Kubota RTV 900 Transmission Parts Diagram Guide

The intricate workings of utility vehicle gear systems play a crucial role in ensuring optimal performance and reliability. A thorough grasp of these components is essential for effective maintenance and troubleshooting. This section aims to illuminate the various elements that comprise the gear assembly, highlighting their functions and interrelations.

By exploring a detailed schematic of these mechanisms, readers will gain insight into how each piece contributes to the overall operation of the vehicle. The understanding of these elements not only facilitates repairs but also enhances the user’s ability to identify potential issues before they escalate.

Equipped with this knowledge, operators can ensure their vehicles remain in peak condition, thus maximizing efficiency during demanding tasks. Delving into the specifics of the gear configuration empowers users to engage more meaningfully with their equipment, ultimately leading to a more effective and enjoyable experience.

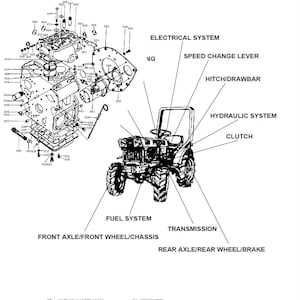

Kubota RTV 900 Overview

This section provides an in-depth look at a versatile utility vehicle designed for rugged tasks and varied terrains. Engineered for efficiency and durability, it is favored by many for both recreational and professional use.

Key features include:

- Robust construction, ensuring longevity and reliability.

- Powerful engine options that deliver excellent performance.

- Advanced drivetrain technology for enhanced traction and stability.

Additionally, the vehicle is equipped with:

- Spacious cargo area suitable for transporting equipment and supplies.

- Comfortable seating for multiple passengers, promoting an enjoyable ride.

- Easy-to-use controls that facilitate smooth operation in various conditions.

Overall, this utility vehicle stands out as a practical choice for those seeking an all-terrain companion for work and play.

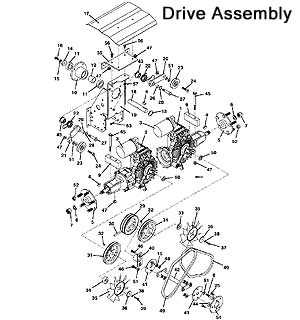

Understanding Transmission Components

The intricate assembly of a vehicle’s drive system plays a crucial role in its overall performance and efficiency. Each element within this system works harmoniously to ensure smooth power delivery from the engine to the wheels. A comprehensive understanding of these components is essential for anyone looking to maintain or troubleshoot their machinery effectively.

Key Elements include gears, clutches, and various linkages that facilitate the transfer of torque. Each part has a specific function, contributing to the seamless operation of the vehicle. For instance, gears are responsible for adjusting speed and torque, while clutches enable smooth engagement and disengagement of power.

Additionally, lubrication systems play a vital role in minimizing friction between moving parts, enhancing durability and performance. Recognizing the importance of these elements can lead to better maintenance practices and a deeper appreciation for the engineering behind modern vehicles.

Importance of Transmission Maintenance

Proper upkeep of a vehicle’s drive system is essential for ensuring optimal performance and longevity. Regular maintenance helps prevent breakdowns and costly repairs while enhancing overall functionality. Understanding the significance of maintaining these crucial components can lead to improved efficiency and reliability.

Benefits of Regular Upkeep

Consistent care of the drive mechanism not only extends its lifespan but also improves fuel efficiency. By addressing minor issues promptly, owners can avoid more severe problems down the line, which can lead to unexpected downtime and expenses.

Key Maintenance Practices

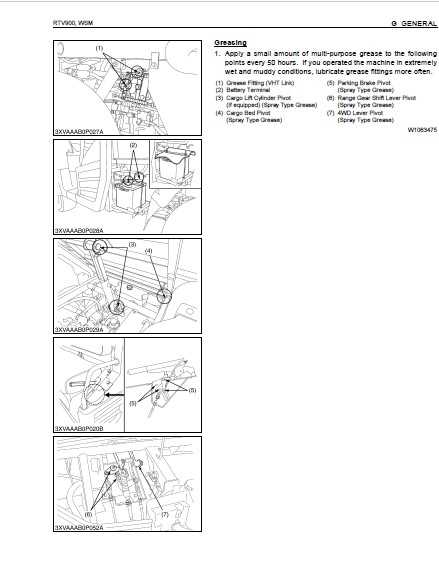

To ensure the reliable operation of the drive system, certain practices should be regularly followed. These include checking fluid levels, inspecting seals and gaskets, and replacing worn components as needed. A proactive approach can significantly enhance the overall performance.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Fluid Level Check | Every 50 hours | Ensures proper lubrication and cooling |

| Visual Inspection | Every 100 hours | Identifies leaks and wear |

| Component Replacement | As needed | Prevents system failures |

Common Issues with RTV 900 Transmission

When operating utility vehicles, various mechanical challenges can arise, particularly in the drive system. These issues can lead to decreased performance, affecting efficiency and reliability. Understanding these common problems can help in timely diagnosis and maintenance.

| Issue | Description | Possible Solutions |

|---|---|---|

| Slipping Gears | Shifting between gears may become erratic or delayed, causing performance issues. | Check fluid levels and condition, inspect linkage for wear, and adjust as necessary. |

| No Movement | The vehicle may fail to engage or move, which could indicate a severe internal issue. | Examine the drive belts and ensure proper engagement; inspect for any blockages. |

| Overheating | Excessive heat can lead to component failure and decreased efficiency. | Monitor fluid levels, clean cooling systems, and check for obstructions. |

| Noisy Operation | Unusual sounds may indicate worn bearings or other internal damage. | Conduct a thorough inspection for wear and replace any damaged components. |

Regular maintenance and attention to these potential issues can significantly enhance the longevity and performance of your vehicle.

How to Identify Transmission Parts

Understanding the components of a power transfer system is essential for effective maintenance and repair. Recognizing each element can significantly enhance your ability to diagnose issues and ensure optimal functionality. Familiarity with these components will empower you to tackle problems with confidence.

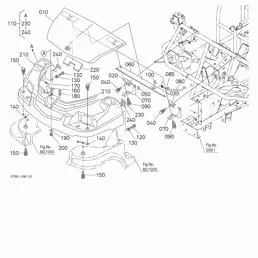

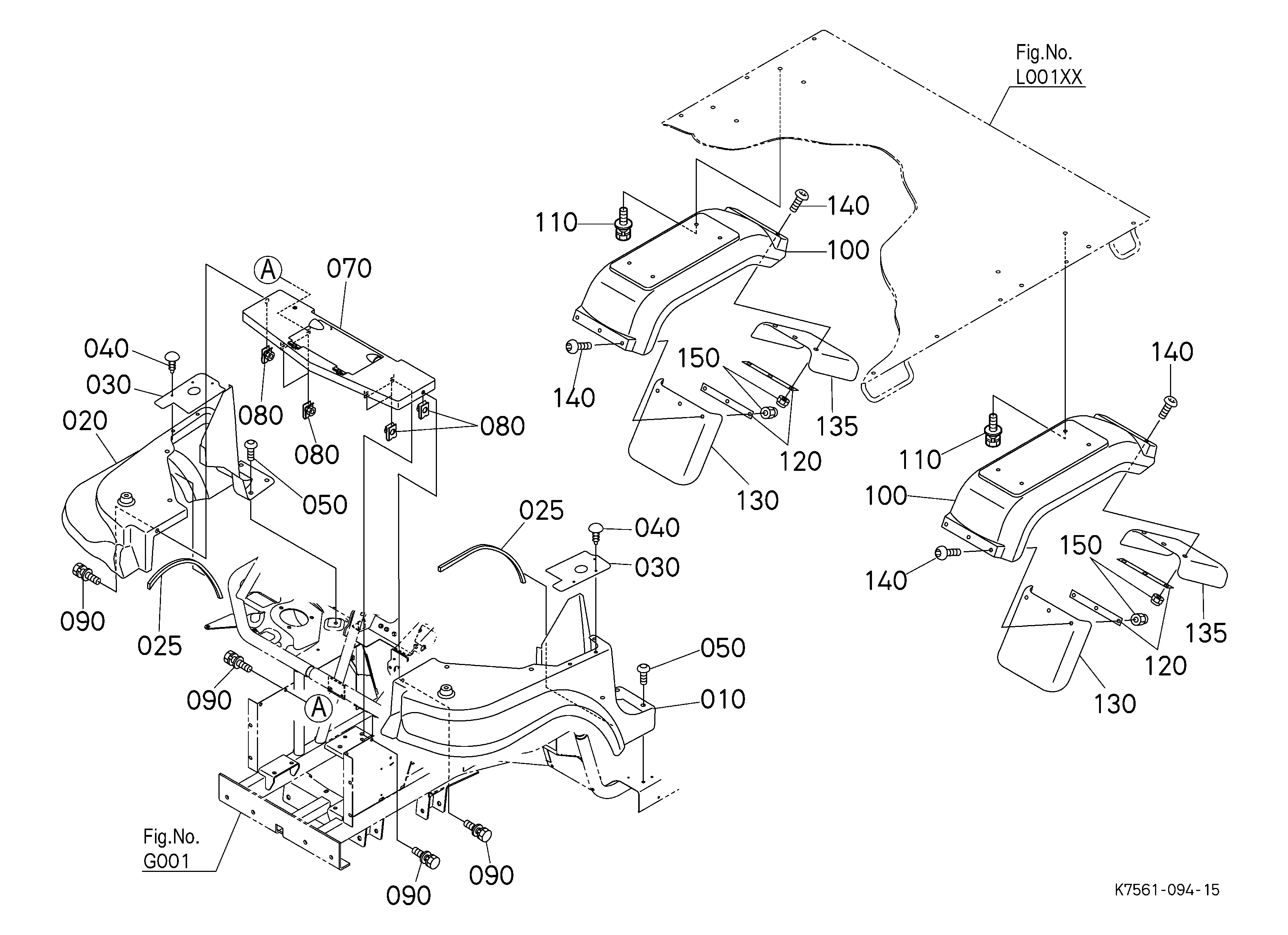

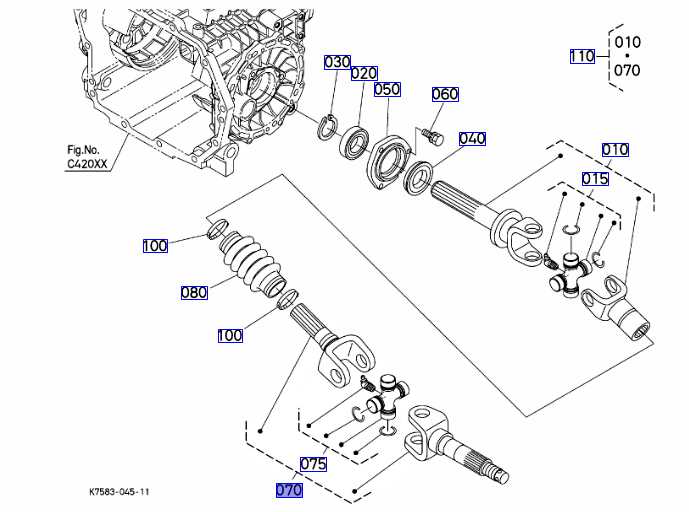

Visual Inspection Techniques

Begin with a thorough visual examination of the assembly. Look for labels, part numbers, or any markings that might indicate the function of specific components. Pay attention to the shape and size of each element, as these characteristics often provide clues about their roles within the system.

Utilizing Reference Materials

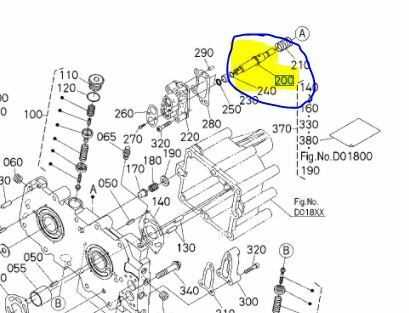

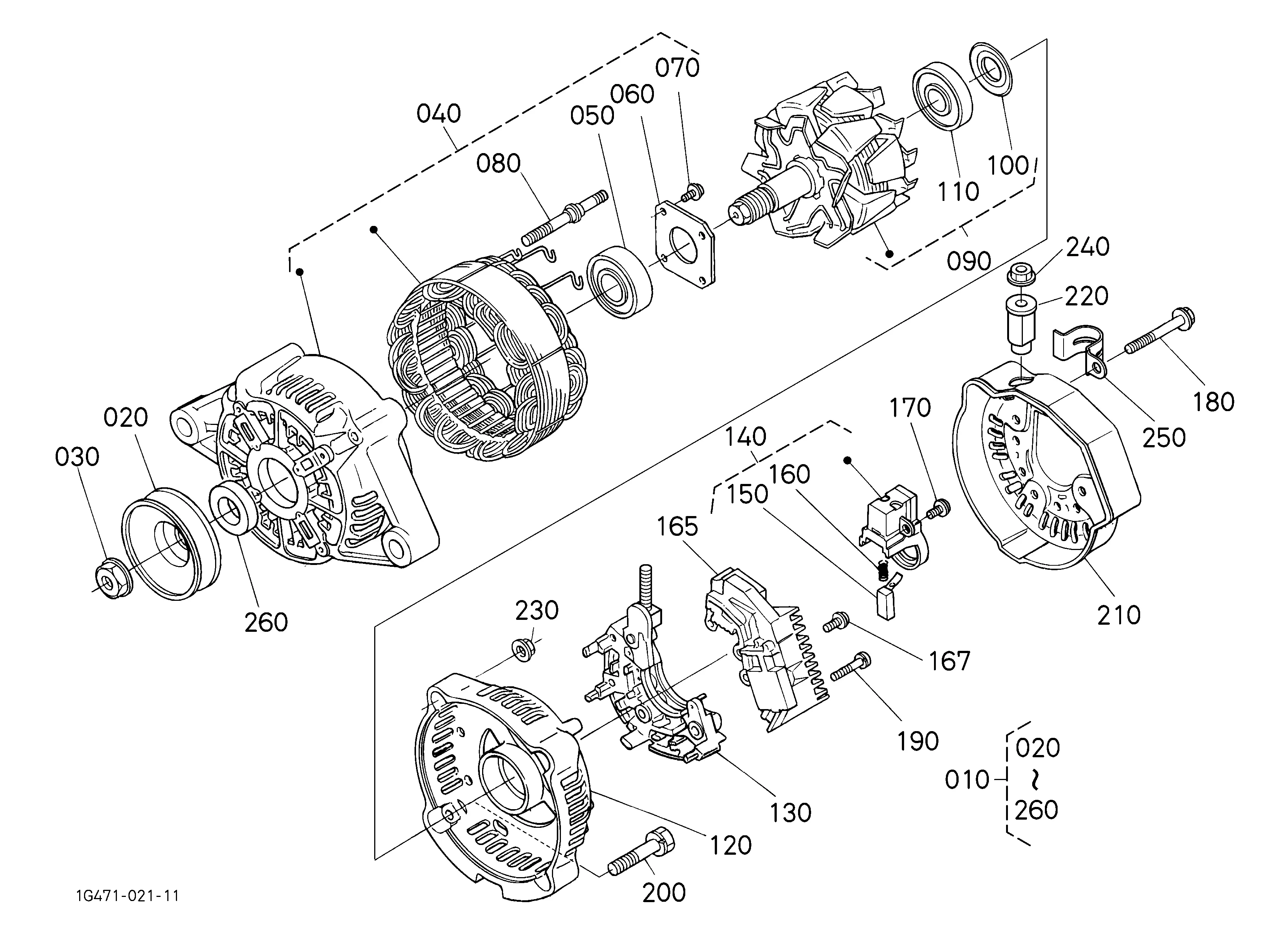

Consulting technical manuals or online resources can be invaluable. These documents typically contain detailed descriptions and illustrations that can aid in identifying each element. Additionally, diagrams may highlight connections and relationships between different components, making it easier to understand their interplay and significance.

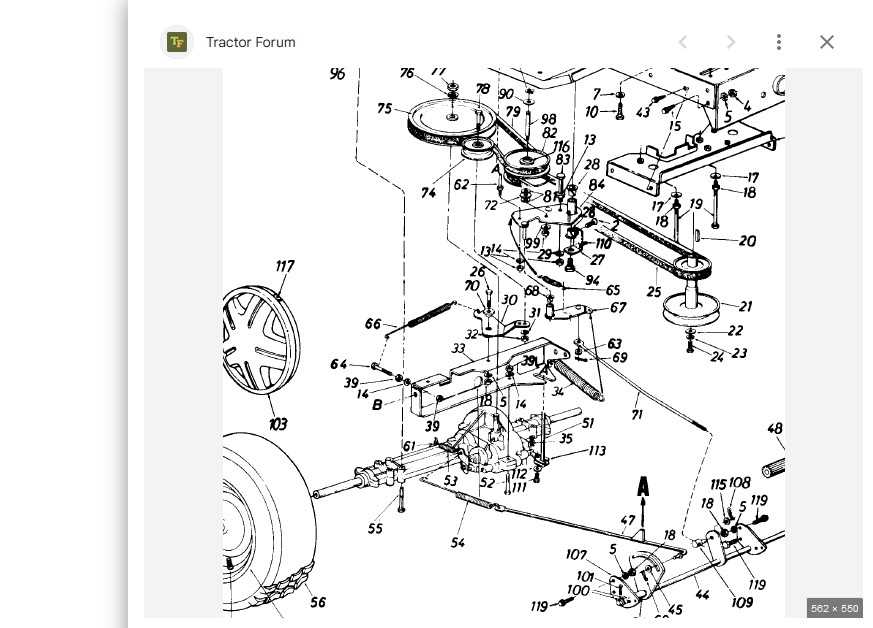

Diagram Analysis for Effective Repairs

Understanding technical schematics is crucial for anyone looking to undertake maintenance or repairs on machinery. These illustrations serve as a roadmap, guiding technicians through complex systems and enabling them to identify components accurately. By analyzing these visuals, users can enhance their problem-solving skills and execute repairs with greater precision.

Key Benefits of Schematic Review

- Improved Understanding: Visual representations clarify the relationships between components.

- Time Efficiency: Quick reference can significantly reduce diagnostic time.

- Enhanced Safety: Knowledge of system layouts helps avoid hazards during repair work.

- Cost-Effective Repairs: Accurate identification of faulty elements minimizes unnecessary part replacements.

Steps for Effective Analysis

- Familiarize Yourself: Begin by understanding the overall layout before diving into specifics.

- Identify Components: Note the functions of different parts and their interconnections.

- Highlight Areas of Concern: Mark sections that require further investigation or have a history of issues.

- Cross-Reference with Manuals: Use manufacturer resources to verify details and gain additional insights.

- Document Findings: Keep records of your analysis for future reference, which can streamline subsequent repairs.

By mastering the interpretation of these visual tools, individuals can significantly enhance their repair capabilities, leading to more effective maintenance practices overall.

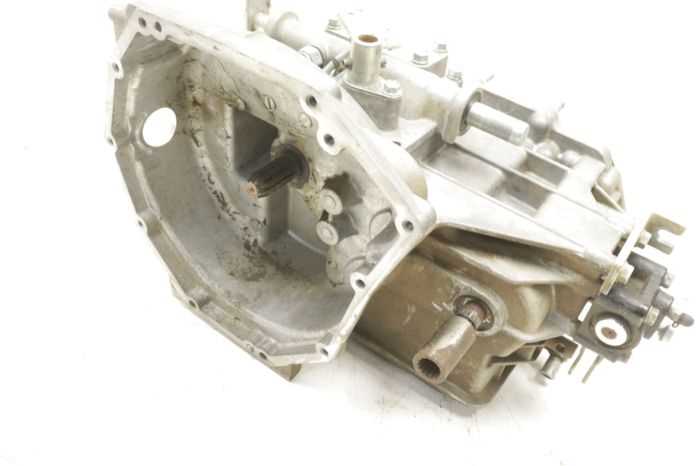

Steps for Transmission Disassembly

Disassembling a complex mechanical system requires careful planning and attention to detail. This process involves multiple stages, from gathering the necessary tools to meticulously separating components. By following a systematic approach, you can ensure the integrity of each part and facilitate easier reassembly.

Preparation and Safety

Before beginning the disassembly, ensure you have all required tools, such as wrenches, screwdrivers, and safety gear. Safety goggles and gloves are essential to protect yourself from potential hazards. Additionally, work in a well-lit and organized area to minimize the risk of losing small components.

Step-by-Step Disassembly

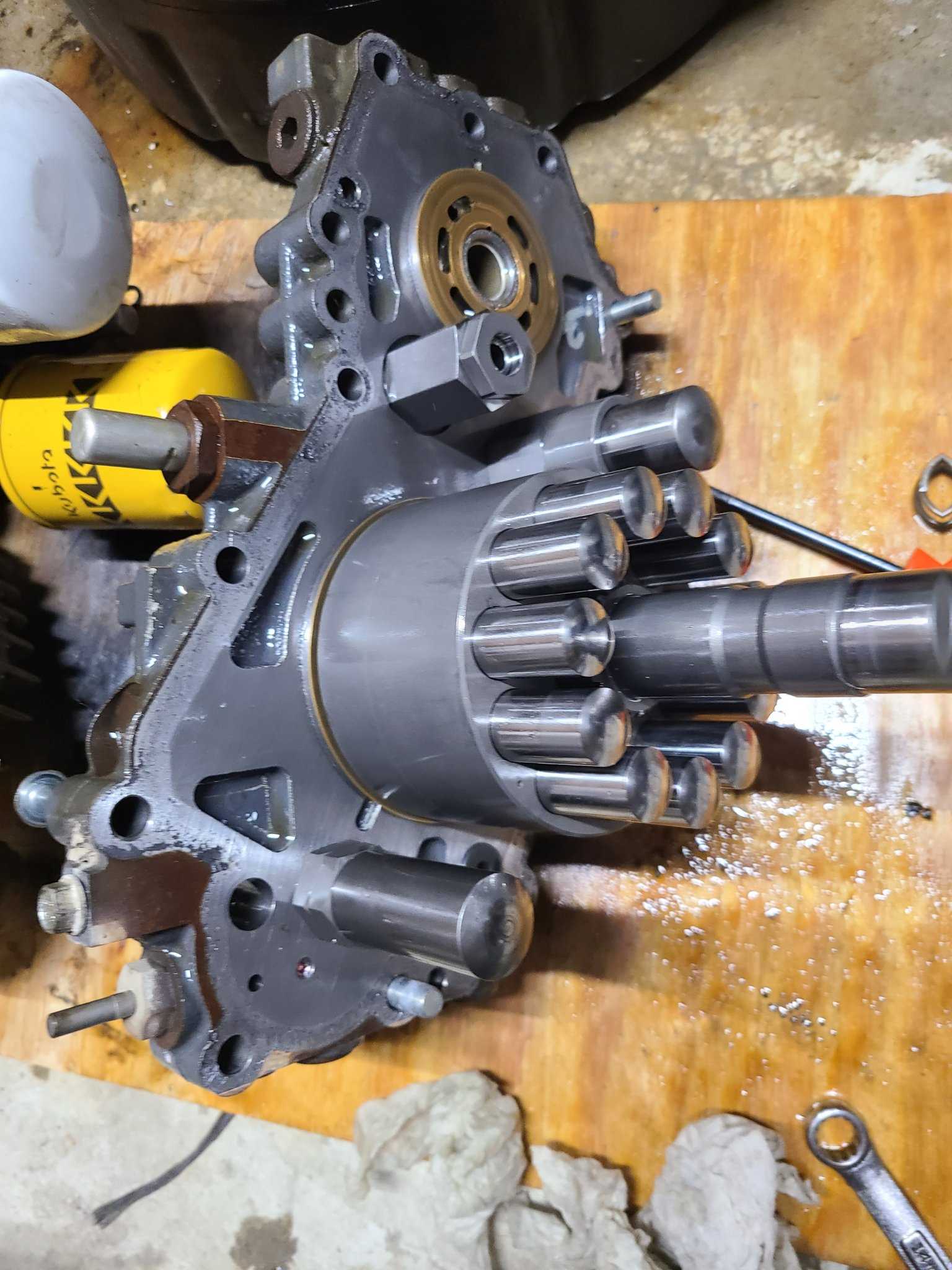

Start by removing any outer casings or protective covers. This often involves unscrewing bolts and clips that secure the housing. Once the exterior is removed, take note of the arrangement of internal components. It is helpful to document their positions either through photographs or sketches.

Next, carefully disconnect any electrical connectors or hydraulic lines. Labeling these connections can prevent confusion during reassembly. Proceed to detach the main assemblies, making sure to keep track of any small parts, such as springs or washers, that may come loose.

After separating the main components, examine each one for wear and damage. This inspection is crucial for determining whether parts need to be replaced or can be reused. Finally, clean all components thoroughly before storing them for future reassembly, ensuring they are free of dirt and debris.

Reassembling RTV 900 Transmission System

Reassembling the power transfer mechanism of your utility vehicle requires careful attention to detail and a systematic approach. This process is essential for ensuring optimal performance and longevity. By following the right steps, you can successfully bring the system back to its intended functionality.

Preparation is key before starting the assembly. Make sure all components are clean and free of debris. Inspect each element for wear and damage, replacing any parts that do not meet standards. A well-organized workspace can significantly enhance efficiency during reassembly.

Begin by attaching the main housing, ensuring that all alignment notches are properly fitted. Follow this by carefully placing the internal gears and ensuring they rotate smoothly. Use the manufacturer’s guidelines as a reference for torque specifications when tightening bolts, as this prevents future malfunctions.

Next, incorporate the auxiliary components, such as the fluid pump and cooling elements. Ensure that seals and gaskets are in good condition to avoid leaks. Proper lubrication is vital; apply the appropriate grease to moving parts to minimize friction.

Finally, conduct a thorough inspection of the entire assembly. Check for any misalignments and confirm that all fasteners are secure. Once everything is in place, reconnect the power source and run a test to confirm that the system operates smoothly and efficiently.

Best Practices for Parts Replacement

Replacing components in machinery requires careful attention to detail and adherence to specific guidelines to ensure optimal performance and longevity. Following established best practices not only enhances functionality but also minimizes the risk of future issues.

1. Choose Quality Components

Always opt for high-quality replacements that meet or exceed the manufacturer’s specifications. Using substandard materials can lead to premature failure and may compromise the entire system. It’s advisable to research and select reputable suppliers who guarantee their products.

2. Proper Tools and Techniques

Utilizing the right tools and methods is crucial when replacing elements. Familiarize yourself with the installation procedures and safety protocols. Ensuring that you have all necessary tools on hand before starting the job will streamline the process and reduce the chance of mistakes.

Remember, taking the time to perform replacements correctly will save you both time and money in the long run. Always refer to the manual for specific instructions related to the machinery in question.

Where to Find Replacement Parts

Finding the right components for your utility vehicle can often feel overwhelming, but knowing where to look can simplify the process significantly. Various sources provide an array of options, ensuring you can locate the necessary items to keep your machine running smoothly.

Online Retailers offer a vast selection of components, making it easy to compare prices and find specific items. Websites specializing in equipment supplies frequently update their inventories, allowing you to browse through various brands and models.

Authorized Dealers are another reliable option. They not only stock genuine components but also offer expert advice and support. Visiting a dealer can give you access to specialized knowledge about your vehicle’s requirements.

Local Repair Shops often have connections to suppliers and may assist in sourcing hard-to-find items. Additionally, they can provide insights based on their experience working with similar vehicles, helping you make informed decisions.

Salvage Yards can be a hidden gem for cost-effective solutions. These locations often have used components in good condition, allowing you to save money while still obtaining quality parts.

Finally, Online Marketplaces can be a useful resource for both new and used components. Community forums and groups dedicated to enthusiasts often share leads on where to find specific items, further expanding your search options.

By exploring these avenues, you can ensure that your utility vehicle remains in optimal condition without excessive hassle.