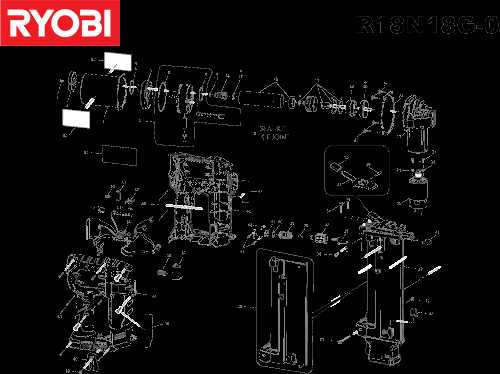

Exploring the Ryobi P320 Parts Diagram for Ultimate Repairs

In the world of power equipment, a comprehensive grasp of the individual elements that make up your device is essential for optimal performance and maintenance. Knowing how each part interacts can enhance your understanding and prolong the life of your tool.

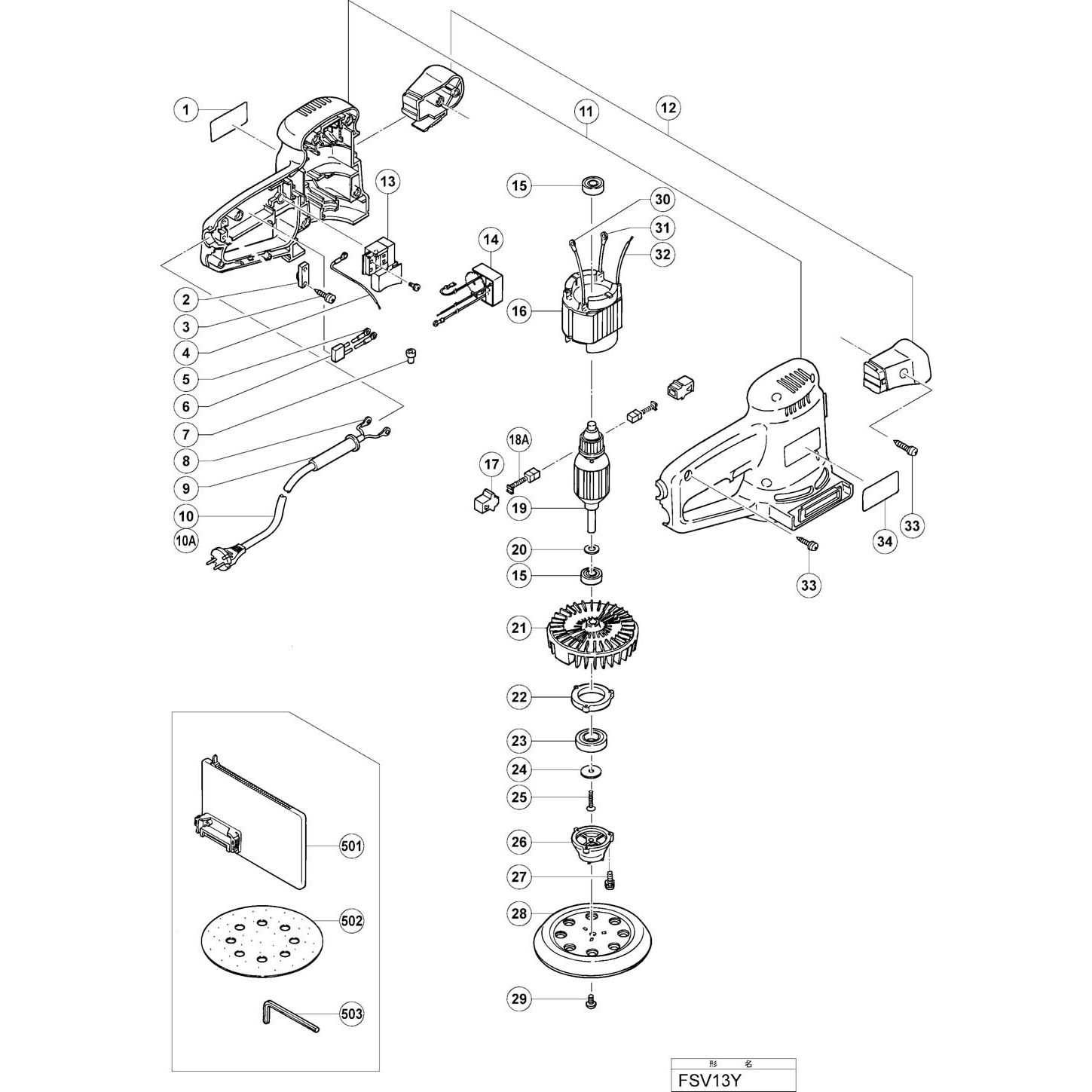

Visual aids can serve as valuable resources, providing insights into the layout and function of each component. These guides allow users to easily identify the necessary elements for repair or enhancement, ensuring that every operation is carried out with precision.

Whether you are a seasoned professional or a DIY enthusiast, delving into the specifics of your equipment will equip you with the knowledge needed for the ultimate efficiency. Empower yourself by exploring the intricacies of your tool’s assembly and functionality.

Understanding the Ryobi P320 Overview

This section aims to provide a comprehensive understanding of a specific model designed for various tasks in home improvement and construction. Its functionality and features make it a valuable addition to any toolkit, ensuring efficiency and effectiveness in various applications.

Key Features and Functionality

The device boasts a powerful motor that enhances performance, allowing users to tackle different materials with ease. Its lightweight design ensures that it is user-friendly, reducing fatigue during extended use. Moreover, the inclusion of adjustable settings empowers users to customize their approach based on specific project requirements.

Applications and Use Cases

From professional contractors to DIY enthusiasts, this tool serves multiple purposes, ranging from simple repairs to intricate installations. Its versatility is one of its standout characteristics, making it suitable for tasks in woodworking, assembly, and more. Emphasizing reliability and ease of use, it stands out as a must-have for anyone looking to improve their work efficiency.

Key Features of the Ryobi P320

This versatile tool is designed to enhance user experience with its impressive functionality and innovative design. It combines power and efficiency, making it suitable for various tasks, whether in a professional setting or for home improvement projects.

One of the standout characteristics is its lightweight construction, which allows for easy maneuverability without sacrificing durability. This ensures that users can handle it comfortably during extended periods of use.

The tool also boasts a high-speed performance, enabling quick and precise results. With adjustable settings, it can be tailored to suit different materials and project requirements, providing flexibility for users.

Another significant feature is its battery compatibility, which ensures convenience and reduces downtime. This allows users to switch between tasks without the need for constant recharging.

Additionally, the design incorporates user-friendly elements, such as a comfortable grip and intuitive controls, making it accessible for both seasoned professionals and DIY enthusiasts.

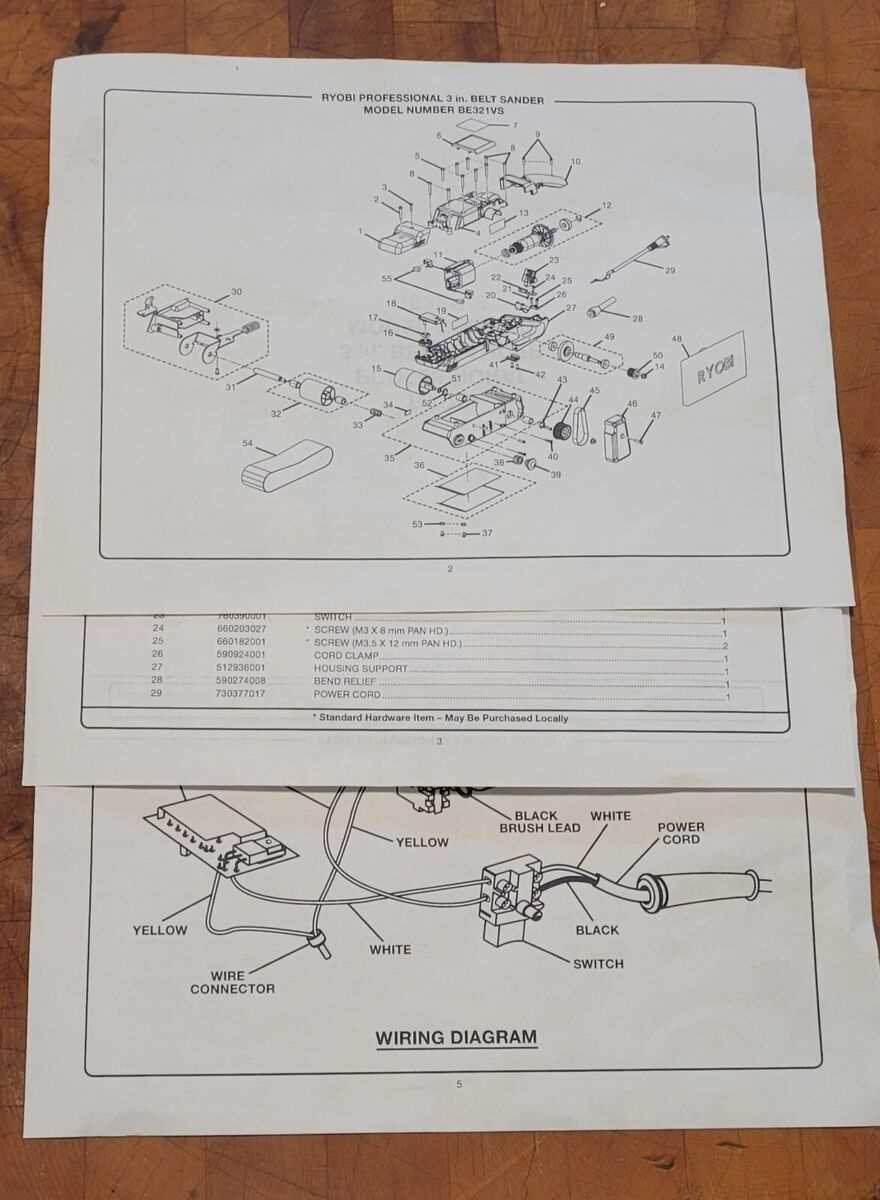

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations of individual elements serve as invaluable resources for both novices and seasoned technicians. They enhance clarity, facilitate troubleshooting, and ensure that tasks are executed efficiently.

Here are some key benefits of utilizing these visual aids:

- Enhanced Clarity: Clear illustrations allow users to easily identify various elements, reducing confusion during assembly or disassembly.

- Streamlined Repair Processes: Knowing the exact placement and function of each component accelerates repair work, minimizing downtime.

- Effective Troubleshooting: Visual guides help pinpoint issues quickly by correlating symptoms with specific parts, making diagnosis simpler.

- Improved Safety: Understanding how different elements interact ensures that users can perform tasks without risking injury or damage.

In summary, visual aids play a crucial role in the effective management of mechanical devices, promoting efficiency and safety in various tasks.

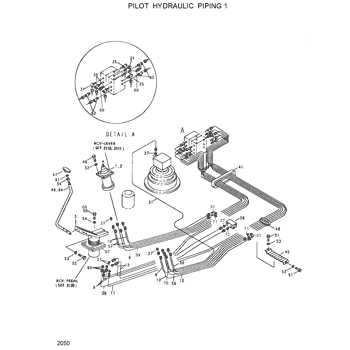

How to Read Parts Diagrams

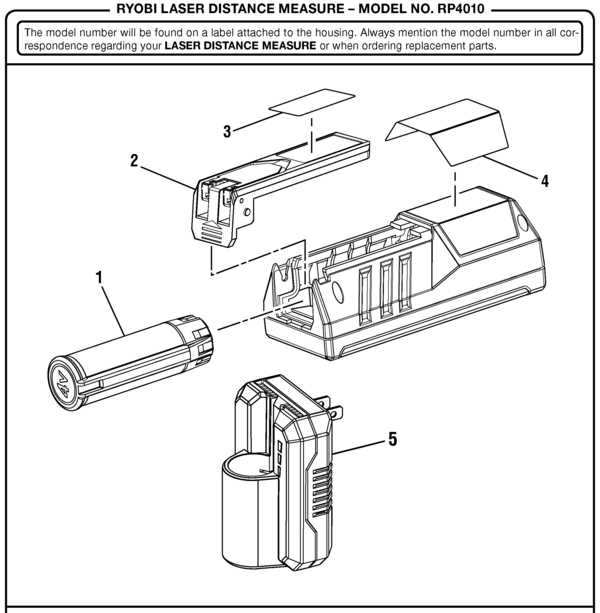

Understanding technical illustrations is essential for anyone involved in maintenance or repairs. These visuals serve as a roadmap, helping users identify individual components and their respective functions within a complex assembly. By grasping how to interpret these images, one can enhance their efficiency in troubleshooting and restoring equipment.

Key Elements to Look For

When examining these visuals, pay attention to several important aspects:

| Element | Description |

|---|---|

| Labels | Clear identifiers indicating the names or numbers of each component. |

| References | Connection points or assembly order that indicate how parts fit together. |

| Legend | A key that explains symbols or color codes used within the illustration. |

| Notes | Additional comments that provide context or tips for assembly and disassembly. |

Steps for Effective Interpretation

To effectively utilize these visuals, follow these steps:

- Familiarize yourself with the overall layout and orientation of the illustration.

- Identify each labeled component, using the legend for clarity.

- Observe how each part connects with others, noting any special instructions or warnings.

- Refer to any supplementary documentation for additional context on specific components.

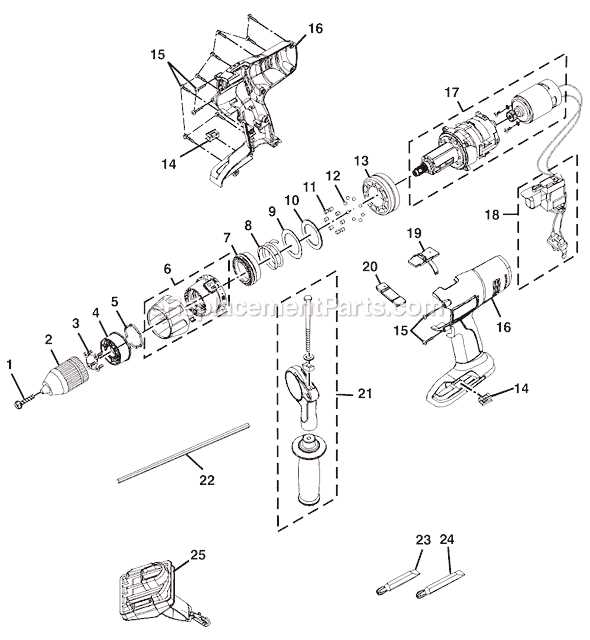

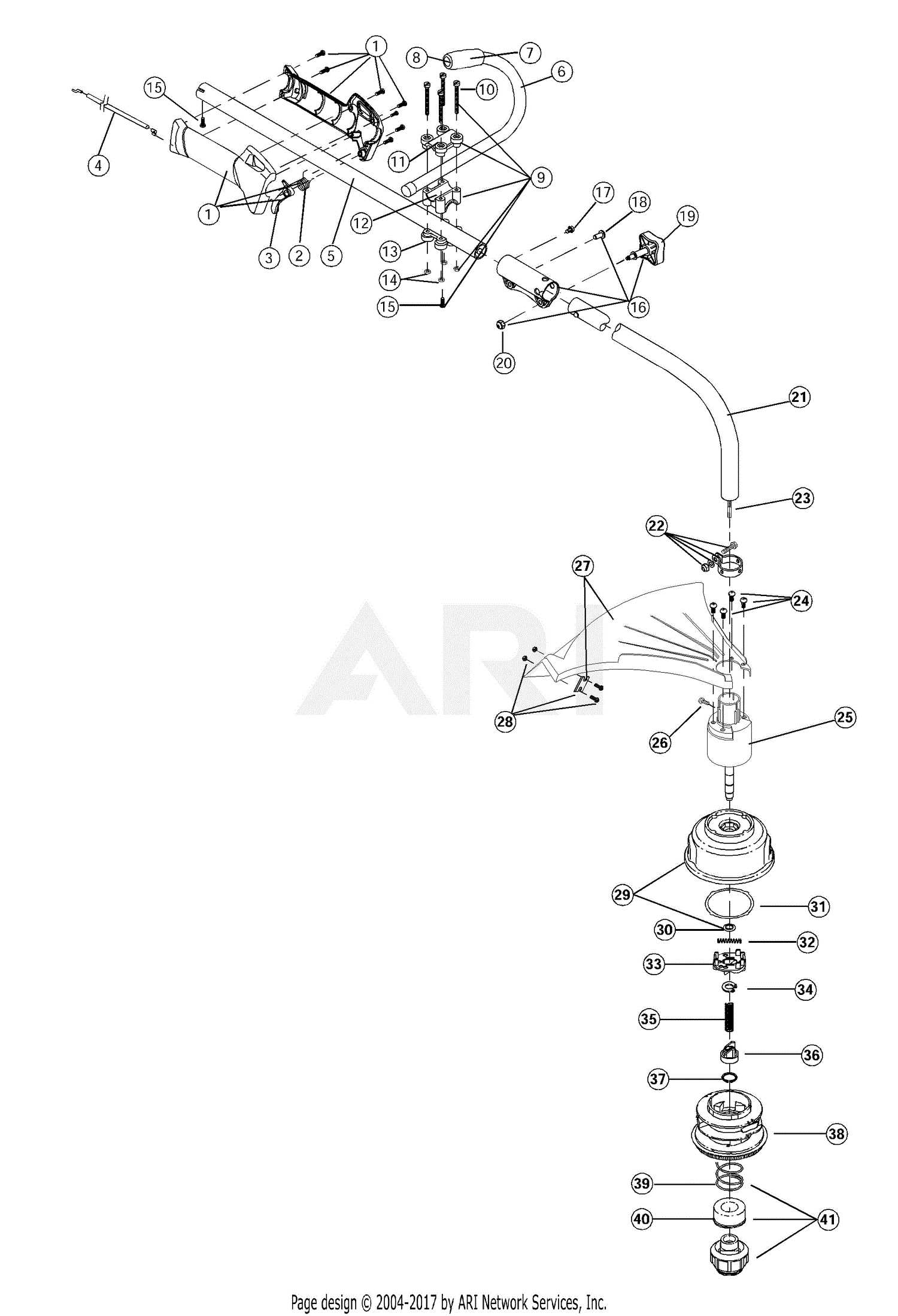

Common Components of the Ryobi P320

Understanding the essential elements of a tool can greatly enhance its usability and maintenance. Each device is comprised of various integral parts that contribute to its overall functionality and performance. Recognizing these components helps users troubleshoot issues and optimize their experience.

The power source is crucial, typically consisting of a battery or cord, enabling mobility and efficiency. The trigger mechanism allows for precise control, while the housing protects internal mechanisms from damage. Additionally, safety features are integrated to prevent accidents during operation.

Another vital component is the fastener mechanism, which determines the type and size of attachments that can be used. Moreover, the depth adjustment feature provides versatility for different applications, ensuring consistent results. Lastly, the exhaust port plays a significant role in maintaining optimal performance by facilitating airflow and preventing overheating.

Where to Find Replacement Parts

When it comes to maintaining and repairing your tools, sourcing high-quality components is essential. Whether you’re looking for a specific piece or a comprehensive set for refurbishment, knowing where to find reliable supplies can make all the difference. Here are some effective options for locating the necessary items to keep your equipment in top condition.

Online Retailers

Many online marketplaces offer a wide variety of components for tools. These platforms often feature user reviews, which can help you gauge the quality and compatibility of the items you’re considering.

Local Hardware Stores

Your neighborhood hardware store can be a valuable resource. Many stores maintain a selection of essential components, and staff members can assist in finding what you need or ordering specific items.

| Source | Benefits |

|---|---|

| Online Marketplaces | Convenience, variety, user reviews |

| Local Hardware Stores | Immediate availability, personalized assistance |

| Manufacturer’s Website | Genuine items, detailed specifications |

| Specialty Supply Shops | Expert knowledge, hard-to-find items |

Benefits of Using OEM Parts

Utilizing original components in repairs and replacements ensures compatibility and optimal performance. These authentic pieces are specifically designed to work seamlessly with the equipment, enhancing longevity and efficiency.

Quality Assurance

Original components typically undergo rigorous testing and quality control, ensuring they meet high standards. This reliability translates to better overall functionality and reduced risk of failure.

Warranty Protection

Choosing genuine items often helps maintain manufacturer warranties. Using substitutes can void these guarantees, leading to higher long-term costs if issues arise.

| Benefit | Description |

|---|---|

| Compatibility | Perfect fit for enhanced performance. |

| Durability | Longer lifespan compared to generic options. |

| Warranty | Preserves the manufacturer’s warranty. |

| Peace of Mind | Confidence in product reliability. |

Maintenance Tips for Ryobi P320

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular attention to detail can prevent issues and ensure that your tool operates efficiently. This section outlines key practices to keep your device in top shape.

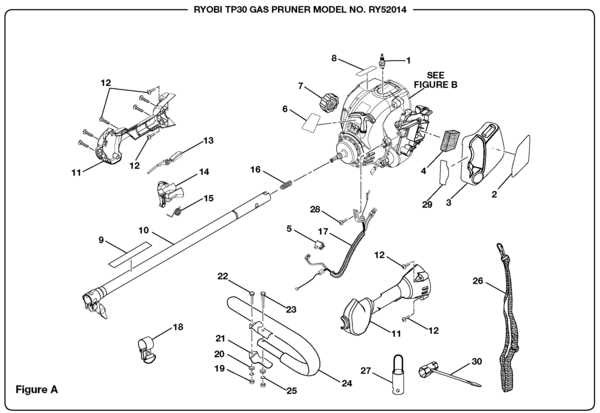

Regular Cleaning: After each use, wipe down the exterior and remove any debris that may have accumulated. This helps prevent wear and keeps components functioning smoothly.

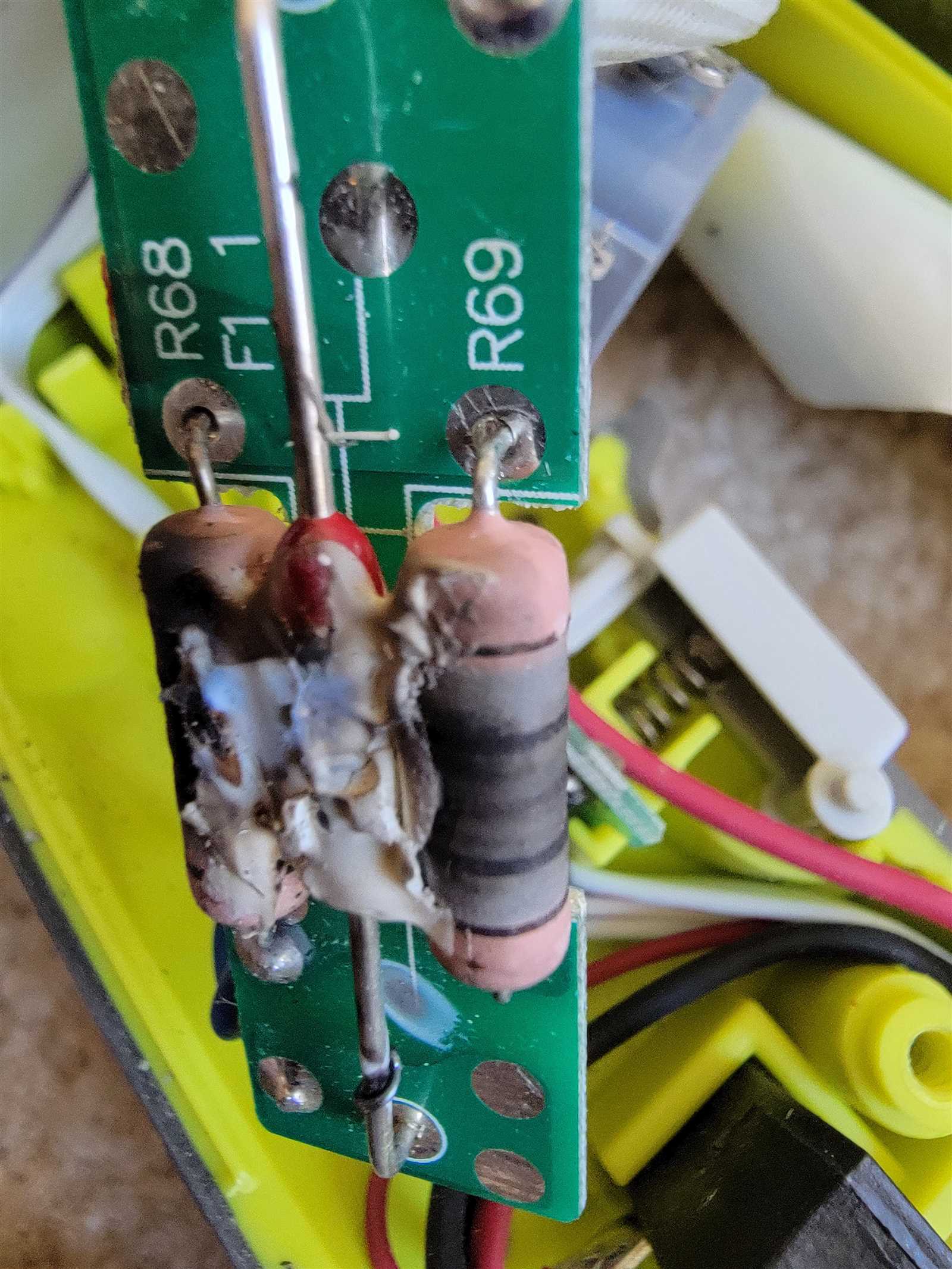

Check and Replace Worn Parts: Periodically inspect all components for signs of wear. Timely replacement of damaged or worn elements is crucial for maintaining functionality and safety.

Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. This minimizes friction and extends the lifespan of mechanical elements.

Battery Care: For battery-operated tools, ensure that batteries are charged correctly and stored in a cool, dry place. This practice helps maintain battery health and performance.

Storage: When not in use, store the tool in a dry environment, preferably in a protective case. This prevents dust accumulation and potential damage from environmental factors.

Troubleshooting Common Issues

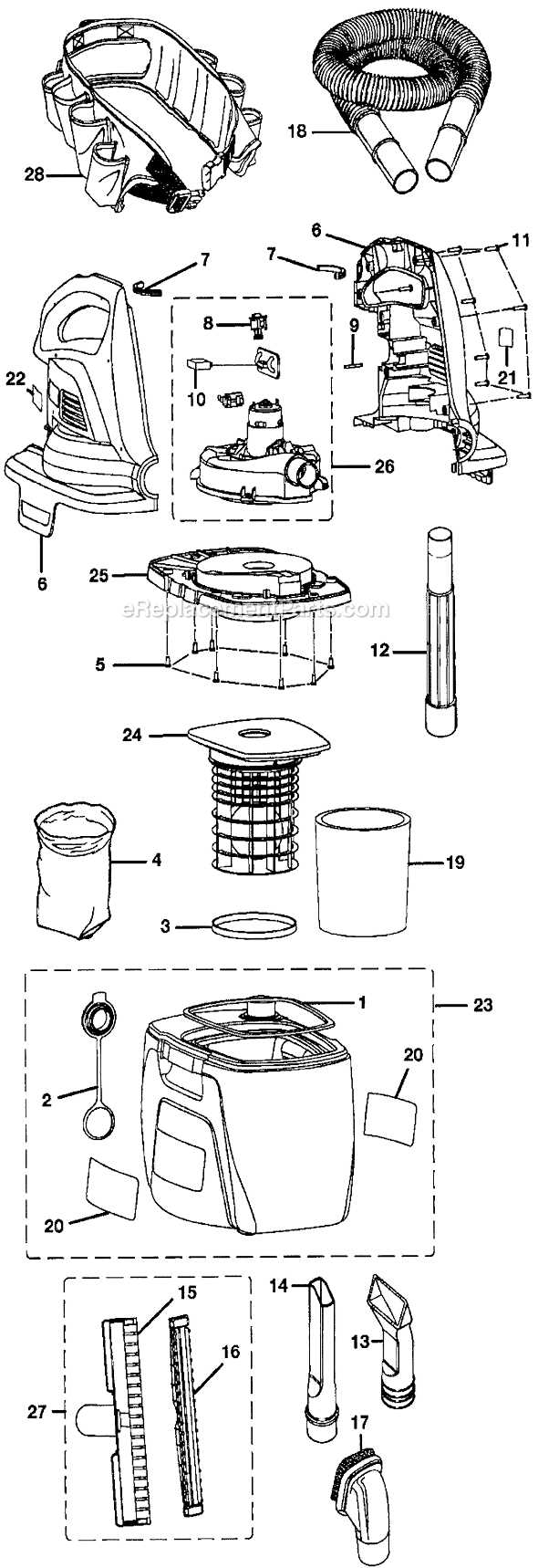

When working with power tools, encountering problems can be frustrating. However, understanding the typical challenges can greatly enhance your repair experience. This section aims to provide insight into frequent malfunctions and offer guidance on resolving them effectively.

Insufficient Power: If the device isn’t operating at full strength, check the battery or power source. Ensure connections are secure and that the battery is charged. If issues persist, consider inspecting the internal components for wear.

Overheating: An overheating tool often indicates a blockage or excessive use. Allow it to cool down, and check for debris obstructing airflow. Regular maintenance can prevent this issue from recurring.

Unusual Noises: Strange sounds may signal internal damage or loose parts. Examine the tool for any signs of wear, and ensure all screws and fittings are tightened. If the noise continues, further disassembly may be necessary to identify the problem.

Inconsistent Performance: If the tool operates intermittently, inspect the trigger mechanism and wiring. Loose connections can lead to erratic behavior, so secure all components thoroughly. Regularly cleaning and lubricating moving parts can enhance performance.

Upgrading Your Ryobi P320

Enhancing the performance of your power tool can significantly improve its efficiency and lifespan. By selecting quality components and making thoughtful modifications, you can achieve a more effective and enjoyable user experience. This section will explore various options for elevating your device’s functionality and adaptability.

Consider focusing on these key areas for enhancement:

| Upgrade Option | Description |

|---|---|

| Battery Upgrade | Opt for a higher capacity battery to extend run time and reduce downtime during projects. |

| Attachment Accessories | Utilize compatible accessories to increase versatility and tackle a wider range of tasks. |

| Performance Modifications | Explore options for tuning the tool’s motor or enhancing the grip for better control. |

| Maintenance Kits | Invest in maintenance products to ensure the longevity and reliability of your device. |

By thoughtfully considering these enhancements, you can maximize the potential of your equipment and ensure it meets your evolving needs.