Understanding the John Deere Push Mower Parts Diagram

The maintenance and repair of lawn machinery are essential for ensuring their longevity and optimal performance. A comprehensive overview of the individual elements that make up these tools can significantly aid users in troubleshooting and servicing their equipment efficiently. By familiarizing oneself with the various components, one can better understand how each part contributes to the overall functionality.

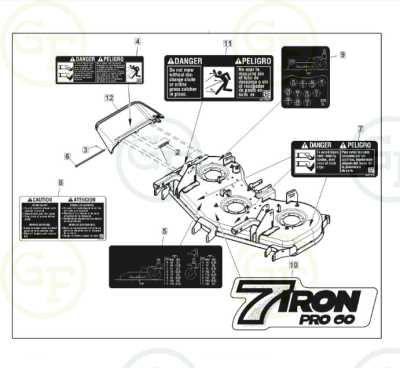

Visual representations play a crucial role in the learning process, offering clarity on how different elements interact within the machinery. These illustrations not only provide a clear view of assembly but also highlight the relationship between components, making it easier to identify potential issues. Such resources empower users to perform repairs and replacements with confidence.

Whether you are a seasoned gardener or a novice, grasping the layout and significance of each component can enhance your maintenance skills. This knowledge not only promotes effective care but also fosters a deeper appreciation for the craftsmanship involved in the design of these essential tools. Embracing this understanding is the first step towards becoming proficient in lawn equipment management.

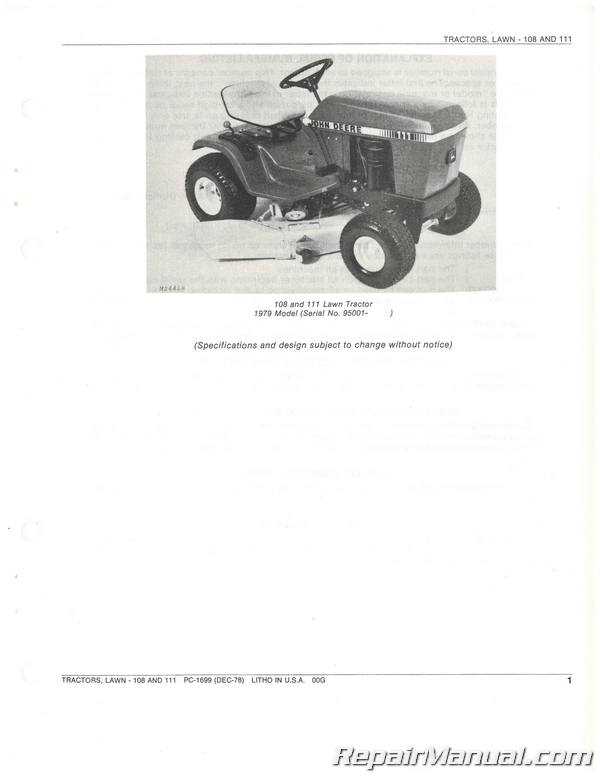

Understanding John Deere Push Mowers

This section explores the essential features and components of a popular type of grass-cutting equipment designed for home use. These machines are known for their reliability and efficiency, making them a preferred choice among homeowners. Familiarity with the various elements can enhance maintenance and troubleshooting, ensuring optimal performance during operation.

Each unit typically consists of a powerful engine, cutting blades, and a robust frame. Knowing how these parts interact can lead to better care and prolong the lifespan of the equipment. Users often find it beneficial to consult visual guides that outline the configuration and function of each section, providing clarity and understanding.

Furthermore, regular upkeep is vital. Simple tasks like blade sharpening and engine checks contribute significantly to the overall effectiveness of the machine. By delving into the intricacies of this equipment, users can achieve the ultimate results in their lawn care efforts.

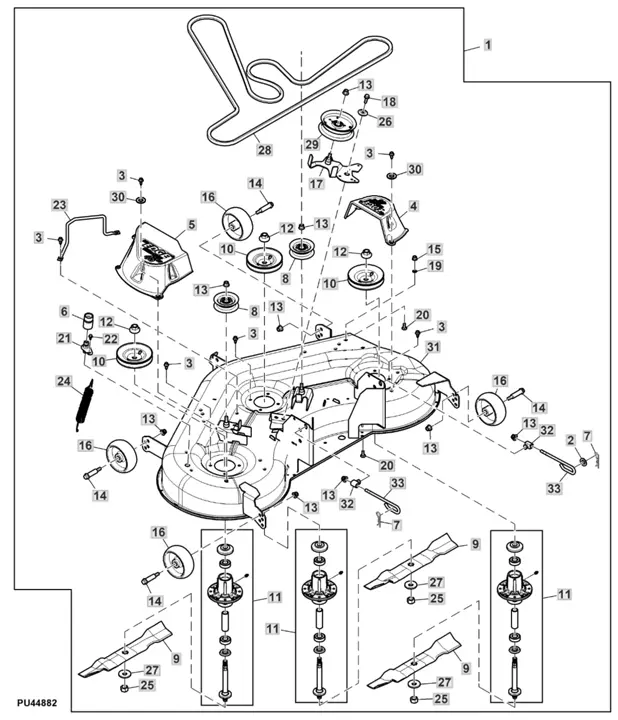

Key Components of Push Mowers

Understanding the essential elements of a lawn care machine is crucial for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance and longevity of the equipment.

- Engine: The heart of the machine, responsible for generating power. Different engines vary in size and efficiency, affecting overall performance.

- Cutting Blade: A sharp, rotating element that determines the quality of the cut. Blade design and sharpness are critical for a clean finish.

- Deck: The protective casing that houses the blade. Its design influences maneuverability and cutting width.

- Wheels: Essential for movement, wheel size and type affect the ease of navigation across various terrains.

- Handle: Provides the user with control and comfort during operation. Adjustable features can enhance user experience.

- Grass Collection Bag: Captures clippings for a tidy lawn. Its capacity and design can impact the frequency of emptying.

Each of these components contributes to the overall functionality and efficiency, making it important for users to familiarize themselves with their specific characteristics and maintenance needs.

Importance of Maintenance and Repairs

Regular upkeep and timely repairs are essential for the longevity and efficiency of any mechanical equipment. Neglecting these aspects can lead to diminished performance, unexpected breakdowns, and ultimately higher costs. Ensuring that all components are in optimal condition is key to preserving functionality and safety.

Maintaining equipment involves a series of proactive steps, including:

- Routine inspections to identify wear and tear.

- Cleaning to prevent debris buildup and corrosion.

- Lubricating moving parts to minimize friction.

Repairs, on the other hand, focus on addressing specific issues that arise over time. This process typically includes:

- Diagnosing problems accurately to avoid missteps.

- Replacing worn or damaged components promptly.

- Testing equipment post-repair to ensure proper function.

By prioritizing maintenance and repairs, users can enhance performance, extend the lifespan of their machinery, and reduce the likelihood of costly emergency fixes. Investing time and resources in these practices ultimately pays off in reliability and efficiency.

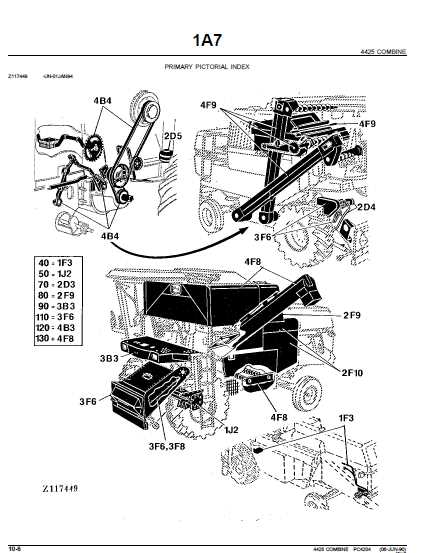

How to Locate Parts Diagrams

Finding illustrations that detail component layouts can be essential for effective repairs and maintenance. These visuals provide clarity on the arrangement and interaction of various elements, facilitating a smoother troubleshooting process.

Online Resources

The internet is a treasure trove of information. Manufacturer websites often feature downloadable manuals, while dedicated forums and community sites may offer user-generated resources that enhance understanding.

Local Dealers and Repair Shops

Your local dealers and service centers can also be invaluable. They typically have access to official documentation and can provide insights or even hard copies of the necessary guides to assist in your endeavors.

Identifying Common Issues

Understanding the typical problems that can arise with your equipment is essential for maintaining its performance. Regular inspections can help you spot potential malfunctions before they escalate into significant repairs. Here, we will explore some prevalent concerns and offer guidance on how to identify them effectively.

Engine Performance Problems

A frequent issue encountered is poor engine operation, which may manifest as stalling or difficulty starting. Such problems can stem from various factors, including fuel quality, air filters, or spark plug condition. Inspecting these components regularly can help ensure optimal functionality and extend the life of your machinery.

Cutting Quality Issues

Another common concern is inadequate cutting performance. This can result in uneven lawns or clippings left behind. Possible causes include dull blades, incorrect height settings, or debris accumulation. Maintaining sharp blades and clearing any obstructions can significantly enhance the effectiveness of your equipment.

Tools Needed for Repairs

When tackling maintenance and restoration tasks, having the right tools is essential for achieving optimal results. A well-equipped toolkit not only facilitates efficient repairs but also ensures safety and accuracy throughout the process.

Essential Tools

Before beginning any repair, it’s important to gather specific instruments that cater to various tasks. Here are some key items to consider:

| Tool | Purpose |

|---|---|

| Screwdrivers | For loosening or tightening screws. |

| Wrenches | To adjust nuts and bolts. |

| Socket Set | For more efficient fastener removal. |

| Safety Goggles | To protect eyes from debris. |

| Work Gloves | To safeguard hands during repairs. |

Additional Considerations

Depending on the specific repair needs, you may also require specialized tools. Always assess the task at hand to ensure you are fully prepared, which can greatly enhance the repair experience.

Ordering Replacement Parts Online

In today’s digital age, acquiring essential components for your outdoor equipment has never been easier. The convenience of online shopping allows enthusiasts to find the necessary items from the comfort of their homes, ensuring quick and efficient repairs.

Firstly, it’s crucial to identify the specific component you need. This ensures that you select the correct item compatible with your machine. Utilize product codes and descriptions for precise identification.

Next, explore various online retailers that specialize in outdoor machinery supplies. Compare prices and shipping options to find the best deal. Don’t forget to check customer reviews to gauge the reliability of the seller.

Finally, always ensure that the website is secure before entering any payment information. Following these steps will help you successfully procure the necessary components for your equipment, restoring its functionality in no time.

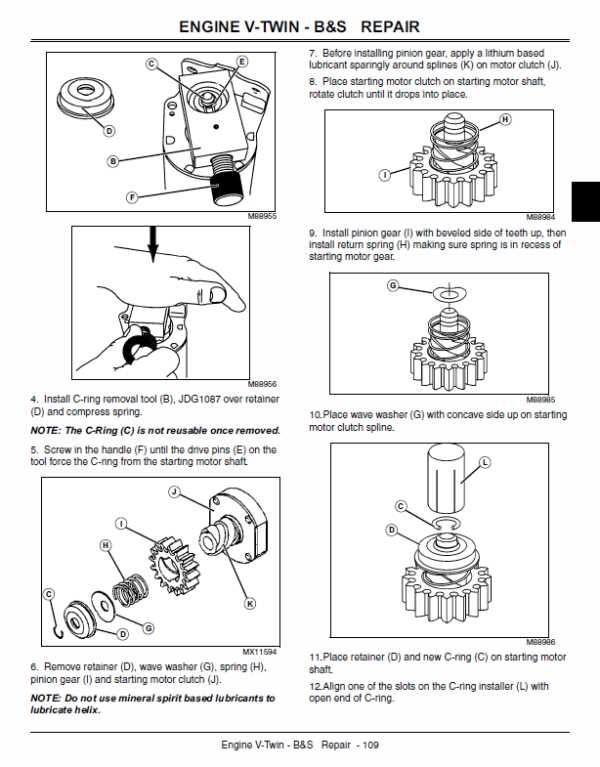

Installing New Components Properly

When it comes to maintaining your equipment, ensuring that new elements are installed correctly is crucial for optimal performance. Proper installation not only enhances functionality but also extends the lifespan of the machinery. By following systematic steps and guidelines, you can ensure that each component fits seamlessly and operates efficiently.

Preparation Steps

Before beginning the installation process, it is important to gather all necessary tools and components. Make sure to review the manufacturer’s guidelines to understand specific requirements for each item. Safety precautions should also be observed; wearing protective gear can prevent accidents during installation.

Installation Process

Begin by removing the existing components carefully, taking note of their arrangement. This will serve as a reference for the new items. When placing the new components, ensure they align with the designated spots. Using appropriate fasteners and securing them firmly is vital for stability. Once everything is in place, conduct a thorough inspection to confirm that all elements are installed correctly before operating the equipment.

Comparing Models and Specifications

When evaluating different outdoor equipment, understanding the variations in features and performance is essential. Each model presents unique attributes that cater to diverse needs, making it crucial to analyze specifications to determine the best fit for your requirements.

Key Features to Consider

In this comparison, focus on the engine power, cutting width, and durability. A robust engine ensures efficient performance, while an optimal cutting width affects the time taken for maintenance tasks. Durability is paramount, as it influences longevity and overall investment value.

Performance Metrics

Examine aspects such as fuel efficiency, ease of handling, and maintenance requirements. Fuel efficiency directly impacts operational costs, while user-friendly designs enhance the experience. Regular maintenance can prolong the lifespan of the equipment, making it a critical consideration.

Tips for Long-lasting Performance

Maintaining optimal functionality is crucial for any outdoor equipment. Implementing a few best practices can significantly enhance the durability and efficiency of your tools.

- Regularly inspect all components for signs of wear or damage.

- Keep the blades sharp for effective cutting and reduced strain.

- Clean the equipment after each use to prevent debris buildup.

- Follow the manufacturer’s guidelines for maintenance schedules.

By adhering to these recommendations, you can ensure your equipment performs at its best over time.

Safety Precautions During Repairs

When undertaking maintenance on outdoor equipment, prioritizing safety is crucial to prevent accidents and ensure a smooth repair process. Understanding and implementing proper precautions can protect both the individual and the machinery.

- Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear.

- Ensure the equipment is turned off and disconnected from any power source before starting repairs.

- Keep your workspace organized and free from clutter to avoid tripping hazards.

- Use the correct tools for the job to prevent injuries and damage to components.

- Read the manufacturer’s manual for specific safety guidelines and repair instructions.

Following these guidelines will help create a safe environment for repairs, ultimately leading to a more efficient and effective maintenance experience.

Understanding Warranty Coverage

Warranty coverage serves as a crucial safety net for consumers, ensuring protection against defects and performance issues. It outlines the obligations of the manufacturer to address problems that may arise during a specified period, providing peace of mind to the owner. Understanding the intricacies of such coverage can significantly influence your satisfaction and the longevity of your equipment.

Typically, warranties encompass a range of components and systems, specifying what is included and any limitations that may apply. Familiarizing yourself with these details can help you determine when to seek repairs and whether certain conditions may void the warranty. It’s essential to maintain proper usage and follow guidelines to ensure your protection remains intact.

Moreover, warranty terms can vary significantly among different manufacturers. Always review the specific documentation that accompanies your equipment, as it contains vital information regarding coverage duration, required maintenance, and processes for filing claims. Being proactive in understanding your warranty can ultimately enhance your ownership experience and safeguard your investment.

Resources for Troubleshooting Guides

When faced with operational challenges, having access to reliable resources can make a significant difference in resolving issues efficiently. This section provides essential references that can aid in understanding common problems and finding effective solutions.

Online Forums: Many enthusiasts gather in online communities to share experiences and solutions. Participating in these discussions can lead to valuable insights.

Manufacturer Websites: Official websites often host a wealth of information, including manuals, FAQs, and technical support that can guide users in troubleshooting.

Video Tutorials: Platforms like YouTube offer visual aids that break down complex repair processes, making it easier to follow along and learn.

Books and Manuals: Comprehensive guides are available in print and digital formats, providing in-depth knowledge and step-by-step instructions for various issues.

Local Repair Shops: Consulting with local professionals can provide personalized advice and hands-on support, ensuring that problems are addressed properly.