Understanding Whynter Ice Maker Parts Diagram for Easy Maintenance

In the realm of household appliances, the seamless functioning of equipment often hinges on a clear understanding of its individual components. By exploring the intricate relationships between various elements, users can enhance their experience and troubleshoot potential issues with ease. This section aims to provide a comprehensive overview of the essential constituents of a specific type of device.

Knowledge of how these elements interact can significantly impact maintenance and efficiency. A well-organized guide not only serves as a reference for identifying parts but also assists in the optimization of the appliance’s overall performance. Through a detailed examination of each segment, users can gain insights that are crucial for effective operation.

Furthermore, being familiar with the structure of your equipment can empower you to undertake minor repairs and adjustments confidently. Understanding the layout of various sections can demystify common problems and facilitate quicker resolutions. This proactive approach ultimately leads to a more satisfying user experience.

Understanding Whynter Ice Maker Components

Gaining insight into the various elements that contribute to the functioning of a refrigeration unit can enhance both its maintenance and efficiency. Each component plays a crucial role, working in harmony to produce chilled products and deliver optimal performance. Familiarity with these essential parts will empower users to troubleshoot issues and ensure longevity.

The core functionality relies on several critical elements, including the condenser, evaporator, and compressor. These components interact seamlessly to facilitate the freezing process, transforming liquid into solid form. Knowledge of how these elements work together can simplify repairs and enhance user experience.

In addition to the primary components, auxiliary parts such as water reservoirs, sensors, and control panels further refine the operation. Understanding their specific functions allows for better oversight and prompt identification of potential malfunctions. A comprehensive grasp of these systems fosters a proactive approach to maintenance.

Ultimately, a thorough comprehension of the internal workings not only aids in effective troubleshooting but also maximizes the efficiency of the unit, ensuring it meets user needs reliably and effectively. Recognizing the significance of each part is essential for optimal performance and longevity.

Key Features of Whynter Ice Makers

This section explores the essential characteristics that define high-quality machines designed for producing frozen water. These features enhance user experience, efficiency, and overall functionality, making them a valuable addition to any kitchen or outdoor setup.

Efficiency and Performance

- Rapid production capabilities, allowing users to generate a significant quantity in a short period.

- Energy-efficient designs that minimize electricity consumption while maximizing output.

- Advanced cooling technology to ensure consistent and reliable performance even in varying temperatures.

User-Friendly Design

- Intuitive control panels for easy operation and monitoring.

- Compact dimensions that facilitate placement in diverse environments, from homes to events.

- Durable materials that ensure longevity and resilience against wear and tear.

Common Issues with Ice Makers

When it comes to producing frozen cubes, various problems can arise that affect performance and efficiency. Understanding these challenges can help users troubleshoot and maintain their equipment effectively. Below are some of the most frequently encountered issues that may disrupt the freezing process.

Insufficient Freezing

A common complaint is the inability to produce adequate amounts of frozen cubes. This may be due to low temperature settings, poor ventilation, or even a malfunctioning thermostat. Ensuring the device is placed in a suitable environment and checking the settings can often resolve this issue.

No Cubes Formation

In some instances, no cubes may form at all. This can occur if there is a blockage in the water supply or if the reservoir is empty. Regular maintenance and inspection of the water lines can help prevent this problem and ensure continuous operation.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any appliance. Proper care not only enhances performance but also minimizes the risk of unexpected breakdowns. By dedicating time to routine inspections and cleanings, users can significantly improve the reliability and efficiency of their equipment.

Investing in maintenance brings several advantages, including:

| Benefit | Description |

|---|---|

| Increased Efficiency | Well-maintained devices operate more effectively, saving energy and resources. |

| Cost Savings | Preventative care reduces the likelihood of costly repairs and replacements. |

| Extended Lifespan | Regular checks and servicing can prolong the functional life of the equipment. |

| Improved Performance | Consistent maintenance ensures that the appliance runs smoothly and performs optimally. |

By prioritizing regular maintenance, users can enjoy the benefits of a reliable and efficient appliance for years to come. Simple actions such as cleaning, inspecting components, and timely servicing can make a significant difference in the overall functionality and durability.

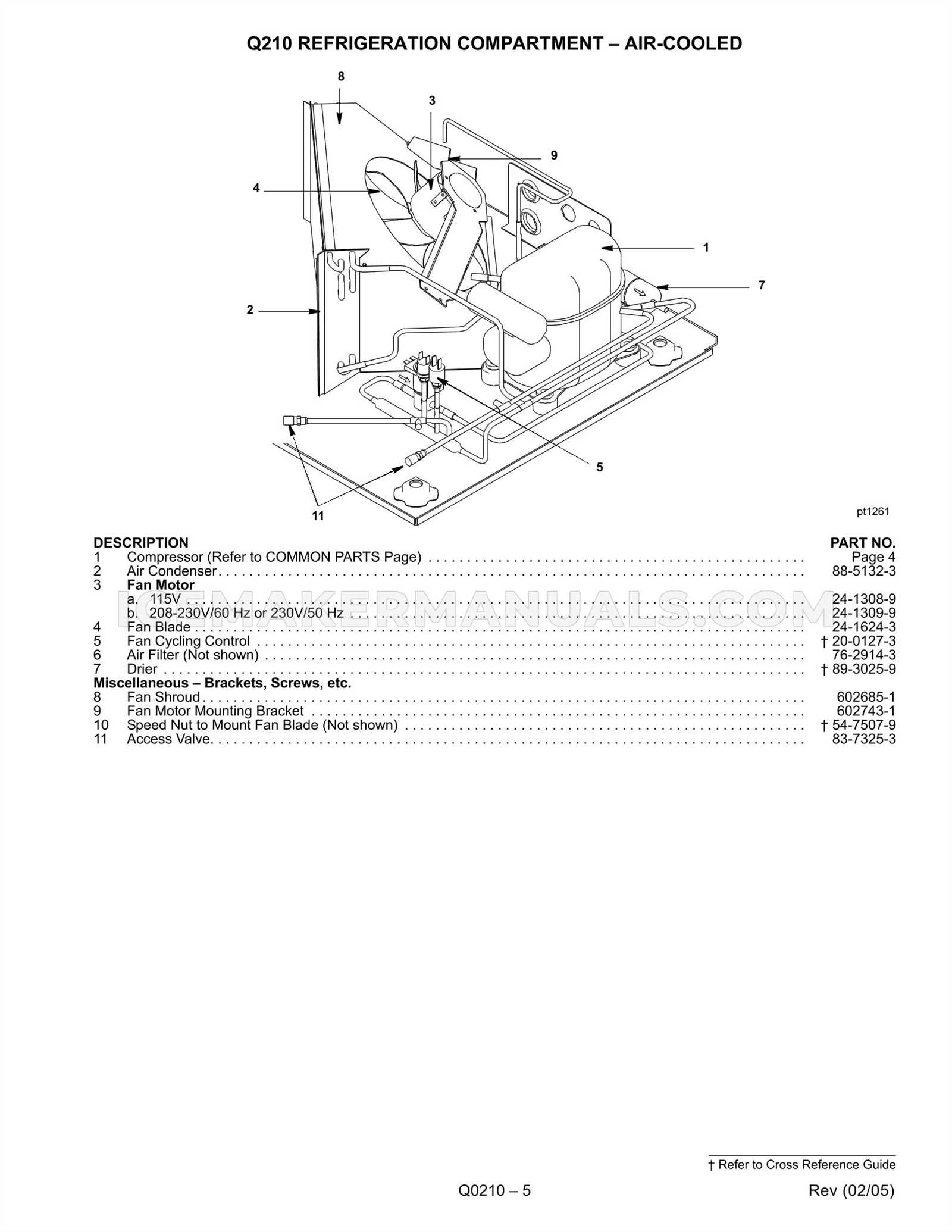

How to Read Parts Diagrams Effectively

Understanding technical illustrations is essential for anyone looking to repair or maintain equipment. These visual representations provide a clear view of components and their relationships, making it easier to identify what is needed for service or replacement. Mastering the skill of interpreting these visuals can save time and reduce frustration.

Start by Familiarizing Yourself with the Key Elements: Each illustration typically includes various symbols and labels that denote specific elements. Take a moment to review the legend or key provided, as it explains what each symbol represents. This foundational knowledge will enhance your ability to navigate the diagram efficiently.

Follow the Flow: Look for arrows or lines that indicate connections between components. Understanding the flow of the system can help you determine how parts interact and where issues may arise. This holistic view is crucial for diagnosing problems effectively.

Pay Attention to Annotations: Notes or numbers next to components often contain important details such as part numbers or specifications. Make sure to read these annotations carefully, as they provide vital information for sourcing replacements or understanding functionality.

Practice Makes Perfect: The more you work with these visuals, the more proficient you’ll become. Try to analyze various diagrams to build your confidence. Over time, you’ll develop an intuitive understanding of how different parts are organized and function within the overall system.

Essential Replacement Parts for Efficiency

Ensuring optimal performance of your appliance often relies on the availability of key components that may need periodic replacement. Understanding which elements are crucial for seamless operation can significantly enhance functionality and prolong the lifespan of the unit.

Key Components to Consider

- Filters: Essential for maintaining cleanliness and preventing contaminants.

- Compressors: Vital for regulating temperature and ensuring proper cooling.

- Hoses: Important for efficient water flow and preventing leaks.

- Thermostats: Crucial for accurate temperature control and system regulation.

- Fan Blades: Necessary for effective air circulation and cooling efficiency.

Benefits of Regular Maintenance

- Improved efficiency: Replacing worn-out components enhances overall performance.

- Cost savings: Preventive measures reduce the likelihood of major repairs.

- Extended lifespan: Keeping essential elements in top condition prolongs the unit’s usability.

- Enhanced safety: Regular checks and replacements minimize potential hazards.

Step-by-Step Repair Guide for Users

This section provides a comprehensive approach to troubleshooting and fixing your appliance. Following a structured method will help you identify issues effectively and apply the necessary solutions to restore functionality.

Step 1: Preparation

Begin by gathering all essential tools and materials. Ensure your workspace is clean and well-lit. Familiarize yourself with the model’s specifications to understand its components better.

Step 2: Identification of Issues

Examine the unit carefully to pinpoint the source of the malfunction. Look for signs of wear, leaks, or unusual noises. Take notes on your observations to assist in the repair process.

Step 3: Disassembly

Carefully disassemble the unit, following the manufacturer’s guidelines. Use appropriate tools to avoid damaging any parts. Keep all screws and components organized for easy reassembly.

Step 4: Inspection

Inspect individual components for damage or malfunction. Test electrical connections and check for blockages that may hinder performance. Replace any faulty parts as needed.

Step 5: Reassembly

Once repairs are completed, reassemble the unit in the reverse order of disassembly. Ensure all components are securely attached and double-check for any loose connections.

Step 6: Testing

After reassembly, power on the appliance to test its functionality. Monitor for any unusual sounds or issues. If problems persist, revisit previous steps to ensure nothing was overlooked.

Step 7: Maintenance Tips

Regular maintenance can prolong the life of your appliance. Clean it periodically, check for wear and tear, and address minor issues before they escalate.

Identifying Faulty Components Quickly

Recognizing malfunctioning elements in a system is crucial for efficient troubleshooting and maintenance. By understanding the typical indicators of issues, users can swiftly isolate and address problems, ensuring optimal performance and longevity of the appliance. This process not only saves time but also minimizes potential damage that can arise from neglecting minor faults.

Common Symptoms of Malfunction

Familiarizing yourself with frequent signs of failure can expedite the diagnostic process. Look for unusual noises, inconsistent performance, or unexpected leaks. These symptoms often point to underlying issues that require immediate attention. Regular monitoring can help catch these indicators early, preventing more significant complications down the line.

Step-by-Step Inspection Process

Conducting a thorough examination involves a systematic approach. Begin by assessing the power supply and connections, as electrical issues are often the root cause of failures. Next, inspect the key components for wear or damage, such as seals and motors. Documenting findings during this inspection can aid in identifying patterns and recurring problems, leading to more informed decisions regarding repairs or replacements.

Safety Tips for Ice Maker Repairs

When engaging in maintenance or fixing equipment designed for producing frozen water, it’s essential to prioritize safety. Proper precautions can prevent accidents and ensure a smooth repair process. Familiarizing yourself with safety measures can lead to a more efficient and hazard-free experience.

Wear Appropriate Protective Gear

Always equip yourself with suitable protective clothing, including gloves and safety goggles. This gear minimizes the risk of injury from sharp components or accidental splashes of cleaning agents. Additionally, closed-toed shoes can protect your feet from falling objects.

Disconnect Power Sources

Before attempting any repair work, ensure that the equipment is completely powered off and unplugged. This step is crucial to prevent electrical shocks and other dangerous situations. Double-checking that there is no power running through the device will give you peace of mind while you work.

Where to Purchase Genuine Parts

Finding authentic components for your appliance is crucial for maintaining its performance and longevity. Using original replacements ensures compatibility and reliability, which can save you time and money in the long run. There are various avenues available for sourcing these essential items, each with its own advantages.

Authorized Retailers

One of the most reliable options is to visit authorized retailers that specialize in appliance components. These vendors are licensed to sell genuine items and often provide additional resources, such as installation guides and customer support. Purchasing from them ensures that you receive high-quality products that meet manufacturer standards.

Online Marketplaces

Another convenient method is exploring online marketplaces. Many reputable e-commerce platforms offer a wide range of authentic items, often with detailed descriptions and customer reviews. When choosing this route, make sure to verify the seller’s credentials to ensure you are getting legitimate merchandise. Additionally, check return policies to safeguard your purchase.

Cost Analysis of Replacement Parts

Evaluating the financial implications of component substitution is crucial for maintaining optimal performance in any appliance. Understanding the expenses associated with acquiring new elements can significantly impact long-term ownership costs. This analysis delves into various factors influencing pricing, enabling users to make informed decisions when faced with the need for replacements.

Market research indicates that prices for individual components can vary widely based on brand, quality, and availability. Generic options may offer cost savings, but they often come with trade-offs in terms of durability and efficiency. Conversely, investing in original or high-quality substitutes can enhance functionality and extend the lifespan of the appliance, potentially reducing future expenses.

Additionally, the frequency of needed replacements should be considered. Regular maintenance and timely upgrades can prevent unexpected breakdowns, leading to substantial savings over time. It is advisable to keep a record of previous replacements to identify patterns and anticipate future costs effectively.

In conclusion, a thorough cost analysis not only aids in budgeting but also enhances the overall value of ownership. By weighing the initial expenses against potential long-term benefits, consumers can make strategic choices that align with their financial goals and operational needs.

Upgrades for Enhanced Performance

Improving functionality and efficiency is essential for any machine. By integrating advanced components, users can achieve higher output, reduce energy consumption, and enhance reliability. This section explores various enhancements that can optimize performance.

| Upgrade Component | Description | Benefits |

|---|---|---|

| High-Quality Compressor | A powerful unit that increases cooling efficiency. | Faster cooling, energy savings, and extended lifespan. |

| Enhanced Insulation | Improved thermal barrier to maintain optimal temperatures. | Reduced energy usage and consistent output. |

| Advanced Control System | Smart technology for monitoring and adjusting settings. | Greater precision, ease of use, and adaptability to user needs. |

| Upgraded Water Filtration | Superior filtration systems for cleaner output. | Improved quality and taste, lower maintenance frequency. |

Customer Reviews on Whynter Models

Consumer feedback plays a crucial role in understanding the effectiveness and reliability of different models. Potential buyers often look for insights from others to inform their purchasing decisions. The following reviews reflect various user experiences with these appliances, highlighting both strengths and areas for improvement.

Many users have praised the efficiency and performance of these units, noting their ability to produce quality output quickly. Common themes in the reviews include:

- Quick production time: Customers frequently mention how rapidly these devices can generate their desired product.

- User-friendly design: The ease of operation is often highlighted, making it accessible for people of all ages.

- Compact size: Users appreciate the space-saving design, which fits well in various environments, from kitchens to outdoor gatherings.

However, not all experiences have been positive. Some feedback points to challenges faced by users, such as:

- Noise level: A few customers have reported that the operation can be louder than expected, which may be a concern in quieter settings.

- Durability issues: Some reviews mention parts that wear out faster than anticipated, leading to concerns about long-term reliability.

- Initial setup: A handful of users found the setup process slightly complicated, requiring additional time and effort.

In summary, the reviews reveal a mix of satisfaction and critique, emphasizing the importance of considering user experiences when evaluating these appliances.