Comprehensive Guide to Husqvarna 129R Parts Diagram

When it comes to maintaining outdoor machinery, having a clear understanding of its individual components is essential. Each part plays a crucial role in ensuring optimal performance, and knowing how they fit together can simplify repairs and upgrades. This knowledge not only enhances the longevity of your device but also empowers you to tackle maintenance tasks with confidence.

In this section, we will explore the various elements that make up a specific model of power equipment. By delving into the intricacies of its assembly, we aim to provide a comprehensive overview that will assist both seasoned users and newcomers. From engine assemblies to cutting mechanisms, every component is designed with precision to achieve outstanding results.

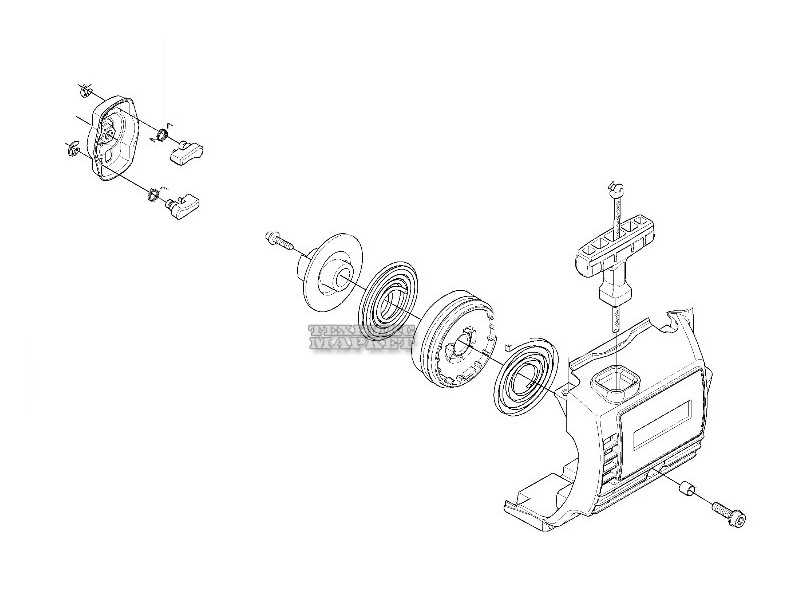

Whether you’re looking to replace a worn-out piece or simply want to familiarize yourself with the inner workings, having access to a visual representation of these parts can be invaluable. This resource will guide you through the essential features, helping you identify each segment and understand its function within the larger system.

Understanding the Husqvarna 129R Parts Diagram

When working with outdoor equipment, a thorough comprehension of its components is crucial for effective maintenance and repairs. Familiarizing yourself with the visual representation of parts can significantly enhance your ability to identify, troubleshoot, and replace necessary elements.

Key Components

Each piece of machinery consists of various essential elements that work together to ensure optimal performance. Below are some common categories found in such visual representations:

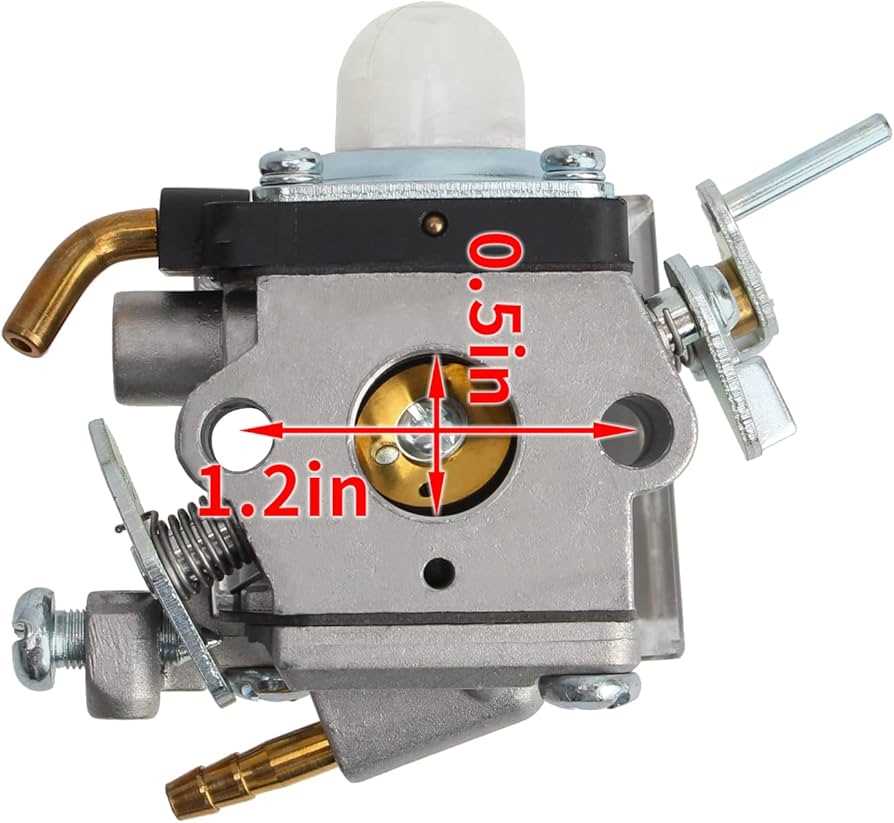

- Engine Parts: Components like pistons, spark plugs, and carburetors are vital for power generation.

- Fuel System: Includes tanks, lines, and filters that ensure a smooth fuel supply.

- Cutting Assembly: Blades and related components that directly affect cutting efficiency.

- Chassis and Housing: The frame and protective casing that hold everything together.

Benefits of Understanding the Visual Representation

Gaining insight into the layout of the equipment’s elements provides several advantages:

- Improved maintenance practices through better identification of wear and tear.

- Streamlined repair processes by knowing which components need replacement.

- Enhanced safety awareness by understanding how parts interact during operation.

In summary, a solid grasp of the visual breakdown of your equipment can lead to more efficient upkeep and extended longevity of your outdoor machinery.

Overview of Husqvarna 129R Model

This section provides an insight into a powerful and versatile outdoor equipment model, designed to meet the needs of both professionals and enthusiasts. Known for its reliability and performance, this tool is ideal for various gardening and landscaping tasks.

Key features include:

- Lightweight design for enhanced maneuverability

- Powerful engine that delivers robust performance

- Easy starting mechanism for user convenience

- Durable construction, ensuring longevity in challenging environments

Maintenance and repair are essential for optimal performance. Understanding the components involved can aid in effective upkeep. The tool is equipped with several critical elements, including:

- Engine assembly

- Fuel system

- Cutting head

- Handle and control systems

In summary, this model stands out due to its combination of efficiency, ease of use, and adaptability, making it a top choice for those engaged in outdoor work.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations of individual elements allow users to grasp the intricate details of assembly and disassembly processes. These illustrations not only enhance comprehension but also facilitate efficient troubleshooting, ensuring that repairs can be carried out swiftly and accurately.

Benefits of Visual Guides

- Enhanced Clarity: Visual aids simplify complex structures, making it easier to identify parts and their functions.

- Streamlined Repairs: With clear references, users can quickly locate the necessary components, reducing downtime.

- Improved Accuracy: Detailed images help in understanding the precise placement and orientation of each piece.

Facilitating Maintenance

- Regular maintenance becomes more manageable when one can easily refer to a visual guide.

- Users can identify wear and tear on specific elements, ensuring timely replacements.

- Such resources encourage a proactive approach to care, ultimately extending the lifespan of equipment.

Key Components of the 129R

The efficiency and performance of any outdoor power tool largely depend on its essential elements. Understanding these core components can significantly enhance the user experience and maintenance practices. This section highlights the vital parts that contribute to the functionality and durability of the equipment.

Engine: The heart of the machine, the engine, provides the necessary power to perform various tasks. A well-functioning engine ensures optimal performance, allowing for smooth operation and reliable results.

Cutting Head: This component is crucial for effective trimming and cutting. The design and quality of the cutting head directly influence the tool’s efficiency and the quality of the finished work.

Fuel System: The fuel system plays a key role in delivering energy to the engine. Proper maintenance and understanding of this system are essential for preventing issues and ensuring consistent performance.

Handle Assembly: Comfort and control are paramount during operation. The handle assembly is designed for ergonomic use, allowing the operator to maneuver the tool with ease while reducing fatigue.

Drive Shaft: This part transmits power from the engine to the cutting head, making it vital for the overall functionality. A durable drive shaft ensures reliable performance and longevity of the tool.

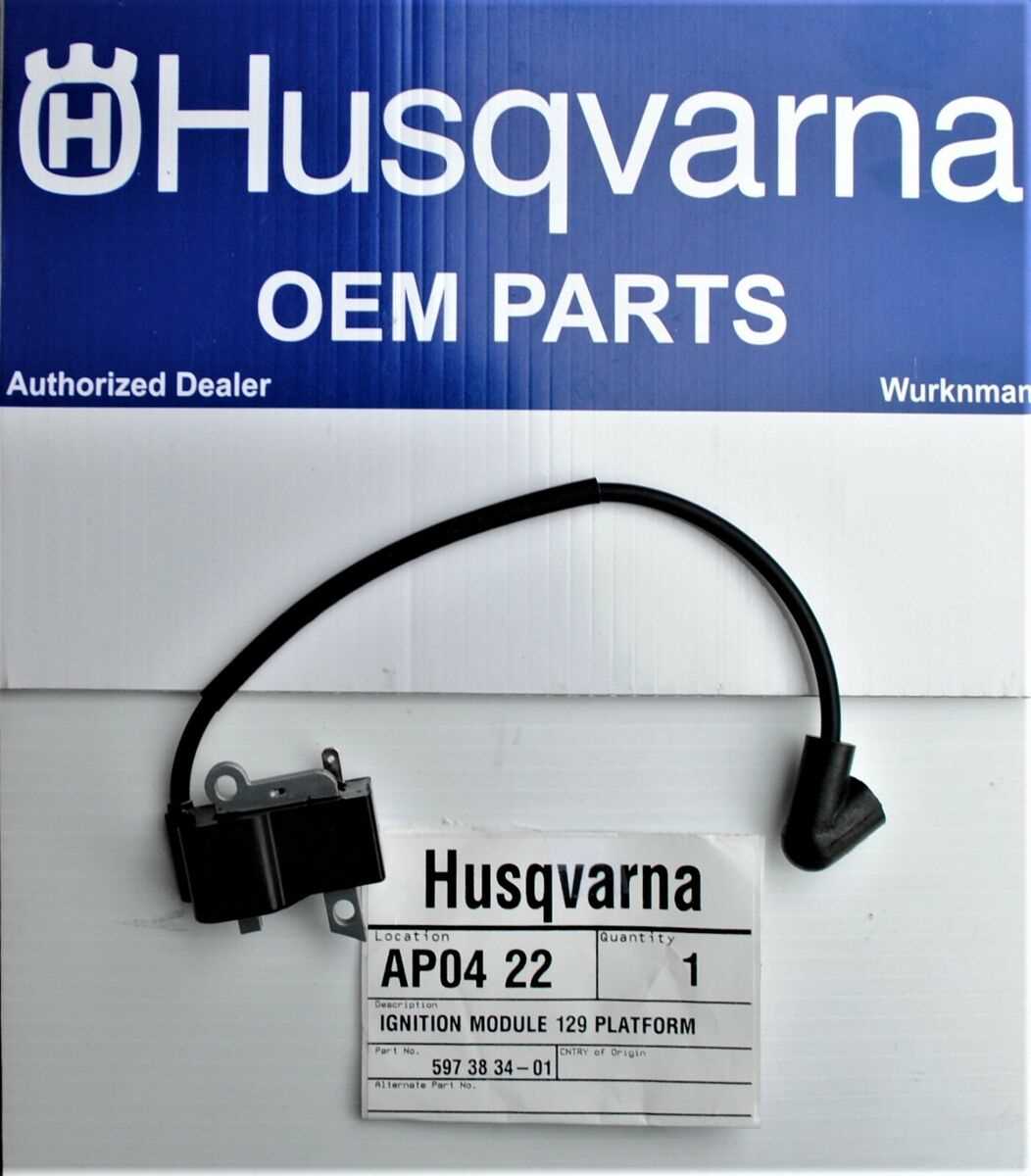

Starter Mechanism: A dependable starting mechanism is critical for ease of use. It allows for quick ignition, enabling the operator to begin work without unnecessary delays.

Understanding these key components not only aids in effective operation but also assists in identifying maintenance needs and potential issues, ensuring the longevity and reliability of the tool.

How to Read the Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This guide provides insights into interpreting the visual layout, helping you identify parts and their functions efficiently. By grasping the key elements of the illustration, you can streamline your workflow and enhance your overall experience.

Key Components

Each illustration typically includes various sections that correspond to different parts of the machinery. Familiarizing yourself with these segments is crucial for a comprehensive understanding. Here are some fundamental elements to consider:

| Element | Description |

|---|---|

| Labels | These provide names or codes for specific parts, facilitating easy identification. |

| Lines and Arrows | Indicate the connections and flow between components, showing how they interact. |

| Legend | A key that explains symbols or colors used in the illustration, offering clarity. |

Steps for Effective Interpretation

To effectively read the visual representation, follow these steps:

- Start by locating the legend to familiarize yourself with symbols.

- Identify major assemblies and their corresponding labels.

- Trace connections to understand how each component integrates with others.

- Note any additional notes or instructions that might assist in the assembly or repair process.

Common Replacement Parts Explained

In the realm of outdoor power tools, understanding the various components that may require periodic substitution is essential for maintaining performance and longevity. Regular wear and tear can affect functionality, making it crucial to identify the most commonly replaced elements. Below, we explore key components that often need attention, providing insights into their roles and importance.

| Component | Description | Signs of Wear |

|---|---|---|

| Air Filter | Prevents debris from entering the engine, ensuring clean airflow. | Reduced power, engine stalling. |

| Fuel Line | Delivers fuel from the tank to the engine. | Leaks, cracks, or discoloration. |

| Spark Plug | Ignites the fuel-air mixture for combustion. | Hard starting, misfiring. |

| Cutting Head | Holds the cutting line or blade, facilitating effective trimming. | Worn edges, difficulty in line feeding. |

| Starter Rope | Used to manually start the engine. | Fraying or breaking. |

By staying informed about these critical components, users can ensure their equipment remains in optimal condition, ready for the demands of outdoor tasks.

Troubleshooting Using the Diagram

When dealing with mechanical issues, a visual representation of components can be invaluable. This approach not only facilitates the identification of individual parts but also aids in understanding their interconnections and functions. By following a structured method, you can effectively pinpoint the root causes of problems, leading to more efficient repairs and maintenance.

The process typically involves comparing the current state of the equipment with the reference illustration. Start by examining each section meticulously to ensure all elements are present and in proper condition. Pay special attention to wear and tear, as well as any misalignments that could impact performance.

| Issue | Potential Cause | Solution |

|---|---|---|

| Engine won’t start | Faulty ignition or fuel supply | Check spark plug and fuel lines |

| Excessive vibration | Worn bearings or loose components | Tighten screws and inspect bearings |

| Loss of power | Clogged air filter or damaged exhaust | Clean or replace filter; inspect exhaust |

By systematically addressing these common issues with the aid of a component illustration, you can enhance both the lifespan and efficiency of your equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring that your outdoor equipment remains efficient and durable over time. By implementing simple maintenance practices, you can significantly extend the life of your machinery, enhancing performance and reducing the likelihood of unexpected repairs.

Here are some key maintenance tips to follow:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean the air filter | Every 10 hours of use | Improves airflow and engine efficiency |

| Inspect the spark plug | Every 25 hours of use | Ensures proper ignition and reduces fuel consumption |

| Check the fuel system | Before each use | Prevents clogging and ensures optimal performance |

| Sharpen the blades | Every 10 hours of use | Enhances cutting efficiency and reduces strain on the engine |

| Lubricate moving parts | Every 20 hours of use | Minimizes wear and tear, promoting smooth operation |

| Store properly | Seasonally | Prevents damage from environmental factors and prolongs lifespan |

By following these maintenance recommendations, you can ensure that your equipment remains in peak condition, allowing for reliable performance throughout its service life.

Where to Find Genuine Parts

Locating authentic components for your outdoor equipment is crucial for maintaining optimal performance and longevity. Ensuring that you use quality replacements can significantly enhance the efficiency and reliability of your machine. Here are some reliable sources to consider:

- Authorized Dealers: These retailers offer a wide selection of genuine replacements, ensuring compatibility with your equipment.

- Manufacturer’s Website: Visit the official site for a catalog of original components, often accompanied by ordering options.

- Specialty Stores: Local shops dedicated to outdoor power tools frequently stock certified components and can provide expert advice.

- Online Marketplaces: Reputable e-commerce platforms often feature listings from verified sellers, ensuring the authenticity of the items.

Before purchasing, always verify the authenticity of the components to avoid compatibility issues and ensure optimal functionality.

Online Resources for Diagrams

Accessing detailed schematics online can greatly simplify maintenance and repair tasks. Numerous platforms offer a wealth of visual guides that illustrate the components and assembly of various equipment. These resources cater to both novices and experienced users, enabling them to find the necessary information quickly and effectively.

Useful Websites

Several websites specialize in providing visual references for various models and brands. Below are some noteworthy options:

| Website | Description |

|---|---|

| Manufacturer’s Official Site | Offers the most accurate and detailed schematics for specific models, often including user manuals and technical support. |

| Parts Retailers | Many online retailers provide visual aids that help customers identify and order the correct components. |

| Community Forums | User-driven platforms where enthusiasts share guides, tips, and links to helpful visuals. |

Benefits of Using Online Resources

Utilizing online visuals not only enhances understanding but also saves time during repair processes. Users can easily cross-reference parts and ensure they have the correct items before beginning any work. This access to information fosters greater confidence in tackling maintenance tasks independently.

Comparison with Similar Models

When evaluating tools in the same category, it’s essential to consider various models that offer comparable features and functionalities. Understanding these alternatives can help users make informed decisions based on their specific needs and preferences. Each model presents unique strengths and weaknesses that cater to different applications and user experiences.

Performance and Efficiency

In terms of performance, similar units often compete on power output and fuel efficiency. Many alternatives showcase advanced engine technology, providing users with improved torque and reduced emissions. Evaluating these aspects allows potential buyers to select the model that best suits their operational requirements and environmental considerations.

Design and Usability

Another crucial factor is the design and overall usability of the tools. Some models feature ergonomic handles and lightweight construction, making them easier to maneuver for extended periods. Comparing the comfort and balance of different units can significantly impact user satisfaction and productivity during tasks.

DIY Repairs: A Step-by-Step Guide

Maintaining your outdoor equipment can significantly extend its lifespan and improve performance. This guide aims to provide you with a clear, methodical approach to tackle common repair tasks on your machinery. By following these steps, you can efficiently diagnose issues and make necessary fixes, all while saving time and money.

Tools You’ll Need

- Screwdrivers (flathead and Phillips)

- Wrenches and pliers

- Replacement components

- Safety goggles and gloves

- Cleaning supplies

Step-by-Step Repair Process

-

Identify the Problem: Start by observing any unusual behavior or performance issues. Take notes on specific symptoms.

-

Gather Information: Consult manuals or online resources for troubleshooting tips relevant to your model.

-

Prepare Your Workspace: Ensure you have a clean, well-lit area to work in. Gather all necessary tools and replacement parts.

-

Disassemble the Unit: Carefully remove screws and components to access the problematic area. Keep parts organized to avoid confusion during reassembly.

-

Inspect and Replace: Examine the parts for wear or damage. Replace any defective components with suitable alternatives.

-

Reassemble: Follow your notes to put everything back together, ensuring all connections are secure.

-

Test the Equipment: Once reassembled, run the machinery to verify that the issue has been resolved and everything operates smoothly.

With the right approach and tools, you can tackle repairs confidently. Regular maintenance will not only enhance functionality but also contribute to the longevity of your equipment.

Customer Reviews and Experiences

In this section, we delve into the perspectives and feedback shared by users of a popular outdoor power tool. Their insights offer a glimpse into the functionality, reliability, and overall satisfaction derived from the product. By examining these testimonials, potential buyers can make informed decisions based on real-world experiences.

Positive Feedback

Many customers appreciate the tool’s robust design and ease of use. One user noted how effortlessly it tackled tough vegetation, making yard work a much simpler task. Additionally, the efficiency of the engine received high praise, with several reviews highlighting the extended runtime that allows for longer sessions without frequent refueling.

Areas for Improvement

While there are numerous positive comments, some users have pointed out areas for enhancement. A common concern is the weight of the device, which can lead to fatigue during prolonged use. Additionally, a few customers have suggested that the instruction manual could be more detailed, particularly for first-time users unfamiliar with similar equipment.