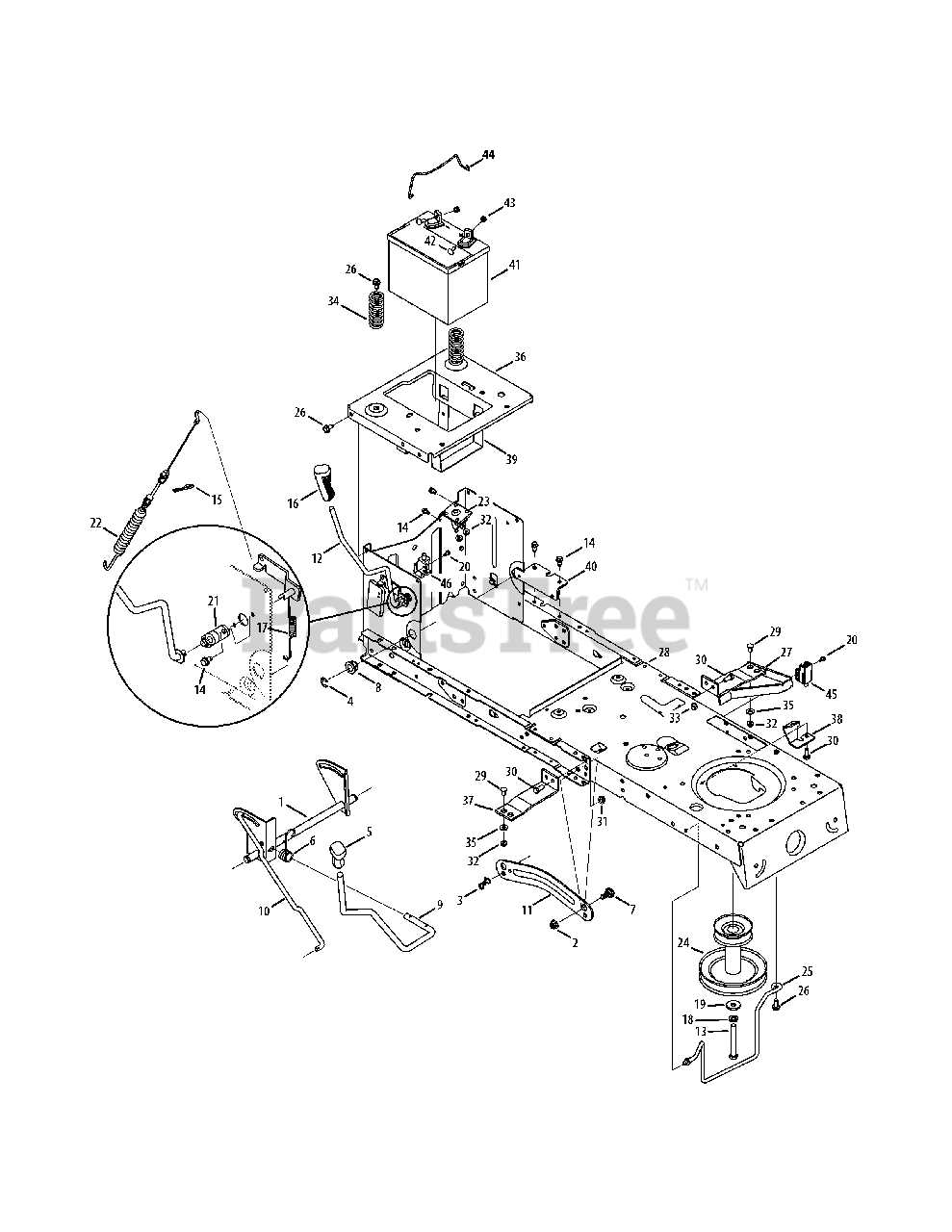

Complete Parts Diagram for the 2004 Craftsman LT2000

In the world of outdoor machinery, a comprehensive understanding of individual elements is crucial for effective maintenance and repair. Every model comprises various segments that work harmoniously to ensure optimal performance. Familiarity with these components allows owners to diagnose issues swiftly and make informed decisions when sourcing replacements.

When it comes to maintaining such equipment, having access to detailed visual representations of its assembly can significantly enhance the repair process. These illustrations serve as invaluable guides, highlighting the arrangement and function of each part. Such resources empower users to engage confidently in troubleshooting and restoration efforts.

Moreover, knowing the specific terminology associated with these components facilitates smoother communication with suppliers and repair professionals. A well-informed approach not only saves time but also minimizes the potential for costly mistakes, ultimately ensuring that the machinery remains in peak condition for years to come.

Understanding the Craftsman LT2000 Model

The model in focus is a popular lawn maintenance machine that combines efficiency with user-friendly features. It has gained a reputation for reliability, making it a favorite among homeowners who need to keep their yards in pristine condition. This section will delve into its essential components, operational advantages, and maintenance considerations.

Key Features and Benefits

This machine is designed to provide ease of use and effective performance. Equipped with a powerful engine, it delivers ample torque for various lawn tasks. The intuitive controls ensure that even novice users can operate it without difficulty. Additionally, its cutting mechanism is tailored for a clean and precise finish, enhancing the overall aesthetic of your lawn.

Maintenance and Care

To ensure longevity and optimal performance, regular upkeep is crucial. This includes routine checks of the engine, blades, and tires. A systematic approach to maintenance will not only prolong the life of the equipment but also ensure that it operates at peak efficiency during peak lawn care seasons.

| Component | Maintenance Tips |

|---|---|

| Engine | Change oil every season and check air filters. |

| Blades | Sharpen regularly and inspect for damage. |

| Tires | Check pressure and tread wear frequently. |

Common Parts of the LT2000

The efficient functioning of any lawn tractor relies on its key components. Understanding these essential elements can greatly enhance maintenance and repair efforts, ensuring that your machine operates smoothly throughout the seasons. This section highlights the primary features that contribute to the overall performance and longevity of your equipment.

Engine: The heart of the machine, responsible for providing the necessary power to operate the mower deck and drive system. A well-maintained engine is crucial for optimal performance.

Transmission: This component transfers power from the engine to the wheels, allowing for smooth movement across various terrains. Regular checks can help prevent operational issues.

Mower Deck: The assembly that houses the blades, crucial for cutting grass evenly. Ensuring the blades are sharp and the deck is free of debris will improve cutting efficiency.

Battery: Supplies the electrical power needed for starting the engine and operating other electrical components. A reliable battery is essential for uninterrupted use.

Wheels and Tires: These components provide traction and stability, affecting maneuverability and comfort during operation. Proper inflation and tread maintenance are important for safety and performance.

Belts: These are vital for transferring motion between different parts, such as the engine and mower deck. Regular inspection for wear and tear can prevent unexpected breakdowns.

By familiarizing yourself with these integral components, you can better manage repairs and maintenance, ensuring that your equipment remains in top condition for years to come.

Importance of a Parts Diagram

Understanding the intricacies of machinery and equipment maintenance is essential for effective repairs and optimal performance. A visual representation that outlines the components and their interrelations plays a crucial role in simplifying the repair process. This tool not only aids in identifying specific elements but also enhances overall comprehension of the machinery’s structure.

Facilitating Repairs

Having a clear illustration of the various components assists technicians in efficiently diagnosing issues. It streamlines the identification of worn-out or damaged elements, allowing for quicker resolution of problems. Moreover, it reduces the risk of overlooking critical parts during maintenance tasks.

Enhancing Knowledge and Skills

For those new to machinery maintenance, a comprehensive visual guide serves as an educational resource. It fosters a deeper understanding of how each piece interacts within the system. This knowledge empowers users to perform more informed repairs, contributing to a greater sense of confidence and capability in handling equipment.

How to Read a Parts Diagram

Understanding a schematic representation of components can greatly simplify the process of maintenance and repairs. These illustrations provide a visual guide to the various elements and their relationships within a system, making it easier to identify what is needed for replacement or service.

Identifying Components

Each element in the illustration is typically labeled with a reference number or code. These identifiers correspond to a list that details the specifications and availability of each component. Familiarizing yourself with these labels is essential for effective troubleshooting and ordering the right items.

Interpreting Relationships

The layout of the visual representation often shows how components connect and interact with each other. Understanding these connections can help in diagnosing issues and planning repairs. Pay attention to the orientation and positioning of elements, as they can indicate how parts should be assembled or disassembled.

| Component | Description | Part Number |

|---|---|---|

| Filter | Cleans air entering the system | 12345-ABC |

| Belt | Transfers power between parts | 67890-XYZ |

| Blade | Essential for cutting | 54321-DEF |

Identifying Key Components

Understanding the essential elements of your equipment is crucial for effective maintenance and repair. Each part plays a significant role in the overall functionality, and recognizing these components helps in troubleshooting and enhancing performance.

Major Elements to Recognize

Begin by familiarizing yourself with the major elements, such as the engine, transmission, and chassis. The engine is the heart of the machine, providing the necessary power. The transmission is responsible for transferring that power to the wheels, while the chassis supports all other components, ensuring stability and durability.

Additional Essential Parts

Besides the primary components, it’s important to note other vital parts like the fuel system, which ensures proper combustion, and the electrical system, which powers various features. A thorough understanding of these elements will greatly assist in maintaining the machine’s efficiency and longevity.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a daunting task. However, numerous resources can assist you in sourcing high-quality items to ensure your machinery remains in optimal condition. From online retailers to local stores, various options are available to meet your needs.

Online Marketplaces

One of the most convenient ways to locate necessary items is through online platforms. Websites like Amazons, eBay, and specialized retailers provide a vast selection of products. These platforms often include customer reviews, which can guide you in selecting the best quality and value.

Local Repair Shops

Another excellent option is visiting local repair shops or hardware stores. These establishments often carry a range of essential components and can provide personalized advice. Additionally, they may offer the opportunity to order specific items that may not be in stock, ensuring you receive precisely what you need.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular care not only enhances performance but also prevents unexpected breakdowns. By following a few simple practices, you can ensure that your machinery operates smoothly for years to come.

Routine Checks

Conducting regular inspections is vital. Look for signs of wear and tear, check fluid levels, and ensure all components are functioning as intended. Addressing minor issues promptly can save you from costly repairs later.

Cleaning and Storage

Keeping your equipment clean is crucial. Debris and dirt can lead to operational inefficiencies. After each use, make it a habit to remove any buildup. Additionally, proper storage protects against environmental damage, ensuring that your machinery remains in top condition.

| Maintenance Task | Frequency |

|---|---|

| Inspect belts and hoses | Monthly |

| Change oil | Every season |

| Clean air filter | Every use |

| Sharpen blades | Every 25 hours of use |

Common Issues and Solutions

Every machine can encounter challenges during its lifespan, leading to performance issues or malfunctions. Understanding these common problems and their remedies can greatly enhance the longevity and efficiency of your equipment. Below are some frequent concerns along with effective solutions.

Starting Difficulties

If your equipment struggles to start, the issue may stem from various sources. Check the fuel level and ensure it is fresh and clean. A clogged fuel filter or a faulty spark plug can also impede ignition. Regular maintenance, such as replacing filters and checking connections, can prevent these issues.

Uneven Cutting Performance

An uneven cutting performance can frustrate users and result in an unsightly lawn. This problem may arise from dull blades or improper tire pressure. Sharpening the blades regularly and ensuring the tires are inflated to the recommended levels can help achieve a uniform cut. Additionally, inspecting the cutting height settings can provide a more consistent finish.

By addressing these common issues proactively, you can maintain optimal operation and extend the lifespan of your machine.

DIY Repairs for LT2000 Owners

Maintaining your lawn equipment can save both time and money, empowering you to handle minor issues before they escalate. Whether you’re facing engine troubles, belt replacements, or electrical glitches, understanding basic repair techniques is essential for any owner. This section will guide you through common fixes that you can tackle on your own.

Start with the Basics: Familiarize yourself with the machinery and tools required for repairs. Keeping a well-stocked toolkit will make the process smoother. Essential items include wrenches, screwdrivers, and safety gear.

Engine Troubles: If your machine won’t start, check the fuel system, spark plug, and battery. Cleaning or replacing these components often resolves starting issues. Regular maintenance, such as oil changes, is crucial for optimal performance.

Belt Replacements: Worn or damaged belts can hinder performance. Consult your manual for instructions on how to remove and replace them. Ensure that you install the new belts correctly to avoid future problems.

Electrical Systems: For issues with lights or the ignition system, inspect fuses and wiring for signs of wear. Tightening connections can often restore functionality. If problems persist, replacing faulty components may be necessary.

By equipping yourself with knowledge and skills, you can effectively address common challenges, keeping your equipment in peak condition while enhancing your confidence in handling repairs.

Resources for Craftsmanship Support

When embarking on any repair or maintenance project, having access to reliable information and tools is essential for success. Various resources are available to assist enthusiasts in enhancing their skills, troubleshooting issues, and obtaining the necessary components for their tasks. These platforms offer valuable insights, whether through manuals, community forums, or instructional videos.

Online Manuals and Guides: Comprehensive manuals provide detailed instructions on assembly, disassembly, and maintenance. They often include troubleshooting tips that can save time and effort when faced with common problems.

Community Forums: Engaging with fellow enthusiasts through online forums can be incredibly beneficial. Members often share their experiences, offer advice, and discuss solutions to specific challenges, fostering a sense of camaraderie.

Tutorial Videos: Visual learners can benefit greatly from tutorial videos available on various platforms. These resources demonstrate techniques and processes in real-time, making it easier to understand complex tasks.

Local Supply Stores: Physical stores can be a great resource for finding quality materials and components. Knowledgeable staff can provide recommendations and advice, ensuring that you have the right tools for your project.

Support Groups: Joining local or online groups dedicated to craftsmanship can provide ongoing support and motivation. These communities often organize events, workshops, and discussions that can enhance skills and foster networking opportunities.

Customer Reviews and Experiences

This section focuses on user feedback and personal accounts related to maintenance and repair. Insights shared by individuals can greatly inform potential buyers and assist current owners in enhancing their experience with their equipment.

Many users highlight the ease of accessing components, which facilitates routine servicing and troubleshooting. Positive experiences often stem from the clear organization of replacement items, making it simple for owners to find what they need quickly. Additionally, reviews indicate satisfaction with the overall reliability and performance when properly maintained.

| Reviewer | Experience | Rating |

|---|---|---|

| John D. | Found parts easily and installation was straightforward. | 5/5 |

| Lisa M. | Good value for the price; excellent performance. | 4/5 |

| Mike R. | Had some trouble with finding specific items but overall satisfied. | 3/5 |

| Susan T. | Reliable service and quick shipping; very pleased. | 5/5 |

Overall, user experiences suggest that with the right resources, maintaining and improving equipment can be a straightforward and rewarding endeavor.