Understanding Briggs and Stratton Lawn Mower Parts Diagram

In the realm of outdoor maintenance, comprehending the various elements that contribute to the functionality of your machinery is essential. A clear visualization of these components aids in effective repairs and enhances overall performance, ensuring your tasks are executed seamlessly.

Familiarizing yourself with the intricate layout of these mechanical elements allows for a deeper appreciation of how they interact. This knowledge not only simplifies troubleshooting but also empowers you to perform necessary maintenance confidently.

Ultimately, having a thorough grasp of your equipment’s anatomy will lead to a more efficient gardening experience. Delve into the specifics, and you’ll find that understanding each segment paves the way for longevity and reliability.

Understanding Briggs and Stratton Mowers

Many homeowners rely on reliable outdoor equipment for maintaining their green spaces. This brand is known for producing high-quality machinery that combines durability with efficiency, catering to various needs in the yard care sector.

Features of Reliable Equipment

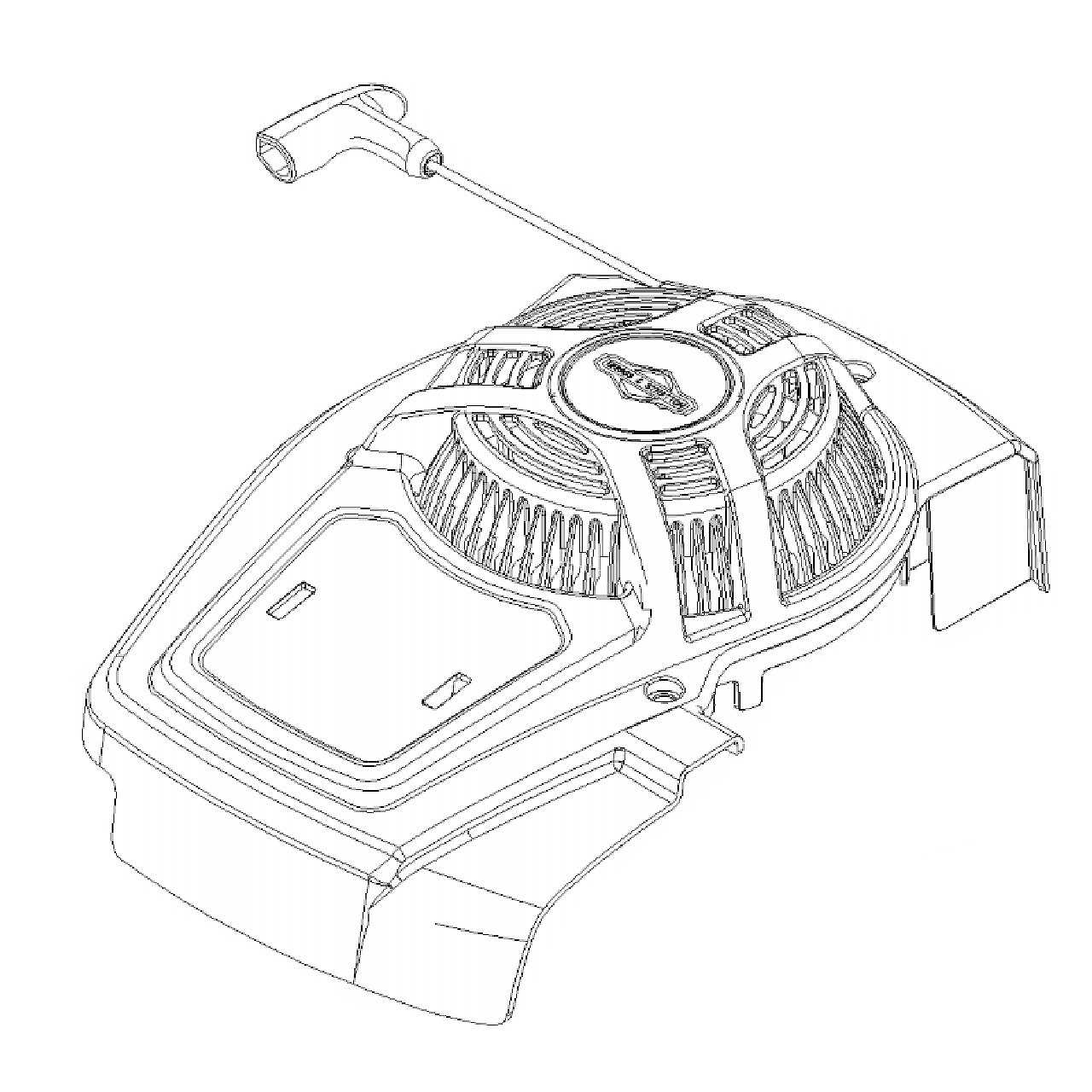

The devices boast robust engines designed to handle diverse terrains and conditions. Performance is key, as these machines are engineered to ensure smooth operation while minimizing maintenance requirements.

Maintenance Tips for Longevity

To maximize the lifespan of these machines, regular upkeep is essential. Inspecting components, changing oils, and cleaning air filters contribute significantly to optimal performance. Understanding the mechanisms allows users to identify potential issues before they escalate.

Importance of Lawn Mower Diagrams

Understanding the layout and components of outdoor equipment is essential for effective maintenance and repair. Visual representations serve as invaluable resources, allowing users to identify parts quickly and accurately.

- Enhances troubleshooting efficiency

- Facilitates proper reassembly after repairs

- Improves safety by highlighting critical components

- Supports DIY enthusiasts in saving time and costs

Ultimately, having access to detailed illustrations can significantly streamline the upkeep process, ensuring optimal performance.

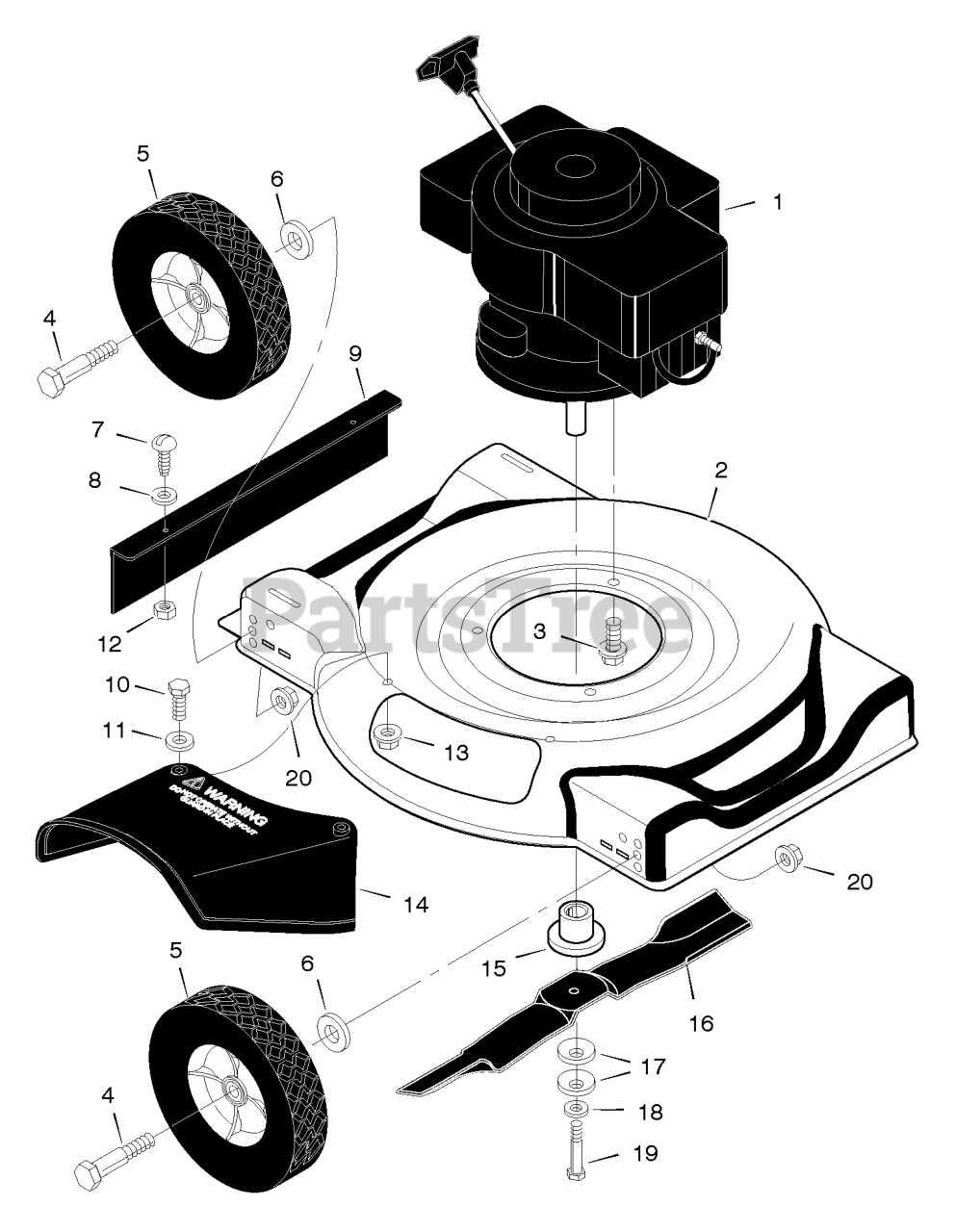

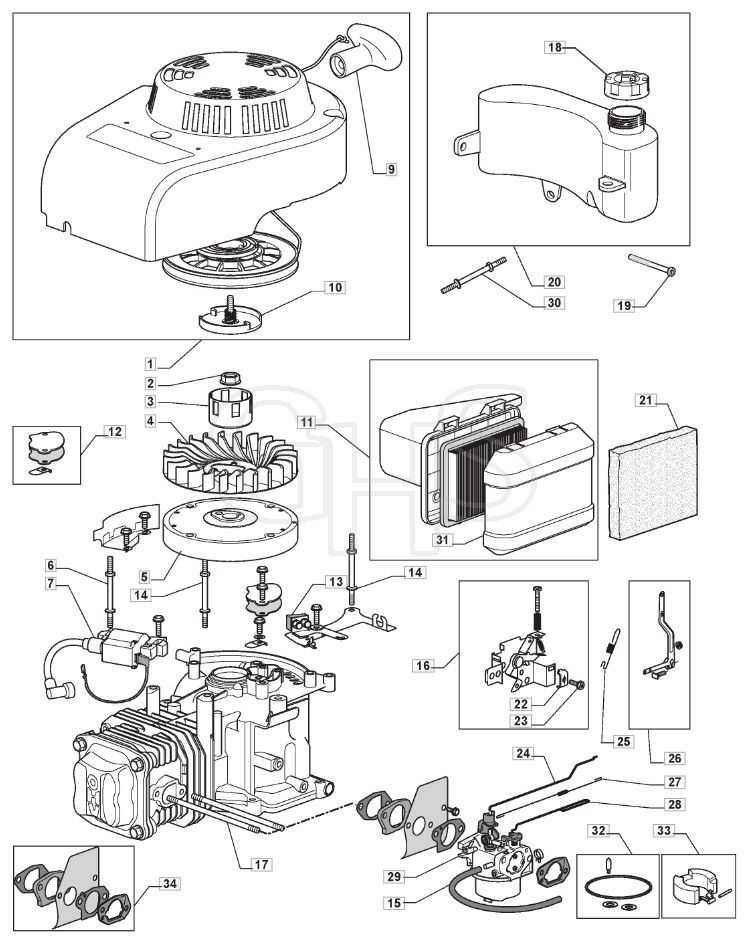

Key Components of Lawn Mowers

Understanding the essential elements of grass-cutting machines is crucial for effective maintenance and operation. These critical parts work together to ensure optimal performance and durability.

- Engine: The power source, providing the necessary energy for operation.

- Deck: The housing that protects internal components and directs clippings.

- Blade: The cutting edge responsible for trimming the grass at the desired height.

- Wheels: Allow for mobility and maneuverability across various terrains.

- Handle: The control mechanism for steering and adjusting the machine.

Familiarity with these vital components can help users troubleshoot issues and enhance the overall lifespan of their equipment.

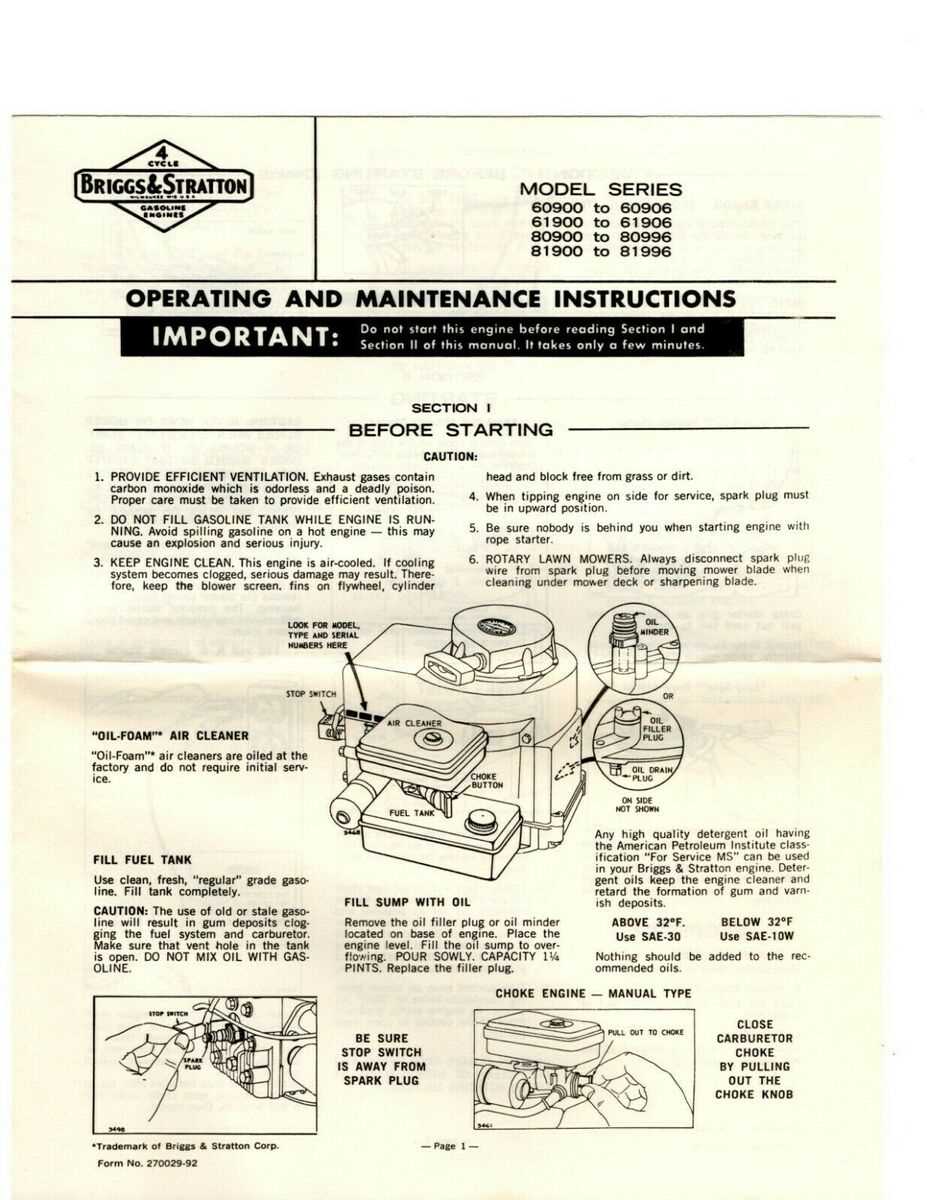

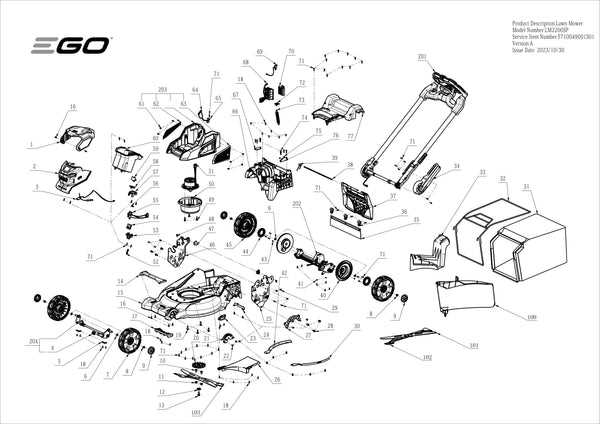

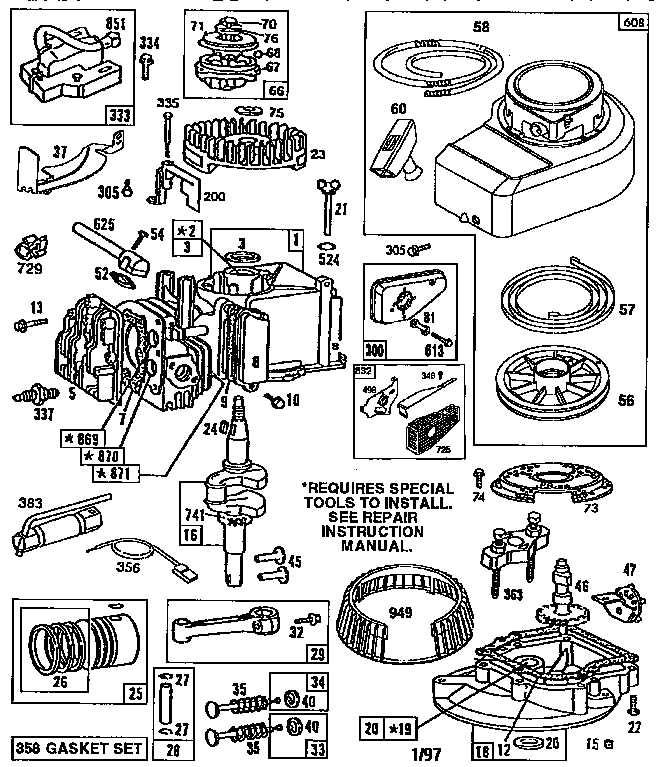

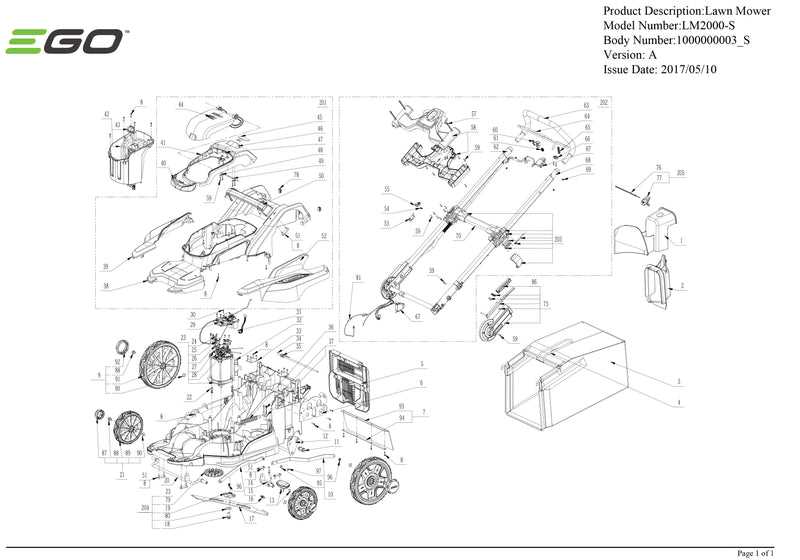

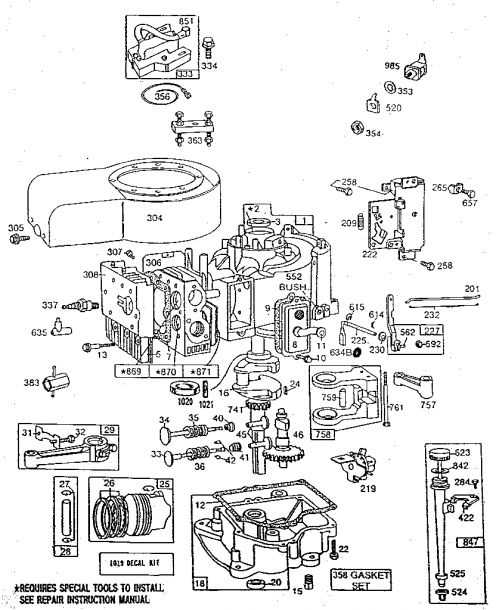

How to Read Parts Diagrams

Understanding the visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide a clear view of individual elements and their relationships, allowing users to identify what they need for service or replacement. Learning to interpret these visuals can significantly enhance your efficiency in handling repairs.

Identifying Key Components

The first step in decoding these visuals is to recognize the symbols and labels used for various items. Each element is typically numbered or color-coded, which corresponds to a list that details specifications. Familiarize yourself with this key to make it easier to locate the necessary components for your project.

Understanding Assembly Relationships

Another crucial aspect is to comprehend how the parts interact with one another. Pay attention to lines and arrows that indicate connections or orientations. This knowledge is vital for reassembling items correctly and ensuring everything functions smoothly after maintenance.

Common Issues with Mower Parts

Maintenance of garden machinery often reveals recurring challenges that can hinder performance and efficiency. Understanding these common problems is essential for ensuring longevity and optimal functioning of the equipment.

| Issue | Description |

|---|---|

| Fuel Problems | Stale or contaminated fuel can lead to starting difficulties and poor operation. |

| Blade Dullness | Worn or dull cutting edges result in uneven cuts and increased strain on the engine. |

| Battery Failure | A weak or dead battery can prevent the engine from starting, causing frustration. |

| Clogged Filters | Dirty air or fuel filters restrict airflow and fuel supply, leading to performance issues. |

Finding Replacement Parts Easily

Locating components for your outdoor equipment can be a straightforward process if approached correctly. Understanding where to look and how to identify the necessary items can save both time and frustration, allowing for a smoother maintenance experience.

Utilizing Online Resources

Many websites offer comprehensive catalogs that help you identify the exact components needed. By entering model numbers or descriptions, you can quickly access diagrams and specifications that guide you in selecting the right replacements.

Local Retailers and Service Centers

Visiting nearby stores or authorized service centers can also yield beneficial results. Knowledgeable staff can assist in pinpointing the correct items and may even have helpful recommendations for your specific model.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of your outdoor equipment. By adhering to a few simple practices, you can extend the life of your machinery and enhance its efficiency.

- Clean After Each Use: Remove grass clippings and debris to prevent rust and buildup.

- Check Oil Levels: Regularly inspect and change the oil to maintain optimal engine performance.

- Sharpen Blades: Keep cutting edges sharp for clean cuts, reducing strain on the engine.

Additionally, consider these important actions:

- Inspect belts and cables for wear and tear; replace as necessary.

- Store in a dry, sheltered place to protect from the elements.

- Review the owner’s manual for specific recommendations tailored to your model.

Implementing these practices will not only enhance functionality but also reduce the likelihood of costly repairs.

Tools Needed for Mower Repair

Maintaining and fixing garden equipment requires specific instruments to ensure efficiency and safety. Having the right tools at your disposal not only simplifies the repair process but also enhances the overall experience. Here’s a breakdown of essential equipment you should consider for effective repairs.

Essential Hand Tools

Basic hand tools are crucial for most repair tasks. These include wrenches, screwdrivers, and pliers, which are necessary for assembling and disassembling various components.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening nuts and bolts. |

| Screwdrivers | Essential for fastening and removing screws in different sizes. |

| Pliers | Helpful for gripping and manipulating small parts. |

Specialized Equipment

In addition to basic tools, some specialized equipment may be necessary for more advanced repairs. These tools allow for precise adjustments and can tackle specific tasks more effectively.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Multimeter | Used for diagnosing electrical issues and measuring voltage. |

| Fuel System Cleaner | Helps maintain optimal performance by cleaning fuel injectors and carburetors. |

Safety Precautions During Repairs

When engaging in mechanical repairs, prioritizing safety is essential to prevent accidents and injuries. Understanding the proper protocols and taking necessary precautions can ensure a secure working environment, allowing for effective and efficient maintenance tasks.

Essential Safety Guidelines

Before beginning any repair work, adhere to the following guidelines to maintain safety:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Utilize gloves, goggles, and appropriate footwear to protect against potential hazards. |

| Disconnect Power Source | Ensure that the device is powered off and unplugged to prevent accidental activation during repairs. |

| Keep Workspace Organized | A tidy area minimizes the risk of tripping and helps in locating tools easily. |

| Use Proper Tools | Select the right tools for each task to avoid injuries and ensure effective repairs. |

Emergency Preparedness

Be ready for unexpected situations by having a first-aid kit nearby and knowing emergency contact numbers. Familiarize yourself with the equipment you’re working on, and consult manuals or guides as needed to ensure a safe repair process.

Online Resources for Parts Information

In the modern age, locating information about equipment components has become easier thanks to various digital platforms. These resources provide detailed visuals and specifications, enabling users to identify the right elements for their machines quickly. Whether you’re a DIY enthusiast or a professional, leveraging these online tools can save time and ensure proper maintenance.

Websites Offering Comprehensive Guides

Several websites serve as valuable repositories of information, showcasing everything from assembly layouts to individual item specifications. These platforms often include user-friendly navigation and search features to facilitate your inquiry.

Community Forums and Support Groups

Participating in online forums can enhance your understanding of specific components. Engaging with fellow users allows you to share experiences, seek advice, and obtain recommendations on reliable resources.

| Resource Type | Examples |

|---|---|

| Manufacturer Websites | Official brand pages with manuals and specs |

| Retailer Sites | Online stores providing detailed product descriptions |

| Instructional Videos | YouTube channels demonstrating repairs and installations |

| Community Forums | Dedicated discussion boards for troubleshooting |

FAQs about Lawn Mower Components

This section addresses common inquiries regarding the various elements found in garden equipment. Understanding these components can enhance maintenance and troubleshooting efforts, leading to more efficient operation and longevity of your device.

What are the essential elements of garden machinery?

The critical components include the engine, cutting deck, blades, wheels, and control systems. Each plays a vital role in ensuring the equipment functions effectively, providing a clean and even cut.

How can I identify worn-out components?

Look for signs of damage such as unusual noises, reduced performance, or visible wear. Regular inspections can help detect issues early, allowing for timely replacements. Consulting a reference guide can also aid in identifying specific parts and their conditions.

Exploring Aftermarket Part Options

When it comes to maintaining outdoor equipment, considering alternatives to original components can be a wise choice. Aftermarket items often provide cost-effective solutions without compromising on quality. This section delves into the benefits and considerations of choosing these substitutes for your machinery needs.

Benefits of Aftermarket Components

One of the primary advantages of opting for alternative items is the potential for significant savings. Many manufacturers offer similar or even superior quality products at a fraction of the cost. Additionally, these alternatives may also enhance performance, providing features that original parts might lack. Customers often find a wider selection of options, allowing for tailored solutions that suit individual preferences.

Considerations When Choosing Alternatives

While the benefits are enticing, it’s important to approach the selection process thoughtfully. Not all aftermarket components are created equal; some may vary in quality and durability. Researching manufacturers and reading reviews can help in making informed decisions. Furthermore, ensure compatibility with your equipment to avoid any issues during installation or operation.