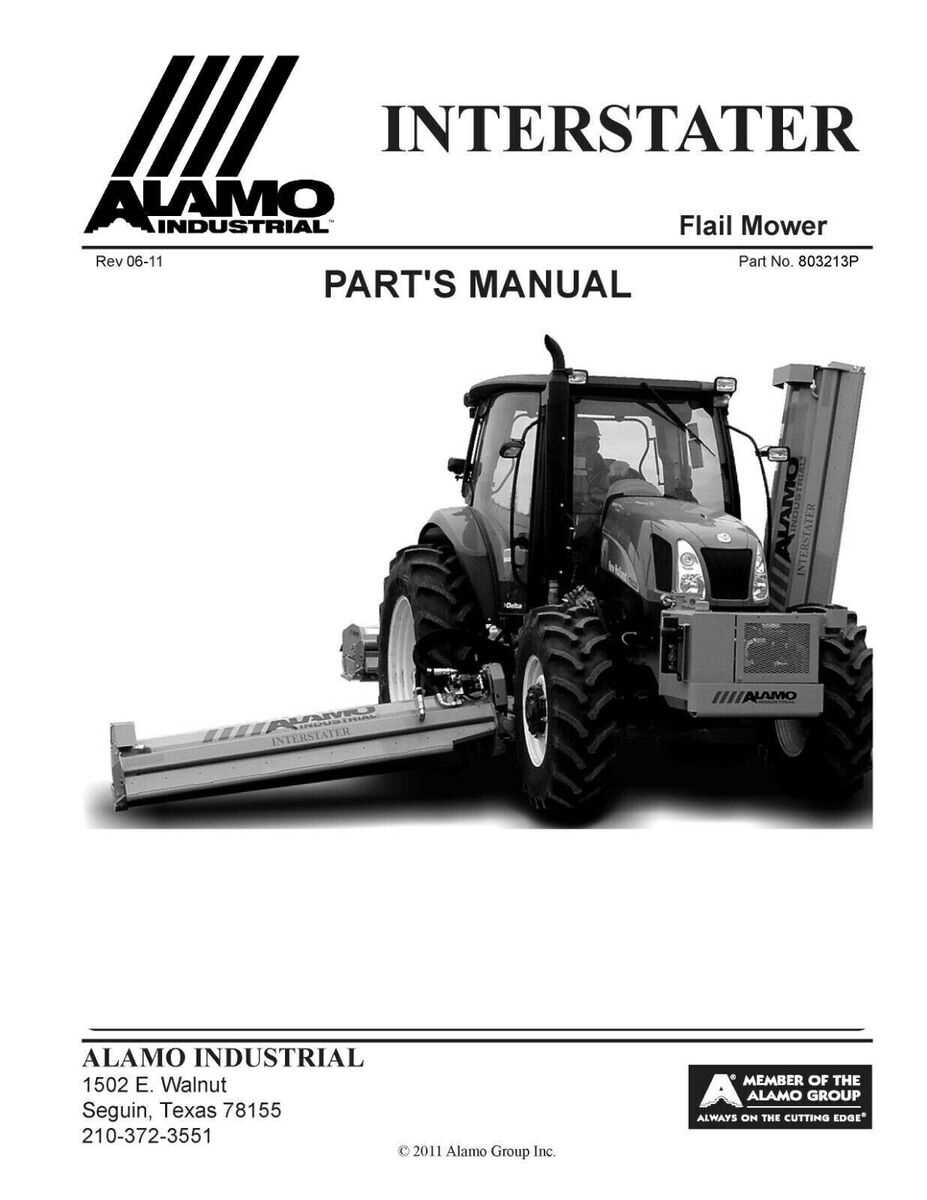

Understanding Alamo Flail Mower Parts Diagram for Better Maintenance

The intricate world of agricultural machinery encompasses a variety of tools designed for efficient land management. Understanding the components of such equipment is essential for maintaining functionality and ensuring longevity. By exploring the various elements involved, operators can enhance their knowledge and operational skills.

Within this realm, visual representations play a crucial role. These illustrations serve as valuable references, enabling users to identify and comprehend the individual elements that contribute to the overall performance of the machinery. Detailed breakdowns provide insights into assembly, maintenance, and troubleshooting.

Equipped with this understanding, operators can engage more effectively with their equipment. Proper identification of each segment not only aids in repair but also optimizes operational efficiency, leading to improved productivity in the field.

Understanding Alamo Flail Mower Basics

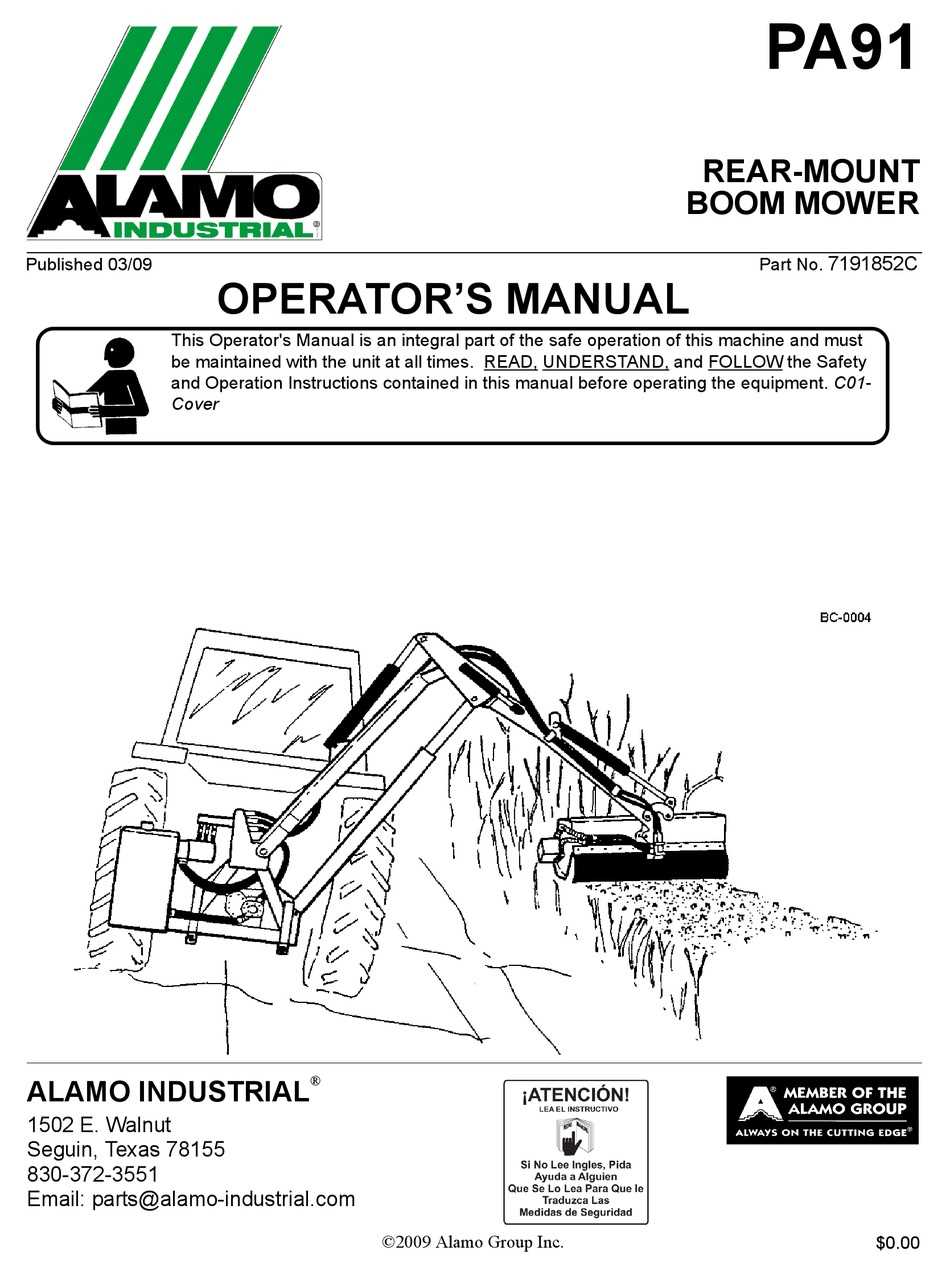

This section aims to provide a foundational understanding of the machinery used for efficient landscape maintenance and vegetation management. These devices are designed to tackle a variety of terrains and effectively manage overgrowth, ensuring a well-maintained environment.

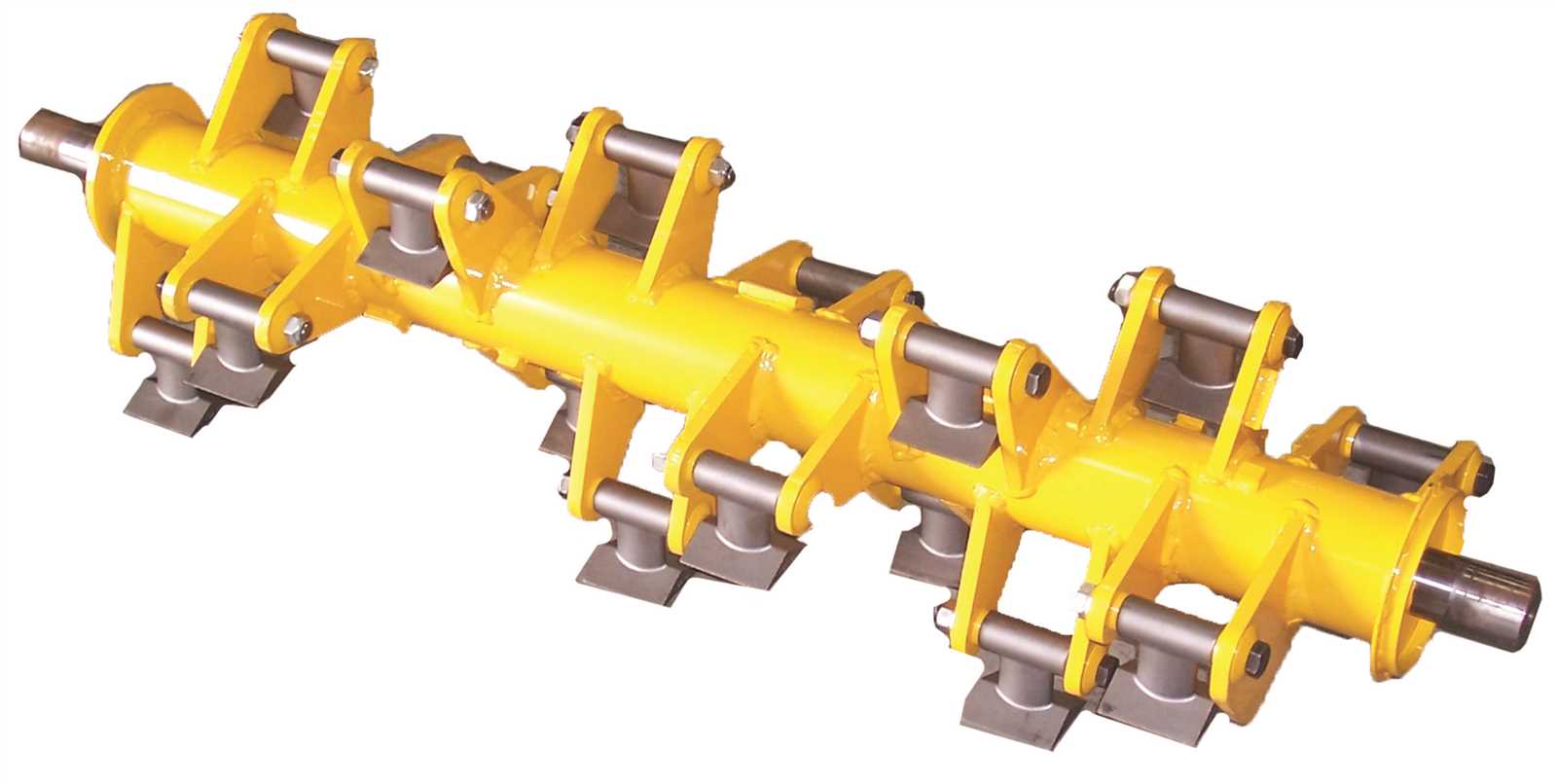

At the core of these machines is a robust mechanism that utilizes rotating elements to achieve precise cutting. This allows for a clean finish while minimizing damage to the underlying soil and surrounding plants. The versatility of these tools enables their application in both agricultural and recreational settings, making them invaluable for maintaining large areas.

Key components play crucial roles in the overall functionality, impacting performance and durability. Recognizing the significance of each element helps users make informed decisions regarding maintenance and upgrades, ultimately enhancing operational efficiency.

Understanding the operational principles is essential for effective use. Familiarity with the mechanics not only improves performance but also aids in troubleshooting common issues that may arise during operation. A solid grasp of these basics empowers users to maximize the potential of their machinery.

Key Components of Flail Mowers

This section explores the essential elements that contribute to the efficient operation of a specific type of agricultural machinery. Understanding these components is crucial for optimal functionality and maintenance.

Main Elements

- Cutting Blades: These are critical for achieving a clean cut and are often designed for durability.

- Drivetrain: This system transmits power from the engine to the cutting mechanism.

- Chassis: The frame supports all other components and ensures stability during operation.

- Hitch: This part connects the machinery to a towing vehicle, facilitating mobility.

Support Features

- Bearings: Essential for smooth rotation and movement of blades.

- Gearbox: Adjusts the speed and torque, allowing for varied cutting conditions.

- Deflectors: Direct debris and ensure safety during operation.

Importance of Maintenance and Repairs

Regular upkeep and timely repairs are essential for ensuring the longevity and efficiency of any equipment. Neglecting these aspects can lead to diminished performance and costly replacements. A proactive approach not only enhances functionality but also safeguards the investment made in machinery.

| Benefit | Description |

|---|---|

| Increased Efficiency | Well-maintained machinery operates smoothly, reducing operational downtime. |

| Cost Savings | Preventative measures can minimize unexpected repair costs over time. |

| Safety | Regular checks help identify potential hazards, ensuring a safer working environment. |

| Enhanced Performance | Routine care leads to optimal functioning and better results in operations. |

Common Issues with Flail Mowers

When maintaining grassy areas or managing vegetation, users often encounter various challenges related to the machinery used. Understanding these common problems can lead to more effective troubleshooting and maintenance, ensuring that the equipment operates smoothly and efficiently.

- Blades Dullness: Over time, the cutting edges can become worn, resulting in inefficient cutting and uneven results.

- Clogging: Accumulation of debris can obstruct movement and impede performance, especially in dense growth areas.

- Drive Issues: Problems with the power transmission can lead to inadequate speed or complete failure to operate.

- Vibration: Excessive shaking may indicate imbalances or loose components, which can affect both performance and user comfort.

- Hydraulic Leaks: Hydraulic systems can develop leaks, compromising efficiency and potentially causing further damage.

By being aware of these issues, operators can take proactive steps to maintain their equipment, ensuring it remains in good working order.

Finding Quality Replacement Parts

When maintaining machinery, sourcing reliable components is essential for optimal performance. Ensuring durability and efficiency requires careful consideration of where to obtain these items. Below are key factors to guide your search.

Where to Look

- Authorized dealers

- Online retailers

- Local hardware stores

- Specialized suppliers

What to Consider

- Quality assurance: Verify the standards of materials used.

- Compatibility: Ensure items fit your specific model.

- Warranty options: Look for guarantees on the components.

- Customer reviews: Read feedback from other users.

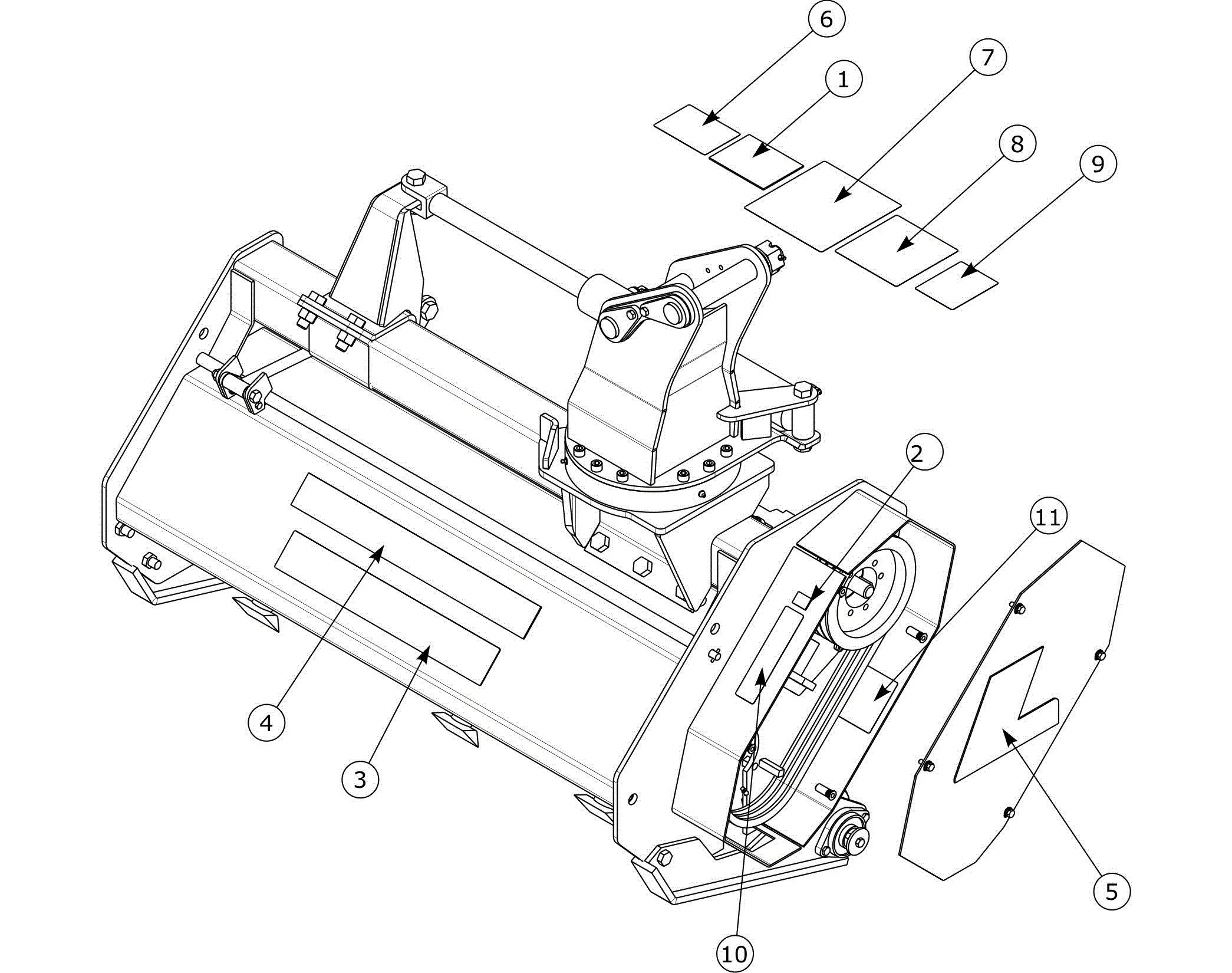

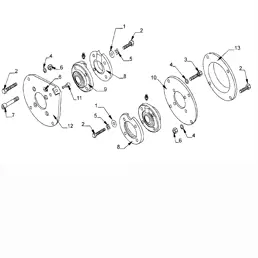

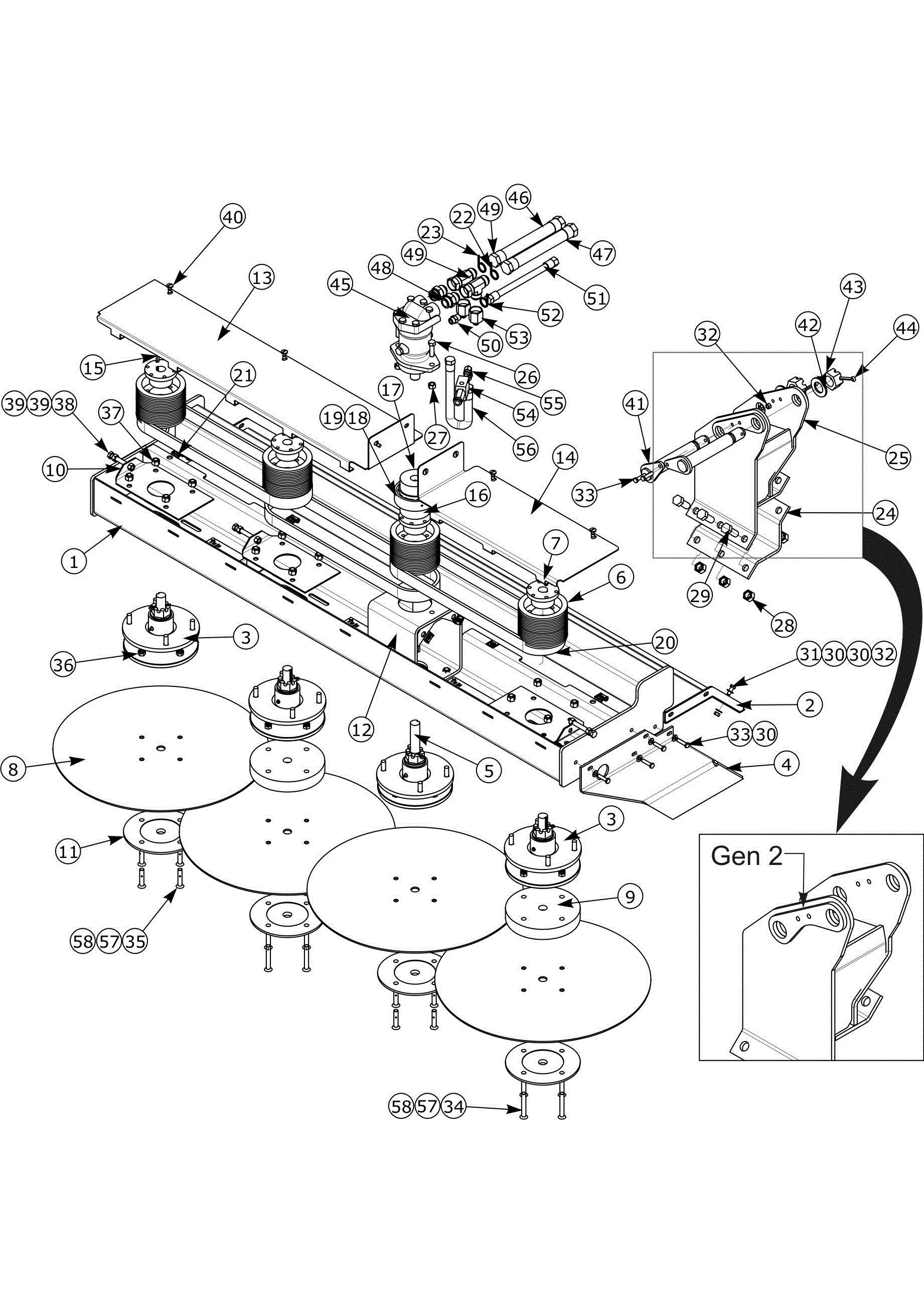

Reading Parts Diagrams Effectively

Understanding schematic representations is essential for anyone looking to navigate the complexities of machinery maintenance and repair. These visual guides serve as a roadmap, helping users identify components and their relationships within a system. Mastering the ability to interpret these illustrations can significantly enhance efficiency and accuracy in the repair process.

Here are some key strategies to improve your comprehension of these representations:

- Familiarize Yourself with Symbols: Each representation employs specific icons to denote various elements. Take time to learn what each symbol signifies.

- Identify Major Sections: Often, these visuals are divided into segments. Recognizing the primary areas can streamline your understanding.

- Follow the Flow: Many illustrations are designed to show the operation sequence. Pay attention to how components interact and function together.

To ensure effective reading, consider these steps:

- Start with the Legend: Always refer to the accompanying legend for clarification on symbols and notations.

- Break Down Complex Areas: For intricate segments, analyze each component individually before connecting them back to the overall assembly.

- Cross-Reference with Manuals: Use user guides to corroborate information and gain additional context regarding the components.

By implementing these techniques, you can develop a more nuanced understanding of schematic illustrations, ultimately leading to better repair outcomes and greater confidence in handling equipment.

Tools Required for Mower Repairs

Maintaining and fixing machinery requires a specific set of instruments to ensure efficiency and safety. Each task may demand different tools, but there are essential items that are universally beneficial for various repairs. Having the right equipment on hand can significantly simplify the process and enhance the quality of the work performed.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To fasten or remove screws with precision. |

| Pliers | Useful for gripping and bending materials. |

| Socket Set | For working on various sizes of fasteners. |

| Hammer | To drive nails or fit parts together. |

| Measuring Tape | For accurate measurements of components. |

| Safety Gear | Essential for personal protection during repairs. |

Investing in quality tools will not only enhance the repair process but also prolong the lifespan of the equipment being serviced. Regular checks and maintenance of these tools ensure they remain effective for any repair challenge that may arise.

Safety Precautions During Maintenance

When performing upkeep on machinery, ensuring safety should be the foremost priority. Proper precautions not only protect the individual conducting the maintenance but also help to prevent damage to the equipment. Understanding potential hazards and implementing measures to mitigate risks is essential for a safe working environment.

Personal Protective Equipment

Utilizing appropriate personal protective gear is crucial. This includes items such as gloves, goggles, and ear protection. Wearing sturdy footwear can prevent injuries from falling objects or heavy equipment. Ensuring that clothing is fitted and free of loose parts minimizes the risk of entanglement in moving components.

Safe Work Practices

Before starting maintenance tasks, always disconnect power sources to eliminate the risk of accidental activation. Maintain a clean workspace to reduce the chance of slips or trips. Familiarize yourself with the machinery’s manual to understand its specific safety protocols. Additionally, having a first aid kit readily available can provide reassurance in case of minor injuries.

Identifying Wear and Tear Signs

Regular maintenance and close inspection of agricultural equipment are essential for prolonging its service life. Over time, components can experience deterioration due to constant use, exposure to harsh environments, and the natural aging of materials. Recognizing the early signs of wear can prevent costly repairs and equipment failures.

Surface Damage and Deformation

One of the first indicators to watch for is surface damage, including cracks, dents, or other deformations. These can occur on various components, especially those subjected to frequent impact or heavy-duty operations. Inspecting the structural integrity of parts regularly helps ensure they function efficiently.

Loss of Efficiency

A noticeable decline in performance, such as uneven cuts or vibrations, often points to underlying wear. Friction and stress may reduce the effectiveness of moving components, signaling the need for adjustments, replacements, or lubrication. Monitoring performance over time helps detect these issues early.

Installation Tips for New Parts

When installing new components, following a systematic approach ensures a smooth process and long-lasting performance. Attention to detail during this phase helps avoid potential issues and ensures that each piece fits correctly within the overall assembly.

Pre-Installation Preparations

Before starting, it’s important to inspect all new elements to ensure they are free of defects. Additionally, reviewing the compatibility of each piece with the existing setup is crucial. Clean the mounting surfaces and check for any wear or damage that could affect installation.

Step-by-Step Guide

To streamline the installation, it’s recommended to follow a structured sequence. Below is a table that outlines the basic steps and the necessary tools required for each stage:

| Step | Action | Tools Needed | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Remove old components carefully, ensuring no damage to surrounding elements. | Wrenches, Screwdriver | |||||||||||

| 2 | Position new components, aligning them with existing mounting

Comparing OEM vs. Aftermarket Parts

When it comes to choosing between original manufacturer components and third-party alternatives, there are several important factors to consider. Each option offers its own set of advantages and potential drawbacks, making it essential to evaluate them based on your specific needs and preferences.

|