Understanding the Components of the Milwaukee M18 Vacuum

In this guide, we will explore the intricate arrangement of various elements that make up a powerful tool designed for efficient cleaning. Each part plays a critical role in ensuring the overall functionality, and understanding how they work together can enhance the user experience. From the motor to the smallest attachments, every piece contributes to optimal performance.

As we delve deeper into the structure of this device, we’ll highlight how different sections interact to deliver consistent results. Whether you’re maintaining or repairing your equipment, having a clear view of the internal and external elements will prove invaluable. By gaining insight into this assembly, users can better manage upkeep and troubleshoot any potential issues.

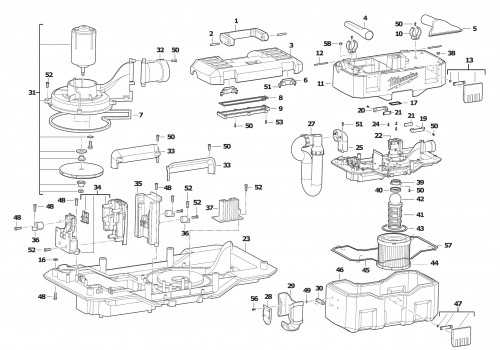

Understanding the Components of a Power Tool

When working with any mechanical device, it is crucial to familiarize yourself with its internal and external elements. Each part plays a specific role in ensuring the tool operates efficiently. Gaining insight into these key elements can help in maintaining performance and extending the lifespan of your equipment.

Key Elements of Operation

- Motor: The engine that powers the tool, converting energy into mechanical movement.

- Battery or Power Source: The energy provider, delivering the required power to keep the tool functioning.

- Control Panel: The interface that allows the user to adjust settings or switch between modes during use.

- Filtration System: Essential for protecting the internal components from dust, debris, or other contaminants.

Additional Features

- Exploring Key Elements for Maintenance

To ensure the longevity and efficient functioning of any equipment, it is essential to understand the key aspects that contribute to its upkeep. Regular attention to specific components helps prevent potential issues and maintains optimal performance over time. In this section, we will outline crucial areas that require periodic inspection and care.

Critical Components to Monitor

- Filters: These require routine cleaning or replacement to maintain air quality and operational efficiency. Clogged filters can reduce performance and increase strain on the motor.

- Seals: Properly functioning seals are crucial for preserving internal pressure. Regularly check for wear or damage to ensure a secure system.

- Power Supply: Inspect connections and power sources for any signs of wear or malfunction to avoid interruptions during use.

Routine Care Practices

- Perform a visual inspection of the exterior to

How to Identify Critical Parts

Understanding the key components of any mechanical or electrical device is crucial for proper maintenance and troubleshooting. By focusing on the most essential elements, you can ensure that repairs are both effective and efficient, helping extend the lifespan of your equipment. This section provides a straightforward approach to recognizing the most important elements within your system, even without specialized knowledge.

Focus on High-Usage Elements

The elements that undergo the most frequent use are typically the first to wear

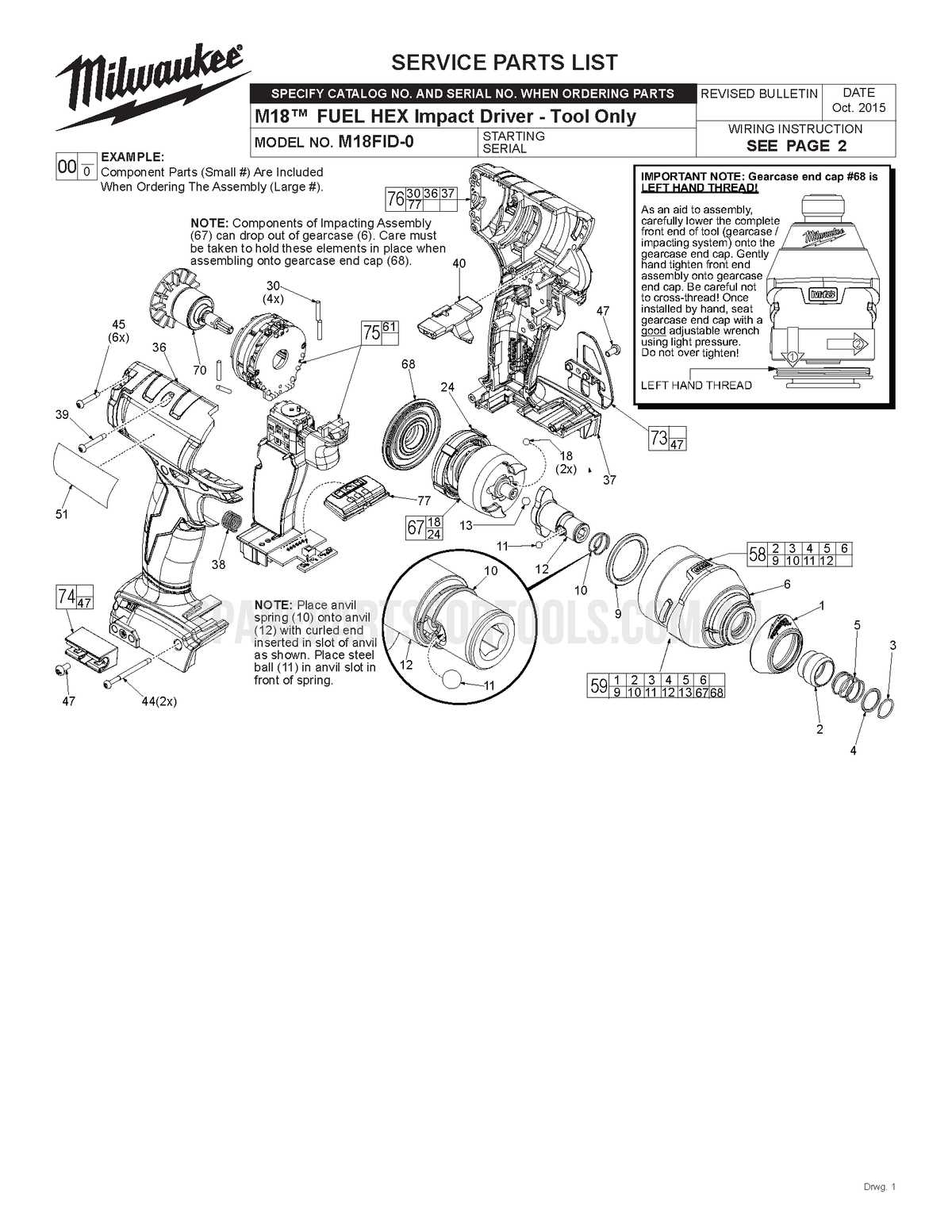

Recognizing Commonly Replaced Elements

When it comes to maintaining an efficient system, understanding which components tend to wear out most frequently is key. Regular upkeep often involves replacing specific parts to ensure smooth operation and prolong the lifespan of the device.

Frequent Replacements

Some components are more prone to wear due to their regular interaction with various elements. These elements can become less effective over time and require timely replacement.

- Filters: These help to capture unwanted particles and need periodic attention to maintain optimal performance.

- Seals: Often exposed to wear, these small parts are essential in maintaining proper airflow and preventing leaks.

- Brushes: Regularly in contact with surfaces, they tend to wear down with use and need to be replaced to maintain efficiency.

Indicators of Wear

Recognizing when these elements need replacement can save

Guide to Proper Assembly

When approaching the process of putting together complex tools, it’s essential to ensure every component fits seamlessly. Understanding the alignment and placement of each piece is crucial to achieving the desired performance and longevity.

Step-by-step preparation is key to preventing issues during assembly. Before starting, review all included elements and ensure that each is ready for installation. Proper planning ensures a smooth workflow and minimizes errors along the way.

Focus on securing connections properly. Incorrect attachment of even a small part can lead to malfunction or reduced efficiency. Double-check that each segment is fastened correctly, following the correct order of assembly to ensure optimal results.

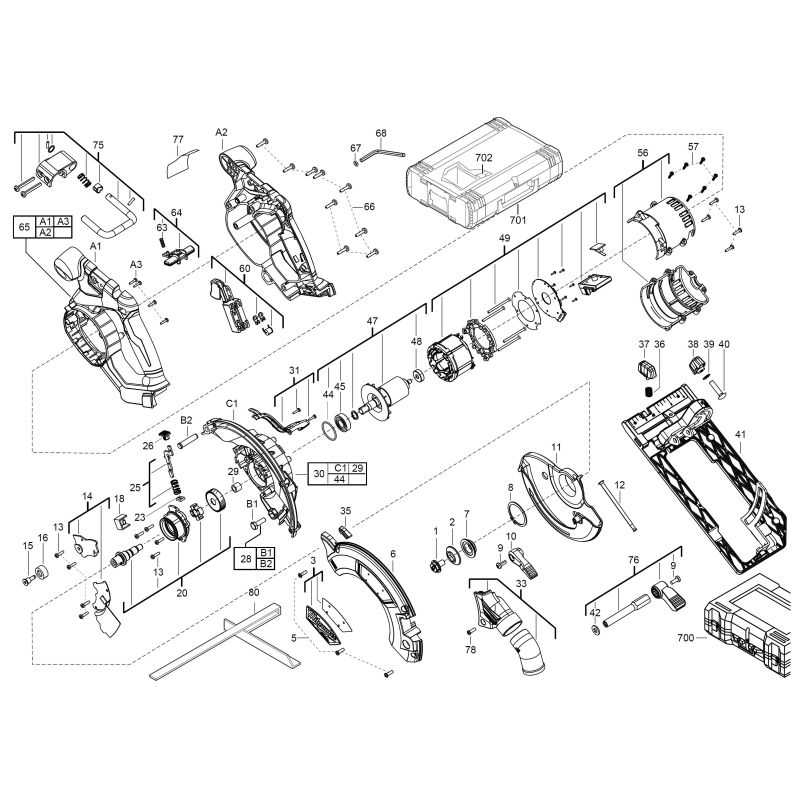

Step-by-Step Overview of Essential Connections

This section provides a detailed examination of the vital linkages within a specific cleaning apparatus, focusing on how each component interacts to optimize performance. Understanding these connections is crucial for effective maintenance and troubleshooting.

Begin by identifying the main sections of the device, which typically include the power supply, motor assembly, and suction mechanisms. Each of these areas contains critical connections that facilitate the transfer of energy and airflow, essential for the unit’s operation.

Next, pay attention to the wiring configurations that ensure proper functionality. Each wire must be securely attached and free from damage to maintain efficiency. Check for any loose or frayed connections that could lead to performance issues.

Additionally, observe how the various components communicate with one another. The motor must receive a consistent power supply to generate the necessary suction, while the filtration system needs to be appropriately aligned to prevent blockages and ensure optimal airflow.

Finally, a thorough inspection of the interconnections will reveal potential areas for improvement or repair. Regular checks can prolong the lifespan of the device and enhance its overall effectiveness, making it a reliable tool for cleaning tasks.

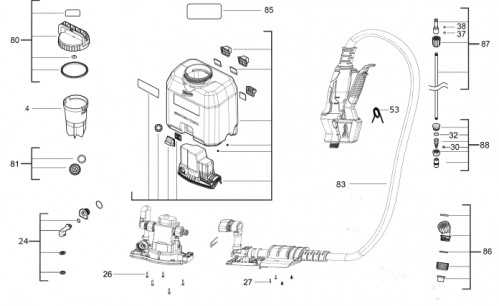

Maintenance Tips for Longevity

To ensure the durability and optimal performance of your cleaning device, regular upkeep is essential. Adopting a consistent maintenance routine can significantly extend the lifespan of your equipment while enhancing its efficiency. Here are some practical suggestions to help you care for your device effectively.

Firstly, it is vital to clean the filter regularly. A clogged filter can impede airflow, reducing suction power and straining the motor. Remove the filter and rinse it under warm water to eliminate dust and debris, allowing it to dry completely before reinserting.

Secondly, inspect the hoses and attachments for any blockages or wear. Clear any obstructions promptly, as these can hinder performance. Additionally, check for cracks or damages in the hoses and replace them if necessary to maintain proper functionality.

Moreover, ensure that the battery is charged appropriately. Overcharging or allowing the battery to fully discharge can shorten its lifespan. Follow the manufacturer’s recommendations for charging cycles to maximize battery health.

Finally, store your equipment in a clean, dry environment to prevent moisture-related issues. A suitable storage location can protect the device from damage and keep it ready for use whenever needed.

Ensuring Optimal Function Over Time

Maintaining peak performance in any device requires regular attention and care. Over time, components may wear out or become less efficient, which can hinder overall effectiveness. Understanding how to preserve functionality is key to extending the lifespan of your equipment.

Regular cleaning and inspection of all elements are essential steps in this process. Accumulation of debris can lead to reduced efficiency and increased strain on the system. By routinely removing dust and foreign particles, you can ensure smoother operation and prevent potential malfunctions.

Additionally, monitoring wear and tear on various components allows for timely replacements. Identifying which parts require attention or are showing signs of fatigue can help prevent larger issues down the line. Keeping track of the performance levels can also aid in making informed decisions regarding maintenance schedules.

Utilizing quality replacement components is another important factor. When parts need to be swapped out, selecting high-grade materials can significantly influence the longevity and effectiveness of the equipment. This commitment to quality helps maintain the integrity of the entire system, allowing it to operate optimally.

Ultimately, consistent upkeep and mindful choices regarding maintenance can greatly enhance the reliability and efficiency of your equipment. By adopting these practices, users can enjoy a more dependable experience and extend the useful life of their devices.

How to Troubleshoot Common Issues

Troubleshooting issues with your cleaning device can often be a straightforward process. By identifying common problems and understanding their possible causes, you can efficiently address and resolve any challenges that arise during operation. This guide will provide insights into typical concerns, enabling you to maintain optimal performance and extend the lifespan of your equipment.

Identifying Performance Problems

If your device is underperforming, it could be due to various factors. Check the filter to ensure it is clean and free of debris. A clogged filter can hinder airflow, leading to decreased suction power. Additionally, inspect the attachments and hoses for blockages. Removing any obstructions can significantly improve performance.

Power and Charging Issues

Should you experience difficulties with power or charging, first verify the battery connection. Ensure it is securely in place and free of dirt. If the device still does not turn on, test the battery with a multimeter to confirm its voltage. If the battery appears to be faulty, consider replacing it for optimal operation.

Quick Fixes for Effective Performance

Maintaining optimal functionality of your cleaning equipment is essential for achieving desired results. Regularly addressing common issues can enhance efficiency and prolong the lifespan of your device. Implementing simple solutions not only saves time but also ensures reliable operation during use.

Check Filters: One of the first steps to ensure effective performance is to inspect and clean or replace the filters regularly. Clogged filters can restrict airflow, leading to reduced suction power. Keeping them clean allows the device to operate at peak efficiency.

Inspect Hoses: A thorough examination of the hoses for any blockages or damage is crucial. If the hoses are kinked or obstructed, airflow will be compromised. Clear any debris or replace damaged sections to restore proper function.

Battery Maintenance: Ensure that the power source is charged and functioning well. A weak or failing battery can significantly impact performance. Regularly check battery health and clean the terminals to maintain a reliable power supply.

Regular Maintenance: Consistent upkeep is vital for long-term effectiveness. Create a routine schedule for cleaning and inspecting all components. This proactive approach can prevent minor issues from escalating into more significant problems.

Where to Source Replacement Components

Finding the right components for your cleaning device can significantly enhance its performance and longevity. Whether you need to replace worn-out elements or upgrade features, there are numerous options available for sourcing high-quality replacements. This guide will help you navigate through various avenues to ensure you acquire the right components for your equipment.

Authorized Retailers

One of the most reliable sources for replacement components is authorized retailers. These establishments often carry a comprehensive selection of genuine parts, ensuring compatibility and quality. Purchasing from authorized vendors not only guarantees that you receive the correct items but also provides peace of mind regarding warranties and return policies.

Online Marketplaces

In addition to physical stores, online marketplaces offer a vast array of components, often at competitive prices. Websites specializing in tools and accessories frequently feature user reviews and ratings, which can assist in making informed decisions. Be sure to verify the seller’s reputation and confirm the return policy before completing a purchase.

Locating Reliable Parts for Your Device

Finding trustworthy components for your equipment is crucial for maintaining its performance and longevity. Quality replacements not only ensure optimal functionality but also enhance the overall user experience. Whether you’re repairing a malfunctioning unit or upgrading certain features, sourcing reliable items is essential.

Researching Authorized Retailers

One of the best ways to secure authentic components is to research authorized retailers. These vendors often provide high-quality replacements that meet the manufacturer’s specifications. Look for established companies with positive customer reviews, as this can indicate their credibility. Furthermore, check if they offer warranties or return policies, as these features can give you additional confidence in your purchase.

Exploring Online Marketplaces

Another effective approach is to explore online marketplaces that specialize in electronic accessories. These platforms usually have a vast selection, making it easier to compare prices and options. However, exercise caution by reading product descriptions thoroughly and verifying seller ratings. Prioritize items from reputable brands to ensure you receive durable and efficient components for your device.

Optimizing Performance through Regular Checks

Maintaining the efficiency of your equipment is crucial for achieving optimal results. Regular assessments can help identify issues before they escalate, ensuring that your device operates at peak performance. By integrating consistent checks into your maintenance routine, you can extend the lifespan of your tool and enhance its functionality.

Start by examining filters and attachments, as these components play a significant role in overall performance. Clean or replace them as necessary to prevent clogging and ensure smooth operation. Additionally, inspect hoses and connections for any signs of wear or damage, as these can impede airflow and reduce effectiveness.

Next, pay attention to the battery and charging system. Ensure connections are secure and that the power source is functioning properly. Regularly charging your device will also maintain battery health and ensure reliable performance when needed.

Lastly, consult the user manual for specific maintenance guidelines tailored to your device. Following these recommendations can help you keep your equipment in top shape, ensuring it consistently delivers the best possible performance.