Poulan Pro Riding Lawn Mower Parts Diagram Explained

In the realm of outdoor maintenance, comprehending the intricate workings of your machinery is essential for optimal performance. Each element plays a pivotal role, contributing to the overall efficiency and functionality of the equipment. A clear representation of these components aids in identifying issues and enhancing usability.

By exploring the various sections of your device, you can gain insights into its structure and how each part interacts with the others. This knowledge empowers users to perform maintenance effectively, ensuring longevity and reliability. With the right understanding, troubleshooting becomes a simpler task, paving the way for successful outdoor endeavors.

Whether you’re a seasoned user or a newcomer, familiarizing yourself with the intricate details of your machine can lead to better care and performance. Delving into the specifics not only equips you with practical skills but also enriches your overall experience. Ultimately, mastering the components will enhance your gardening and landscaping tasks.

Poulan Pro Mower Overview

This section offers a comprehensive look at a specific type of outdoor maintenance equipment, designed for efficient grass trimming and landscape upkeep. It encompasses various features that enhance usability, performance, and durability, catering to both residential and commercial users.

Known for their reliability, these machines are equipped with powerful engines and ergonomic controls, ensuring a smooth operation. Users appreciate the cutting efficiency and the ease with which these tools can navigate diverse terrains.

Additionally, the availability of a range of attachments and accessories allows for customized usage, making them versatile for multiple gardening tasks. Understanding the core components and functionalities is essential for optimal performance and maintenance.

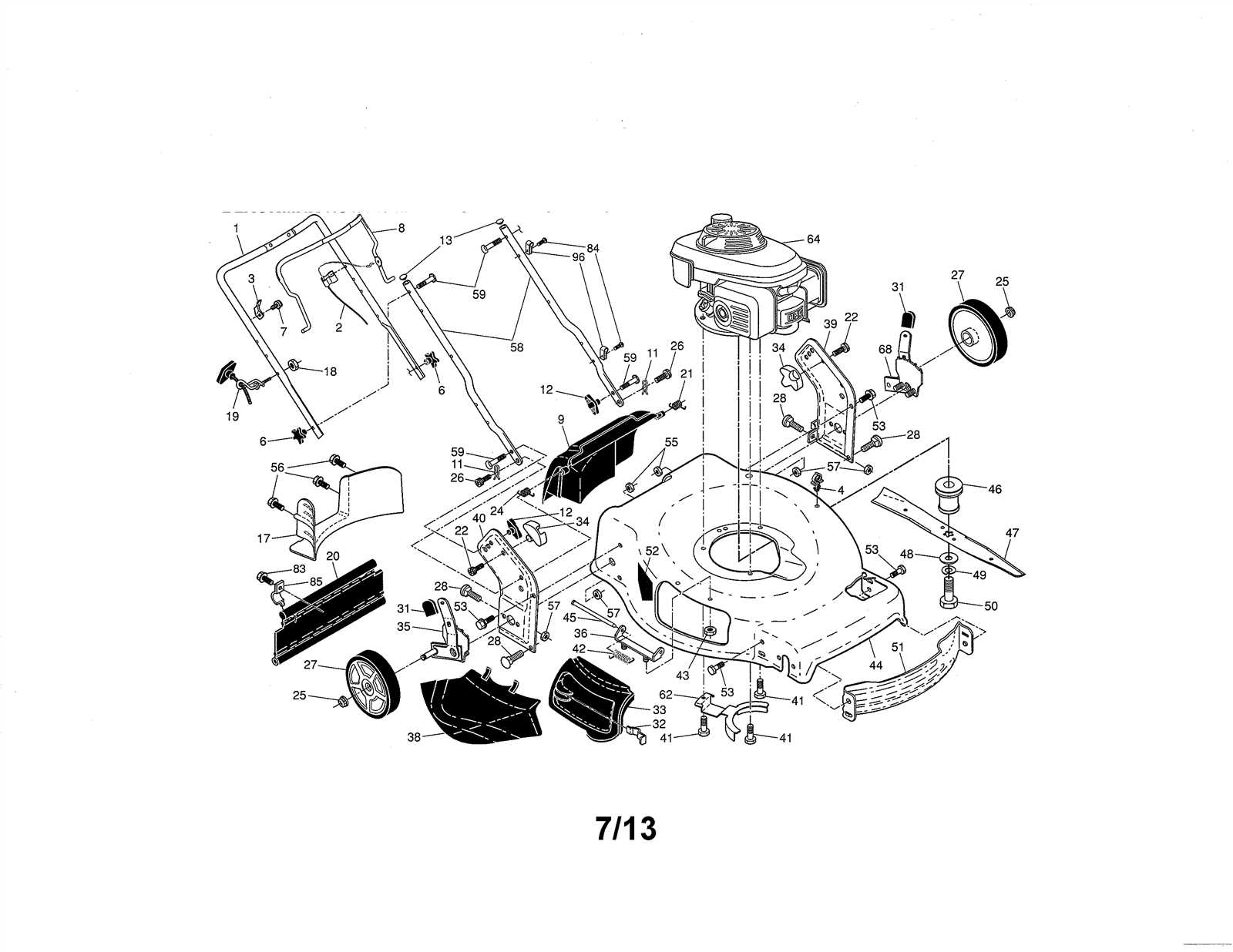

Key Components of Riding Mowers

Understanding the essential elements of these machines can significantly enhance their performance and maintenance. Each component plays a crucial role in ensuring efficiency and longevity.

- Engine: The powerhouse responsible for providing the necessary energy.

- Transmission: This system transfers power from the engine to the wheels, affecting speed and maneuverability.

- Chassis: The frame that supports all other components, providing stability and durability.

- Cutting Deck: This is where the grass is trimmed, featuring blades that require regular inspection and sharpening.

- Wheels: Essential for mobility, their size and tread influence traction and handling.

Each of these elements contributes to the ultimate functionality of the equipment, making it vital to understand their individual significance.

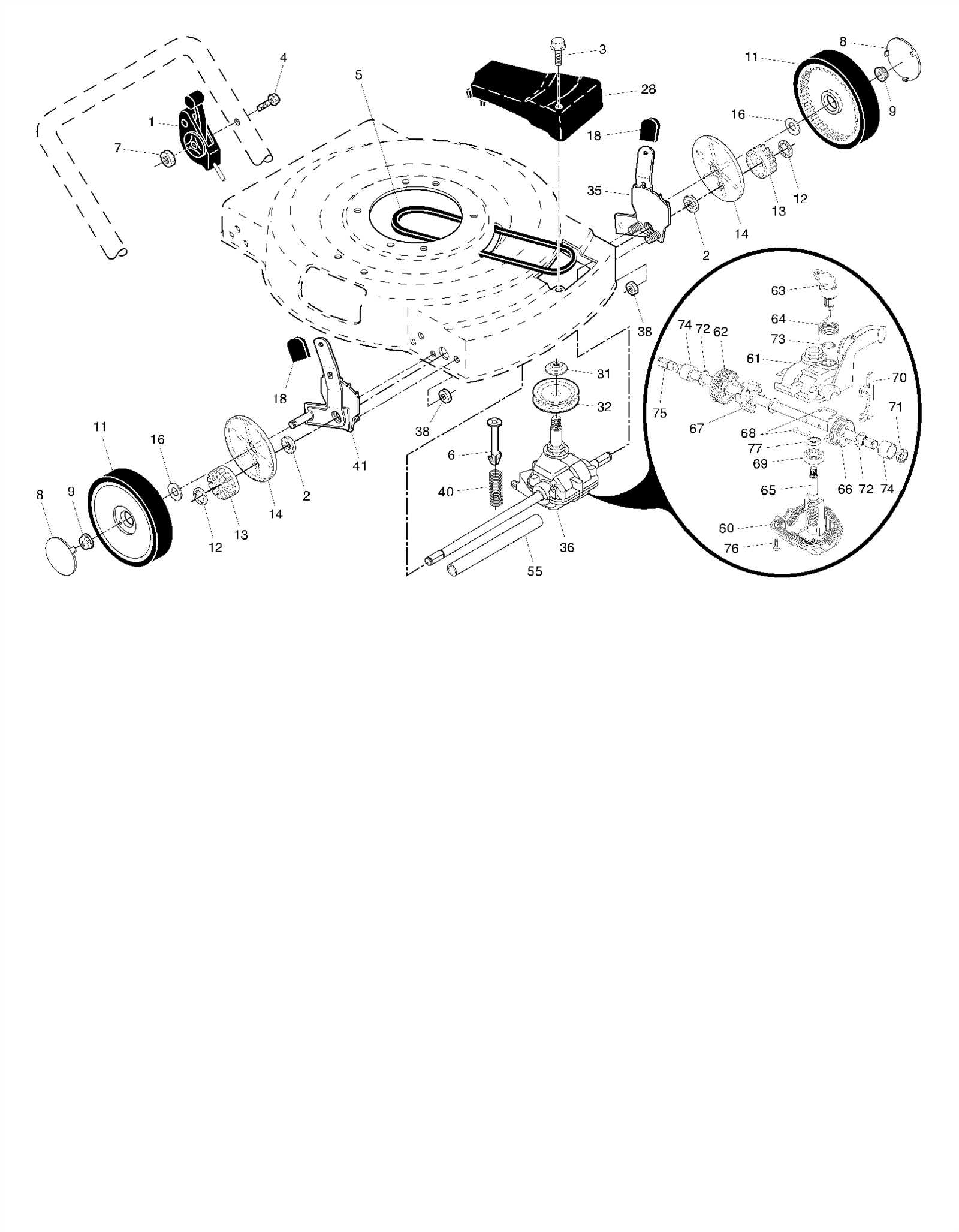

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing clarity on the arrangement and function of each element. This knowledge empowers users to tackle issues efficiently, reducing downtime and improving performance.

Enhancing Troubleshooting

Accurate illustrations facilitate quick identification of malfunctioning components, allowing for timely interventions. Users can pinpoint problems without extensive disassembly, streamlining the repair process.

Streamlining Replacement Processes

Having clear visuals aids in ensuring the correct selection of substitutes. Users can confidently navigate their options, minimizing errors during replacements.

| Benefit | Description |

|---|---|

| Clarity | Provides a clear view of the assembly. |

| Efficiency | Reduces time spent on repairs. |

| Accuracy | Ensures correct parts are identified. |

Common Issues with Lawn Mower Parts

Understanding the frequent challenges faced with garden maintenance equipment can significantly enhance its performance and longevity. Regular use often reveals various concerns that may hinder functionality, making it crucial to identify and address these issues promptly.

Mechanical Failures

One of the most prevalent difficulties arises from mechanical malfunctions. Wear and tear on moving components can lead to decreased efficiency. Routine checks can help spot signs of fatigue early on, preventing more extensive repairs.

Fuel System Problems

Another common challenge involves the fuel delivery system. Blockages or contamination can disrupt the flow, resulting in poor operation. Regular cleaning and maintenance of the fuel components are essential to ensure optimal performance.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. By familiarizing yourself with the layout and labels, you can quickly identify necessary items and their functions within a system.

Key Elements to Focus On

When examining a schematic, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Indicate the specific names or numbers of components. |

| Lines | Show connections or relationships between various parts. |

| Legend | Provides explanations for symbols or codes used in the representation. |

Steps to Interpret the Representation

Begin by locating the legend to understand the symbols. Next, follow the lines to grasp how components interact, and finally, use the labels to find replacement options or to order additional items.

Where to Find Poulan Pro Diagrams

Locating schematics for outdoor equipment can significantly enhance maintenance and repair processes. Understanding the layout and components of your machinery not only simplifies repairs but also helps in sourcing the right components. Fortunately, there are several reliable resources available for obtaining these valuable illustrations.

Online Resources

The internet offers a plethora of platforms where users can access detailed schematics. Manufacturer websites often host downloadable versions, ensuring that users have the most accurate and updated information. Additionally, forums and community websites dedicated to outdoor equipment are excellent places to find shared resources from experienced users.

Local Dealerships and Repair Shops

Visiting local dealerships or repair shops can provide direct access to printed or digital schematics. Professionals in these establishments can offer insights and additional advice on repairs and part replacements. Moreover, they might have access to exclusive resources that are not readily available online.

| Resource Type | Description |

|---|---|

| Manufacturer Website | Official site offering downloadable schematics and manuals. |

| Online Forums | Community-driven platforms for sharing resources and advice. |

| Local Dealerships | Physical locations with knowledgeable staff and printed resources. |

| Repair Shops | Specialized services that can provide both diagrams and repair assistance. |

Maintenance Tips for Riding Mowers

Regular upkeep is essential for ensuring the longevity and efficiency of your outdoor machinery. Proper care not only enhances performance but also minimizes the risk of unexpected breakdowns. Implementing a consistent maintenance routine can lead to optimal functionality and a smoother operation.

Check the Oil: Periodically inspect and change the lubricant to keep the engine running smoothly. Clean oil prevents wear and tear, contributing to a longer lifespan.

Sharpen the Blades: Ensuring that the cutting edges are sharp allows for clean cuts, promoting healthy growth of grass and reducing stress on the engine.

Clean the Deck: Regularly remove grass clippings and debris from the underside of the cutting deck to maintain efficiency and prevent rust.

Inspect Tires: Keep an eye on tire pressure and tread wear. Properly inflated tires ensure better traction and maneuverability.

Replace Air Filters: A clean air filter enhances engine performance. Check and replace filters as needed to ensure proper airflow.

Store Properly: During off-seasons, store your equipment in a dry, sheltered place to protect it from the elements and prolong its life.

Replacing Worn-Out Components

Over time, various elements of machinery can experience wear and tear, affecting overall performance and efficiency. Addressing these issues promptly not only enhances functionality but also extends the lifespan of the equipment.

Identifying Wear Signs

Recognizing the signs of deterioration is crucial for timely replacements. Common indicators include unusual noises, decreased efficiency, and visible damage.

Replacement Process

Once worn components are identified, the replacement process involves several steps. Ensure the machine is turned off and disconnected from power. Follow a systematic approach to remove the faulty parts and install the new ones.

| Component | Symptoms of Wear | Recommended Action |

|---|---|---|

| Belt | Slipping or fraying | Replace immediately |

| Blade | Dullness or chips | Sharpen or replace |

| Battery | Short life or failure to charge | Install a new battery |

Identifying Part Numbers Quickly

Efficiently locating the correct identifiers for machinery components is crucial for seamless maintenance and repair. A clear understanding of the various elements involved can significantly expedite this process, allowing users to minimize downtime and enhance productivity.

| Component | Identifier | Description |

|---|---|---|

| Blade | 123456 | Standard cutting blade for optimal performance. |

| Engine | 654321 | Powerful engine with reliable output. |

| Wheel | 789012 | Durable wheel for enhanced mobility. |

| Deck | 345678 | Sturdy deck for improved stability. |

Tools Needed for Repairs

Proper maintenance and repair of outdoor machinery require specific instruments to ensure efficiency and safety. Utilizing the right tools not only facilitates the repair process but also enhances the longevity of the equipment. A well-equipped toolbox is essential for tackling various tasks, from minor adjustments to major overhauls.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for assembling and disassembling components. For more intricate work, socket sets and ratchets are invaluable, allowing access to tight spaces. Additionally, specialty tools like torque wrenches are crucial for ensuring that bolts are tightened to the manufacturer’s specifications.

Safety equipment should not be overlooked. Wearing gloves, goggles, and masks protects the user from potential hazards during repair tasks. Keeping a first-aid kit nearby is also advisable in case of unexpected accidents.

Lastly, having a good work surface, such as a sturdy bench or a clean floor space, can significantly improve efficiency. With the right tools and preparation, repairing machinery can become a manageable and rewarding endeavor.

Purchasing Genuine Poulan Pro Parts

When it comes to maintaining outdoor equipment, choosing authentic components is crucial for optimal performance and longevity. Genuine items ensure compatibility and reliability, safeguarding your investment while enhancing efficiency.

Benefits of Authentic Components

Utilizing original pieces guarantees a perfect fit, minimizing the risk of malfunction. Quality materials and precise engineering translate into superior functionality, ultimately prolonging the lifespan of your machinery. Investing in these parts is a wise choice for anyone seeking durability.

Where to Find Genuine Items

Reputable dealers and official retailers are the best sources for authentic components. Researching online platforms can also yield reliable options, ensuring you receive what you need without compromise. Remember, choosing the right source is just as important as the component itself.

Upgrades for Enhanced Performance

Improving the efficiency and effectiveness of your outdoor equipment can significantly enhance your experience and outcomes. By focusing on key areas such as power, handling, and versatility, you can ensure that your machine operates at its best, providing superior results in various conditions. Strategic upgrades can transform a standard model into a high-performing tool that meets specific needs.

One effective way to boost performance is by upgrading the engine components. A high-efficiency air filter or a performance exhaust system can improve airflow, resulting in better combustion and increased power output. Additionally, enhancing the fuel system with high-grade fuel injectors can optimize fuel delivery, leading to smoother operation and improved fuel efficiency.

Another crucial area for enhancement is the cutting system. Investing in high-quality blades that are designed for durability and sharpness can significantly improve cutting efficiency. Opting for mulching blades can also allow for better grass decomposition, enriching the soil in your yard while reducing waste.

For improved maneuverability, consider upgrading the tires to ones designed for better traction and stability. This adjustment can make a noticeable difference when navigating uneven terrain or during wet conditions. Furthermore, adding a suspension system can enhance comfort and control, allowing for a more enjoyable operation.

Lastly, incorporating advanced technology can elevate performance levels. GPS navigation systems or automatic shut-off features can provide added convenience and efficiency, making tasks easier and more precise. By thoughtfully selecting upgrades, you can create a tailored solution that maximizes productivity and effectiveness in your outdoor endeavors.

Safety Considerations During Repairs

When engaging in mechanical maintenance, prioritizing safety is essential to ensure a secure and effective repair process. Understanding the potential hazards associated with machinery is vital for any individual undertaking such tasks.

First and foremost, always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. This minimizes the risk of injuries from sharp components or accidental contact with moving parts.

Additionally, ensure that the machine is turned off and disconnected from any power source before beginning any work. This simple step can prevent unexpected starts that could lead to serious accidents.

It is also important to keep the workspace organized and free of clutter. A clean environment reduces the likelihood of slips, trips, and falls, allowing for a more focused and efficient repair experience.

Lastly, familiarize yourself with the equipment’s manual and guidelines. Understanding the machinery’s functions and specifications is crucial for safe and effective repairs, ensuring you can delve deeper into any issues that arise.