handling and safety.

- Battery Care: Ensure the battery terminals are clean and connections are secure. Check the battery’s charge regularly to avoid starting issues.

- Inspection of Belts and Cables: Examine belts for signs of wear or damage. Replace any frayed or cracked belts to prevent operational failures.

- Regular Service Intervals: Follow the manufacturer’s recommended service schedule for tune-ups and inspections to catch potential issues early.

- Storage Considerations: Store the vehicle in a dry, shaded area to protect it from the elements and minimize rust and fading.

By incorporating these maintenance practices into your routine, you can significantly extend the lifespan of your vehicle and ensure it remains a reliable companion for your tasks.

Where to Find Replacement Parts

When it comes to maintaining your utility vehicle, sourcing quality components is essential for optimal performance and longevity. Whether you’re in need of specific elements or general accessories, various avenues can provide you with the necessary resources. Understanding where to look can save you both time and money while ensuring your machine remains in excellent working condition.

Online Retailers

One of the most convenient options for acquiring replacement components is through online retailers. Numerous platforms specialize in outdoor and utility vehicle supplies, offering a wide range of products at competitive prices. It is advisable to read reviews and check seller ratings to ensure reliability.

Local Dealers and Service Centers

For those who prefer to shop in person, local dealers and authorized service centers can be a valuable resource. These establishments typically stock a comprehensive selection of genuine components and can provide expert guidance on installation and maintenance.

| Source | Advantages |

|---|---|

| Online Retailers | Convenience, wide selection, competitive prices |

| Local Dealers | Genuine products, expert advice, immediate availability |

| Aftermarket Suppliers | Cost-effective options, alternative brands |

| Salvage Yards | Used components at reduced prices, unique finds |

Comparing OEM vs. Aftermarket Options

When it comes to selecting components for your vehicle, the choice between original equipment manufacturer (OEM) and alternative aftermarket solutions can significantly impact performance, longevity, and cost. Understanding the key differences between these two categories can help you make an informed decision that best suits your needs.

| Feature | OEM | Aftermarket |

|---|---|---|

| Quality | Manufactured to meet specific standards set by the original maker, ensuring high reliability. | Varies widely; some may match or exceed OEM quality, while others may fall short. |

| Cost | Typically more expensive due to brand reputation and guaranteed fit. | Generally lower prices, but may require additional investment in research and testing. |

| Warranty | Often comes with a comprehensive warranty covering defects. | Warranties can vary; some products may not offer any guarantee. |

| Availability | Usually available through official dealerships, which can limit options. | Widely accessible through various retailers, providing a broader selection. |

| Compatibility | Designed specifically for the vehicle model, ensuring proper fit and function. | Compatibility may vary; some may require adjustments for optimal performance. |

Ultimately, the decision between these two options hinges on your priorities, whether they be budget constraints, quality assurance, or specific performance needs. Careful evaluation of each choice can lead to better maintenance and satisfaction with your vehicle.

Understanding the Assembly Process

Effective assembly of complex machinery involves a systematic approach to ensure all components fit together seamlessly. This intricate procedure requires a detailed understanding of each element’s role and how they interact within the larger system. By grasping the nuances of assembly, operators can enhance both performance and longevity of the equipment.

The initial stage of assembly focuses on organization and preparation. This includes gathering all necessary components and tools, as well as reviewing assembly instructions. A clear workspace helps facilitate an efficient process, minimizing the risk of errors.

Following preparation, the next step involves sequential assembly, where each part is added in a specific order. This method not only aids in avoiding confusion but also ensures that weight distribution and alignment are optimized, which is crucial for functionality.

Finally, the inspection phase plays a vital role in confirming that all elements are securely attached and that there are no visible defects. Conducting thorough checks helps prevent potential issues during operation, thereby enhancing the overall reliability of the machinery.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial for both personal well-being and equipment longevity. Adhering to established guidelines can prevent accidents and facilitate a smoother repair process. This section emphasizes the importance of taking necessary precautions to protect oneself and the machinery.

1. Personal Protective Equipment (PPE): Always wear appropriate safety gear, including gloves, goggles, and sturdy footwear. This equipment shields against potential hazards, such as sharp edges and chemical exposure.

2. Work Area Organization: Keep the workspace tidy and free of clutter. A well-organized area minimizes risks of trips and falls, allowing for a more efficient and focused repair effort.

3. Secure the Vehicle: Before beginning any work, ensure that the vehicle is parked on a level surface, with the brakes engaged. Use wheel chocks to prevent accidental movement, especially when working under the unit.

4. Disconnect Power Sources: Always disconnect the battery or other power sources before starting repairs. This precaution prevents unexpected activation of electrical components, reducing the risk of injury.

5. Follow Manufacturer Guidelines: Consult the manual for specific instructions related to maintenance and repair. Following the manufacturer’s recommendations ensures that procedures are conducted safely and effectively.

6. Work with a Buddy: If possible, enlist a partner when undertaking repairs. Having someone nearby can provide assistance in case of emergencies and enhance safety during challenging tasks.

By adhering to these safety measures, individuals can ensure a more secure and efficient repair experience, minimizing risks associated with maintenance activities.