Troy Bilt Lawn Tractor Parts Diagram Guide

For enthusiasts and professionals alike, maintaining outdoor machinery is essential for ensuring optimal performance. An intricate network of elements works together seamlessly to achieve efficiency and reliability. Familiarity with these components can significantly enhance your ability to troubleshoot and repair equipment when necessary.

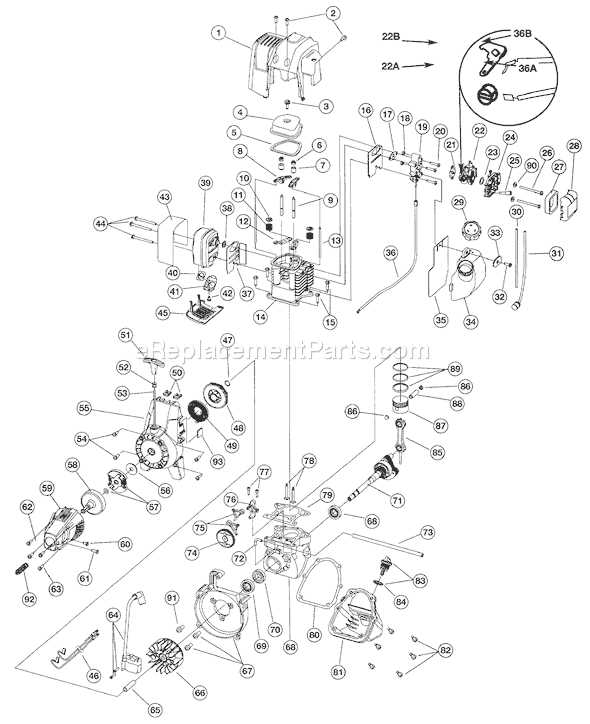

Visual representations of machinery layouts play a crucial role in grasping how each piece interacts with others. These illustrations not only simplify the identification of specific components but also provide insights into their functions and placements. By delving into these visual aids, users can develop a more profound understanding of their tools, facilitating better care and management.

Whether you’re embarking on a repair project or simply looking to familiarize yourself with your equipment, having access to comprehensive visual guides is invaluable. They serve as a reference point for anyone seeking to enhance their skills and ensure their machines operate at peak efficiency. Understanding the intricate design of your tools empowers you to maintain them effectively and prolong their lifespan.

Understanding Troy Bilt Lawn Tractors

In the realm of outdoor machinery designed for residential landscaping, there exists a category of robust, multi-functional vehicles that facilitate various tasks across expansive green spaces. These machines embody a blend of mechanical prowess and ergonomic design, tailored to enhance efficiency and comfort during prolonged operation.

The Essence of Modern Garden Workhorses

These vehicles serve as stalwart companions in the realm of garden maintenance, offering a harmonious fusion of power, precision, and adaptability. They are meticulously engineered to navigate intricate terrain with finesse, leveraging a symphony of mechanical components that harmoniously cooperate to deliver reliable performance.

Within this specialized niche, the focus rests not merely on functionality but on the seamless integration of intuitive controls and ergonomic features. This ensures that operators can maneuver effortlessly, translating their intentions into precise actions without undue physical strain.

Embodying Innovation and Reliability

Embedded within the core of these machines is a commitment to innovation, where each iteration refines the artistry of outdoor care. They represent a pinnacle of technological advancement, incorporating cutting-edge materials and engineering principles to withstand the rigors of prolonged use under varying environmental conditions.

Ultimately, these garden workhorses stand as a testament to the intersection of craftsmanship and utility, offering homeowners and landscapers alike a reliable ally in their pursuit of maintaining verdant, meticulously manicured lawns.

Key Components of Lawn Tractors

Understanding the essential elements of these machines is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance, contributing to efficiency and reliability during usage. Familiarity with these key aspects allows users to troubleshoot issues and perform necessary repairs.

Engine: The heart of the machine, it powers all functions and determines performance levels. Different types and sizes of engines offer varying capabilities, impacting speed and cutting efficiency.

Transmission: This component transmits power from the engine to the wheels, allowing for smooth operation. There are various types of transmissions, including manual and automatic, each providing different user experiences.

Cutting Deck: Responsible for the actual mowing process, this part houses the blades. The design and size of the cutting deck significantly influence the quality of the cut and the width of the mowing path.

Chassis: The frame supports all other components and ensures stability. A robust chassis contributes to the durability and longevity of the equipment.

Wheels and Tires: These components provide mobility and traction. The size and tread design can affect maneuverability and performance on various terrains.

Fuel System: This system supplies the engine with the necessary fuel for operation. Proper maintenance of the fuel lines and filter is essential for efficiency and performance.

Electrical System: This includes the battery, wiring, and ignition system. A well-functioning electrical system is crucial for starting the machine and powering lights and accessories.

By gaining a deeper understanding of these fundamental components, users can enhance their experience and ensure their machinery remains in peak condition.

Common Parts Diagrams Explained

Understanding the various components of outdoor machinery is essential for effective maintenance and repair. Visual representations of these components serve as valuable guides, helping users identify each part and its function. This section delves into the significance of these illustrations and how they can simplify the repair process.

These graphical aids not only clarify the arrangement of individual elements but also highlight the relationships between them. By familiarizing oneself with these visuals, one can enhance troubleshooting skills and ensure a smoother workflow when dealing with mechanical issues.

| Component | Description | Function |

|---|---|---|

| Engine | The powerhouse of the machine. | Generates the necessary power for operation. |

| Deck | The main body housing the cutting mechanism. | Provides stability and houses blades for cutting. |

| Transmission | System responsible for power transfer. | Controls speed and direction of movement. |

| Wheels | Supportive structures for mobility. | Facilitate movement across various terrains. |

By utilizing these illustrations, users can more effectively locate and address issues, ensuring longevity and optimal performance of their equipment.

Importance of Accurate Diagrams

Clear and precise illustrations play a crucial role in the maintenance and repair of machinery. They provide a visual representation that simplifies complex systems, enabling users to understand the components and their interconnections more effectively. Accurate schematics are essential for anyone seeking to troubleshoot issues or perform replacements, ensuring that tasks are executed with confidence and precision.

Facilitating Repairs and Maintenance

When engaging in repairs, having reliable visuals helps in identifying specific elements quickly. This efficiency minimizes downtime, allowing for smoother operation and longevity of equipment. Furthermore, well-detailed illustrations can prevent errors during assembly or disassembly, reducing the risk of costly mistakes and enhancing overall safety.

Enhancing Learning and Understanding

Illustrations not only assist in practical tasks but also contribute to a deeper understanding of how systems function. For novices and experienced users alike, these visuals serve as educational tools that promote better comprehension of machinery. By studying accurate representations, individuals can develop skills that lead to more informed decision-making in the long run.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visual guides break down components into clear segments, making it easier to identify each element’s role and relationship within the overall system. By familiarizing yourself with these visuals, you can streamline your repair processes and enhance your troubleshooting skills.

To effectively interpret these illustrations, follow these steps:

| Step | Description |

|---|---|

| 1 | Begin by examining the title or legend, which typically explains the purpose of the illustration and the specific model it pertains to. |

| 2 | Look for a key that indicates the symbols used in the image. This will help you understand what each mark represents. |

| 3 | Identify major assemblies or groups, as these are often highlighted to show how parts work together. |

| 4 | Focus on individual components, noting their names and numbers. This is crucial for ordering replacements or making adjustments. |

| 5 | Pay attention to any directional arrows or annotations that provide additional context or instructions for assembly and disassembly. |

By following these steps, you’ll enhance your ability to navigate technical illustrations, making repairs and maintenance more efficient and accurate.

Maintenance Tips for Lawn Tractors

Regular upkeep is essential to ensure the longevity and efficiency of your outdoor equipment. Proper maintenance not only enhances performance but also helps prevent costly repairs down the line. Here are some key practices to keep your machinery in top condition.

Routine Checkups

- Inspect the oil levels and change it according to the manufacturer’s recommendations.

- Check and clean or replace air filters to ensure optimal airflow.

- Examine the blades for wear and sharpen or replace them as necessary.

- Inspect belts and cables for signs of wear or damage.

- Look over the tires for proper inflation and any signs of cracking.

Seasonal Maintenance

- Before winter, store the machine in a dry place and consider using a fuel stabilizer.

- In spring, perform a thorough cleaning to remove any debris or rust.

- Check the battery and connections, ensuring everything is secure and free of corrosion.

- Review safety features, such as the emergency shut-off and safety switches, to ensure they are functioning correctly.

Implementing these strategies will not only extend the lifespan of your equipment but also improve its overall performance, making your outdoor tasks more efficient and enjoyable.

Identifying Worn Out Parts

Recognizing components that have reached the end of their service life is crucial for maintaining optimal performance and extending the lifespan of your equipment. This process involves careful observation and evaluation to ensure that all elements function harmoniously. Various indicators can signal that a component may need replacement, helping you avoid potential issues down the line.

Here are some common signs to look for when assessing the condition of your machinery:

| Indicator | Description |

|---|---|

| Visible Damage | Cracks, dents, or excessive wear can compromise functionality. |

| Noisy Operation | Unusual sounds during operation may indicate internal issues. |

| Performance Decline | Reduced efficiency or power loss suggests potential failures. |

| Excessive Vibration | Shaking or rattling may point to misalignment or wear. |

| Fluid Leaks | Leakage from seals or gaskets can signal deterioration. |

Regular inspections can help catch these signs early, allowing for timely replacements and ensuring your equipment remains in peak condition.

Where to Find Replacement Parts

Finding the right components for your outdoor equipment can be a daunting task, but with the right resources, it becomes much easier. Whether you’re looking for specific elements to enhance performance or to replace worn-out items, knowing where to search is crucial.

Online Retailers are often the first stop for many enthusiasts. Websites that specialize in gardening and landscaping tools typically have a vast selection of components available. Make sure to check user reviews to ensure quality.

Manufacturer Websites provide direct access to authentic items. This is particularly useful for those who prefer original replacements, as these sources often guarantee compatibility and reliability.

Local Dealers can be invaluable, especially if you prefer seeing the components before purchase. Visiting a physical store allows you to consult with knowledgeable staff who can offer guidance and recommendations based on your specific needs.

Online Marketplaces such as auction sites and classifieds can yield great deals on both new and used items. Just be cautious about the seller’s reputation to avoid potential pitfalls.

Finally, forums and community groups dedicated to outdoor equipment can provide insights and even leads on where to find hard-to-locate items. Engaging with other enthusiasts often opens up new avenues for sourcing what you need.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components in maintenance and repairs offers a range of advantages that can significantly enhance the performance and longevity of your machinery. These authentic items are specifically designed to fit seamlessly, ensuring optimal operation and reducing the likelihood of complications.

Quality Assurance

One of the primary benefits of using original components is the guarantee of quality. OEM items undergo rigorous testing to meet industry standards, which translates to reliability and durability in use.

Perfect Compatibility

Another critical aspect is compatibility. Original items are engineered to align perfectly with your equipment, minimizing installation issues and promoting efficient performance. This precision helps avoid the pitfalls often associated with aftermarket alternatives.

| Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

| Quality Control | High | Variable |

| Compatibility | Exact Fit | Often Inexact |

| Warranty | Comprehensive | Limited |

| Performance | Optimal | Inconsistent |

Aftermarket Components: Advantages and Disadvantages

Exploring alternatives to original equipment manufacturer (OEM) parts for your machinery involves weighing various factors that can impact performance, reliability, and cost-effectiveness. Aftermarket components, which encompass non-OEM options, present both opportunities and challenges in maintaining equipment.

Advantages of Aftermarket Parts

1. Cost: Often available at lower prices compared to OEM parts.

2. Availability: Widely accessible through multiple suppliers and retailers.

3. Variety: Offer a range of options from different manufacturers, potentially providing enhanced features or specifications.

Disadvantages of Aftermarket Parts

| 1. Quality Concerns: | Varies widely; some may not meet OEM standards, potentially affecting performance or longevity. |

| 2. Compatibility: | Not guaranteed to fit perfectly or integrate seamlessly with your specific equipment. |

| 3. Warranty: | May void the original manufacturer’s warranty if used in place of OEM parts. |

Troubleshooting Common Issues

Addressing frequent challenges with outdoor machinery can enhance their performance and longevity. Identifying the source of problems is crucial for effective resolution. This section covers common symptoms, potential causes, and practical solutions to help users maintain their equipment efficiently.

Engine Starting Difficulties

If the engine fails to start, several factors might be at play. Check the fuel level, as an empty tank can halt operations. Additionally, inspect the battery for adequate charge and ensure that connections are secure. A clogged air filter or faulty spark plug can also prevent ignition. Cleaning or replacing these components may resolve the issue.

Cutting Quality Issues

Inconsistent cutting can result from dull blades or incorrect height settings. Regularly sharpening blades ensures a clean cut. Furthermore, verify that the cutting deck is level and not obstructed by debris. If problems persist, examining the drive belt for wear may be necessary, as a damaged belt can affect overall functionality.

DIY Repairs: What You Need

Undertaking repairs on outdoor machinery can be both rewarding and cost-effective. Having the right tools and resources at your disposal is crucial for successful maintenance and troubleshooting. This section will guide you through essential items and considerations to make your repair experience smooth and efficient.

First and foremost, a comprehensive toolkit is necessary. Basic hand tools such as wrenches, screwdrivers, and pliers will serve as your foundation. Additionally, specialized tools like socket sets or torque wrenches may be required for specific tasks. Always ensure your tools are in good condition to avoid complications during repairs.

Next, understanding the components of the machine you’re working on is vital. A clear reference, such as a schematic or manual, will help identify parts and their functions. These documents often include troubleshooting tips that can save you time and effort.

Safety gear is another essential aspect of any repair project. Protective eyewear, gloves, and appropriate clothing can prevent injuries while you work. Remember to prioritize safety to create a secure environment.

Finally, consider the availability of replacement items. Researching suppliers or local shops can streamline the process, ensuring you have the necessary components on hand when needed. Being prepared will minimize downtime and enhance your overall repair experience.

Resources for Further Assistance

In this section, you will find a curated collection of supplementary aids designed to enhance your understanding and resolve queries related to components, layouts, and technical representations pertaining to your gardening equipment.

Additional Guidance: Explore these valuable avenues for expanded insights and detailed clarifications concerning the intricacies of device elements, configurations, and illustrative depictions.

Further Support: Delve into these resources to access enriched explanations and visual guides that can elucidate intricate aspects and configurations of mechanical components.