Kubota Transmission Parts Diagram Explained

In the realm of machinery, grasping the configuration of intricate elements is essential for optimal performance and maintenance. This section explores the visual representation of these crucial mechanisms, offering insights into their functions and interrelationships.

Efficient operation relies on a clear comprehension of how various sections integrate and interact. By examining these illustrations, one can uncover the ultimate pathways of energy transfer and mechanical action, facilitating effective troubleshooting and repairs.

Additionally, these visual tools serve as valuable resources for both seasoned professionals and newcomers alike. They provide a comprehensive view that enhances understanding and encourages effective engagement with complex systems.

Understanding Kubota Transmission Components

Grasping the intricacies of vehicle gear systems is essential for optimal performance and longevity. These systems encompass various elements that work harmoniously to ensure smooth operation and effective power transfer. Each component plays a crucial role, and a thorough understanding can greatly enhance maintenance and troubleshooting efforts.

Key Elements of the Gear Mechanism

The heart of the system consists of essential pieces such as gears, shafts, and clutches. Gears are designed to adjust speed and torque, while shafts serve as the conduits for power distribution. Clutches, on the other hand, facilitate seamless engagement and disengagement, allowing for responsive driving experiences.

Importance of Regular Maintenance

Maintaining these components is vital for preventing wear and tear. Regular checks can help identify issues before they escalate, ensuring that the entire system functions effectively. By delving into each part’s role, owners can achieve the ultimate reliability and efficiency from their machinery.

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repairs. These illustrations serve as essential guides, enabling technicians to identify and locate specific elements quickly, reducing the risk of errors during assembly or disassembly. Clarity in these visuals not only streamlines the repair process but also enhances overall efficiency.

Moreover, accurate representations foster a deeper understanding of the mechanical system, helping operators grasp the relationships between different parts. This knowledge empowers them to troubleshoot issues more effectively and make informed decisions when selecting replacements or performing upgrades.

Ultimately, the reliability and longevity of machinery hinge on the quality of these visual resources. Investing time in obtaining and utilizing precise schematics can lead to significant cost savings and improved operational performance.

Common Issues with Kubota Transmissions

In the realm of machinery, several challenges can arise, impacting the efficiency and performance of vehicles. Understanding these common problems can help operators identify symptoms early and implement effective solutions. This section explores frequent complications that can affect power transfer systems, ensuring longevity and reliability.

1. Fluid Leaks

One of the most prevalent concerns is fluid leakage, which can lead to inadequate lubrication and overheating. Regular inspections are crucial to detecting signs of leakage, such as puddles under the equipment or low fluid levels. Prompt repairs can mitigate severe damage.

2. Overheating Issues

Another significant problem is overheating, often caused by blocked cooling lines or insufficient fluid levels. Monitoring temperature gauges and ensuring proper maintenance of cooling systems can prevent overheating and prolong the lifespan of components.

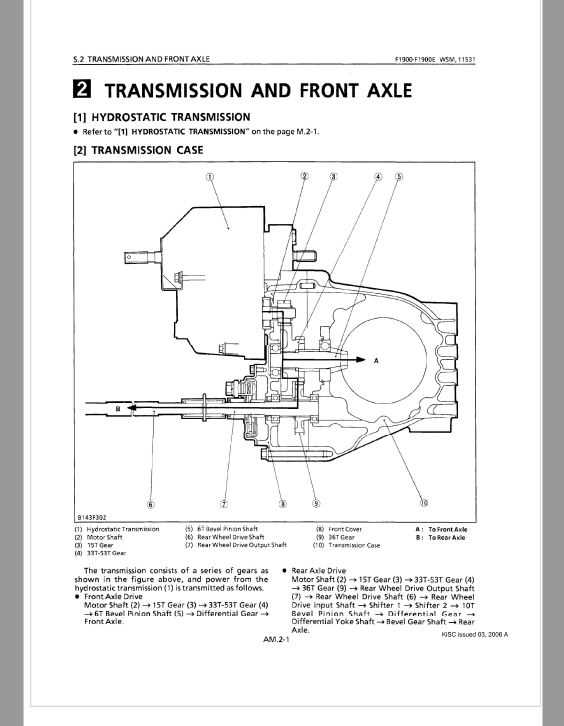

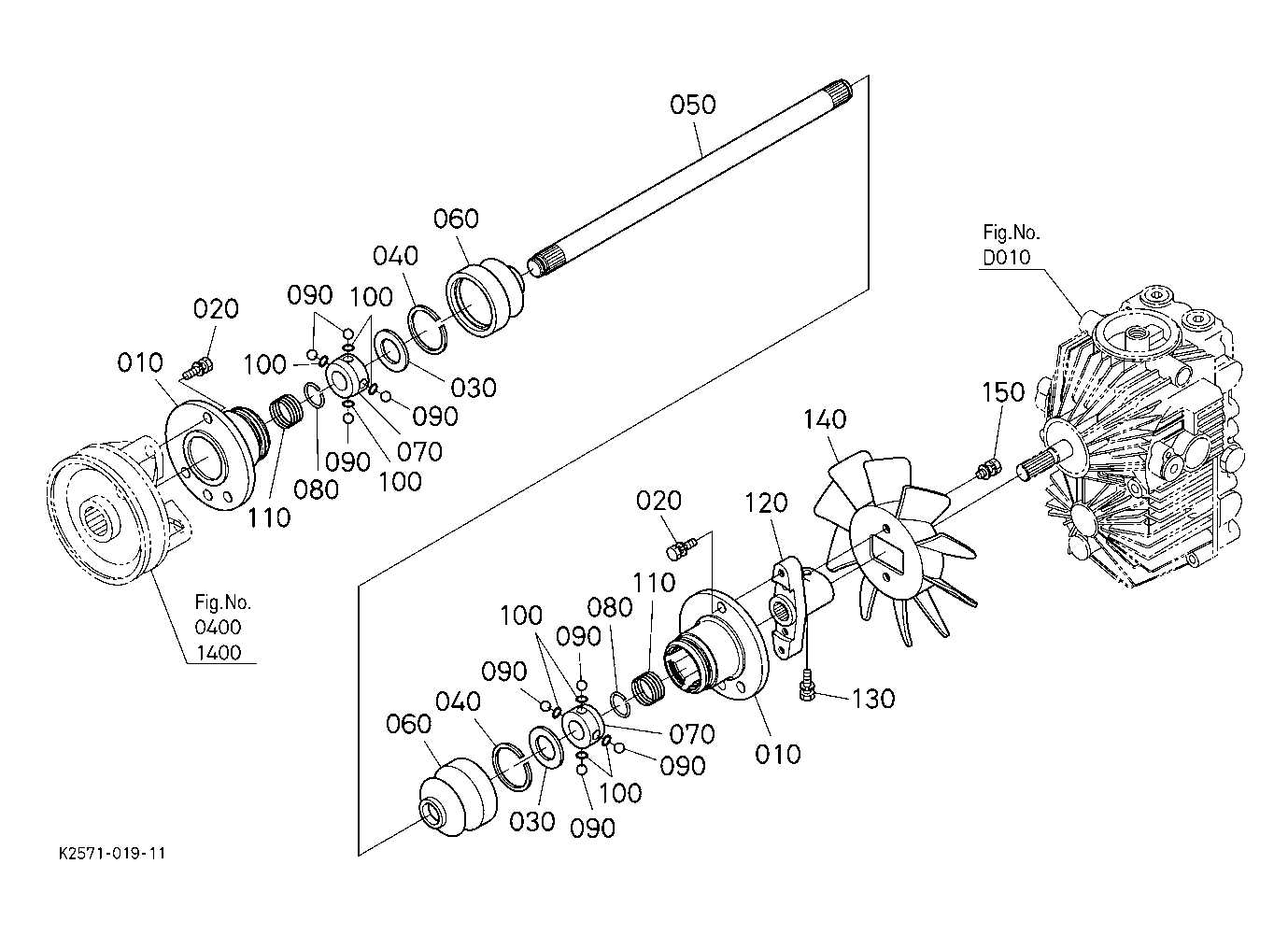

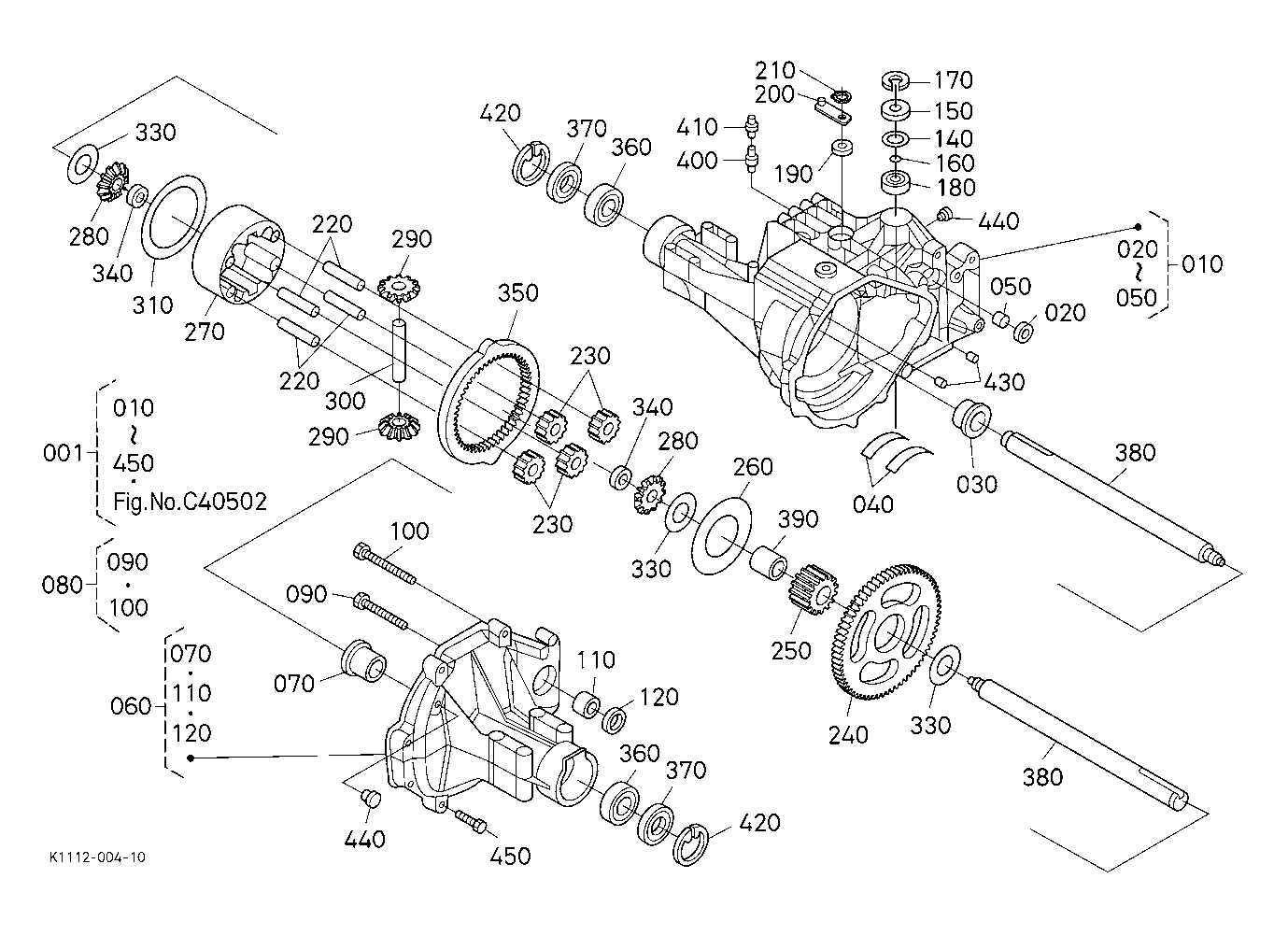

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a guide to identify individual elements, their relationships, and their placement within a larger assembly.

Key Elements to Observe

- Labels: Each part is usually marked with a unique identifier, often corresponding to a reference list.

- Connections: Arrows or lines indicate how components interact or fit together.

- Groupings: Related pieces may be clustered, highlighting their function as a unit.

Steps for Effective Interpretation

- Start by reviewing the legend or key to understand symbols and numbers.

- Identify the main assembly and locate the components you need.

- Cross-reference identified pieces with a parts list for ordering or replacement.

Maintenance Tips for Transmission Systems

Ensuring optimal performance of your vehicle’s shifting mechanism requires regular care and attention. Proper upkeep not only extends the lifespan of the components but also enhances efficiency and safety. Here are some essential maintenance tips to keep in mind.

- Regular Fluid Checks: Monitor the fluid levels frequently. Low fluid can lead to inadequate lubrication, causing wear and tear.

- Fluid Changes: Replace the lubricant according to the manufacturer’s recommendations. Fresh fluid helps in maintaining effective operation.

- Inspect Filters: Clean or replace filters to prevent debris from entering the system, which can cause blockages and damage.

- Monitor for Leaks: Regularly check for signs of leakage. Early detection can prevent larger issues down the line.

- Listen for Unusual Noises: Be alert to any strange sounds while operating. Uncommon noises may indicate internal problems that need addressing.

- Check for Overheating: Ensure that the cooling system is functioning properly to prevent overheating of the components.

By adhering to these practices, you can significantly improve the longevity and reliability of your vehicle’s shifting mechanism, ensuring it performs at its best for years to come.

Identifying Parts by Diagram Reference

Understanding how to pinpoint components through visual representations is crucial for efficient maintenance and repair. These illustrations serve as a guide, allowing users to locate and recognize various elements systematically.

Utilizing Visual Guides

Visual guides can simplify the identification process. By analyzing these representations, one can trace connections and understand the function of each item within the assembly. This approach not only enhances comprehension but also streamlines the repair procedure.

Common Challenges and Solutions

Identifying components can sometimes pose challenges, especially for complex systems. To overcome this, it’s beneficial to refer to a comprehensive reference manual that includes detailed labels and explanations. Familiarizing oneself with the layout can ultimately lead to greater efficiency in troubleshooting.

Replacing Worn Kubota Transmission Parts

Maintaining the efficiency of machinery involves timely replacement of worn components to ensure smooth operation. Addressing these issues promptly can prevent further damage and extend the life of your equipment.

Signs of Wear

- Unusual noises during operation

- Difficulty in shifting gears

- Increased vibrations

- Fluid leaks

Replacement Steps

- Identify the worn components.

- Gather the necessary tools and replacement items.

- Follow the manufacturer’s guidelines for removal.

- Install the new components securely.

- Test the machinery to ensure proper functionality.

Tools Needed for Transmission Repair

Proper tools are essential for efficiently addressing issues within mechanical systems. Having the right equipment not only speeds up the repair process but also ensures accuracy and safety. Below is a list of essential tools that every technician should consider for effective maintenance and repair tasks.

| Tool | Description |

|---|---|

| Socket Set | Includes various sizes for loosening and tightening bolts. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Pliers | Useful for gripping, twisting, and cutting wires or small parts. |

| Screwdrivers | Different types for various screw heads, essential for disassembly. |

| Cleaning Tools | Brushes and solvents for removing dirt and debris from components. |

| Sealant | For ensuring leaks are prevented during reassembly. |

| Diagnostic Tools | Devices for identifying and troubleshooting issues within the system. |

Where to Find Diagrams Online

Locating visual guides for machinery components can significantly simplify maintenance and repair tasks. The internet offers a variety of resources to access these essential illustrations, making it easier for users to understand assembly and functionality.

One of the most reliable sources is official manufacturer websites, which often provide comprehensive resources, including user manuals and schematics. Online forums and communities dedicated to machinery enthusiasts can also be invaluable, as members frequently share links and personal insights.

Additionally, specialized online retailers sometimes offer downloadable resources alongside their product listings. Social media platforms can serve as another avenue, with groups focused on equipment sharing visual aids and advice. Overall, utilizing these diverse platforms can lead to finding the ultimate guides needed for effective equipment management.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These original items are specifically designed to fit and function seamlessly with your equipment, promoting efficiency and reliability.

Quality Assurance: Genuine components undergo rigorous testing to meet industry standards, ensuring you receive products that are durable and dependable.

Enhanced Performance: By choosing original items, you support the ultimate functionality of your equipment, resulting in better operation and reduced downtime.

Long-term Savings: Investing in authentic components may seem costlier initially, but they reduce the likelihood of malfunctions, leading to fewer repairs and maintenance expenses over time.

Warranty Protection: Many manufacturers offer warranties for genuine components, providing peace of mind and financial protection against defects or failures.

In conclusion, opting for authentic components not only safeguards your investment but also maximizes the performance and lifespan of your machinery.