Comprehensive Guide to Yamaha F200XB Parts Diagram

When it comes to maintaining the longevity and efficiency of your marine power unit, comprehending its various elements is essential. A thorough exploration of the intricate structures within these engines not only aids in effective repairs but also enhances performance. This section aims to provide an insightful overview of the essential components that contribute to the smooth operation of your vessel.

Identifying each part is crucial for anyone looking to optimize their boating experience. From the vital mechanisms that drive performance to the auxiliary features that ensure functionality, a clear understanding can prevent potential issues and costly repairs. As we delve into this topic, you will discover how each element interacts harmoniously to create a reliable marine system.

Equipped with this knowledge, you can make informed decisions about maintenance and upgrades. Ultimately, being familiar with the inner workings of your engine empowers you to address challenges proactively, ensuring that your maritime adventures remain uninterrupted.

Understanding Yamaha F200XB Components

Grasping the intricacies of marine engine elements is crucial for effective maintenance and optimal performance. Each component plays a significant role in the overall functionality of the vessel, and recognizing these parts enhances both knowledge and capability for troubleshooting.

Key Elements of the Engine

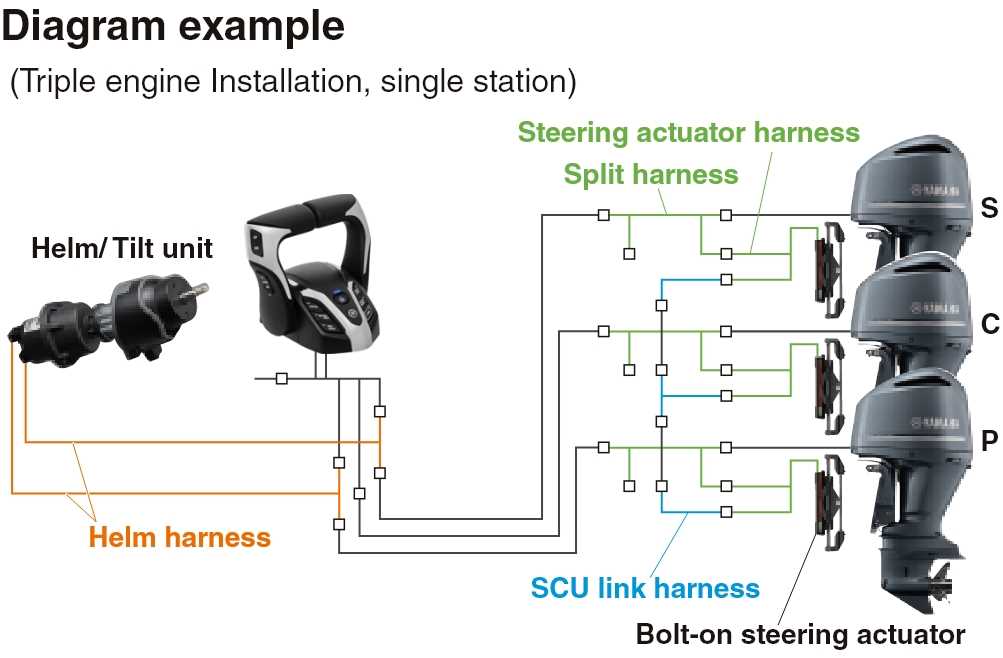

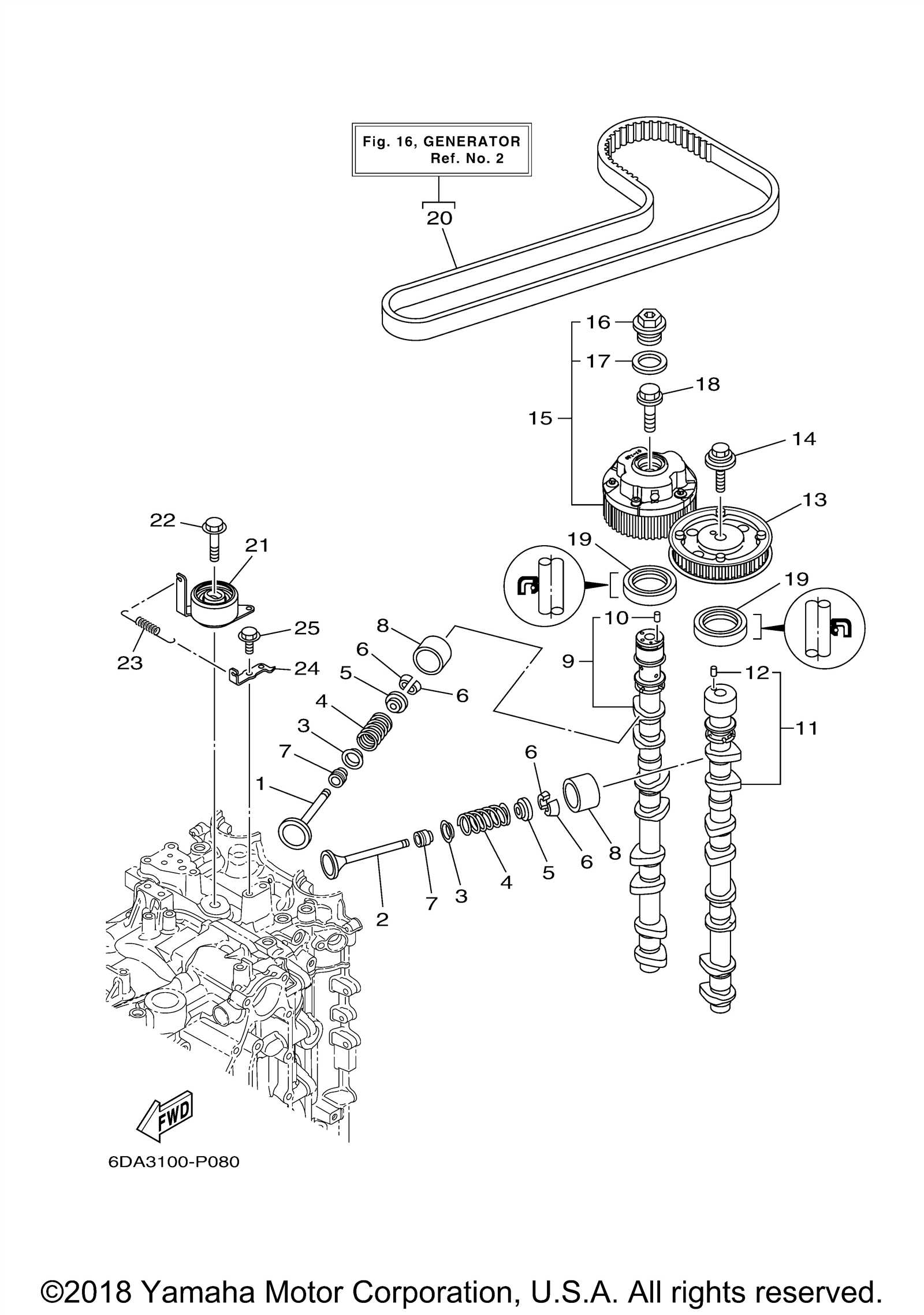

The core constituents include the powerhead, lower unit, and electrical systems, each contributing uniquely to the engine’s operations. The powerhead is responsible for the combustion process, while the lower unit facilitates propulsion through the water. Electrical components ensure smooth starting and efficient operation.

Maintenance Considerations

Regular inspection and maintenance of these elements are vital for longevity. Understanding how each part interacts can prevent issues and enhance the performance of your marine craft, ensuring that every journey is as smooth as possible.

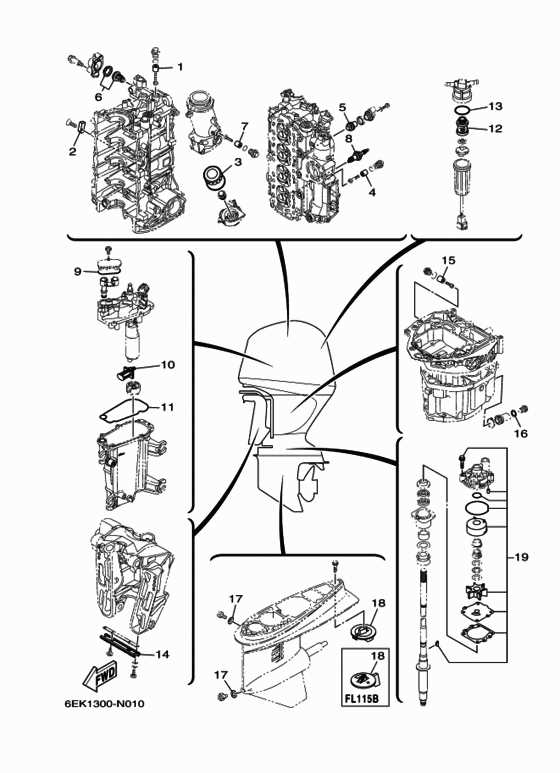

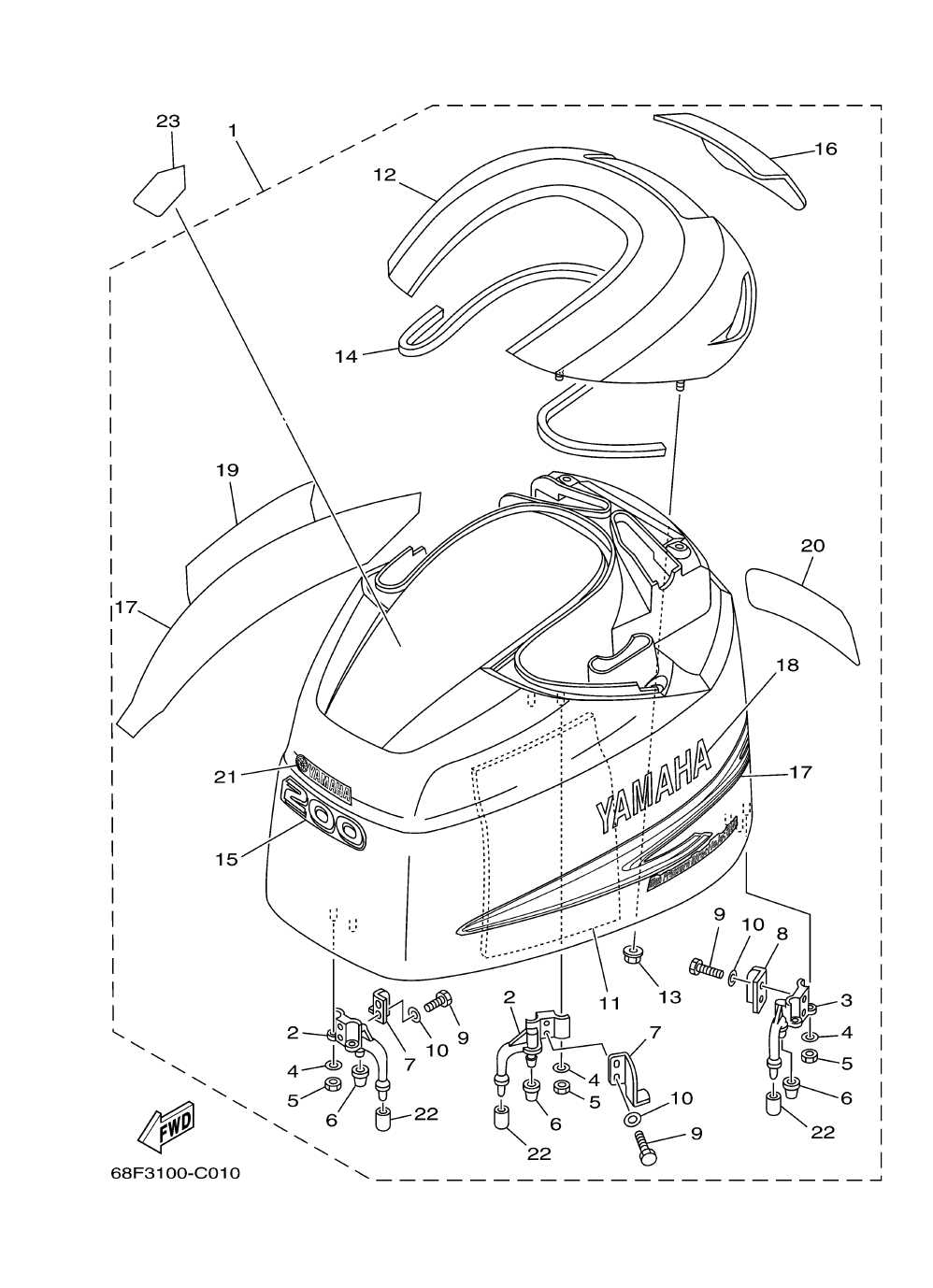

Importance of Parts Diagrams

Understanding the layout and organization of components within machinery is crucial for efficient maintenance and repair. Visual representations enhance clarity, enabling users to identify necessary elements quickly and accurately. This facilitates better communication among technicians and aids in troubleshooting efforts.

Benefits of Visual Representations

- Streamlined repair processes

- Reduced downtime for equipment

- Enhanced understanding of complex systems

- Improved accuracy in ordering replacements

Practical Applications

- Guiding assembly and disassembly tasks

- Assisting in inventory management

- Supporting training initiatives for new technicians

- Facilitating communication with suppliers

Common Issues with Yamaha F200XB

When operating a marine engine, certain challenges may arise that can affect performance and reliability. Understanding these potential problems is essential for effective maintenance and longevity of the unit.

Overheating is a frequent concern, often linked to insufficient cooling system function or blockage. Regular checks of the water intake and thermostat can help prevent this issue.

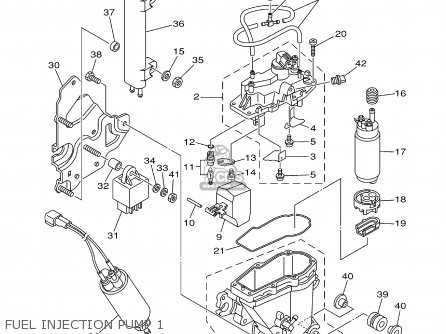

Fuel delivery problems can also surface, often caused by clogged filters or fuel lines. Ensuring a clean fuel system is vital for optimal operation.

Electrical failures may occur due to corroded connections or faulty components. Routine inspections of the electrical system can mitigate these risks.

Lastly, exhaust leaks can lead to decreased efficiency and potential hazards. Regular monitoring of exhaust components is advisable to identify and address any issues promptly.

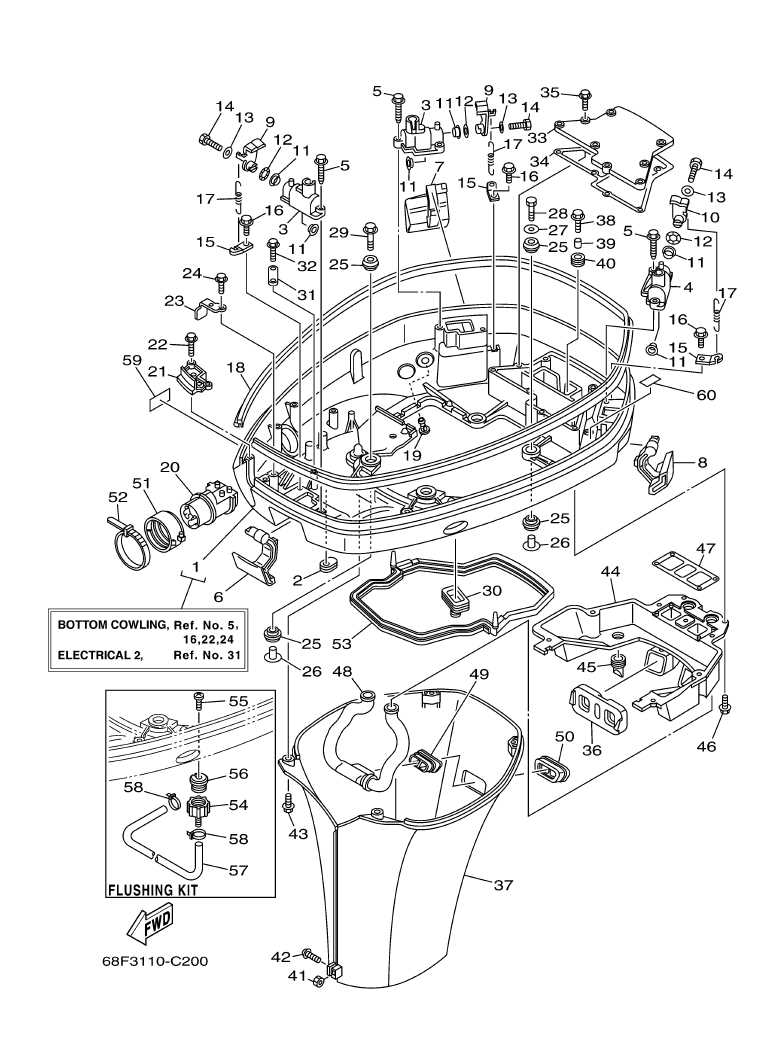

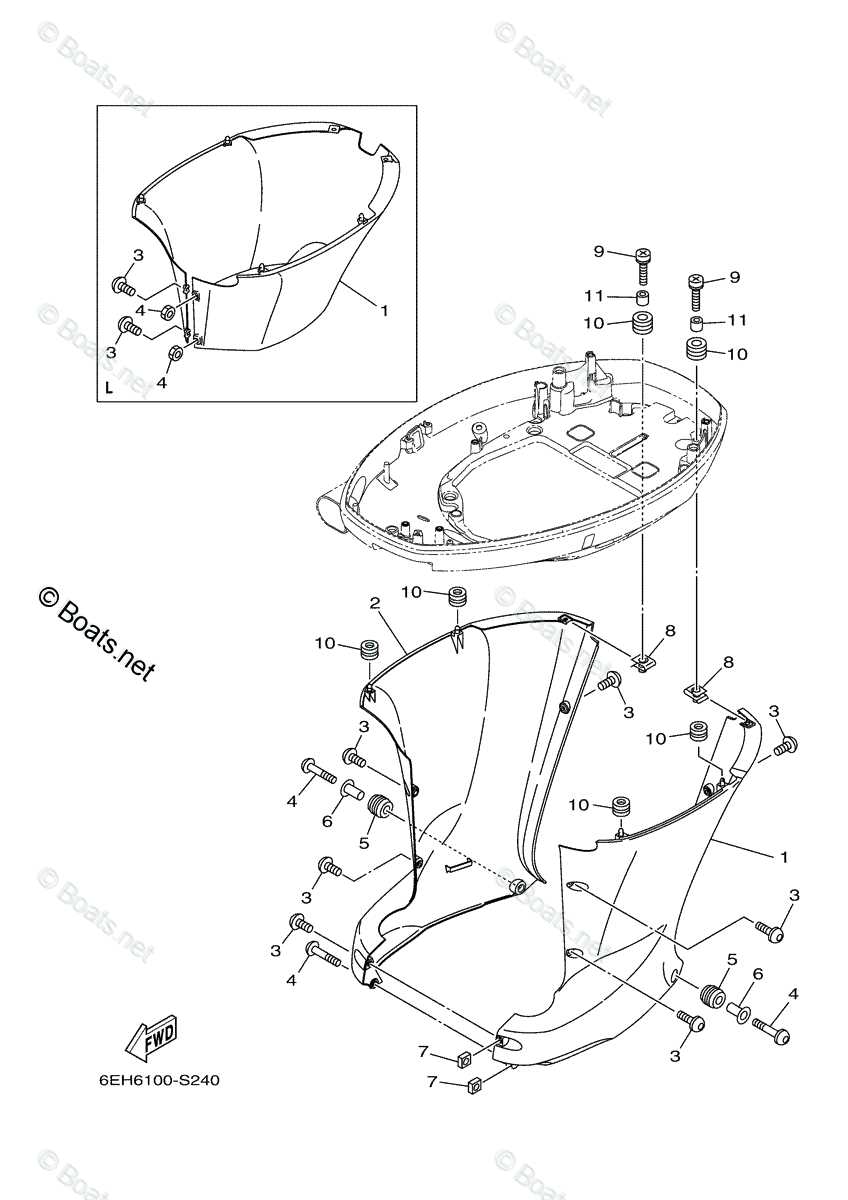

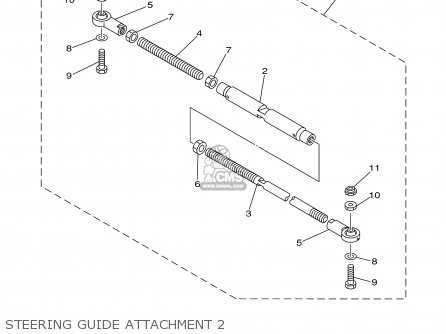

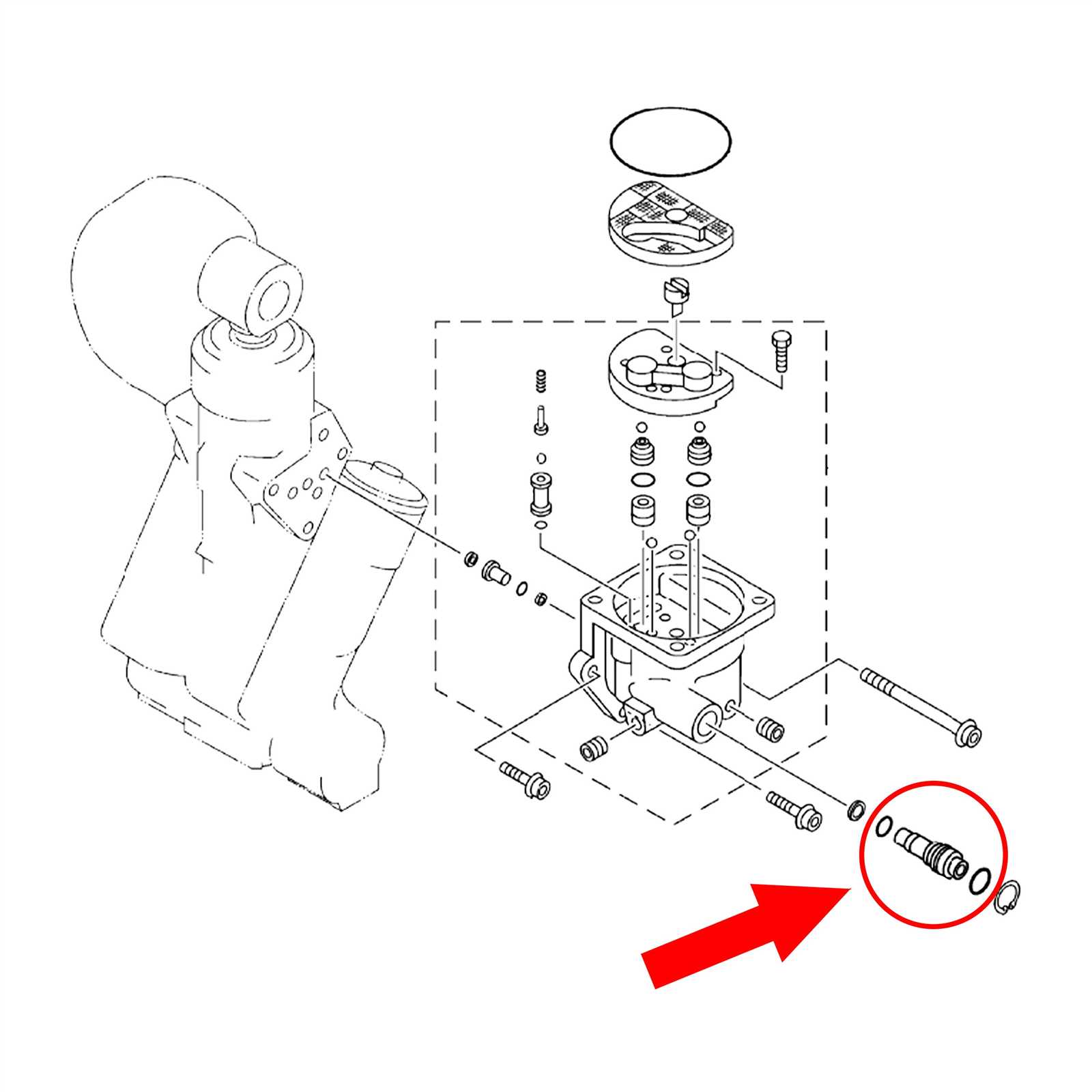

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations offer a detailed view of components and their relationships, making it easier to identify specific items needed for service. Familiarizing yourself with the layout and symbols used in these illustrations can enhance your ability to quickly locate parts and comprehend their functions.

Start by identifying the key sections within the illustration, often categorized by functionality or assembly order. Look for a legend or key that explains any symbols or numbering used, as this will provide clarity on how different elements relate to one another. Additionally, pay attention to the orientation and scale, which can help in visualizing how components fit together in the actual assembly.

As you delve deeper, note any accompanying notes or annotations that may provide further insight into installation or troubleshooting. This information can prove invaluable when determining the ultimate course of action for repairs or replacements. With practice, interpreting these illustrations will become a straightforward task, allowing for more efficient project completion.

Essential Tools for Maintenance

Regular upkeep of marine engines requires a variety of essential equipment to ensure optimal performance and longevity. Having the right tools on hand simplifies the maintenance process and allows for efficient repairs, ultimately enhancing the reliability of your vessel.

Basic Hand Tools

- Wrenches: For tightening and loosening bolts.

- Screwdrivers: Essential for fastening screws of various sizes.

- Pliers: Useful for gripping and bending components.

Specialized Equipment

- Multimeter: For electrical diagnostics and troubleshooting.

- Oil Extractor: Facilitates easy oil changes.

- Compression Tester: Assesses engine performance effectively.

Identifying Replacement Parts Easily

When it comes to maintaining and repairing your equipment, understanding how to find and select the correct components is essential. With the right approach, you can streamline the process of sourcing necessary items, ensuring optimal performance and longevity. This section will explore effective strategies to make identification straightforward and efficient.

Utilize Online Resources: A wealth of digital platforms offers detailed illustrations and descriptions of various components. By leveraging these tools, you can quickly locate what you need.

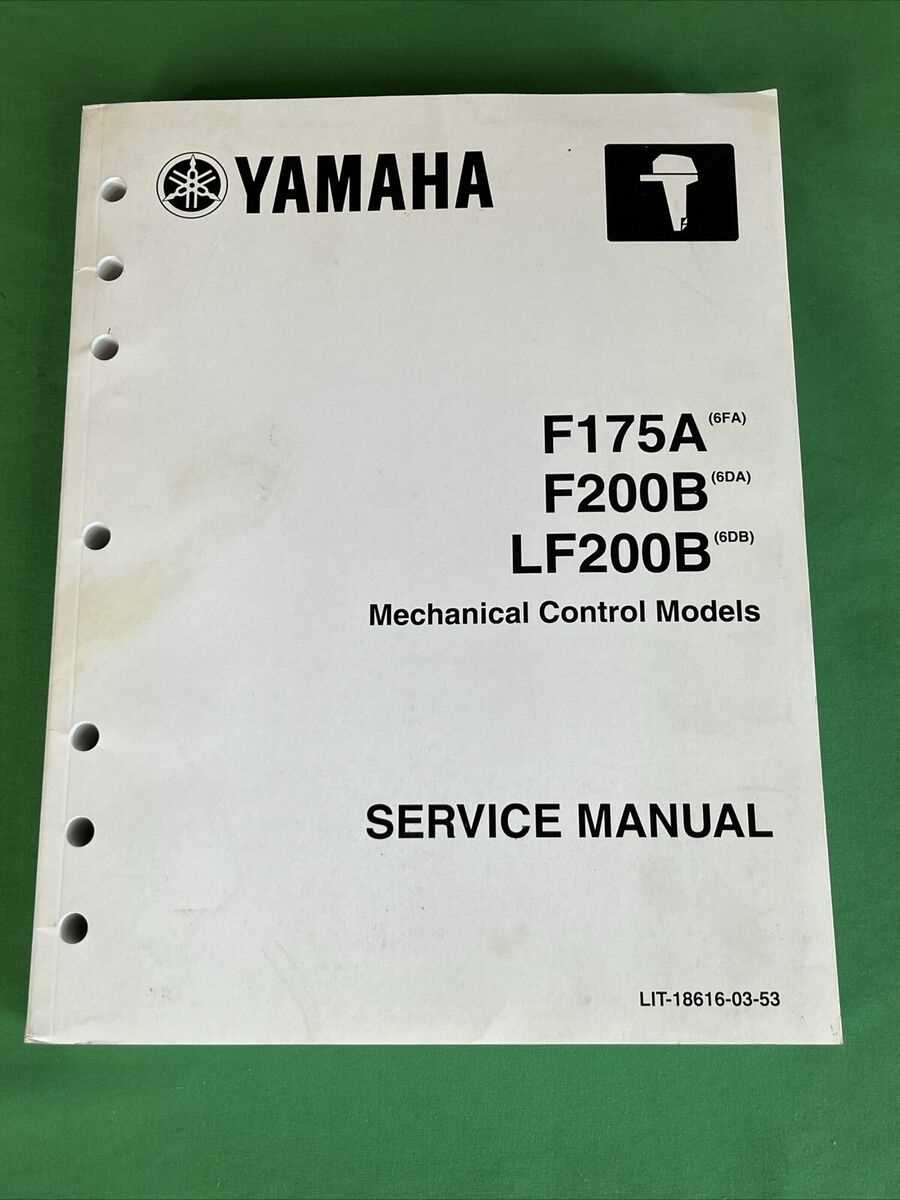

Consult User Manuals: Manuals often contain specific information regarding each component’s function and compatibility. They serve as invaluable guides for accurate identification.

Engage with Online Communities: Forums and discussion groups can be great places to seek advice from experienced users. Their insights can help clarify any uncertainties about specific items.

Visit Local Dealers: Establishing a relationship with local suppliers can provide personalized assistance. They often possess extensive knowledge about the products they sell.

By combining these methods, you can ensure that you make informed decisions when selecting replacements, ultimately enhancing the efficiency of your repairs.

Maintenance Tips for Yamaha F200XB

Proper upkeep is essential for ensuring optimal performance and longevity of your outboard motor. Regular inspections and maintenance routines can prevent unexpected issues and enhance efficiency. This section provides practical advice to keep your engine running smoothly.

First, regularly check the fluid levels, including oil and coolant, to ensure they are within the recommended range. Change the oil as per the manufacturer’s schedule to maintain engine health. Additionally, inspect fuel lines and filters for any signs of wear or blockage, as clean fuel is crucial for performance.

It’s also important to clean and inspect the cooling system. Remove debris from the intake and ensure that the water pump is functioning correctly. Regularly flushing the engine with fresh water after use in saltwater conditions helps prevent corrosion.

Finally, conduct a thorough check of the electrical systems and connections. Ensure that all terminals are clean and secure to avoid electrical failures. By following these maintenance tips, you can maximize the reliability and efficiency of your outboard motor.

Where to Find Genuine Parts

When seeking high-quality components for your marine engine, it’s essential to know where to look. Authentic pieces ensure optimal performance and longevity, helping you maintain your vessel in prime condition. This guide outlines the best sources for obtaining reliable replacements.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers offer a comprehensive selection of original components with manufacturer guarantees. |

| Official Websites | Many manufacturers have online platforms that provide direct access to authentic products. |

| Specialized Marine Shops | Local stores often carry a range of genuine items and can provide expert advice. |

| Online Marketplaces | Reputable e-commerce sites may have verified sellers offering authentic replacements. |

Comparing Aftermarket vs. OEM Parts

When considering replacements for mechanical components, a crucial decision arises between choosing original equipment and alternative options. Each category has its own advantages and disadvantages, which can significantly impact performance, cost, and reliability.

Quality and Performance

Original components are typically engineered to meet strict manufacturer standards, ensuring a high level of reliability and performance. In contrast, alternative options may vary in quality, with some brands offering impressive durability while others might compromise performance.

Cost Considerations

Pricing is often a decisive factor. Original products tend to be more expensive due to their guaranteed standards and warranty, whereas aftermarket solutions can provide cost-effective alternatives, appealing to budget-conscious consumers. However, it’s essential to assess long-term value rather than just initial costs.

Step-by-Step Repair Procedures

This section provides a detailed guide for performing maintenance and repairs on your marine engine. Following a systematic approach can help you identify issues efficiently and ensure proper functionality after repairs. Each step is designed to simplify the process, making it accessible for both novice and experienced technicians.

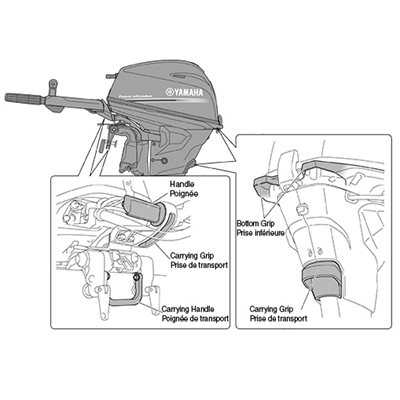

Preparation and Safety Measures

Before starting any repair work, ensure you have the necessary tools and safety equipment. Disconnect the power supply and secure the vessel to prevent any movement during the procedure. It’s essential to have a clean workspace to avoid losing small components. Always refer to the manufacturer’s guidelines for specific safety protocols.

Step-by-Step Repair Process

Begin by diagnosing the issue, paying close attention to any unusual sounds or performance problems. Once the problem is identified, gather the required replacement components. Carefully disassemble the affected area, taking note of the order and orientation of parts for reassembly. Clean any surfaces before installing new components, ensuring a tight fit. After replacing the faulty parts, reassemble everything in reverse order, double-checking each connection. Finally, test the engine to confirm that repairs were successful.

Online Resources for Yamaha Owners

For enthusiasts and owners of marine engines, accessing the right information is crucial for maintenance and performance enhancement. Fortunately, there are numerous online platforms that provide valuable resources, including forums, instructional videos, and comprehensive manuals. These tools can significantly aid in the upkeep and understanding of your equipment, ensuring it runs efficiently and safely.

Key Online Platforms

Here are some notable websites that offer valuable insights and support:

| Website | Description |

|---|---|

| BoatUS | A community forum where boat owners can share tips and troubleshoot issues together. |

| iBoats | A resource-rich site featuring user reviews, guides, and a marketplace for parts. |

| YouTube | A platform filled with DIY tutorials and maintenance tips provided by experienced users. |

| MarineEngine.com | An online database for manuals and replacement components tailored to various models. |

Utilizing Online Communities

Engaging with online communities can provide immediate assistance and foster a sense of belonging among fellow enthusiasts. These platforms allow users to ask questions, share experiences, and learn from each other, creating a collaborative environment that benefits everyone involved.