Comprehensive Guide to the Lt1046 Parts Diagram

In the realm of machinery, a comprehensive overview of the various elements that make up a system is essential for both maintenance and repair. Each component plays a vital role in ensuring the efficient operation of equipment, and recognizing their interconnections can lead to better troubleshooting and optimization of performance. This knowledge is particularly valuable for those involved in the upkeep of outdoor machinery.

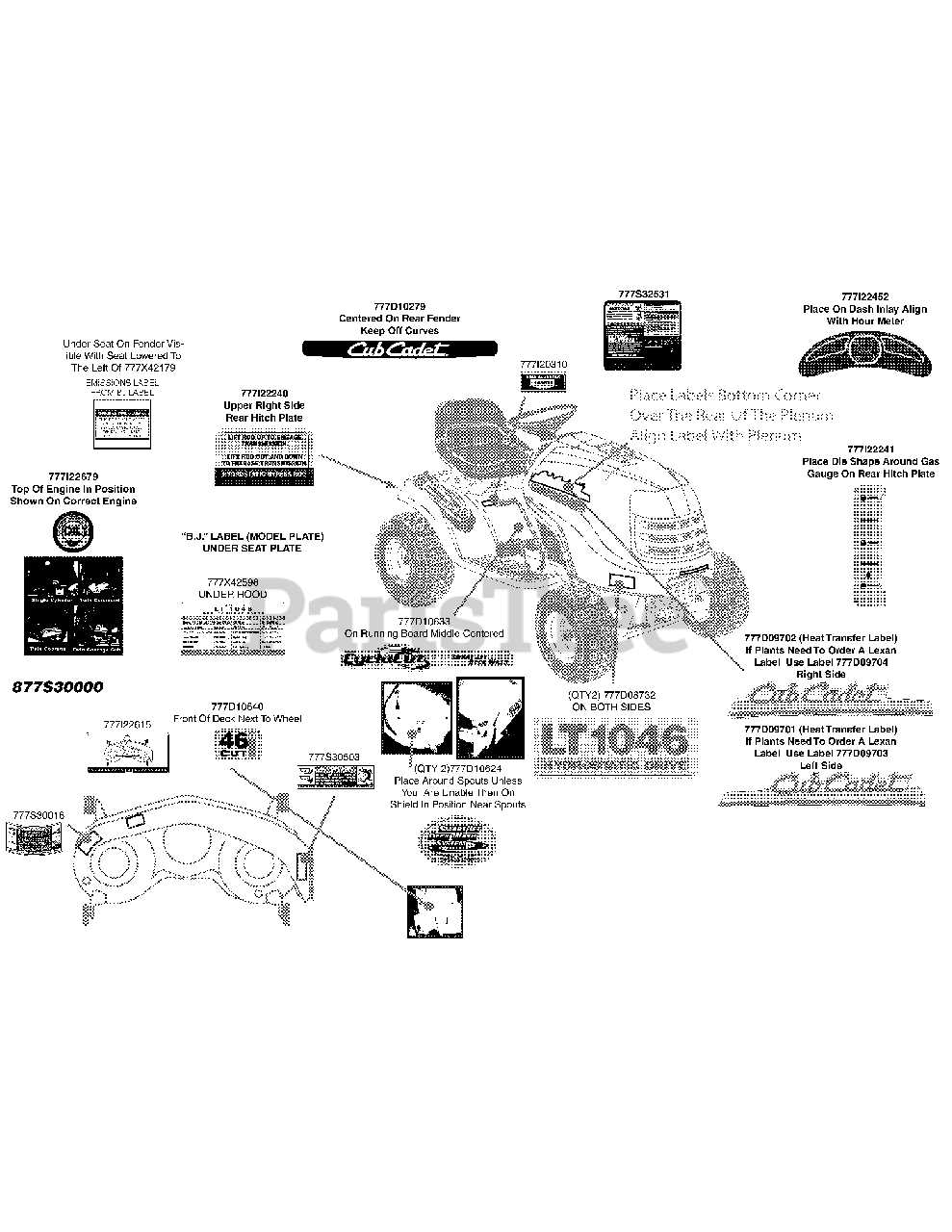

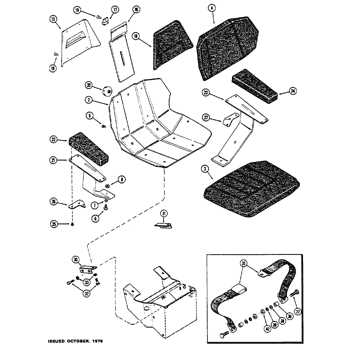

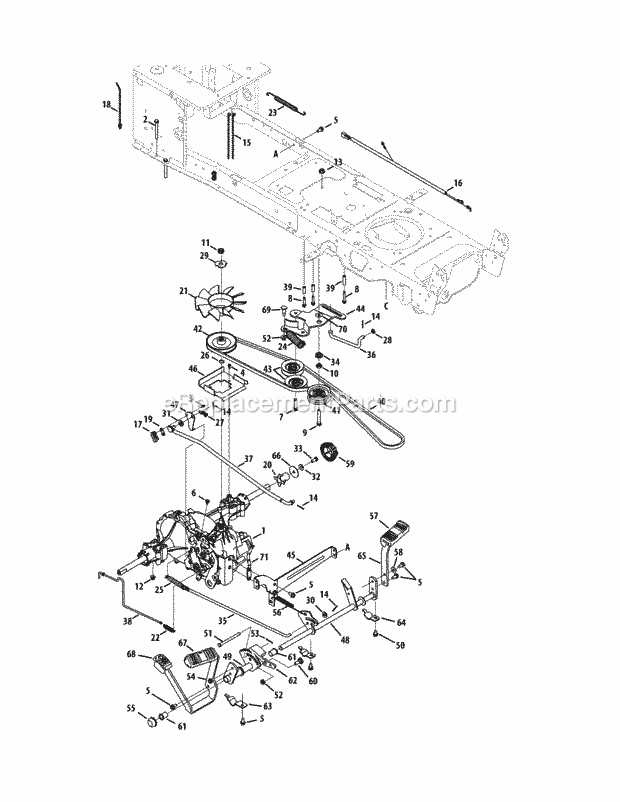

Visual representations of these elements serve as indispensable tools for users and technicians alike. By providing a clear and organized view of how parts fit together, these illustrations enhance understanding and streamline the repair process. Moreover, they can help in identifying potential issues before they escalate into more significant problems, thereby saving time and resources.

As we delve into the intricacies of these mechanical assemblies, we will explore the specific configurations and functionalities that characterize each part. Gaining insight into these structures not only empowers users but also fosters a deeper appreciation for the engineering that underpins modern machinery. Understanding these details can ultimately lead to improved efficiency and longevity of equipment.

Understanding Lt1046 Parts Diagram

The examination of mechanical components and their organization is essential for effective maintenance and troubleshooting. A well-structured illustration serves as a crucial reference for identifying individual elements and their functions within a larger assembly. Grasping the relationships among these elements can significantly enhance the efficiency of repair processes and operational understanding.

Key Elements of the Illustration

Each component is typically labeled, providing clarity on its role and location. This labeling allows users to quickly reference parts when seeking replacements or performing routine checks. The layout often highlights connections and interactions, helping users visualize how each piece contributes to the overall functionality.

Importance of Familiarity

Being well-acquainted with such illustrations can prevent potential issues during assembly or disassembly. Users are encouraged to study these representations thoroughly, as they can provide insights that are not immediately apparent through practical experience alone. A deep understanding fosters confidence and precision in handling machinery.

Importance of Accurate Diagrams

Clear and precise visual representations are essential for understanding complex systems. They serve as a roadmap, guiding users through intricate components and relationships, ensuring that each part functions harmoniously within the whole. The significance of these illustrations cannot be overstated, as they facilitate effective communication and comprehension among diverse users.

Having reliable visuals aids in troubleshooting and maintenance tasks, allowing technicians to quickly identify issues and implement solutions. This efficiency reduces downtime and enhances overall productivity. Moreover, accurate visuals promote safety by providing essential information that helps prevent errors during assembly or repair processes.

Furthermore, detailed representations are invaluable in training scenarios, equipping new users with the knowledge needed to navigate systems confidently. They bridge gaps in understanding, making complex information accessible to all, regardless of prior experience. In an era where precision is paramount, the role of these illustrations in various fields cannot be underestimated.

Components of the Lt1046

This section explores the essential elements that contribute to the functionality and efficiency of the specified model. Understanding these components is crucial for maintenance, repair, and overall performance optimization.

Core Elements

The primary features include various mechanical and electronic components that work in unison to ensure optimal operation. These parts are designed to withstand wear and tear while providing reliable performance. Each element plays a specific role, whether it’s facilitating movement, regulating power, or enhancing control.

Supporting Features

In addition to the main elements, several auxiliary components enhance the system’s overall capabilities. These may include sensors, connectors, and safety devices that contribute to user experience and operational safety. Understanding their function helps in troubleshooting and upgrading the system effectively.

How to Read the Diagram

Understanding a schematic representation can seem daunting at first, but with a few key insights, it becomes much easier to navigate. These illustrations serve as a visual guide, breaking down complex systems into manageable components. Familiarizing yourself with their layout and symbols is essential for effective interpretation.

Identifying Components

Each element within the visual aid has a specific role. Look for labels and numbers that indicate part names and functions. These identifiers are crucial for understanding how each section interacts with others. Pay attention to the orientation and placement, as they often reveal the relationship between the different parts.

Interpreting Connections

Lines and arrows signify relationships and pathways between components. Solid lines typically represent physical connections, while dashed lines might indicate optional or auxiliary links. Recognizing these distinctions helps in tracing the flow of energy or information throughout the system.

Common Issues with Lt1046 Parts

When dealing with complex machinery, certain challenges frequently arise that can impact functionality and performance. Understanding these common difficulties is essential for effective maintenance and repair. Many users encounter similar concerns that, if addressed promptly, can prolong the life of their equipment.

One prevalent issue is wear and tear on components due to regular use. Over time, essential elements may degrade, leading to decreased efficiency. Regular inspections can help identify signs of deterioration before they become critical failures.

Another significant problem is improper installation of replacements. If components are not fitted correctly, this can lead to operational issues or even damage to adjacent systems. It is crucial to follow manufacturer guidelines during the installation process to avoid these pitfalls.

Compatibility is also a frequent concern. Using incompatible components can result in poor performance or failures. Ensuring that all parts are suitable for your specific model is vital for maintaining optimal function.

Finally, neglecting regular maintenance can exacerbate issues, leading to more significant and costly repairs. Establishing a routine maintenance schedule is essential to keep everything running smoothly.

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for achieving efficient and effective results. Utilizing appropriate tools not only facilitates the repair process but also enhances safety and accuracy. Below is a list of essential items that can help streamline your repair efforts.

- Screwdrivers: A variety of sizes and types (flathead and Phillips) are crucial for loosening or tightening screws.

- Wrenches: Both adjustable and fixed wrenches are necessary for gripping and turning nuts and bolts.

- Pliers: Needle-nose and standard pliers assist in holding, bending, and cutting wire or small components.

- Socket Set: A comprehensive socket set allows for quick and efficient tightening or loosening of fasteners.

- Multimeter: Useful for electrical diagnostics, a multimeter helps in checking voltage, current, and resistance.

Having these tools readily available can significantly improve your ability to perform repairs effectively. Organizing them in a dedicated workspace will also save time and reduce frustration during the process.

- Torque Wrench: Essential for applying precise torque to fasteners to prevent damage.

- Cutting Tools: Utility knives or snips are useful for cutting various materials as needed.

- Safety Gear: Goggles, gloves, and masks are critical for protecting yourself while working.

- Lubricants: Oils and greases can help reduce friction and prevent wear on moving parts.

- Cleaning Supplies: Rags, brushes, and solvents are important for maintaining a clean working environment.

By equipping yourself with these necessary tools and supplies, you will be better prepared to tackle any repair project that comes your way.

Step-by-Step Repair Process

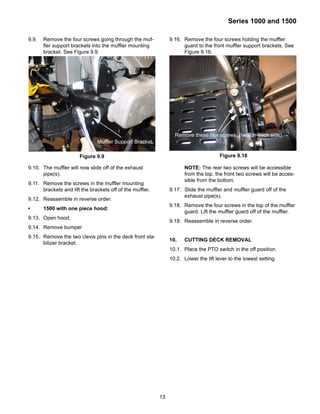

This section outlines a comprehensive approach to addressing mechanical issues. Following a structured method ensures efficiency and clarity, helping you resolve problems effectively.

-

Assessment of the Problem: Begin by thoroughly examining the equipment. Identify any visible signs of wear or damage.

-

Gather Necessary Tools: Collect all essential tools and materials needed for the repair. This may include wrenches, screwdrivers, and replacement components.

-

Disassembly: Carefully disassemble the unit, taking care to remember the order of components. Use labeled containers to keep small parts organized.

-

Inspection: Inspect each part for defects. Check for cracks, rust, or other damage that may require replacement or repair.

-

Replacement: Replace any damaged or worn components with new or refurbished parts. Ensure compatibility with existing mechanisms.

-

Reassembly: Reassemble the unit in the reverse order of disassembly. Double-check connections to ensure everything is secure.

-

Testing: Once reassembled, conduct a test run to ensure proper functionality. Monitor for any unusual noises or issues during operation.

-

Final Inspection: After testing, perform a final inspection. Confirm that all components are functioning as intended and make any necessary adjustments.

By following these steps, you can efficiently navigate the repair process, ensuring a successful outcome and extending the lifespan of your machinery.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the optimal performance and extended lifespan of your equipment. By adhering to a few key practices, you can significantly enhance reliability and efficiency, preventing costly repairs and replacements down the line.

Routine Checks

Performing consistent inspections is crucial. Look for signs of wear and tear, ensuring that all components are functioning correctly. This proactive approach helps identify potential issues before they escalate.

Proper Cleaning

Keeping your machinery clean is vital. Dust and debris can hinder performance and lead to premature deterioration. Implement a cleaning schedule that includes both interior and exterior maintenance.

| Task | Frequency | Benefits |

|---|---|---|

| Inspection of Components | Monthly | Identifies potential issues early |

| Lubrication | Quarterly | Reduces friction and wear |

| Cleaning | Weekly | Prevents buildup and promotes efficiency |

| Fluid Checks | Biweekly | Ensures proper function and prevents overheating |

Finding Replacement Parts Easily

Locating suitable components for machinery can often seem daunting. However, with the right approach, the process can be streamlined and efficient. Here are some strategies to simplify your search for the necessary items.

- Utilize Online Resources: Websites dedicated to equipment maintenance and repair can provide extensive catalogs. Look for platforms that specialize in the machinery you are working with.

- Consult User Manuals: Manuals often contain valuable information about compatible components, including specifications and part numbers.

- Join Online Communities: Forums and social media groups can be a great resource for advice and recommendations from other users who have faced similar challenges.

By employing these methods, you can significantly enhance your ability to find the right replacements, ensuring your equipment remains operational and efficient.

- Identify your specific needs.

- Search for trusted suppliers.

- Compare prices and availability.

- Read reviews and ratings before making a purchase.

Staying organized and informed will ultimately lead to a more successful maintenance experience.

Online Resources for Diagrams

Accessing visual guides and schematics online has become increasingly essential for enthusiasts and professionals alike. These resources provide crucial insights into various components and systems, enabling users to effectively understand and troubleshoot complex machinery. A wealth of information is now just a click away, making it easier to find the specific illustrations needed for any project.

Comprehensive Databases

Many websites curate extensive libraries filled with illustrations and schematics across various fields. These databases often include search functionalities that allow users to quickly locate the information they require. Utilizing keywords relevant to your needs can lead to an array of visual aids, enhancing both understanding and practical application.

Community Forums and Discussion Boards

Engaging with online communities is another excellent way to find valuable resources. Forums often host discussions where users share links to helpful visuals, along with personal experiences and tips. Participating in these exchanges not only enriches your knowledge but also connects you with others who share your interests and challenges.

Comparing Diagrams of Similar Models

When exploring technical schematics of various machinery, understanding the nuances between similar models can significantly enhance maintenance and repair processes. By analyzing these representations, one can identify both common features and unique components, allowing for a more informed approach to service and functionality.

First and foremost, comparing schematics helps in recognizing standard parts that may be interchangeable across different units. This interchangeability can save time and resources when sourcing replacements. Additionally, it can provide insights into design evolutions, showcasing improvements or adaptations made to enhance performance or efficiency.

Furthermore, examining differences in layout can reveal specific functionalities unique to a model. For instance, variations in the arrangement of elements may indicate different operational capabilities or enhanced safety features. Understanding these distinctions is vital for technicians aiming to optimize their work and ensure compliance with manufacturer specifications.

In summary, a thorough comparison of technical representations of similar machines not only aids in effective troubleshooting but also fosters a deeper appreciation of engineering advancements and design philosophy.

Expert Advice on Troubleshooting

When dealing with mechanical systems, identifying issues can be a complex task. A systematic approach is essential to pinpoint the root cause of malfunctions. This section provides valuable insights into effective methods for diagnosing and resolving problems, ensuring optimal performance and longevity of your equipment.

Begin by observing the unit’s behavior. Note any unusual sounds, vibrations, or performance drops. Keeping a detailed log can help in understanding patterns and recurring issues. Next, inspect critical components for wear or damage. Regular maintenance is crucial, as it can prevent minor issues from escalating into significant failures.

| Common Issues | Possible Causes | Suggested Solutions |

|---|---|---|

| Unusual Noises | Loose parts or lack of lubrication | Tighten fasteners and apply appropriate lubricants |

| Overheating | Blocked airflow or malfunctioning cooling system | Clear obstructions and check cooling components |

| Poor Performance | Worn components or incorrect settings | Replace worn parts and recalibrate settings |

| Frequent Breakdowns | Inadequate maintenance or improper usage | Establish a regular maintenance schedule and review usage practices |

Utilizing these strategies not only enhances troubleshooting efficiency but also fosters a proactive mindset toward maintenance. Keeping a record of findings and solutions can aid future diagnostics, creating a repository of knowledge that benefits both novice and experienced users alike.