Understanding the John Deere LT160 Mower Deck Parts Diagram

The effective functioning of a lawn care machine relies heavily on its individual components, which work harmoniously to achieve optimal performance. Understanding these elements can significantly enhance maintenance practices and overall longevity.

For enthusiasts and professionals alike, having a clear visual representation of these crucial segments can simplify repairs and replacements. This knowledge not only empowers users to tackle issues independently but also ensures that the machinery operates at peak efficiency.

In this section, we will explore the intricate layout of these elements, providing insights that allow for a deeper understanding and effective troubleshooting. By delving into each component, one can appreciate the engineering that goes into creating reliable lawn care solutions.

Understanding the LT160 Mower Deck

The functionality and design of lawn care equipment play a crucial role in maintaining healthy and aesthetically pleasing outdoor spaces. Exploring the components and mechanisms involved in these machines can enhance both performance and efficiency.

Key Features: One of the most important aspects to consider is how the assembly interacts with various terrains and grass types. Understanding these features can lead to improved results and less wear and tear.

Maintenance Insights: Regular upkeep of the various components ensures longevity and optimal performance. Familiarizing oneself with the different elements helps in troubleshooting and enhancing the overall operation.

In summary, delving into the intricacies of these machines provides insights that can lead to a more satisfying lawn care experience, ultimately achieving the desired results with ease.

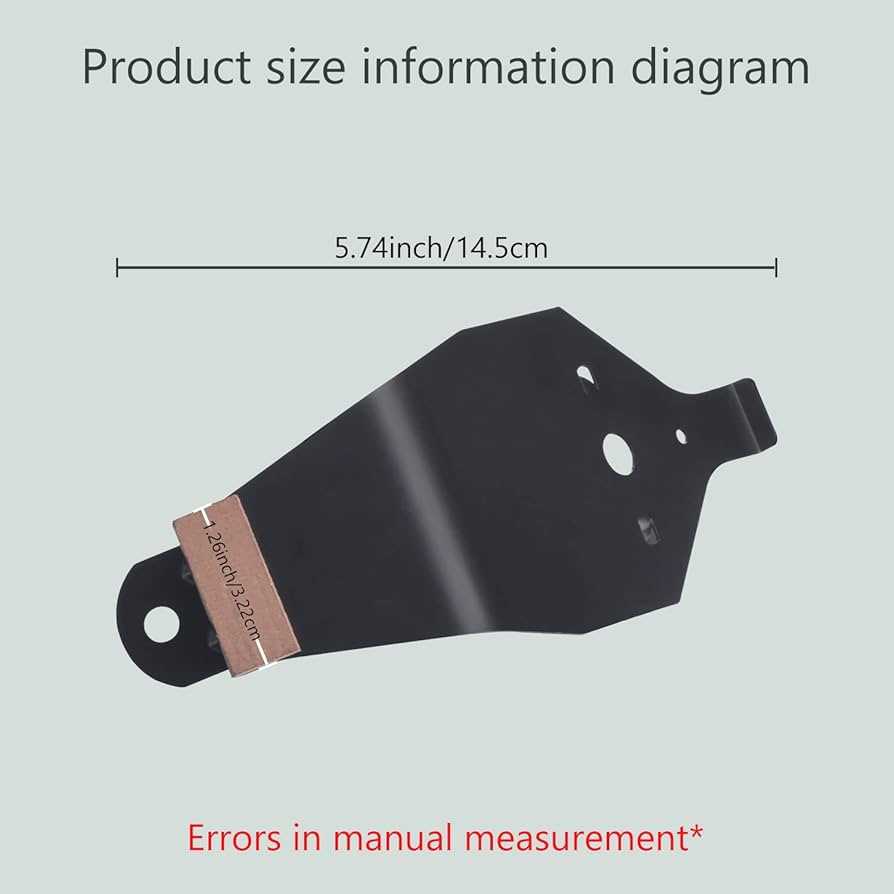

Key Components of Mower Deck

Understanding the essential elements of a cutting apparatus is crucial for maintaining optimal performance and longevity. Each part plays a significant role in ensuring effective operation and achieving the desired results in landscaping tasks.

Essential Elements

- Blades: The primary cutting tools that determine the quality of the trim.

- Spindles: Support and drive the blades, enabling them to rotate efficiently.

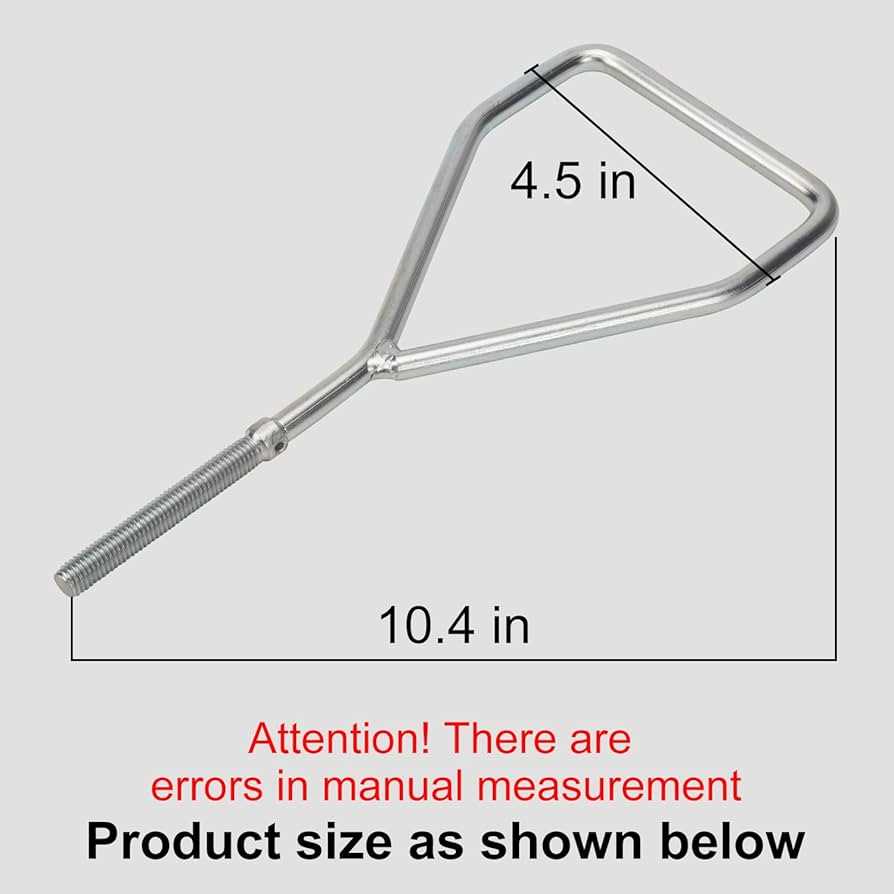

- Belt: Transfers power from the engine to the blades, essential for movement.

- Housing: Protects the internal components and provides structural integrity.

Additional Components

- Wheels: Aid in mobility and maneuverability across different terrains.

- Adjustable Hangers: Allow for customization of cutting height to suit various needs.

- Anti-scalp Wheels: Prevent the blades from damaging the lawn by keeping the cutting height consistent.

Importance of Regular Maintenance

Consistent upkeep is essential for the longevity and efficiency of any equipment. Regular attention not only ensures optimal performance but also helps in identifying potential issues before they escalate into significant problems. By adhering to a maintenance schedule, users can enhance the reliability of their machinery and reduce the risk of unexpected failures.

Routine checks and servicing contribute to better functionality, allowing equipment to operate at peak capacity. This proactive approach minimizes downtime, which can be costly, both in terms of repairs and lost productivity. Furthermore, maintaining equipment can lead to improved safety for users, as well-functioning machinery is less likely to malfunction.

Additionally, regular care can positively impact the overall value of the equipment. Well-maintained items typically retain their worth longer, making them more appealing for resale or trade-in. Overall, investing time in maintenance pays off by ensuring efficiency, safety, and longevity.

How to Identify Part Numbers

Identifying component identifiers can be crucial for maintaining and repairing equipment. Understanding how to locate and interpret these numbers ensures that you can efficiently find the correct replacements or accessories. This section will guide you through the process of determining these identifiers and provide tips for successful identification.

Steps to Locate Component Identifiers

Begin by examining the equipment closely. Most identifiers are printed on or near the component itself. Here are some common locations:

- On the surface of the part

- Near mounting points

- On accompanying documentation or manuals

Using Manufacturer Resources

Manufacturers often provide resources to assist in identifying component identifiers. Utilizing online catalogs, official websites, or customer service can enhance your search. Here is a simple reference table for quick identification:

| Location | Tip |

|---|---|

| Part Surface | Look for raised or engraved numbers |

| Manuals | Check for illustrations or reference tables |

| Online Resources | Utilize search functions for quick access |

Common Issues with LT160 Deck

When maintaining a lawn care machine, various challenges may arise, impacting its overall performance and efficiency. Understanding these common complications can aid users in troubleshooting and ensuring optimal functionality.

1. Uneven Cutting

One prevalent concern is uneven cutting, which can result from misaligned components or worn blades. Regular inspection and adjustment of the cutting elements are essential to achieving a uniform lawn appearance.

2. Excessive Vibration

Excessive vibration during operation can indicate issues such as imbalance or loose fixtures. Addressing these problems promptly not only enhances comfort but also prolongs the lifespan of the machine.

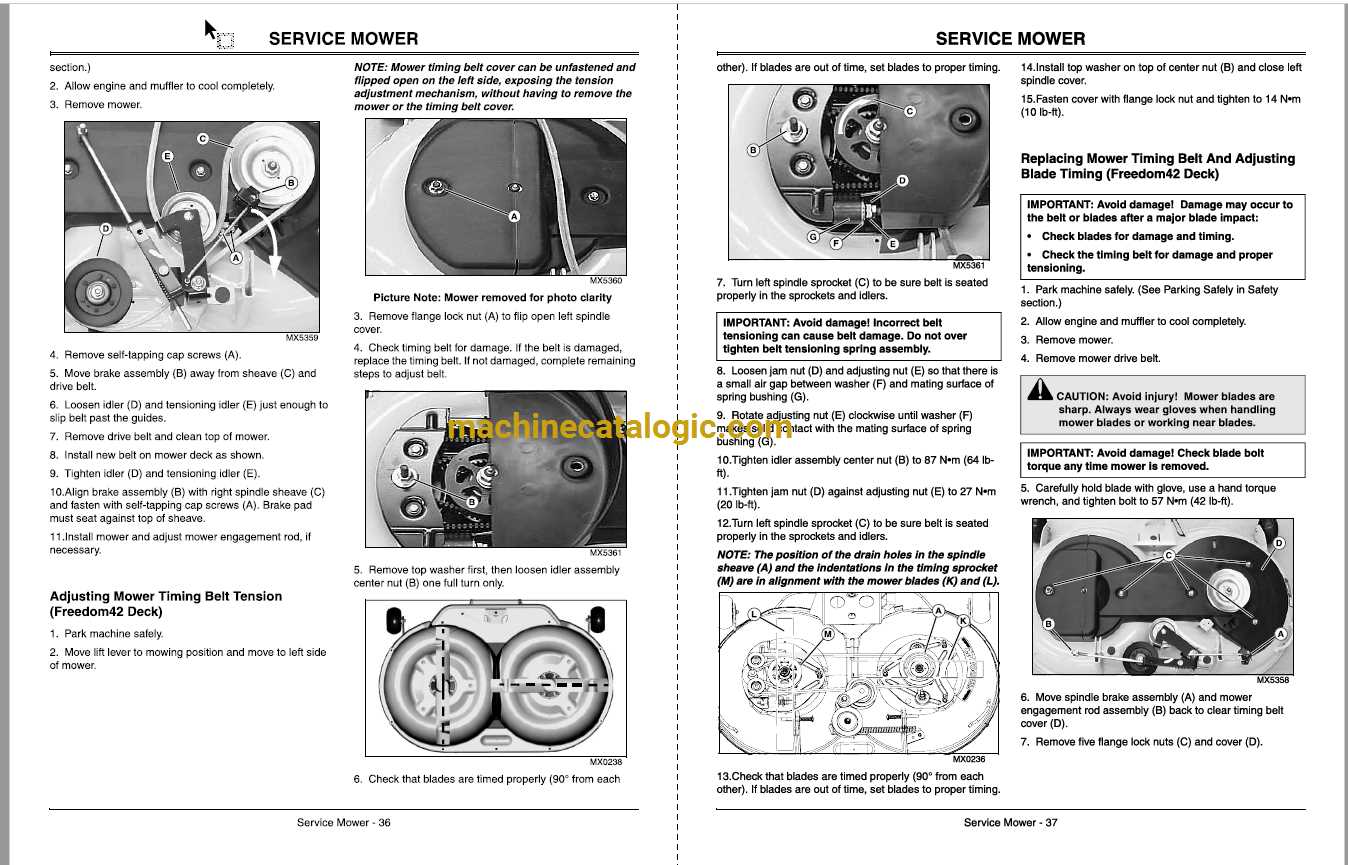

Step-by-Step Assembly Guide

This section provides a detailed approach to assembling the components of your gardening equipment efficiently. By following these instructions carefully, you can ensure that each part fits correctly, enhancing the performance and longevity of your machine.

Before beginning, gather all necessary tools and components. Ensure you have a clean workspace to prevent any small items from getting lost during the assembly process.

| Step | Description |

|---|---|

| 1 | Start by laying out all components in an organized manner, categorizing by type for easy access. |

| 2 | Begin attaching the frame pieces, ensuring each part aligns with the designated slots. |

| 3 | Secure all connections with the appropriate fasteners, checking for tightness without over-tightening. |

| 4 | Install any belts or chains, making sure they are routed correctly to avoid slippage during operation. |

| 5 | Attach any additional components, such as guards or covers, to protect moving parts from debris. |

| 6 | Perform a final inspection of all connections and ensure that moving parts operate smoothly. |

Following these steps will lead to a successful assembly, readying your equipment for effective use in your gardening tasks. Remember to consult your manual for any specific details related to your model.

Tips for Effective Troubleshooting

When encountering issues with machinery, a systematic approach can significantly enhance problem resolution. Identifying symptoms and understanding the underlying mechanisms will streamline the process and lead to quicker fixes.

Step-by-Step Approach

Begin by isolating the problem. Take note of any unusual sounds, vibrations, or performance drops. Document your observations, as these details can guide your investigation.

Common Issues and Solutions

| Issue | Potential Solution |

|---|---|

| Unresponsive engine | Check fuel supply and battery connections. |

| Uneven performance | Inspect blades for damage or obstruction. |

| Overheating | Examine air filters and cooling systems. |

Upgrading Your Mower Deck

Enhancing your cutting apparatus can lead to improved performance and efficiency in your lawn maintenance tasks. By selecting quality components and ensuring compatibility with your existing machinery, you can achieve a superior finish and increased durability. This section will explore the key considerations and options for upgrading your equipment.

Benefits of Upgrading

Investing in advanced components can result in a smoother operation, reduced maintenance requirements, and enhanced grass handling. Upgraded systems may also provide more precise cutting, allowing for a healthier lawn overall.

Essential Components to Consider

| Component | Description |

|---|---|

| Blades | High-quality, sharp blades can make a significant difference in cutting efficiency and finish. |

| Spindles | Reliable spindles ensure smooth rotation and reduce wear over time, enhancing overall performance. |

| Belts | Durable belts are crucial for optimal power transfer and preventing slippage during operation. |

Where to Buy Replacement Parts

Finding high-quality components for your equipment is essential for maintaining its performance and longevity. There are several reliable sources where you can acquire these necessary items, ensuring your machinery remains in top shape.

Online Retailers

Numerous online platforms specialize in offering a wide range of components. Websites like Amazon and eBay provide convenient options, allowing you to compare prices and read customer reviews. Additionally, dedicated suppliers often have extensive inventories tailored to specific models.

Local Dealerships and Stores

Visiting nearby dealerships or hardware stores can be beneficial. Many local establishments stock essential components or can order them for you. Building relationships with local suppliers may also lead to expert advice on compatibility and installation.

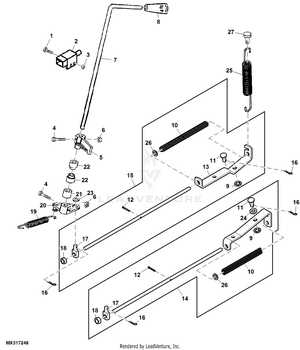

Diagram Overview for Easy Reference

This section aims to provide a clear visual representation for better understanding and quick identification of components related to the machine’s operational mechanism. Having an organized illustration allows users to easily locate and recognize each element, facilitating efficient maintenance and troubleshooting.

| Component | Description |

|---|---|

| Blade Assembly | Includes the sharp cutting blades responsible for trimming grass effectively. |

| Chassis | The main frame that supports the entire unit, ensuring stability during operation. |

| Drive Belt | A crucial component that transfers power from the engine to the cutting mechanism. |

| Wheel Housing | Encases the wheels, providing protection and facilitating smooth movement. |

| Height Adjustment Lever | Allows the user to modify the cutting height for different grass types and conditions. |

Expert Recommendations for Longevity

Maintaining the efficiency and lifespan of your lawn care equipment requires a proactive approach. Regular upkeep not only ensures optimal performance but also reduces the likelihood of costly repairs down the line. Here are some essential tips to enhance durability and reliability.

Regular Cleaning: Keeping your equipment clean is crucial. Debris buildup can lead to rust and wear. After each use, take a moment to remove grass clippings and dirt to prevent corrosion.

Routine Inspections: Conduct frequent checks of all components. Look for signs of wear, such as cracks or loose fittings. Identifying issues early can prevent more significant problems and extend the life of your machinery.

Proper Lubrication: Ensure all moving parts are adequately lubricated. This reduces friction and wear, allowing components to function smoothly. Use high-quality oils and greases recommended by manufacturers.

Seasonal Maintenance: At the start of each season, perform comprehensive maintenance. This should include changing filters, sharpening blades, and checking belts. Seasonal upkeep keeps equipment running efficiently during peak usage times.

Storage Practices: Store your machinery in a dry, sheltered area. Protect it from extreme weather conditions that can lead to deterioration. Covering equipment when not in use also helps prevent dust accumulation.

By following these expert recommendations, you can significantly enhance the longevity of your lawn care tools, ensuring they remain in excellent working condition for years to come.