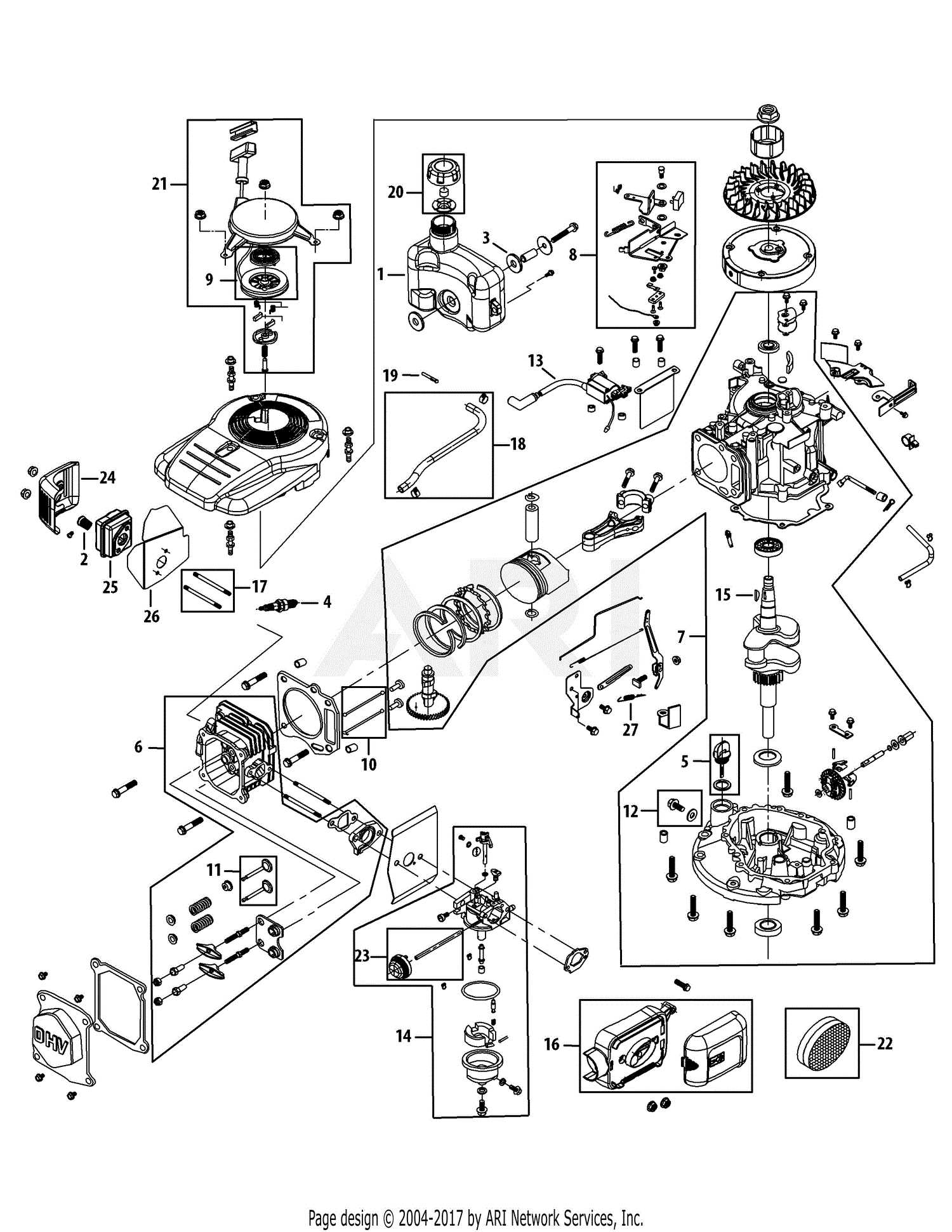

Mtd Engine Parts Diagram Overview

When delving into the complexities of outdoor equipment, it is essential to grasp the fundamental components that contribute to its functionality. Each element plays a crucial role in ensuring smooth operation, and recognizing how they interconnect can enhance both maintenance and performance. A comprehensive overview of these integral features is invaluable for any enthusiast or professional.

By exploring the layout of these essential components, users can gain insights into troubleshooting and repair processes. Understanding the arrangement and interaction of various elements fosters a deeper appreciation of how your tools perform under different conditions. This knowledge empowers users to make informed decisions, ultimately prolonging the lifespan of their machines.

Whether you are a seasoned mechanic or a curious novice, familiarizing yourself with the specific features of your equipment will facilitate better care and optimization. This exploration not only aids in effective upkeep but also instills confidence in handling potential challenges that may arise during operation. Knowledge is the key to unlocking the full potential of your machinery.

Mtd Engine Parts Overview

This section provides a comprehensive look into the components that contribute to the functionality of small machinery. Understanding these elements is essential for effective maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Components

- Power Source: Vital for driving the overall system.

- Fuel Delivery System: Ensures proper combustion and energy efficiency.

- Cooling Mechanism: Prevents overheating during operation.

- Lubrication System: Reduces friction and wear among moving parts.

- Air Intake: Facilitates the necessary airflow for combustion.

Maintenance Tips

- Regularly check and replace filters to ensure clean airflow and fuel delivery.

- Inspect the cooling system for blockages or leaks.

- Change oil periodically to maintain lubrication and prevent wear.

- Monitor performance and listen for unusual sounds during operation.

- Keep all components free of debris for optimal functionality.

Understanding Engine Component Functions

The functionality of various elements within a mechanical system is crucial for its overall performance. Each component plays a specific role, contributing to the harmonious operation of the whole assembly. Understanding these roles enhances our ability to maintain and optimize the machinery effectively.

Key Functions of Major Components

Every segment of the system is designed with a particular purpose in mind. By breaking down the functionalities, we can gain insights into how these parts interact and support one another.

| Component | Function |

|---|---|

| Crankshaft | Transforms linear motion into rotational motion. |

| Pistons | Compress fuel and air mixture and transfer energy. |

| Camshaft | Regulates the timing of valve openings and closings. |

| Valves | Control the flow of air and fuel in and out of the combustion chamber. |

| Connecting Rods | Link pistons to the crankshaft, facilitating movement. |

Importance of Each Role

Recognizing the importance of each function helps in diagnosing issues and improving performance. A well-coordinated operation among these elements is essential for achieving optimal efficiency and longevity.

Common Issues with Mtd Engines

Users often encounter various challenges with their machinery, which can stem from several underlying factors. Recognizing these frequent problems can lead to more effective maintenance and enhanced performance. Understanding the typical failures helps in troubleshooting and ensures longevity of the equipment.

Performance Problems

One of the most prevalent issues is a decline in performance. This can manifest as reduced power output or difficulty in starting. Factors contributing to this may include clogged filters, stale fuel, or wear and tear on internal components. Regular checks and replacements can mitigate these risks.

Overheating Concerns

Another common dilemma is overheating, which can lead to significant damage if not addressed promptly. This issue may arise from inadequate lubrication, blocked cooling fins, or malfunctioning cooling systems. Ensuring proper oil levels and keeping the cooling mechanisms clean are essential preventative measures.

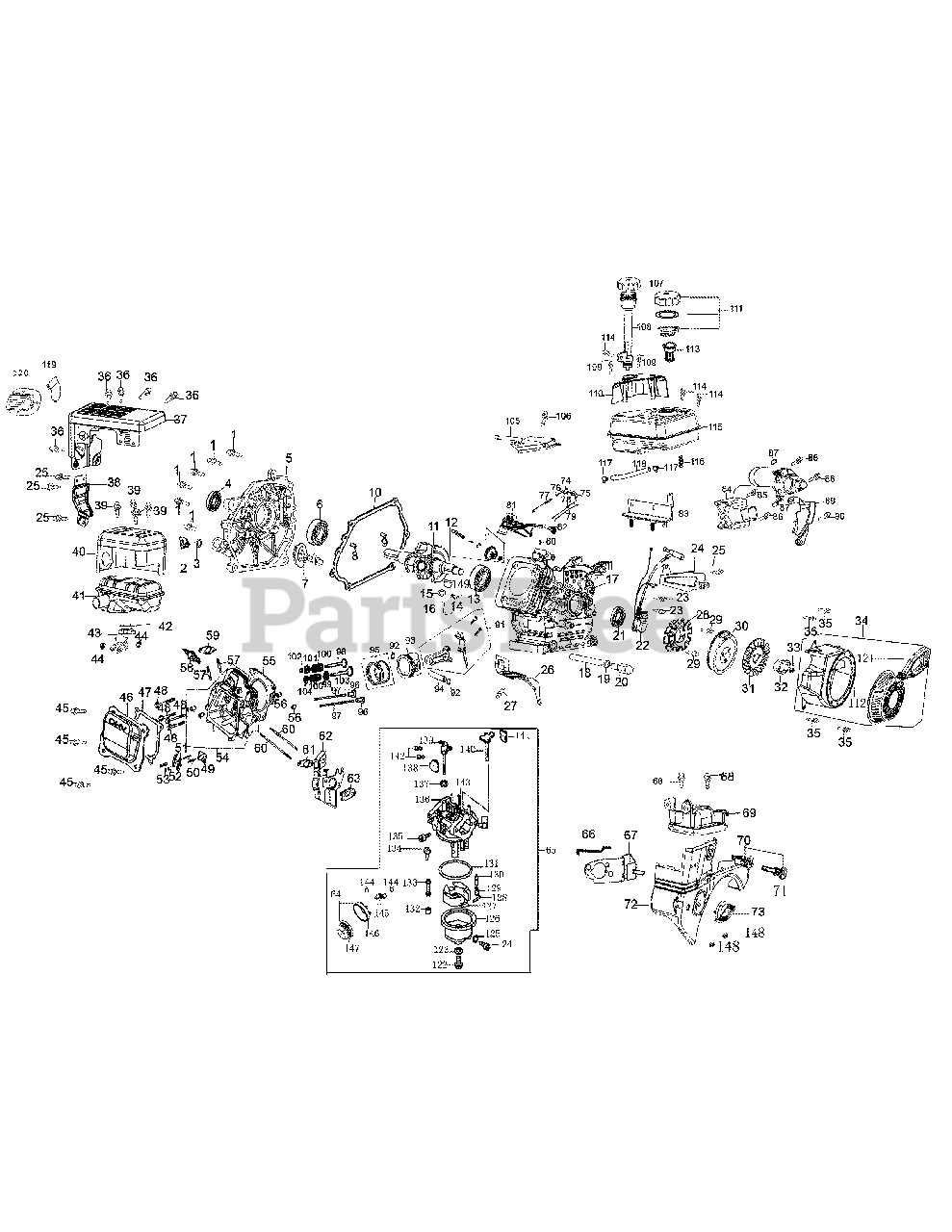

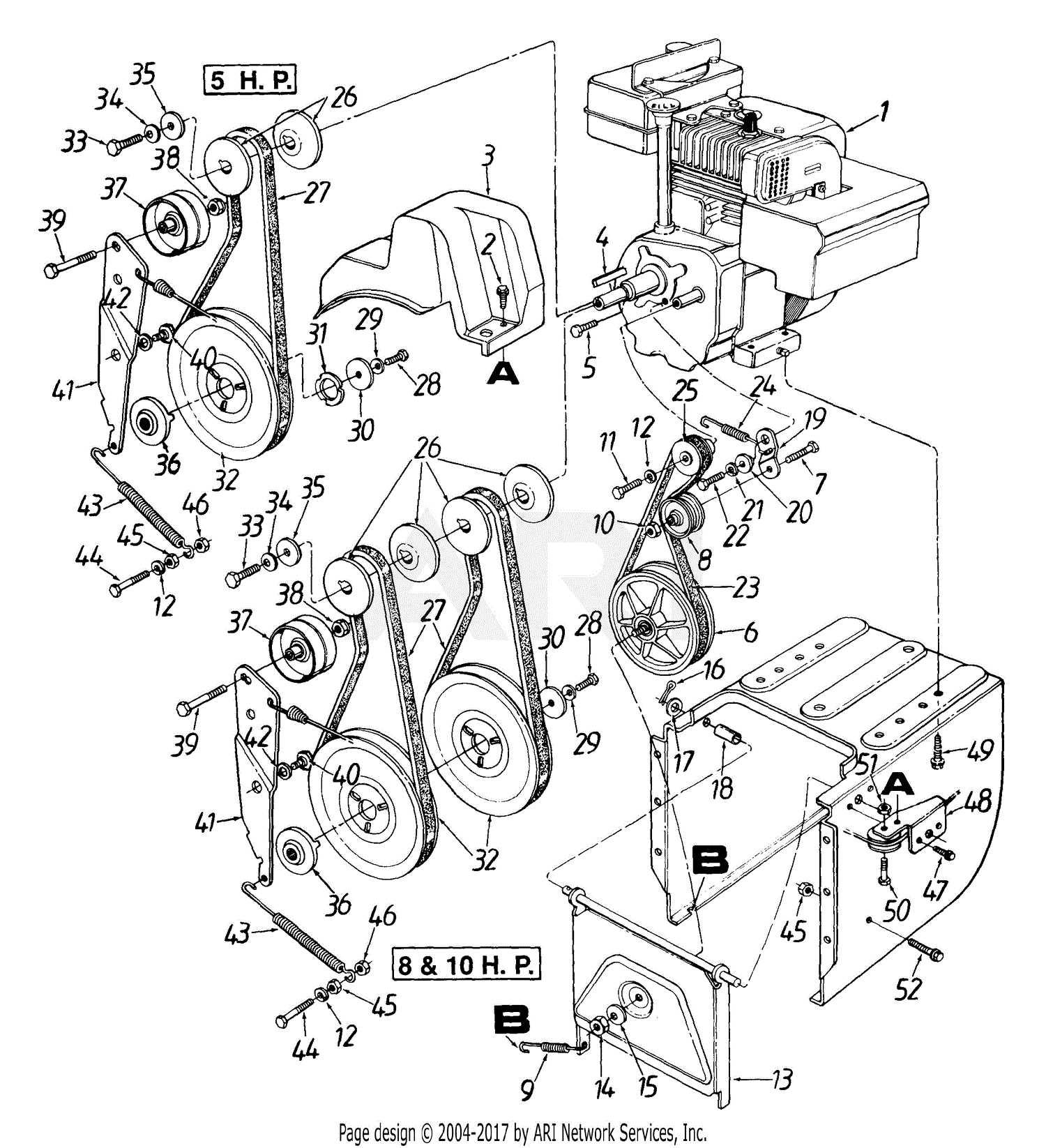

How to Read Engine Diagrams

Understanding visual representations of mechanical systems is essential for effective maintenance and troubleshooting. These illustrations provide a simplified view of complex structures, helping users identify components and their relationships. Familiarity with symbols and conventions used in these visuals is key to interpreting the information accurately.

Start by familiarizing yourself with the basic symbols and notations. Each component is often represented by a unique shape or icon, and knowing what each symbol stands for will enable you to navigate the illustration more easily. Look for a legend or key, which usually accompanies these visuals, as it will explain the meaning of each symbol.

Next, pay attention to the layout. Components are typically arranged in a logical sequence that reflects their operational flow. Understanding this flow is crucial, as it helps in grasping how various elements interact within the system. Notice how lines connecting different components indicate relationships, such as movement or power transmission.

Additionally, take note of any numerical labels or annotations. These often provide specifications such as dimensions, part numbers, or other vital data that can assist in identifying the correct replacements or repairs. When you see multiple views of the same component, use them to gain a comprehensive understanding of its structure and functionality.

Lastly, practice makes perfect. The more you work with these visual guides, the more intuitive reading them will become. Over time, you will develop a keen eye for details, allowing you to troubleshoot issues with confidence and efficiency.

Essential Tools for Maintenance

Proper upkeep of machinery requires a selection of crucial instruments that facilitate effective repairs and ensure longevity. Understanding the necessary tools not only streamlines the maintenance process but also enhances the overall efficiency of operations. Below, we outline the key implements that should be included in every maintenance toolkit.

Basic Tools

Every maintenance technician should start with a fundamental set of tools. These essentials lay the groundwork for any repair task, making them indispensable.

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening fasteners. |

| Screwdrivers | To drive screws and adjust components. |

| Pliers | For gripping, bending, and cutting wire. |

| Hammer | To drive nails or apply force to components. |

Specialized Equipment

In addition to basic tools, specialized equipment can greatly enhance maintenance capabilities. These items address specific tasks and provide additional support for more complex repairs.

| Equipment | Function |

|---|---|

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Diagnostic Scanner | Helps identify issues through error codes. |

| Multimeter | Measures voltage, current, and resistance in electrical systems. |

| Oil Filter Wrench | Facilitates the removal of oil filters during servicing. |

Replacing Worn Engine Parts

Maintaining optimal performance in machinery often requires the timely replacement of components that show signs of wear. Addressing these issues proactively not only enhances efficiency but also prolongs the lifespan of the entire system. Understanding when and how to replace these elements is crucial for achieving reliable functionality.

Identifying Worn Components

Recognizing the indicators of deterioration is the first step in ensuring smooth operation. Common signs include:

- Unusual noises during operation

- Decreased performance or power output

- Increased vibration or instability

- Visible wear or damage on the surface

- Fluid leaks or excessive emissions

Steps for Replacement

Once worn components are identified, the following steps can guide the replacement process:

- Gather necessary tools and replacement items.

- Ensure the machinery is powered off and secure.

- Carefully remove the damaged elements, noting their arrangement.

- Install the new components, ensuring proper alignment and fit.

- Test the machinery to confirm functionality and address any issues.

Regular inspection and timely replacement of essential elements can significantly enhance performance and reliability, leading to a more effective and durable operation overall.

Locating Replacement Parts Online

Finding suitable components for machinery can often be a daunting task, especially when dealing with older models or specialized equipment. Fortunately, the internet provides a wealth of resources to simplify this process. By leveraging various online platforms, users can access an extensive range of items that meet their specific requirements.

Start by identifying reliable websites that specialize in outdoor equipment or tools. Many of these sites feature user-friendly search functions, allowing you to enter model numbers or descriptions to locate what you need quickly. Additionally, it is beneficial to explore forums and community groups dedicated to your machinery type, as members often share valuable insights on sourcing components.

Comparing prices across different online retailers is essential to ensure you find the best deal. Pay attention to customer reviews and ratings, as they can provide insights into product quality and seller reliability. Additionally, consider reaching out to customer service for assistance in finding hard-to-locate items.

Don’t overlook the potential of online marketplaces. Many sellers offer new, used, or refurbished components at competitive prices. Always verify the authenticity of the sellers and check return policies before making a purchase. By following these steps, you can streamline your search and effectively secure the necessary components for your equipment.

Comparing Mtd Engine Models

This section delves into the various models within a specific range of small mechanical units, focusing on their unique features, performance metrics, and overall efficiency. Understanding the differences among these variations can assist users in selecting the most suitable option for their needs.

Performance Characteristics

Each model presents distinct performance characteristics, including power output, fuel efficiency, and torque. Some variations are designed for heavy-duty tasks, while others excel in lighter applications. Evaluating the specifications is crucial for making an informed decision based on the intended usage.

Design and Durability

The design and construction quality of these mechanical units also play a significant role in their longevity and reliability. Some models incorporate advanced materials and engineering techniques that enhance durability. Users should consider factors such as maintenance requirements and warranty options when comparing these choices to ensure long-term satisfaction.

Tips for Engine Troubleshooting

Diagnosing mechanical issues can often be a daunting task. However, with a systematic approach, identifying the root cause of malfunctions becomes manageable. By following a few practical strategies, one can streamline the troubleshooting process and enhance the chances of a successful resolution.

1. Begin with the Basics: Always start by checking the most fundamental aspects. Ensure that fuel levels are adequate and that there are no visible leaks. Inspect the battery connections for corrosion and tightness, as these can greatly impact performance.

2. Listen for Unusual Sounds: Pay attention to any abnormal noises during operation. Sounds such as knocking, grinding, or hissing can provide crucial clues about underlying problems. Documenting these noises can help in pinpointing issues more effectively.

3. Monitor Performance: Keep track of how the system behaves during use. Any changes in responsiveness, power output, or efficiency may indicate areas needing attention. Note down when these changes occur to help narrow down potential causes.

4. Check for Error Codes: If applicable, use diagnostic tools to retrieve error codes. These codes can offer specific insights into malfunctions, guiding you toward the components that may require inspection or replacement.

5. Consult the Manual: Referring to the user manual can provide valuable information regarding troubleshooting steps tailored to your model. It often includes detailed instructions and specifications that can assist in the diagnosis.

6. Seek Professional Help: If the problem persists despite your efforts, consider enlisting the help of a qualified technician. Sometimes, a trained eye can spot issues that may not be immediately obvious, saving time and resources in the long run.

By employing these strategies, one can effectively navigate through the challenges of mechanical issues and work towards a timely resolution.

Preventative Maintenance Strategies

Implementing effective preventative measures is crucial for enhancing the longevity and performance of machinery. By establishing a proactive approach, individuals and organizations can minimize unexpected breakdowns and ensure smooth operations over time.

Here are several key strategies to consider:

- Regular Inspections: Schedule consistent evaluations to identify potential issues before they escalate.

- Lubrication: Ensure all moving components are adequately lubricated to reduce friction and wear.

- Cleaning: Maintain cleanliness by removing debris and contaminants that can affect functionality.

- Monitoring Performance: Use diagnostic tools to track performance metrics and identify any anomalies.

- Scheduled Replacements: Replace worn or outdated components on a predetermined schedule to prevent failures.

By adopting these strategies, operators can not only enhance the efficiency of their systems but also extend the lifespan of their equipment, ultimately leading to cost savings and improved productivity.

Expert Recommendations for Mtd Owners

Maintaining your outdoor machinery is crucial for optimal performance and longevity. Proper care and regular check-ups can significantly enhance the efficiency and reliability of your equipment. Below are some key insights and practices to help you keep your tools in top shape.

Regular Maintenance Tips

- Inspect and clean the air filter regularly to ensure proper airflow.

- Change the oil according to the manufacturer’s schedule to keep components lubricated.

- Sharpen blades frequently to improve cutting performance and reduce strain on the motor.

- Check and tighten any loose bolts or screws to prevent operational issues.

- Store the equipment in a dry, sheltered area to protect it from the elements.

Parts Replacement Guidance

Knowing when to replace specific components can save you time and money in the long run. Consider the following:

- Monitor the condition of belts and cables; replace them if you notice fraying or cracking.

- Examine tires for wear and tear; maintain proper inflation for optimal traction.

- Regularly check for leaks in fuel lines and seals; prompt replacement can prevent more significant issues.

- Keep an eye on battery health; replace if you notice a decline in performance.

By following these expert recommendations, you can ensure that your machinery remains efficient and reliable throughout its lifespan.