Lawn Mower Briggs and Stratton Parts Diagram Guide

In the realm of outdoor equipment, comprehending the intricate relationships between various components is crucial for maintenance and troubleshooting. A thorough exploration of these elements provides users with valuable insights, enabling them to optimize performance and extend the lifespan of their machines. This section delves into the essential aspects of engine assembly, highlighting key elements and their functions.

Every engine consists of numerous interconnected parts, each serving a specific purpose. From the power source to the cutting mechanism, understanding how these pieces fit together is vital for effective operation. Familiarity with these components not only aids in diagnosing issues but also empowers users to undertake repairs with confidence.

Furthermore, recognizing the roles of individual elements enhances one’s ability to make informed decisions regarding upgrades and replacements. As technology advances, ensuring compatibility between components becomes increasingly important. This guide aims to provide a clear overview of the essential elements involved, fostering a deeper appreciation for the mechanics behind the machinery.

Lawn Mower Maintenance Essentials

Regular upkeep is crucial for ensuring the longevity and efficiency of your gardening equipment. Proper care not only enhances performance but also minimizes the risk of breakdowns. Understanding the fundamental aspects of maintenance can lead to a healthier and more productive outdoor space.

One of the primary tasks involves checking and replacing the cutting element. Keeping it sharp ensures clean cuts, promoting healthier growth. Additionally, examining the fuel system helps maintain optimal performance. Using fresh fuel and replacing filters regularly prevents potential clogs and promotes efficient operation.

Another vital aspect is inspecting and changing the lubricant. Clean oil reduces friction and wear on internal components, significantly extending the lifespan of your equipment. Regular cleaning of the exterior prevents dirt accumulation, which can affect functionality and aesthetics.

Finally, ensuring that all connections and controls are in good working order is essential for safe operation. Routine inspections and addressing any signs of wear or damage promptly will keep your machinery running smoothly throughout the seasons.

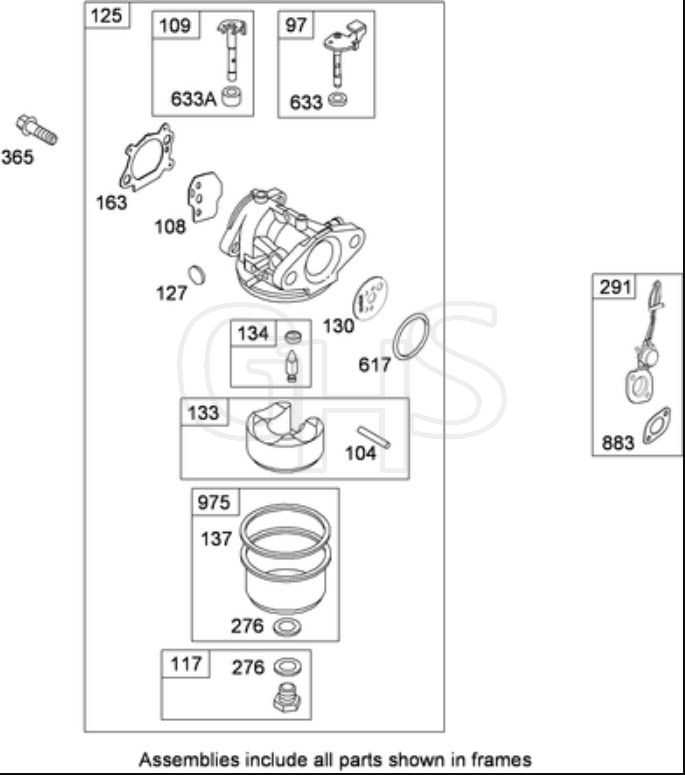

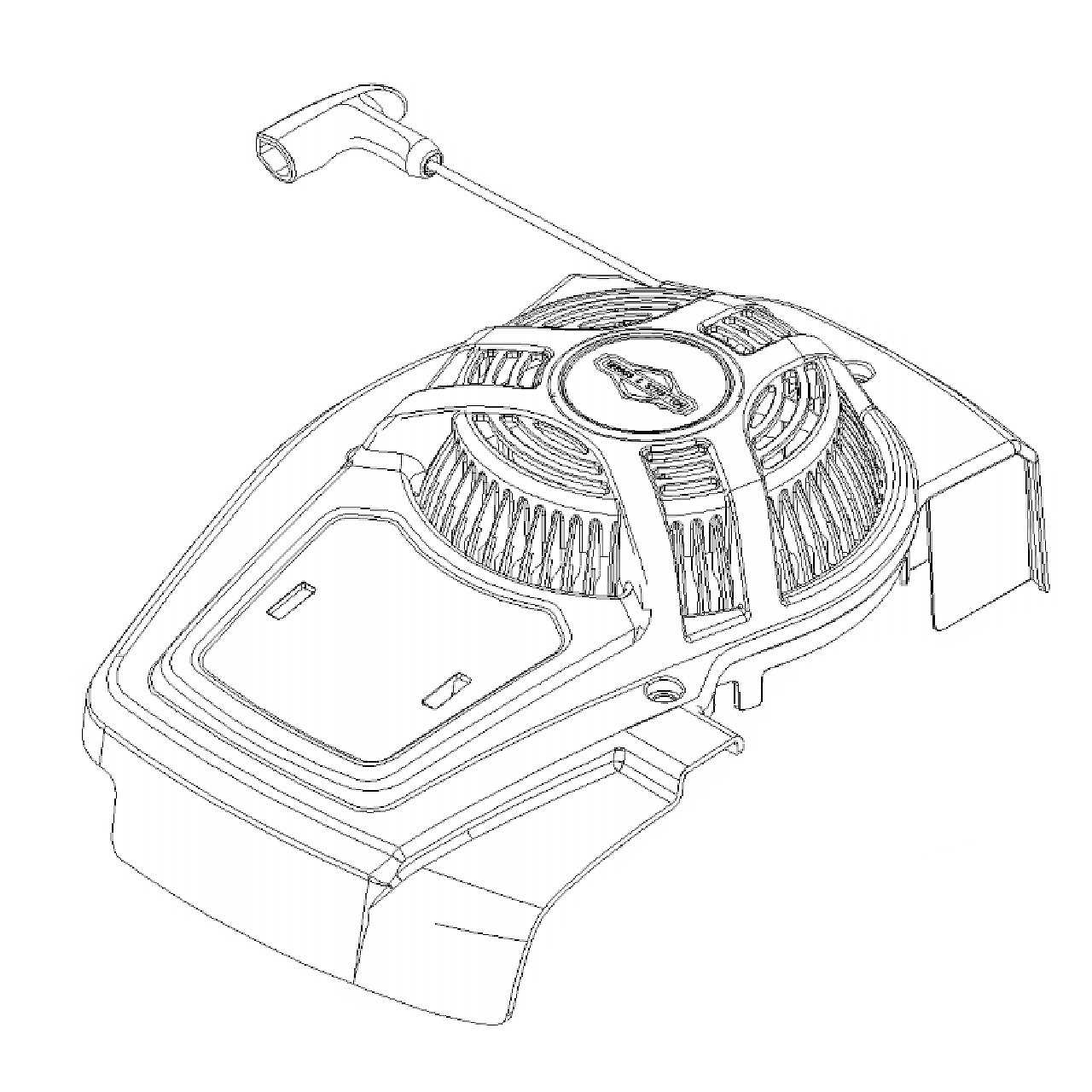

Understanding Engine Components and Functions

Grasping the various elements that make up an engine is essential for comprehending its operation. Each component plays a specific role in ensuring smooth functionality and efficiency. From initiating combustion to generating power, every piece is integral to the overall performance of the mechanism.

Engines typically consist of several critical elements, each designed to perform distinct tasks. The interaction among these components is vital for optimal functioning, making it important to understand their roles. Below is a table outlining some of the key elements and their respective functions:

| Component | Function |

|---|---|

| Crankshaft | Transforms linear motion from the pistons into rotational motion to power the system. |

| Piston | Moves up and down within the cylinder, creating pressure to ignite the fuel mixture. |

| Camshaft | Regulates the timing of the opening and closing of the valves for optimal air-fuel intake and exhaust. |

| Valves | Control the entry of air-fuel mixture into the combustion chamber and the exit of exhaust gases. |

| Fuel Injector | Delivers the correct amount of fuel into the combustion chamber for ignition. |

Understanding these components allows for better insight into maintenance and troubleshooting, ultimately enhancing the longevity and performance of the engine.

Common Issues and Troubleshooting Tips

Maintaining equipment can often present challenges, but understanding frequent problems can help users resolve them efficiently. Identifying symptoms early can save time and reduce frustration during usage. This section outlines typical difficulties encountered and offers practical solutions for effective handling.

1. Engine Won’t Start: This issue may arise from a variety of factors such as insufficient fuel, a faulty spark plug, or a clogged air filter. Check the fuel level and ensure it is fresh. Inspect the spark plug for damage or dirt, and replace it if necessary. Additionally, ensure the air filter is clean and unobstructed.

2. Uneven Cutting: If the cutting surface is inconsistent, the blades might be dull or damaged. Regularly sharpen or replace blades as needed. Furthermore, ensure the equipment is level and that all wheels are properly adjusted.

3. Excessive Vibration: This can result from loose bolts or an unbalanced blade. Check all connections and tighten any loose components. If the blade is bent or warped, it should be straightened or replaced to ensure smooth operation.

4. Overheating: Overheating may occur due to blocked cooling fins or insufficient oil levels. Regularly clean any debris from cooling areas and check the oil level, adding more if necessary to maintain proper lubrication.

5. Fuel Leaks: Leaks can be caused by damaged fuel lines or a loose tank cap. Inspect all fuel lines for cracks and replace them if needed. Ensure the tank cap is secure to prevent spills.

By addressing these common challenges proactively, users can enhance the longevity and efficiency of their equipment, ensuring optimal performance throughout its use.

Replacement Parts: What You Need

When it comes to maintaining your equipment, knowing the essential components for replacement is crucial. Ensuring that your machinery operates efficiently often requires understanding which elements may wear out over time. Having a reliable source for these items can enhance the longevity and performance of your machine.

Below is a table detailing commonly needed items for upkeep, along with their corresponding functions:

| Component | Description |

|---|---|

| Air Filter | Prevents dust and debris from entering the engine, ensuring optimal performance. |

| Fuel Filter | Traps impurities in the fuel, protecting the engine from damage. |

| Spark Plug | Ignites the fuel-air mixture, crucial for starting the engine. |

| Blade | Cuts the grass effectively; requires regular sharpening or replacement. |

| Belt | Transfers power from the engine to the cutting mechanism; may wear out with use. |

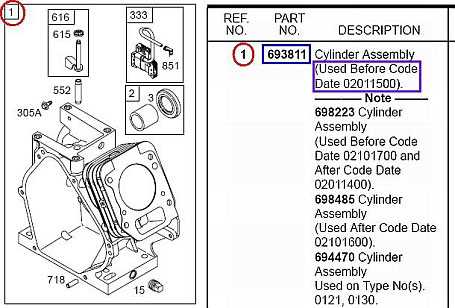

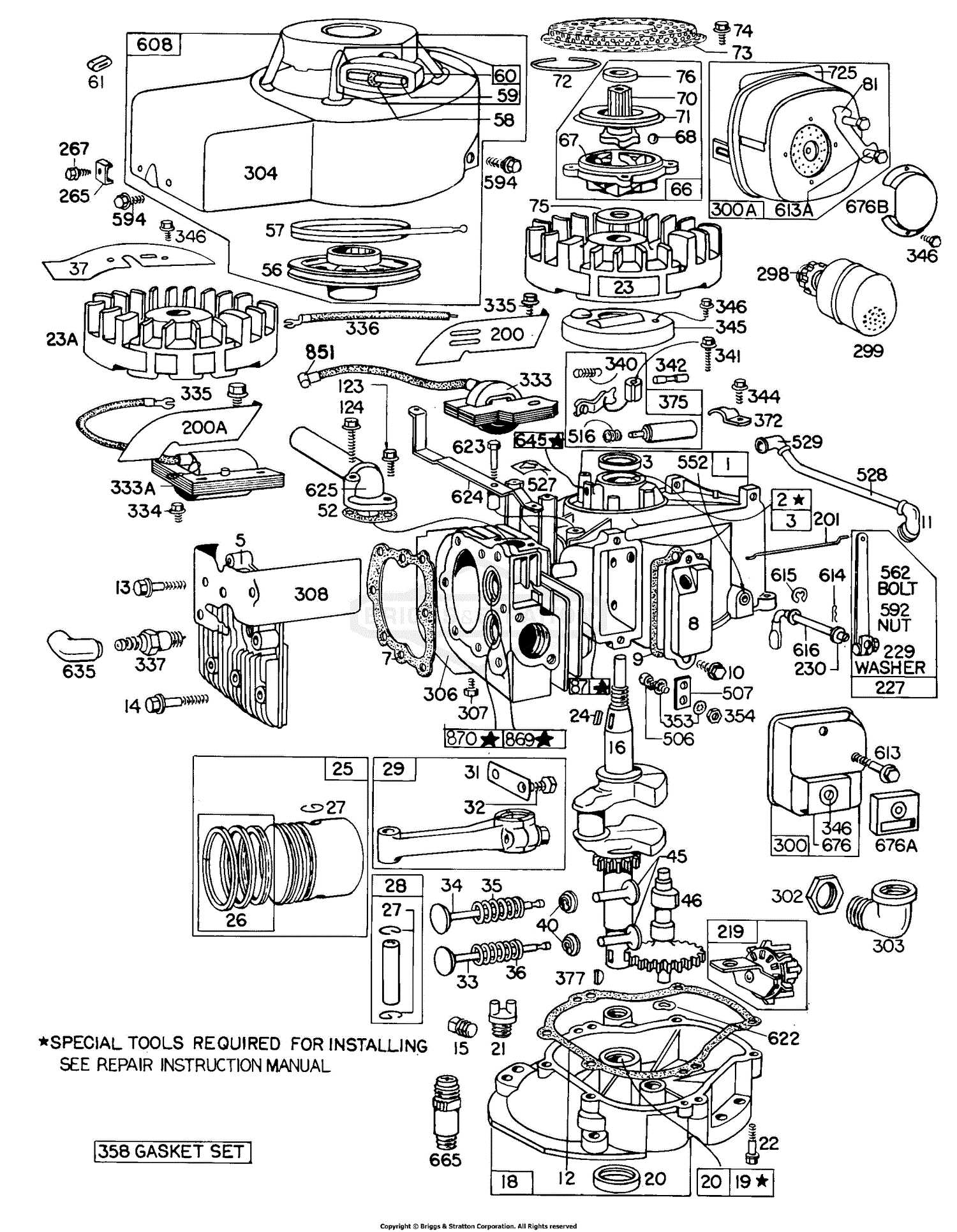

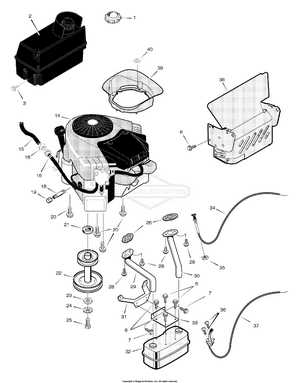

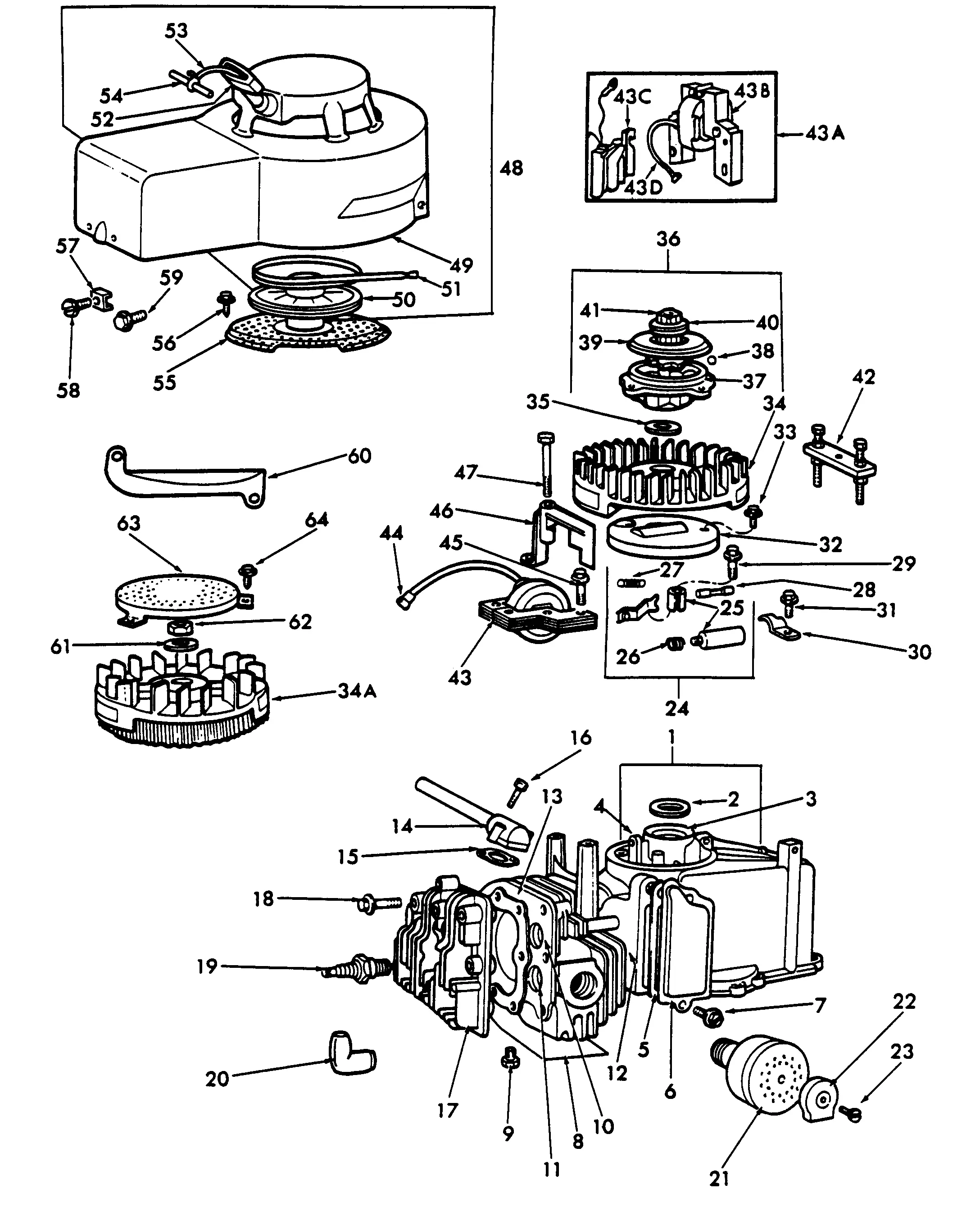

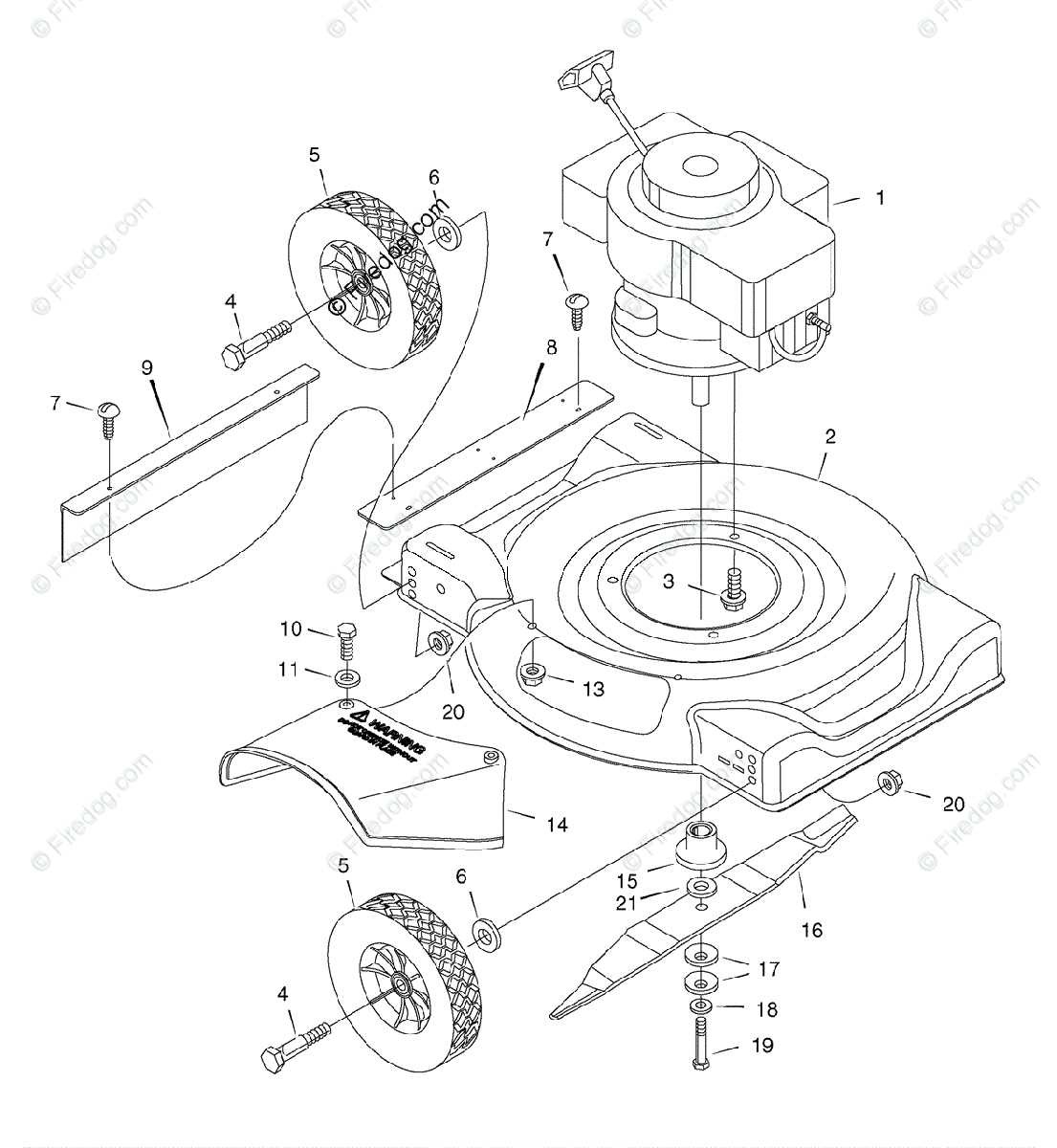

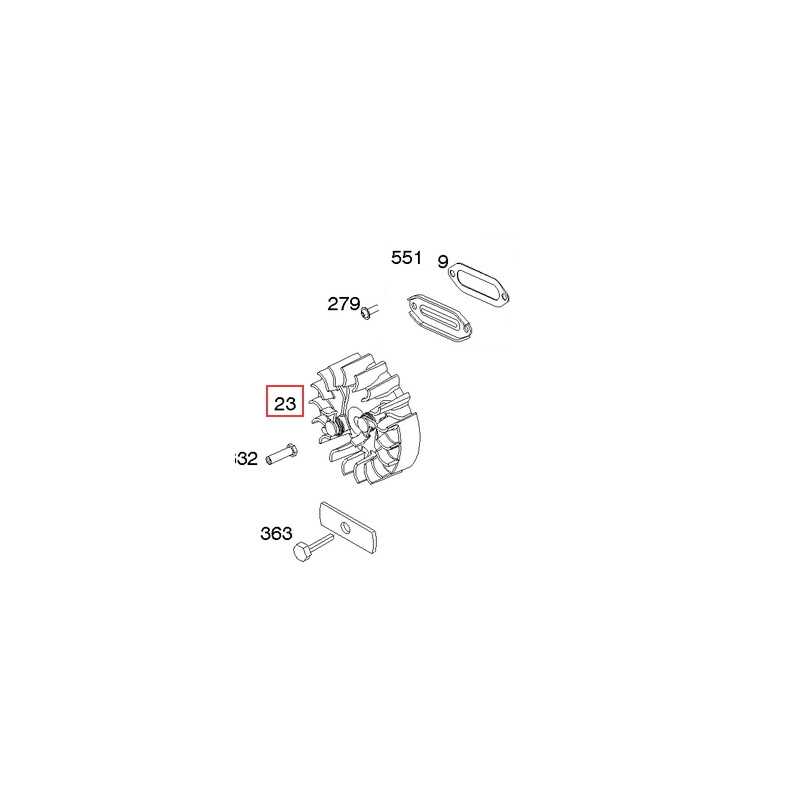

Diagram Interpretation for DIY Repairs

Understanding visual representations is crucial for effective home maintenance and repair tasks. These illustrations serve as essential guides, providing valuable insights into component arrangement and functionality. Familiarizing oneself with these resources can significantly enhance the repair process, making it more efficient and straightforward.

When approaching a visual representation, consider the following key aspects:

- Symbols and Labels: Each symbol corresponds to a specific component or action. Take time to decipher these notations, as they often denote critical information.

- Color Coding: Many illustrations use colors to differentiate parts or highlight areas of concern. Pay attention to these cues, as they can indicate important repair priorities.

- Component Orientation: Understanding the placement of parts is vital. Ensure you recognize how components fit together and their respective orientations.

- Sequence of Assembly: Often, diagrams will indicate the order in which parts should be assembled or disassembled. Following this sequence can prevent damage and streamline the repair process.

For a successful repair, follow these steps:

- Gather all necessary tools and materials before starting.

- Carefully study the visual guide, noting any complex components or connections.

- Organize the components systematically as you disassemble or assemble them.

- Refer back to the illustration frequently to ensure accuracy throughout the process.

By mastering the interpretation of these visual resources, you can approach repair tasks with confidence and clarity, leading to successful outcomes.

Tips for Finding Genuine Parts

Ensuring the longevity and efficiency of your equipment relies heavily on sourcing authentic components. This not only enhances performance but also safeguards your investment. Identifying original elements can seem challenging, but with a few strategic approaches, you can make the process smoother.

Research Reputable Suppliers

Start by exploring established retailers and authorized dealers known for their reliability. These sources often guarantee that the items they offer are genuine and of high quality. Checking online reviews and ratings can provide insight into the trustworthiness of a supplier. Additionally, consider visiting local shops where experienced staff can offer guidance and assistance in selecting the correct components.

Verify Part Numbers and Specifications

When searching for components, always check the part numbers and specifications against the manufacturer’s recommendations. Each component typically has a specific identifier that ensures compatibility and quality. If possible, cross-reference these details on the official website or in the user manual. This step can help prevent costly mistakes and ensure that you are acquiring the right item for your needs.

Safety Precautions During Repairs

When undertaking maintenance on mechanical devices, it is crucial to prioritize safety to prevent accidents and injuries. Ensuring a secure working environment and adhering to specific guidelines can significantly reduce risks associated with repairs. By following proper safety protocols, individuals can work more effectively and confidently.

Before beginning any task, it is essential to disconnect power sources to eliminate the chance of unintentional start-ups. Additionally, wearing protective gear such as gloves, goggles, and sturdy footwear can safeguard against potential hazards. Always ensure that your workspace is well-lit and free from clutter, allowing for better visibility and movement.

Familiarizing yourself with the equipment and its components is vital. Review manuals or documentation related to the device to understand its operation thoroughly. This knowledge helps in identifying parts that require attention and can also guide you in executing repairs more effectively.

Furthermore, it is advisable to use the right tools for the job. Utilizing appropriate instruments not only enhances efficiency but also reduces the likelihood of damaging components. If unsure about a procedure, seeking assistance from experienced individuals or consulting professionals can provide additional safety and reassurance.

Best Practices for Lawn Mower Care

Proper maintenance is essential for ensuring the longevity and efficiency of your grass cutting equipment. By following a few key guidelines, you can keep your machine operating smoothly and minimize the risk of breakdowns. Regular care not only enhances performance but also contributes to a healthier yard.

Regular Inspection

Conducting frequent checks of your equipment is crucial. Look for any signs of wear and tear, such as frayed cables or loose components. Addressing minor issues promptly can prevent more significant problems later. Always ensure that all moving parts are in good condition and that the oil levels are appropriate.

Cleaning and Storage

After each use, clean the exterior and undercarriage to remove debris, grass clippings, and dirt. This helps to prevent rust and ensures optimal airflow for cooling. When storing the device, keep it in a dry, sheltered area to protect it from the elements. Investing time in proper care will extend its lifespan and maintain its effectiveness.

Choosing the Right Tools for Repairs

Selecting the appropriate instruments for maintenance tasks is crucial for achieving effective and efficient results. Having the right equipment on hand can significantly simplify the repair process and enhance overall performance. In this section, we will explore essential tools that every enthusiast should consider when undertaking repairs, ensuring a smooth experience.

Essential Tools

When tackling maintenance projects, it is vital to have a comprehensive toolkit. Start with basic items such as screwdrivers, wrenches, and pliers. These versatile tools are fundamental for loosening and tightening components. Additionally, consider investing in specialized instruments, such as a socket set or a torque wrench, to accommodate specific needs.

Safety Equipment

Prioritizing safety during repair work is paramount. Always wear protective gear, including gloves and safety glasses, to shield against potential hazards. Furthermore, ensure that your workspace is well-lit and organized to minimize accidents. Proper safety measures not only protect you but also contribute to a more efficient workflow.

Seasonal Maintenance for Optimal Performance

Preparing your equipment for each season ensures it runs smoothly and efficiently. Regular care can prevent costly repairs and extend the lifespan of various components. By addressing specific tasks, you can keep everything in peak condition, ready to perform when needed.

- Spring: Inspect the fuel system and replace old fuel. Check and clean the air filter, replacing it if necessary. Review the spark system to ensure a smooth start-up and efficient operation.

- Summer: Monitor fluid levels and inspect for leaks. Sharpen any moving blades to maintain effective cutting. Check tire pressure for balanced operation on various surfaces.

- Fall: Clean out any buildup from summer use. Inspect belts, bolts, and other fasteners for wear or damage. Lubricate moving parts to prevent rust and ensure smooth performance in the following season.

- Winter: Drain fuel to prevent clogs and corrosion. Store in a dry area, away from moisture. Disconnect the power source if possible, and protect key components from freezing temperatures.

By adhering to these seasonal tasks, you help maintain reliable performance and improve the overall longevity of your equipment. Investing time in maintenance ensures optimal functionality and readiness for each new season.

Upgrading Your Lawn Mower’s Efficiency

Enhancing the performance of your outdoor power equipment is a practical way to achieve better results while saving time and effort. By implementing a few targeted upgrades, you can transform a standard machine into an efficient, high-performing tool that tackles even the most demanding tasks with ease. This section will cover key strategies to help you make the most of your equipment’s potential.

Optimize the Engine

One of the most impactful ways to improve efficiency is by optimizing the engine. Regularly replacing components such as the air filter, spark plug, and fuel filter ensures your equipment operates smoothly and with maximum power output. These small but significant changes reduce the strain on the engine, resulting in longer lifespan and enhanced fuel efficiency.

Upgrade the Cutting Mechanism

For a more precise and powerful cut, consider upgrading the cutting blades. High-quality, sharper blades make for cleaner, faster cuts, which not only improves the appearance of your yard but also reduces the time required for each session. Stronger, durable blades are less prone to wear and tear, saving you money on replacements and maintenance over time.

Additional Tips for Maintenance: Keeping your machine in top shape involves more than just engine and blade upgrades. Regular oil changes, checking tire pressure, and cleaning the undercarriage are simple tasks that contribute significantly to overall efficiency. By paying attention to these areas, you’ll ensure your equipment runs reliably and remains an asset for years to come.