John Deere 755 Parts Diagram Overview

In the realm of machinery, comprehending the intricate relationships between various elements is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring the seamless functioning of the equipment, contributing to its overall performance and longevity.

By exploring the arrangement and interconnection of these essential features, operators can enhance their understanding and troubleshooting capabilities. A clear representation of these elements aids in identifying potential issues, facilitating timely repairs and replacements, which ultimately leads to improved productivity.

Familiarity with the configuration and characteristics of these units not only empowers users but also promotes better decision-making regarding maintenance and upgrades. This knowledge is invaluable for anyone involved in the upkeep and operation of such sophisticated machinery.

Understanding the essential elements of agricultural machinery is crucial for efficient operation and maintenance. These components work in unison to ensure optimal performance, contributing to the overall functionality of the equipment. Familiarity with these parts can aid in identifying potential issues and enhancing longevity.

Major Systems

The primary systems of a tractor encompass various functionalities that support its operation. Below are some key systems that are vital to its performance:

| System | Description |

|---|---|

| Engine | Drives the machinery and provides power for all operations. |

| Hydraulics | Facilitates lifting and controlling attachments, enhancing versatility. |

| Transmission | Transfers power from the engine to the wheels, influencing speed and torque. |

| Electrical | Powers ignition, lights, and various electronic components for operation. |

Attachments and Implements

In addition to the main systems, tractors are equipped with various attachments that enhance their capabilities. Understanding these implements can maximize productivity and efficiency in fieldwork.

| Attachment | Function |

|---|---|

| Plow | Used for turning soil and preparing land for planting. |

| Seeder | Distributes seeds uniformly in the soil for planting. |

| Tiller | Breaks up soil to create a fine seedbed for planting. |

| Loader | Facilitates lifting and moving materials for construction or agriculture. |

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for technicians, allowing them to identify and locate individual elements within complex systems. This clarity enhances efficiency and reduces the likelihood of errors during servicing.

Facilitating Repairs

Having access to clear visual aids simplifies the repair process. Technicians can quickly pinpoint specific items, enabling faster and more accurate repairs. This reduces downtime and enhances overall productivity, making the machinery operational sooner.

Enhancing Communication

Visual references also improve communication between technicians and customers. When discussing issues or repairs, using illustrations can help convey complex ideas in a straightforward manner. This fosters better understanding and trust between parties involved in the maintenance process.

Identifying Replacement Parts Easily

Finding the correct components for machinery can often be a challenging task, especially when faced with various models and specifications. By understanding the structure and organization of equipment, users can simplify the process of locating the necessary elements, ensuring efficient repairs and maintenance.

Understanding Component Designations

Each piece of equipment has a unique coding system that categorizes its elements. Familiarizing oneself with these designations helps in quickly identifying what is needed. Typically, these codes can include numbers, letters, or a combination that signifies the type and function of the component.

Utilizing Resourceful Tools

Accessing comprehensive resources, such as manuals or online databases, can streamline the search for components. These tools provide detailed descriptions and visual representations, making it easier to match the required items.

| Category | Description |

|---|---|

| Engine Components | Parts related to the engine’s functionality, including filters and gaskets. |

| Hydraulic Systems | Components involved in the hydraulic mechanisms, such as hoses and valves. |

| Electrical Elements | Parts related to the electrical system, including batteries and wiring harnesses. |

| Frame and Chassis | Structural components that support the equipment’s overall framework. |

Common Issues with John Deere 755

Many users encounter several typical challenges when operating their agricultural machinery. Understanding these common problems can help in maintaining the equipment efficiently and prolonging its lifespan. Identifying these issues early can save time and reduce repair costs.

Engine Performance Problems

One frequent issue involves engine performance, which may manifest as reduced power or stalling. These symptoms can arise from various factors, including fuel delivery issues, air filter blockages, or spark plug malfunctions. Regular maintenance, such as replacing filters and checking fuel lines, can prevent these complications.

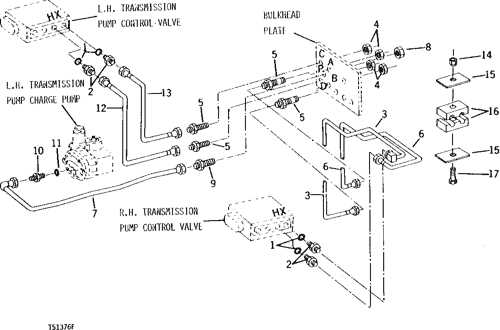

Hydraulic System Failures

Hydraulic system failures can significantly impact the operation of the machinery. Common symptoms include slow response times or complete loss of function in hydraulic implements. Potential causes may include leaks, low fluid levels, or worn seals. Regular inspections of hydraulic hoses and timely fluid changes are essential for optimal performance.

Step-by-Step Repair Process

Repairing machinery requires a systematic approach to ensure efficiency and effectiveness. By following a structured method, individuals can tackle issues more easily, minimizing downtime and enhancing overall performance. This section outlines a comprehensive guide to executing repairs, emphasizing the importance of each step in achieving optimal results.

1. Identify the Issue: Begin by thoroughly examining the equipment to determine the specific problem. Look for visible signs of wear, leaks, or malfunctions. Accurate diagnosis is crucial for effective repairs.

2. Gather Necessary Tools: Collect all required tools and replacement components before starting the repair process. Having everything at hand streamlines the procedure and reduces the likelihood of interruptions.

3. Prepare the Work Area: Ensure the workspace is clean and organized. Adequate lighting and a safe environment facilitate better focus and efficiency during repairs.

4. Disassemble Components: Carefully take apart the necessary parts of the machinery. Keep track of screws and small components to avoid losing them during the process. Document the order of disassembly for easier reassembly later.

5. Replace or Repair Parts: Depending on the diagnosis, either replace damaged components or repair them as needed. Follow manufacturer guidelines to ensure compatibility and effectiveness.

6. Reassemble the Machinery: Once repairs are complete, reassemble the equipment carefully. Refer to your earlier documentation to ensure all parts are put back in the correct order.

7. Test the Equipment: After reassembly, conduct thorough tests to ensure the machinery operates correctly. Monitor for any irregularities and make adjustments as necessary.

8. Document the Repair: Finally, record the repairs made, along with any parts replaced. Keeping accurate records helps in future maintenance and repairs, providing valuable insight into the machine’s history.

Tools Needed for Maintenance

Proper upkeep of machinery is essential for optimal performance and longevity. Having the right tools on hand not only facilitates efficient repairs but also enhances safety during maintenance tasks. A well-equipped toolkit enables you to tackle various challenges that may arise during routine servicing.

Common tools that are beneficial include wrenches, screwdrivers, and pliers, which are fundamental for general adjustments and replacements. Additionally, specialized equipment such as torque wrenches and diagnostic devices can be crucial for specific tasks. Always ensure that your tools are in good condition to prevent mishaps and achieve the best results.

Where to Find Quality Parts

When searching for reliable components for your machinery, it’s essential to explore various sources that can offer high-quality options. Whether you are looking for OEM replacements or aftermarket alternatives, knowing where to look can significantly impact your equipment’s performance and longevity.

Here are some recommended avenues to consider when sourcing superior components:

| Source | Description |

|---|---|

| Authorized Dealers | These vendors provide original equipment manufacturer items, ensuring compatibility and quality. |

| Online Retailers | Websites specializing in equipment parts often have a vast selection, competitive pricing, and customer reviews to guide your choice. |

| Local Auto Parts Stores | These establishments may carry a range of components, and their staff can often provide valuable advice. |

| Salvage Yards | A great option for finding used parts at lower prices; ensure that the items are in good condition before purchasing. |

| Trade Shows | Attending industry events can connect you with manufacturers and suppliers offering the latest products and innovations. |

By exploring these options, you can find the necessary components to keep your equipment running smoothly and efficiently.

Comparing OEM and Aftermarket Options

When it comes to selecting components for machinery, understanding the differences between original equipment manufacturer (OEM) and aftermarket alternatives is crucial. Each option offers its own set of advantages and considerations that can significantly impact performance, cost, and reliability.

Quality and Reliability

OEM components are typically designed and manufactured to meet the specifications set by the original manufacturer, ensuring a high level of quality and compatibility. Aftermarket options, on the other hand, may vary in quality depending on the manufacturer, which can affect performance and longevity.

Cost Considerations

While OEM parts often come with a higher price tag, they can provide peace of mind due to their guaranteed quality. Aftermarket alternatives can be more affordable, offering potential savings. However, it’s essential to evaluate whether the lower cost translates to sufficient performance and durability.

| Feature | OEM | Aftermarket |

|---|---|---|

| Quality | High, consistent | Variable, depends on manufacturer |

| Cost | Generally higher | Often lower |

| Compatibility | Guaranteed fit | May vary, check specifications |

| Warranty | Typically comes with a warranty | Varies by manufacturer |

Tips for Proper Parts Installation

Ensuring the correct assembly of components is crucial for optimal performance and longevity of your machinery. Attention to detail during the installation process can prevent issues down the line, ensuring that your equipment operates smoothly and efficiently. Below are some essential guidelines to help you achieve a successful installation.

Preparation and Organization

Before beginning the installation, gather all necessary tools and components. Organizing your workspace can significantly enhance efficiency. Create a checklist to verify that all required elements are present. This preparation will streamline the process and minimize the risk of errors.

Follow Manufacturer Guidelines

Always refer to the manufacturer’s instructions for installation procedures. Adhering to these guidelines ensures that each component is fitted correctly and reduces the likelihood of complications. Additionally, using the recommended torque specifications can help avoid damage and ensure that everything is secure.

Maintaining Your John Deere 755

Proper upkeep of your agricultural machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only helps in preventing unexpected breakdowns but also enhances the efficiency of the equipment. By adhering to a systematic maintenance routine, you can prolong the life of your machinery and ensure it operates smoothly.

Start by checking the fluid levels regularly, including engine oil, hydraulic fluid, and coolant. Keeping these fluids at the recommended levels is vital for preventing overheating and ensuring efficient operation. Additionally, inspect the air and fuel filters, as clogged filters can reduce performance and fuel efficiency. Replacing these components as needed will keep the engine running cleanly.

Cleaning and lubrication are crucial aspects of maintenance. Ensure that all moving parts are adequately lubricated to minimize wear and tear. Pay attention to the tracks, belts, and other mechanical components, as proper lubrication can significantly enhance their lifespan. Regularly cleaning the exterior and interior will also help in identifying any potential issues before they escalate.

Lastly, consult the manufacturer’s manual for specific maintenance schedules and procedures. This will provide you with valuable insights on when to perform major services, such as replacing the battery or inspecting the electrical systems. Following these guidelines will ensure that your agricultural machinery remains in excellent working condition.

Resources for Further Information

When seeking comprehensive details and guidance about equipment components, it is essential to utilize a variety of resources that can enhance understanding and support informed decisions. Various platforms offer valuable insights, diagrams, and specifications to aid in the maintenance and repair of machinery.

For in-depth knowledge, consider consulting manufacturer websites, where official documents and manuals are often available. These sources typically provide accurate information and visual aids to assist users in identifying and acquiring necessary items. Additionally, online forums and communities can be beneficial, allowing individuals to share experiences and solutions related to their equipment.

Furthermore, specialized publications and instructional videos are excellent tools for visual learners. These resources can demonstrate proper maintenance techniques and highlight potential issues, ultimately contributing to more effective management of your machinery.

In conclusion, leveraging a mix of official documents, community insights, and multimedia resources will empower users to navigate the complexities of machinery maintenance with confidence and ease.