Comprehensive Guide to John Deere 4440 Parts Diagram

Understanding the intricate details of heavy-duty farming equipment is essential for optimal performance and maintenance. A thorough examination of individual elements can significantly enhance the efficiency and longevity of these machines. This section delves into the various components of a specific model, providing insight into their structure and function.

Farm machinery comprises numerous interconnected parts, each playing a vital role in ensuring seamless operation. By familiarizing oneself with these components, operators can better manage repairs and replacements, leading to reduced downtime and increased productivity. Accurate knowledge of each piece contributes to a more effective and sustainable agricultural practice.

In the following sections, we will present a detailed visual representation of the assembly, highlighting key features and offering guidance on maintenance and troubleshooting. This resource aims to empower users, equipping them with the necessary tools to maintain their equipment effectively.

Understanding the John Deere 4440

This section delves into the intricate workings and features of a renowned agricultural machine that has left a significant mark in the farming industry. By exploring its design and functionality, one can appreciate the engineering that makes it a favored choice among professionals.

Key Features and Benefits

The machine is equipped with a powerful engine, ensuring reliable performance in various conditions. Its advanced hydraulic system allows for efficient operation, making it ideal for heavy-duty tasks. The user-friendly interface enhances productivity, enabling operators to manage complex functions with ease.

Maintenance and Upkeep

Regular maintenance is crucial for longevity and optimal performance. Routine checks on fluid levels, filters, and belts can prevent potential issues. Understanding the machine’s components and their roles is essential for effective upkeep, ensuring that it continues to operate at peak efficiency.

Key Features of the 4440 Model

The model in question is renowned for its blend of power, efficiency, and versatility, making it a staple in various agricultural settings. Its robust construction and advanced engineering set a benchmark in the industry, providing operators with a reliable machine that excels in demanding tasks.

Powerful Engine: The heart of this machine is its high-performance engine, which delivers exceptional horsepower. This enables it to tackle heavy-duty operations with ease, ensuring that tasks are completed efficiently and effectively.

Advanced Hydraulics: Equipped with a sophisticated hydraulic system, this model allows for smooth and precise control over implements. The enhanced lifting capacity and responsiveness significantly improve productivity on the field.

Durable Build: Designed with longevity in mind, the sturdy frame and quality materials ensure that the machine can withstand harsh conditions. This durability reduces maintenance needs and extends the lifespan of the equipment.

User-Friendly Controls: The intuitive layout of the controls allows operators to navigate functions effortlessly. This ease of use minimizes training time and enhances operational efficiency, making it suitable for both seasoned and novice users.

Versatility: Its ability to adapt to various attachments and implements makes this model incredibly versatile. Whether it’s tilling, plowing, or hauling, it proves to be a dependable ally across multiple applications.

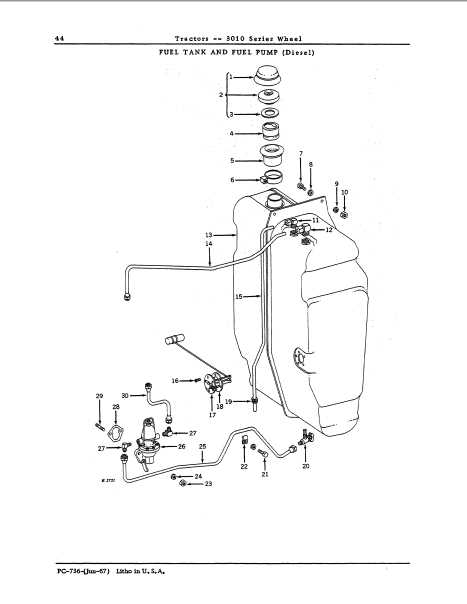

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as invaluable resources, allowing technicians to identify, locate, and manage various elements effectively. These illustrations not only enhance comprehension but also streamline the troubleshooting process, minimizing downtime.

Benefits of Visual Guides

Utilizing visual aids offers several advantages in the context of equipment management. Firstly, they simplify complex structures, making it easier for operators to grasp the relationships between different components. Secondly, they facilitate accurate ordering of replacements, ensuring that the right items are procured swiftly.

Efficiency in Repairs

Incorporating these visual tools can significantly increase repair efficiency. Technicians can quickly reference illustrations to pinpoint issues and strategize repairs. This approach reduces the likelihood of errors, ultimately leading to a more effective and timely restoration of functionality.

| Advantage | Description |

|---|---|

| Enhanced Understanding | Clarifies component relationships and functions. |

| Accurate Ordering | Ensures the correct replacement parts are sourced. |

| Reduced Downtime | Streamlines the repair process for quicker solutions. |

| Minimized Errors | Lowers the chances of mistakes during maintenance. |

Commonly Replaced Components

In the realm of agricultural machinery, certain elements often require replacement due to wear and tear or performance degradation. Recognizing these frequently swapped-out parts can greatly enhance the efficiency and longevity of the equipment. Maintenance becomes simpler when operators are aware of which components typically need attention and when to address them.

Engine Components

Among the critical areas of focus are engine elements. Filters, such as oil and fuel filters, are vital for maintaining optimal performance and should be checked regularly. Additionally, gaskets and seals often experience deterioration over time, leading to leaks and reduced efficiency. Regular replacement of these items can prevent more extensive damage and costly repairs.

Transmission and Hydraulic Parts

The transmission and hydraulic systems are also prone to wear. Hydraulic hoses and couplings can develop leaks or become brittle, compromising system performance. Furthermore, clutches and shifters may require replacement to ensure smooth operation. Staying ahead of these common issues can significantly reduce downtime and enhance productivity in the field.

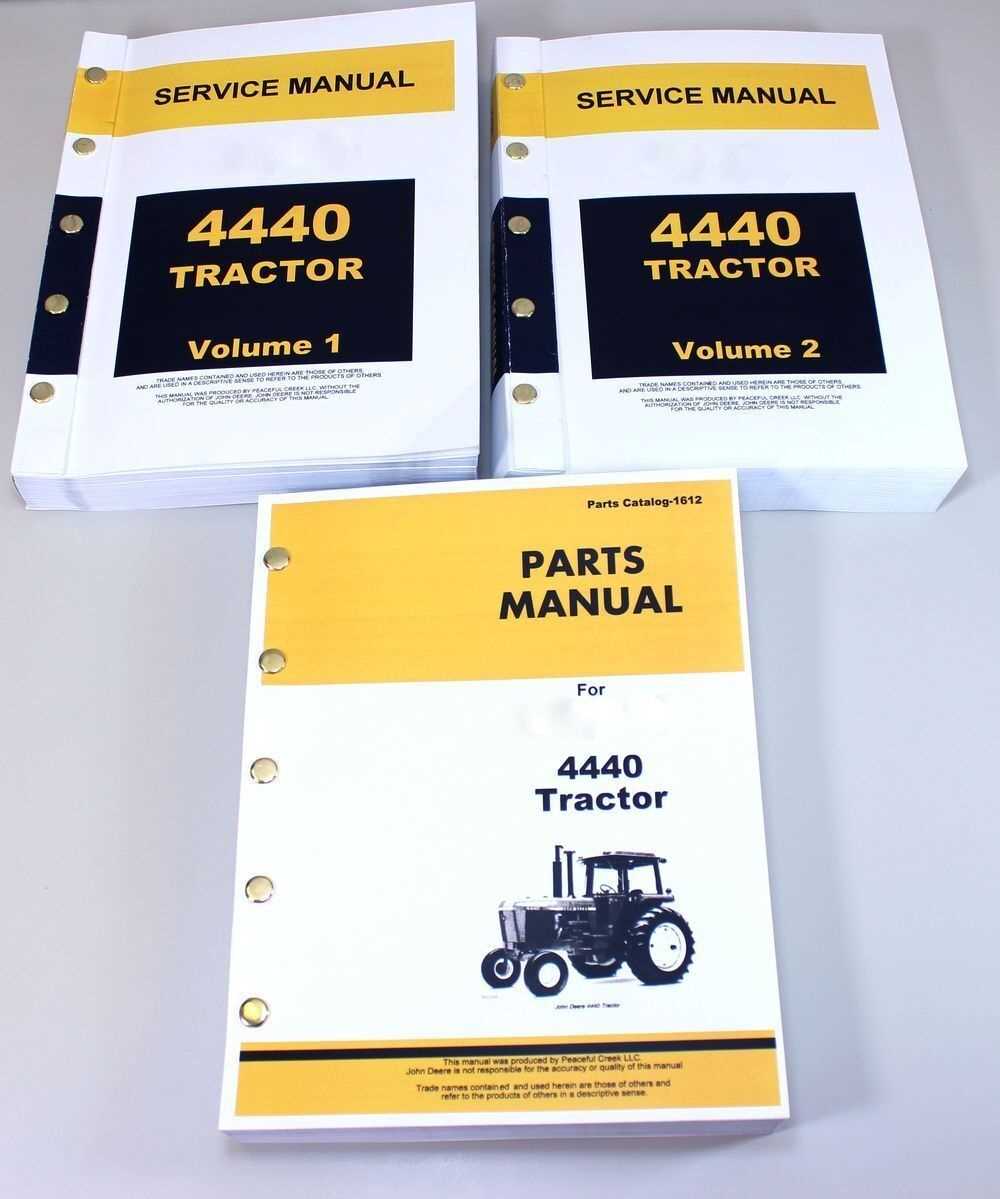

Where to Find Parts Diagrams

Locating comprehensive illustrations for machinery components is essential for effective maintenance and repairs. These resources can help users identify and order the necessary elements to ensure optimal functionality.

Here are several reliable sources for accessing these valuable resources:

- Official Manufacturer Websites: Many companies provide online resources, including technical manuals and visual aids, directly on their platforms.

- Online Retailers: Numerous e-commerce sites specialize in machinery components and often offer detailed visual references alongside product listings.

- Forums and Community Groups: Engaging with user communities can yield shared insights and access to visual resources from experienced users.

- Service Manuals: Printed or digital manuals typically contain detailed visuals and can be obtained through authorized dealers or online marketplaces.

- Parts Catalogs: Specialized catalogs often include comprehensive breakdowns, making it easier to find specific items.

Utilizing these resources can significantly streamline the process of sourcing the necessary components for effective equipment upkeep.

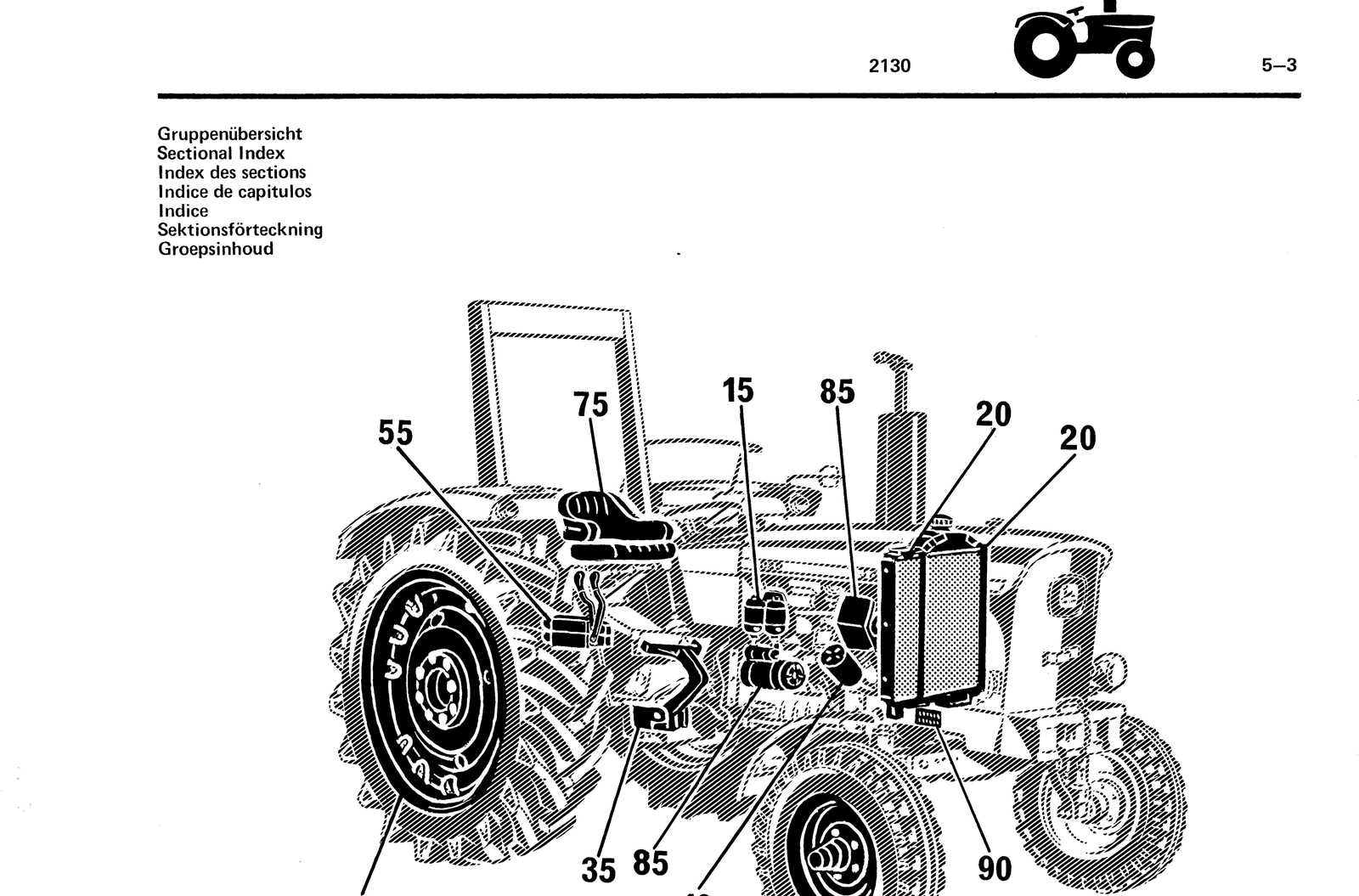

Reading a Parts Diagram Effectively

Understanding technical illustrations is crucial for anyone involved in machinery maintenance. These visuals provide essential insights into component relationships and functionalities, enabling users to identify necessary replacements and repairs efficiently.

To interpret such visuals successfully, consider the following steps:

- Familiarize Yourself with Symbols: Each illustration typically employs specific icons to denote various components. Take time to understand these symbols to avoid confusion.

- Study the Legend: Most diagrams include a legend that explains the symbols and colors used. Refer to this section frequently to ensure accurate comprehension.

- Follow the Sequence: Many visuals are designed to illustrate assembly or disassembly processes. Pay attention to the order presented, as it often indicates the most effective way to handle components.

- Identify Key Sections: Break down the illustration into smaller sections to focus on specific areas. This approach makes it easier to locate and analyze particular parts.

- Take Notes: As you review, jot down any important details or observations. This practice can help reinforce your understanding and serve as a reference during maintenance tasks.

By following these strategies, you can enhance your ability to read and interpret technical illustrations, leading to more effective maintenance and repair outcomes.

Maintenance Tips for the 4440

Regular upkeep is essential to ensure optimal performance and longevity of your machinery. Implementing a consistent maintenance routine can prevent unexpected breakdowns and enhance overall efficiency. This guide provides practical advice to keep your equipment in top shape.

Routine Inspections

Conducting regular inspections is crucial. Check fluid levels, filters, and belts frequently. This will help you identify potential issues before they escalate. Pay close attention to any unusual sounds or vibrations during operation, as these can be early signs of wear and tear.

Lubrication and Cleaning

Proper lubrication is vital for moving parts. Ensure that all grease points are regularly serviced according to the manufacturer’s recommendations. Additionally, keeping your equipment clean prevents dirt buildup, which can lead to premature wear. Use appropriate cleaning solutions to maintain the exterior and prevent corrosion.

Aftermarket vs. OEM Parts

The decision between original manufacturer components and alternative solutions is crucial for equipment maintenance and repair. Understanding the differences can significantly impact performance, longevity, and overall satisfaction. Each option presents its own set of advantages and drawbacks, making it essential for owners to evaluate their specific needs.

Advantages of OEM Components

- Quality Assurance: Manufactured to exact specifications, ensuring compatibility and reliability.

- Warranty Coverage: Often comes with a guarantee, providing peace of mind for users.

- Resale Value: Utilizing original components can enhance the resale potential of the equipment.

Benefits of Aftermarket Solutions

- Cost-Effectiveness: Generally more affordable than their original counterparts.

- Variety of Options: A wide range of choices available, allowing for customization and specific needs.

- Accessibility: Often easier to find and purchase through various retailers.

Ultimately, the choice between these two types of components should be guided by individual priorities, such as budget, equipment usage, and long-term plans. Careful consideration of both options will ensure the best outcome for maintenance and performance needs.

Restoration Projects for 4440 Owners

Undertaking restoration projects can be a rewarding endeavor for enthusiasts seeking to breathe new life into their beloved machinery. Whether aiming to enhance performance or simply preserve its classic appeal, these initiatives often require careful planning and execution. From minor repairs to complete overhauls, owners have a variety of options to explore, ensuring their equipment remains functional and visually appealing for years to come.

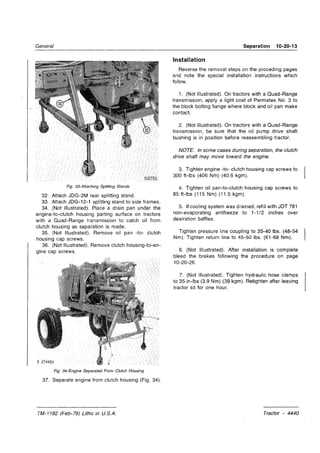

Essential Steps for Restoration

Starting a restoration project involves several key phases that can make or break the outcome. Here’s a brief overview of essential steps:

| Step | Description |

|---|---|

| Assessment | Evaluate the current condition of the machine, identifying areas that need attention. |

| Planning | Develop a detailed plan outlining the scope of work, necessary tools, and materials. |

| Disassembly | Carefully take apart components to inspect and clean them, preparing for repairs or replacements. |

| Restoration | Repair or replace damaged parts, ensuring all components are restored to their original function. |

| Reassembly | Put all components back together, following the initial assessment and planning steps. |

| Testing | Conduct thorough tests to ensure the equipment operates smoothly and safely. |

Common Upgrades and Modifications

While restoration is often about returning machinery to its original state, many owners opt for upgrades that enhance functionality. Popular modifications include improving hydraulic systems, upgrading electrical components, or adding modern technology for better efficiency. These enhancements not only modernize the equipment but can also increase its resale value, making the investment worthwhile.

Identifying Part Numbers Easily

Recognizing component identifiers can significantly streamline the maintenance and repair process for machinery. By utilizing the correct references, users can ensure they obtain the right replacements, thus enhancing efficiency and performance. Understanding how to locate and interpret these identifiers is essential for anyone involved in equipment management.

| Identifier Type | Description |

|---|---|

| Manufacturer Code | A unique code assigned by the manufacturer to identify specific components. |

| Model Number | A designation that indicates the specific design or version of the equipment. |

| Serial Number | A unique number that provides information about the production batch and history of the unit. |

| Catalog Reference | A reference found in parts catalogs that correlates with available components. |

By familiarizing yourself with these identifiers, you can navigate the resources available for your machinery with greater ease and confidence. Knowing where to find this information and how to interpret it will save time and minimize errors in procurement.

Utilizing Online Resources

In the digital age, accessing information and components for machinery has become easier than ever. Online platforms offer a wealth of resources that can assist enthusiasts and professionals in finding what they need quickly and efficiently. This section explores the various avenues available for sourcing and utilizing these resources effectively.

Types of Online Resources

- Manufacturer Websites: Official sites often provide comprehensive catalogs, manuals, and specific guides for various models.

- Online Marketplaces: Platforms such as eBay and Amazon allow users to find both new and used items, often at competitive prices.

- Forums and Community Groups: Online communities can be invaluable for sharing experiences, recommendations, and tips for sourcing components.

- Video Tutorials: Many users create instructional content that details repairs, maintenance, and part identification.

Best Practices for Effective Use

- Verify Credibility: Always check the reliability of the source before making a purchase or following advice.

- Utilize Search Functions: Use specific keywords to narrow down search results, making it easier to find relevant information.

- Engage with Communities: Ask questions and participate in discussions to gain insights from experienced individuals.

- Bookmark Useful Links: Save frequently used sites for quick access in the future.

By leveraging these online resources effectively, users can enhance their knowledge and streamline their search for necessary equipment components, ensuring their machinery remains in optimal condition.

Common Issues and Solutions

When operating heavy machinery, it’s not uncommon to encounter various challenges that may affect performance and efficiency. Understanding these frequent problems and their remedies can significantly enhance the longevity of equipment and ensure smooth operations.

- Engine Performance Issues:

- Problem: Difficulty starting or stalling.

- Solution: Check the fuel system, including filters and injectors, and inspect the ignition components.

- Hydraulic System Failures:

- Problem: Slow or unresponsive hydraulic functions.

- Solution: Examine the hydraulic fluid levels, hoses, and connections for leaks or blockages.

- Transmission Difficulties:

- Problem: Shifting issues or slipping gears.

- Solution: Inspect the transmission fluid and replace worn-out components such as seals and filters.

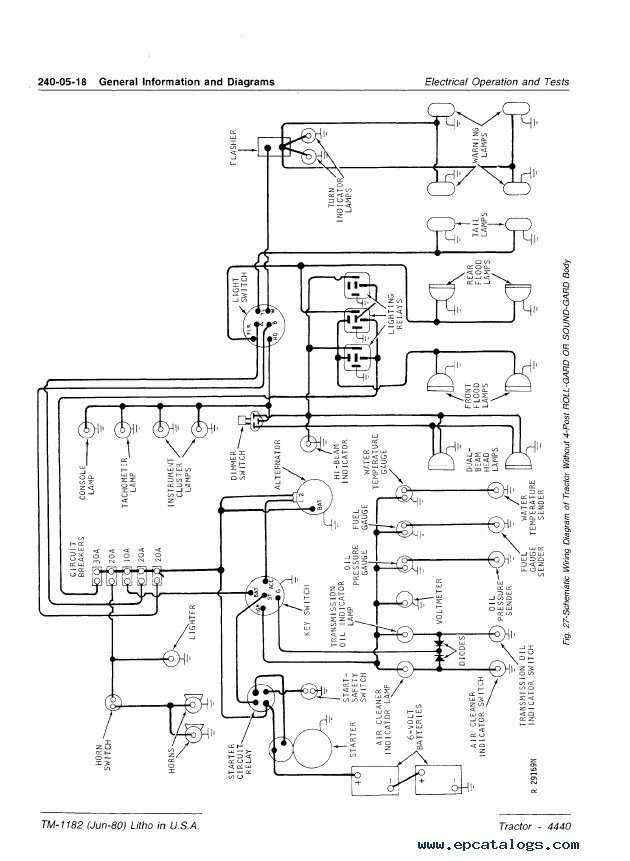

- Electrical System Glitches:

- Problem: Malfunctioning lights or instrumentation.

- Solution: Test the battery and wiring connections, ensuring all components are secure and free from corrosion.

- Cooling System Challenges:

- Problem: Overheating during operation.

- Solution: Check coolant levels, inspect the radiator for clogs, and ensure the fan is functioning properly.

By proactively addressing these common issues, operators can maintain optimal performance and avoid more serious complications down the line.

Expert Recommendations for Parts Replacement

When it comes to maintaining heavy machinery, understanding the nuances of component replacement is crucial. Regular inspections and timely updates can significantly enhance the performance and longevity of your equipment. Here are some expert insights to consider when it’s time to replace essential components.

- Assess Wear and Tear: Regularly check for signs of wear, such as unusual noises or decreased efficiency. Early detection can prevent costly breakdowns.

- Quality Over Price: Always prioritize high-quality replacements over cheaper alternatives. Investing in durable components pays off in the long run.

- Consult Manuals: Reference your equipment’s manual for specific guidance on replacement procedures and compatible components.

- Use OEM Parts: Whenever possible, opt for original equipment manufacturer parts to ensure compatibility and reliability.

Following these recommendations will help ensure that your machinery operates smoothly and efficiently, ultimately saving time and resources.