Understanding John Deere PTO Parts Diagram

The functionality of agricultural equipment relies heavily on various mechanical elements that work in harmony. These components are crucial for transferring energy efficiently, ensuring optimal performance during field operations. Familiarity with the layout and relationships of these parts can significantly enhance maintenance and troubleshooting efforts.

Exploring the intricate arrangements of these mechanisms reveals how they contribute to the overall efficiency of farming machinery. Recognizing the connections between different elements aids in identifying potential issues and implementing effective solutions. This knowledge not only facilitates smoother operation but also prolongs the lifespan of the equipment.

By gaining insights into the structure and functionality of these essential components, operators can make informed decisions regarding repairs and upgrades. A comprehensive understanding of these intricate systems empowers users to optimize their equipment for various agricultural tasks, enhancing productivity and effectiveness in the field.

Understanding PTO in Agricultural Equipment

The mechanism responsible for transferring power from a machine’s engine to various attachments plays a crucial role in enhancing productivity in farming operations. This system enables the use of multiple implements, allowing farmers to perform a wide range of tasks efficiently. By harnessing the engine’s power, this mechanism provides the versatility needed for diverse agricultural activities.

In the context of farming machinery, the connection between the engine and the implement is essential for optimal performance. Understanding how this system works helps operators maximize the efficiency of their equipment. Proper maintenance and awareness of potential issues can significantly impact the overall functionality and longevity of the machinery.

Various components within this power transfer system are designed to ensure smooth operation. Regular inspections and timely replacements of worn or damaged parts are vital for preventing breakdowns and maintaining high performance levels. Farmers should familiarize themselves with these components to enhance their equipment’s reliability and operational capacity.

Components of a PTO System

A power take-off system is essential for transferring mechanical energy from a source to various attachments and implements. Understanding its components is crucial for efficient operation and maintenance.

The main elements of this system include:

- Drive Shaft: This component transmits power from the engine to the implements.

- Clutch: It engages and disengages the system, allowing for controlled operation.

- Coupler: This connects the drive shaft to the implement, ensuring a secure link.

- Gearbox: It modifies the rotational speed and torque delivered to the attachment.

- Safety Guards: These protect users by preventing accidental contact with moving parts.

Each part plays a significant role in ensuring that the energy transfer is effective and safe, ultimately enhancing the overall performance of the machinery.

How PTO Works in Tractors

The power transmission system in agricultural vehicles is essential for connecting various implements and attachments, allowing for versatile operations. This mechanism enables the engine’s power to be transferred to different tools, enhancing productivity in farming tasks. Understanding how this system operates can significantly improve efficiency and effectiveness in fieldwork.

Mechanism of Power Transfer

This system utilizes a rotating shaft that is driven by the engine. The process can be broken down into several key components:

- Power Source: The engine generates power that needs to be transmitted.

- Connection: A coupling mechanism connects the engine to the transmission shaft.

- Rotation: As the engine runs, it causes the shaft to rotate, transferring energy.

- Implement Attachment: The shaft connects to various tools or equipment, allowing them to operate.

Operational Benefits

Utilizing this system provides several advantages, including:

- Increased versatility in equipment use.

- Improved efficiency in completing tasks.

- Reduced physical labor for operators.

- Enhanced performance of attachments, leading to better crop management.

Common Issues with PTO Parts

Various mechanical components associated with power transfer systems can encounter a range of difficulties during operation. Understanding these issues is essential for effective maintenance and ensuring optimal performance. Recognizing potential problems can lead to timely interventions, minimizing downtime and repair costs.

Wear and Tear

Excessive usage can lead to deterioration of components, affecting their efficiency. Regular inspections are necessary to identify signs of wear, such as cracks or unusual noises during operation. Proper lubrication and timely replacement of worn elements can significantly enhance longevity and functionality.

Alignment Issues

Misalignment of components can cause operational challenges, resulting in vibrations and increased wear. Ensuring that all elements are correctly aligned during installation is crucial. Utilizing alignment tools and following manufacturer guidelines can help mitigate these issues, promoting smoother operation.

Maintenance Tips for PTO Systems

Regular upkeep of power transfer systems is essential for ensuring their optimal performance and longevity. By implementing effective maintenance strategies, operators can prevent potential issues, reduce downtime, and extend the lifespan of the equipment. This section provides key recommendations for maintaining these critical components.

Routine Inspections

Conducting regular inspections is vital for identifying wear and tear before it leads to significant problems. Check for signs of damage or excessive wear on the connection points and any moving parts. Pay attention to abnormal noises or vibrations during operation, as these can indicate underlying issues that require immediate attention.

Lubrication and Cleaning

Maintaining proper lubrication is crucial for the smooth operation of transfer systems. Ensure that all moving parts are adequately lubricated according to the manufacturer’s specifications. Additionally, keep the area clean and free from debris, as accumulated dirt can hinder performance and lead to premature wear. Regularly cleaning the components will enhance efficiency and reliability.

Implementing these maintenance practices will significantly contribute to the reliable operation of power transfer systems. Regular attention to inspections and proper care can help avoid costly repairs and ensure that the machinery remains in top working condition.

Benefits of Regular PTO Inspections

Conducting routine examinations of the power take-off system is essential for maintaining the efficiency and longevity of agricultural machinery. These assessments help identify potential issues before they escalate into significant problems, ultimately ensuring smoother operation and minimizing downtime.

One major advantage of consistent inspections is the enhancement of safety for operators and bystanders. By identifying wear and tear on components, the risk of mechanical failure during operation is significantly reduced. Furthermore, addressing any irregularities promptly can prevent accidents and injuries associated with equipment malfunctions.

Another benefit is the optimization of equipment performance. Regular evaluations allow for the timely replacement of worn parts, ensuring that machinery operates at peak efficiency. This not only boosts productivity but can also lead to lower fuel consumption and reduced operating costs in the long run.

In addition, maintaining a routine inspection schedule can prolong the lifespan of machinery. By keeping all systems in check and addressing maintenance needs as they arise, owners can avoid costly repairs and extend the service life of their equipment. Investing time in regular examinations ultimately pays off through enhanced reliability and performance.

Choosing Quality PTO Replacement Parts

When it comes to maintaining machinery, selecting high-quality components is crucial for ensuring optimal performance and longevity. The reliability of these elements significantly impacts the efficiency of equipment, and investing in superior alternatives can save time and resources in the long run. It’s essential to consider various factors when deciding which replacements to choose, as these decisions can affect both functionality and safety.

One of the primary aspects to evaluate is the material used in the manufacturing of these components. Durable materials often offer better resistance to wear and tear, enhancing the overall lifespan of the equipment. Additionally, compatibility with existing machinery is vital, as improper fit can lead to malfunctions and costly repairs.

| Feature | Importance |

|---|---|

| Material Quality | Ensures durability and longevity |

| Compatibility | Prevents malfunctions and damage |

| Manufacturer Reputation | Indicates reliability and support |

| Warranty | Provides assurance of quality |

Moreover, considering the reputation of the manufacturer can provide insights into the reliability of the replacements. Established brands often have a track record of producing trustworthy components, along with customer support and warranty options that add to the peace of mind. By taking the time to assess these criteria, one can make informed decisions that contribute to the efficient operation of machinery.

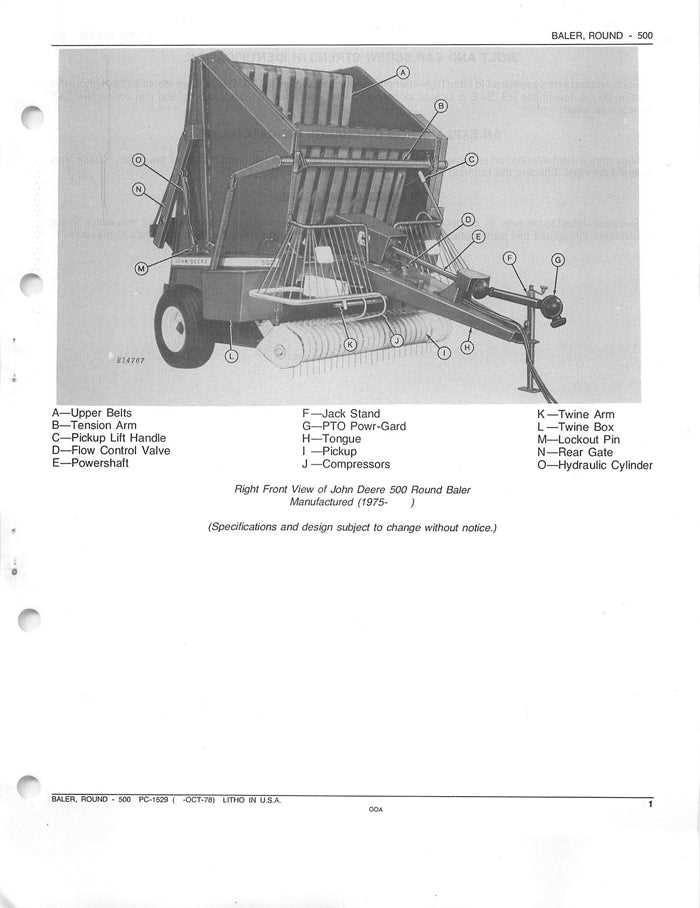

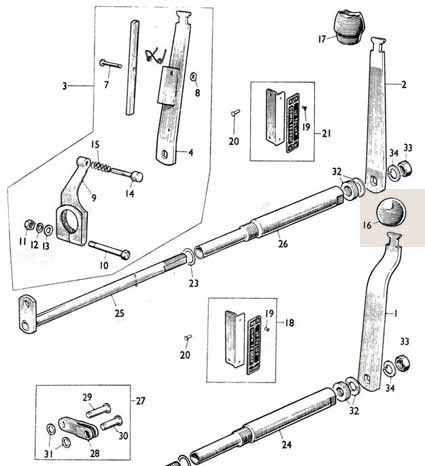

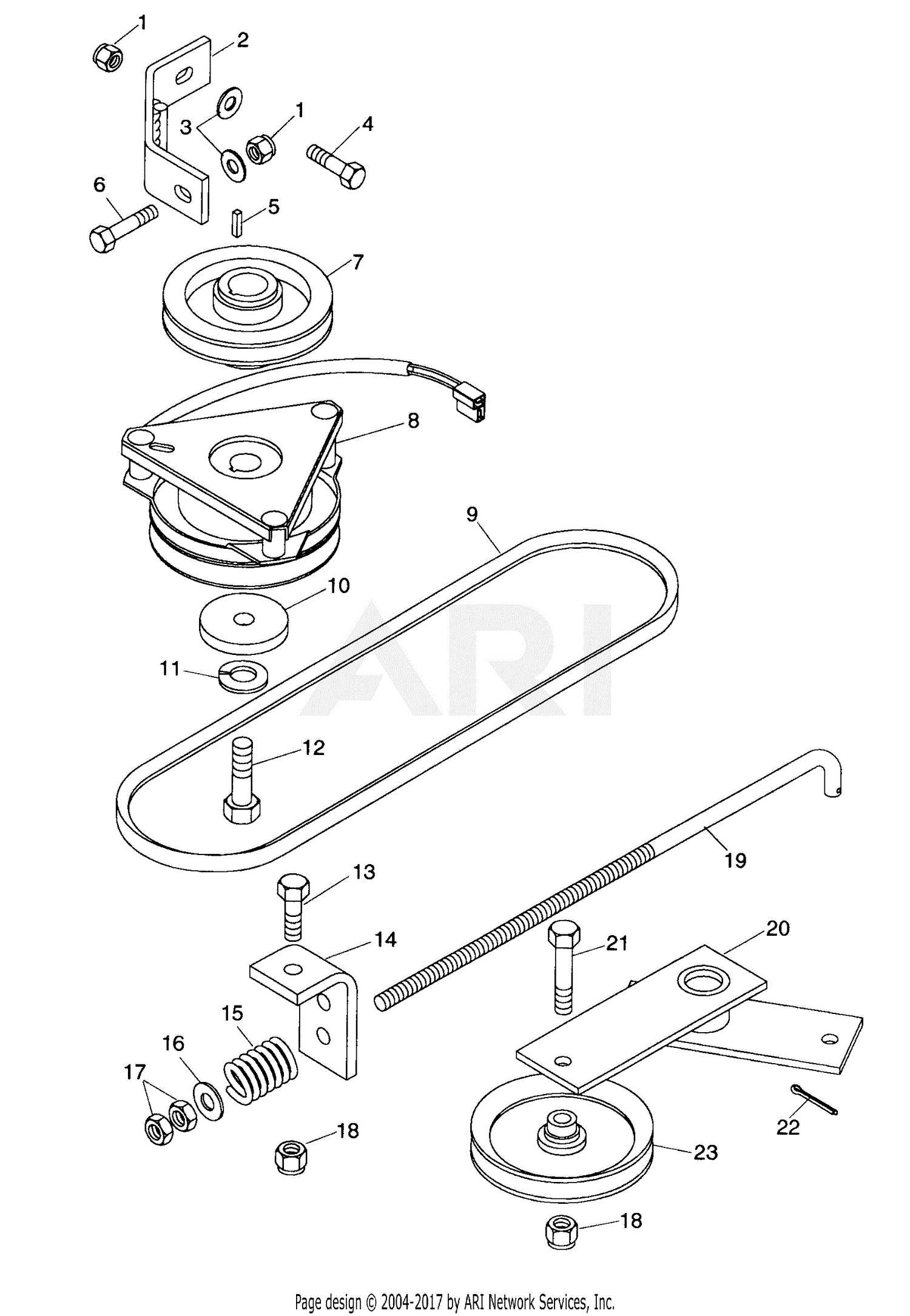

How to Read a PTO Diagram

Understanding the layout and components of a power transfer mechanism is crucial for effective maintenance and troubleshooting. A schematic representation serves as a visual guide, illustrating how various elements interact within the system. By grasping the basic symbols and connections, users can identify specific parts and their functions.

Familiarize Yourself with Symbols

Each symbol on the illustration corresponds to a particular component. Recognizing these symbols is essential for accurate interpretation. Pay attention to details, as variations in shape and size can indicate different functionalities or specifications. Common symbols may represent items like gears, bearings, or couplings.

Follow the Flow of Motion

Trace the lines that depict movement throughout the system. These lines illustrate the path of power transfer from one element to another. Understanding the flow helps identify how energy is transferred, which is key for diagnosing potential issues. By following these connections, one can better understand how components work together in harmony.

Identifying PTO Parts by Function

Understanding the components of a power transmission system is essential for effective maintenance and operation. Each element plays a crucial role in facilitating the transfer of power from the engine to various implements. By recognizing the functions of these elements, operators can ensure optimal performance and address any issues that may arise.

| Component | Function |

|---|---|

| Connector | Links the engine to the implement, allowing power transfer. |

| Coupling | Ensures a secure attachment, minimizing power loss during operation. |

| Gearbox | Adjusts speed and torque to match the requirements of the implement. |

| Shield | Protects operators from moving parts and potential hazards. |

| Brake | Stops or slows down the implement to ensure safety during operation. |

Upgrading PTO Components for Efficiency

Improving the efficiency of power transfer systems is crucial for enhancing overall machinery performance. Upgrading specific components can lead to smoother operations, reduced energy consumption, and extended equipment lifespan. This section explores effective strategies for enhancing these vital systems.

Benefits of Component Enhancement

- Increased Performance: Upgrading can lead to more reliable energy transmission, ensuring optimal functionality.

- Enhanced Durability: High-quality components are less prone to wear and tear, resulting in fewer maintenance requirements.

- Improved Energy Efficiency: Better materials and designs can reduce energy losses during operation.

Key Components to Consider for Upgrades

- Connection Elements: Reinforcing connection parts can prevent slippage and ensure steady power flow.

- Transmission Gears: Selecting gears designed for efficiency can reduce friction and enhance power delivery.

- Control Systems: Advanced controls can optimize performance and adapt to varying loads, improving overall efficiency.

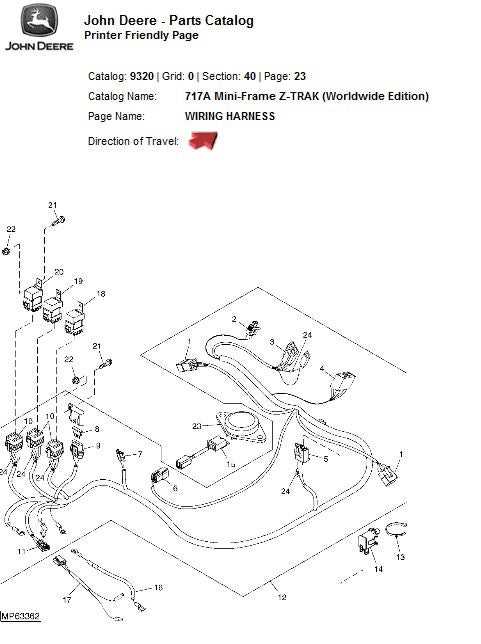

Resources for PTO Parts Diagrams

Accessing comprehensive resources for components associated with power take-off systems is essential for effective maintenance and repair. These resources provide visual aids and detailed information, ensuring users can easily identify and understand the various elements involved.

Several avenues exist for obtaining valuable information on these systems:

- Manufacturer Websites: Many manufacturers offer official resources that include schematics and information on component compatibility.

- Online Forums: Engaging with community forums can provide insights and shared experiences from other users facing similar challenges.

- Repair Manuals: Detailed guides often include illustrations and instructions for assembly and disassembly of these systems.

- YouTube Tutorials: Video content can visually demonstrate the functionality and installation processes, enhancing understanding.

- Local Dealerships: Authorized dealers can provide printed materials and expert advice on specific component inquiries.

Utilizing these resources can facilitate a deeper understanding of the mechanisms at play, ultimately leading to more efficient and effective repairs.