Audi Engine Parts Diagram Explained

The intricate machinery that powers modern vehicles consists of numerous components, each playing a crucial role in ensuring optimal performance. To truly grasp the functionality of these elements, one must explore their interconnections and operations. This section aims to provide a comprehensive overview of these vital structures.

By breaking down the various segments of this complex system, readers will gain insight into how each piece contributes to the overall efficiency and reliability of the vehicle. A detailed exploration allows enthusiasts and professionals alike to deepen their knowledge and appreciate the precision involved in automotive engineering.

As we delve into the specifics, it is essential to highlight the significance of maintenance and understanding the layout of these components. A thorough comprehension of their arrangement can lead to better troubleshooting and enhancements, ultimately elevating the performance to its ultimate potential.

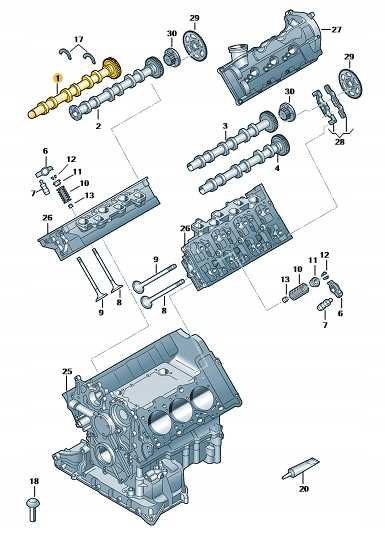

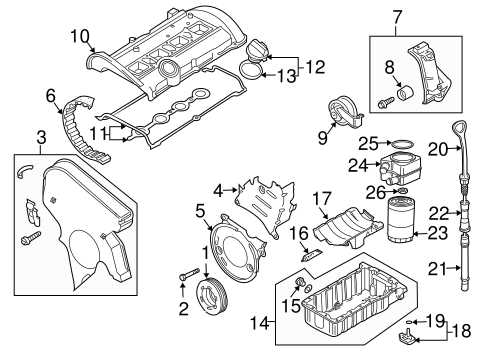

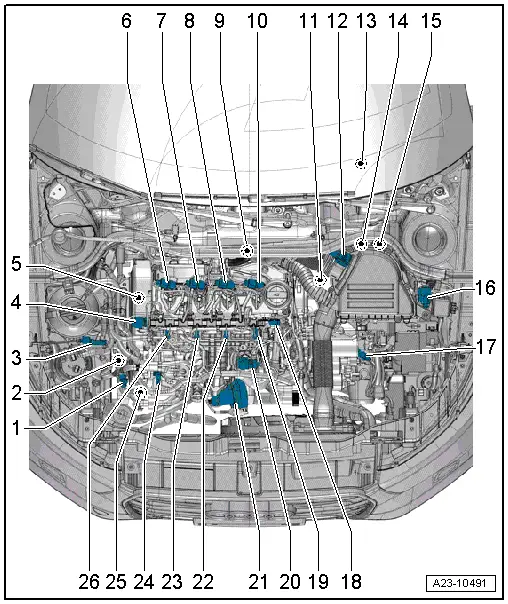

Audi Engine Components Overview

This section aims to provide a comprehensive look at the various elements that make up the internal machinery of a vehicle. Understanding these components is essential for grasping how they work together to create optimal performance and efficiency.

Core Components: The primary elements include the block, which serves as the foundation, and the cylinder heads that house the combustion chambers. These pieces are crucial for facilitating the power generation process.

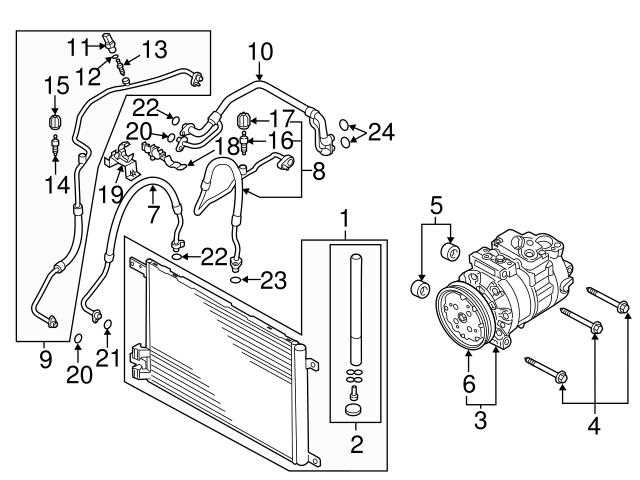

Supporting Systems: Various systems, such as the cooling and lubrication frameworks, ensure that everything operates smoothly. These systems are vital for maintaining optimal temperatures and reducing friction, which can lead to wear over time.

Additional Features: Other significant components include the intake and exhaust systems, which manage airflow, and the ignition system, responsible for initiating combustion. Each of these plays a pivotal role in enhancing overall performance.

In summary, a thorough understanding of these components can significantly impact maintenance and performance, ultimately contributing to the longevity of the vehicle.

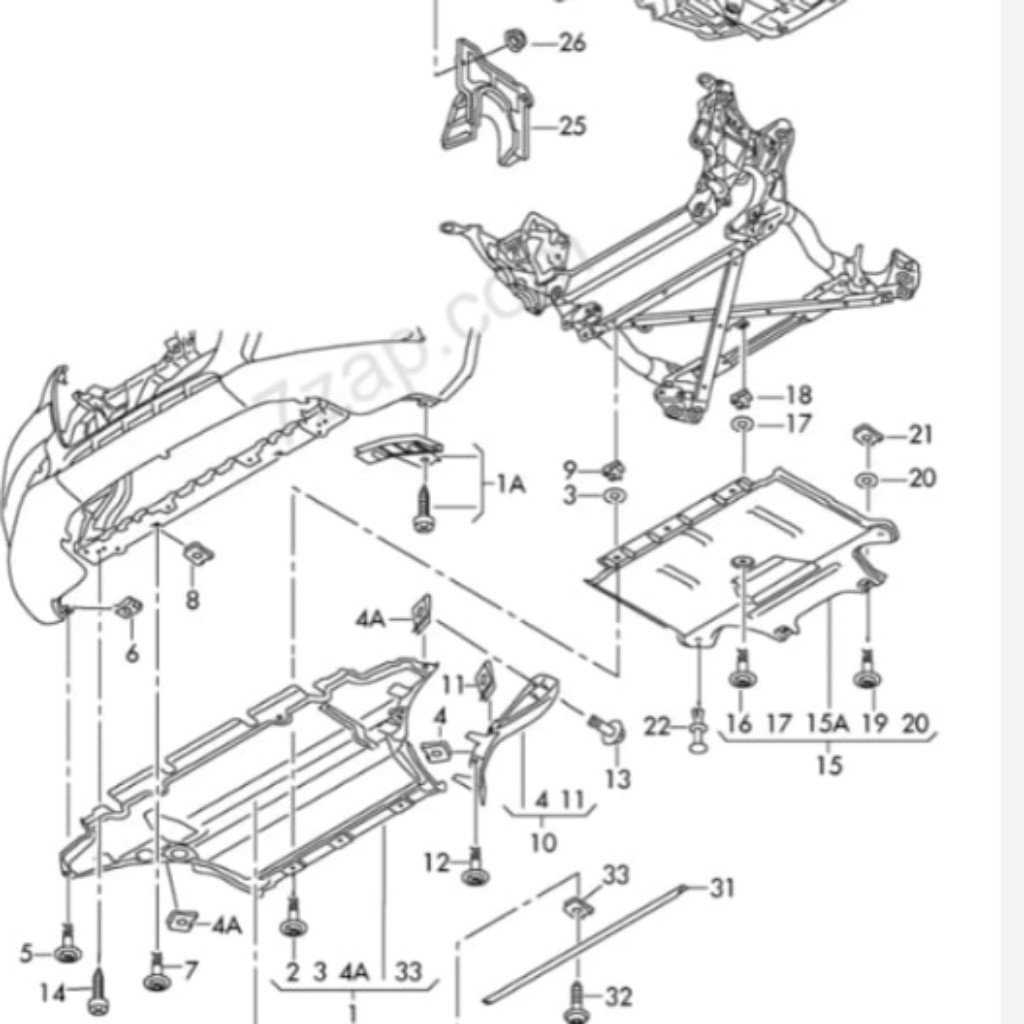

Understanding Engine Layouts

Comprehending the structure of a power unit is crucial for both enthusiasts and professionals. Each configuration offers distinct characteristics that influence performance, efficiency, and handling. By examining these setups, one can gain insights into how various components interact and contribute to overall functionality.

Types of Configurations

Common arrangements include inline, V-shaped, and flat formations. Each type has unique advantages. For instance, inline configurations are often praised for their simplicity and balance, while V-shaped layouts tend to provide more power in a compact design. Flat setups, on the other hand, are known for their lower center of gravity, enhancing stability.

Impact on Performance

The layout significantly affects several aspects, such as weight distribution, thermal efficiency, and vibration characteristics. A well-designed structure can lead to improved acceleration and handling, while an inefficient one may result in sluggish performance. Understanding these relationships is essential for optimizing any vehicle’s capabilities.

Common Audi Engine Parts Explained

This section aims to explore various essential components found within a specific automotive power unit, detailing their functions and significance. Understanding these elements can enhance your appreciation of how they contribute to overall performance and efficiency.

Key Components

Each component plays a vital role in the system’s operation, ensuring smooth performance and longevity. Here are some of the primary elements:

| Component | Function |

|---|---|

| Cylinder Head | Seals the top of the cylinders, allowing combustion to occur. |

| Crankshaft | Converts linear motion into rotational motion, powering the vehicle. |

| Pistons | Move up and down within the cylinders, creating the necessary pressure for combustion. |

Importance of Maintenance

Regular upkeep of these components ensures optimal functionality and extends the lifespan of the entire system. Neglecting any element can lead to performance issues or costly repairs.

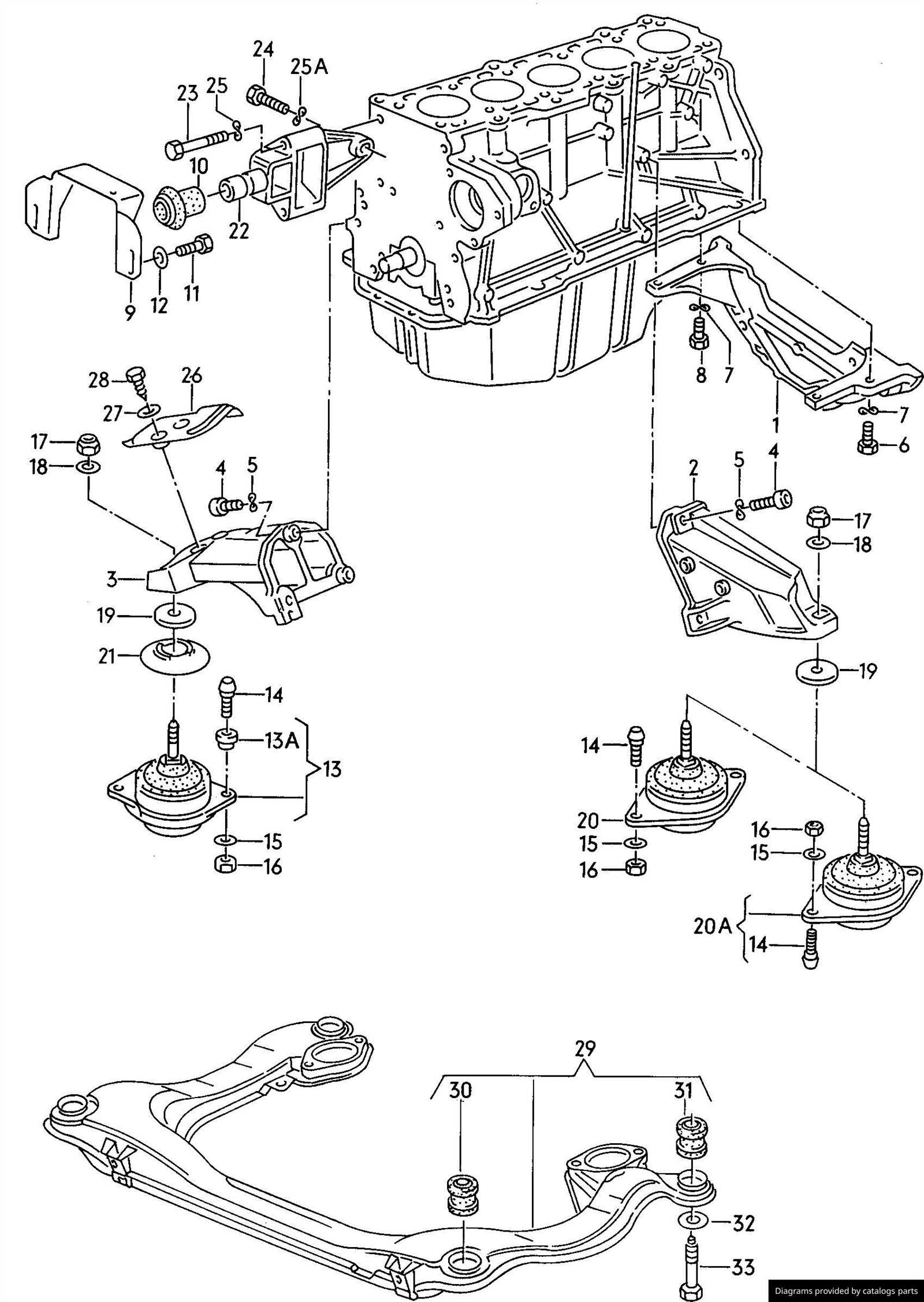

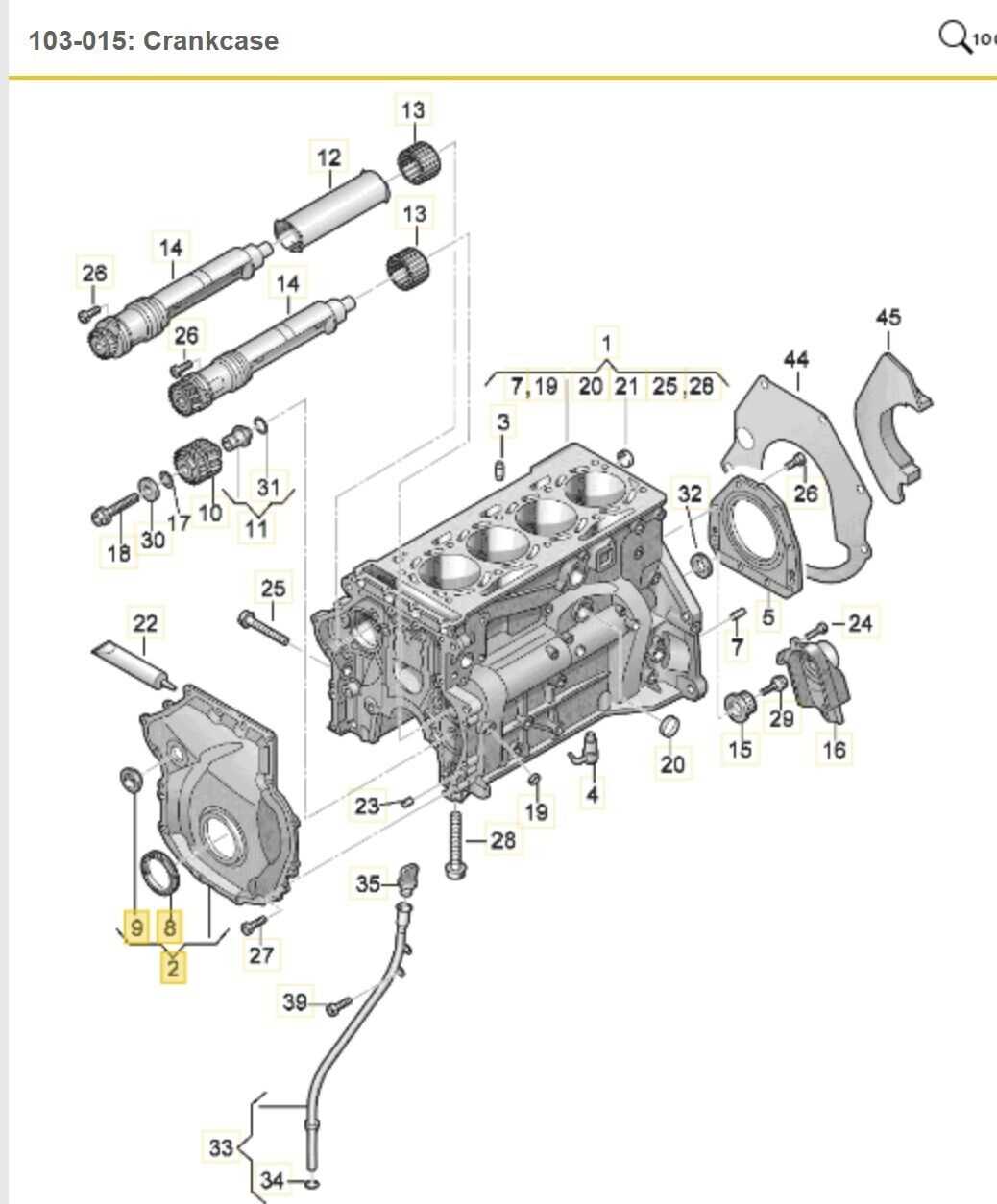

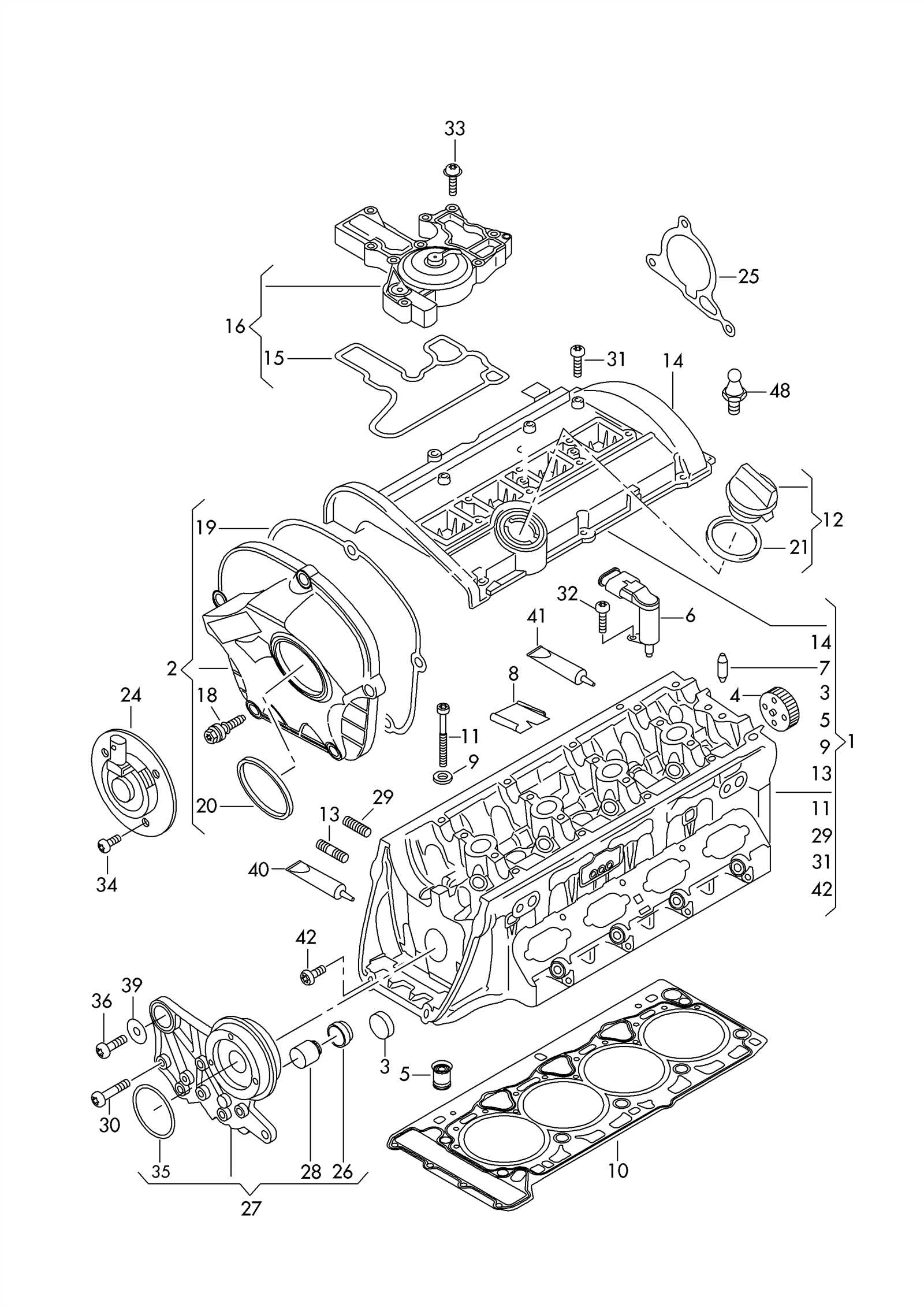

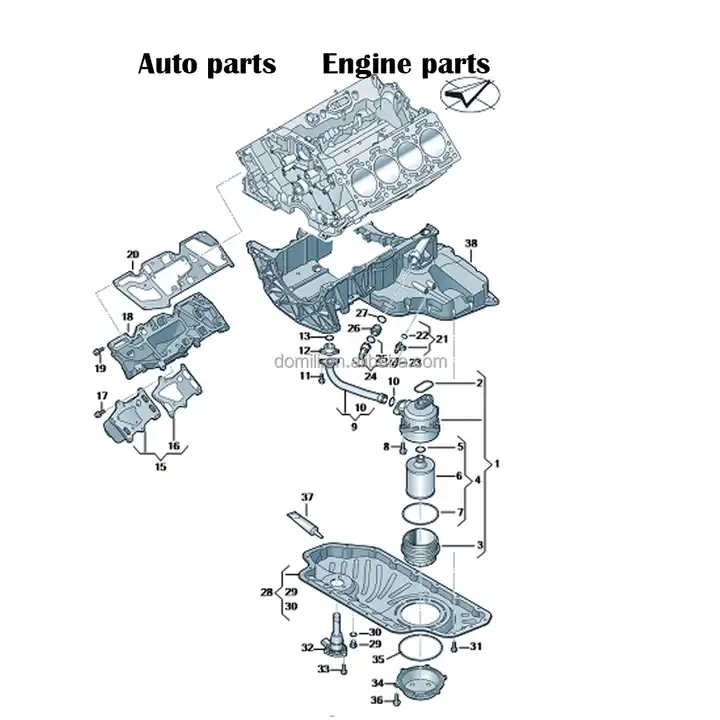

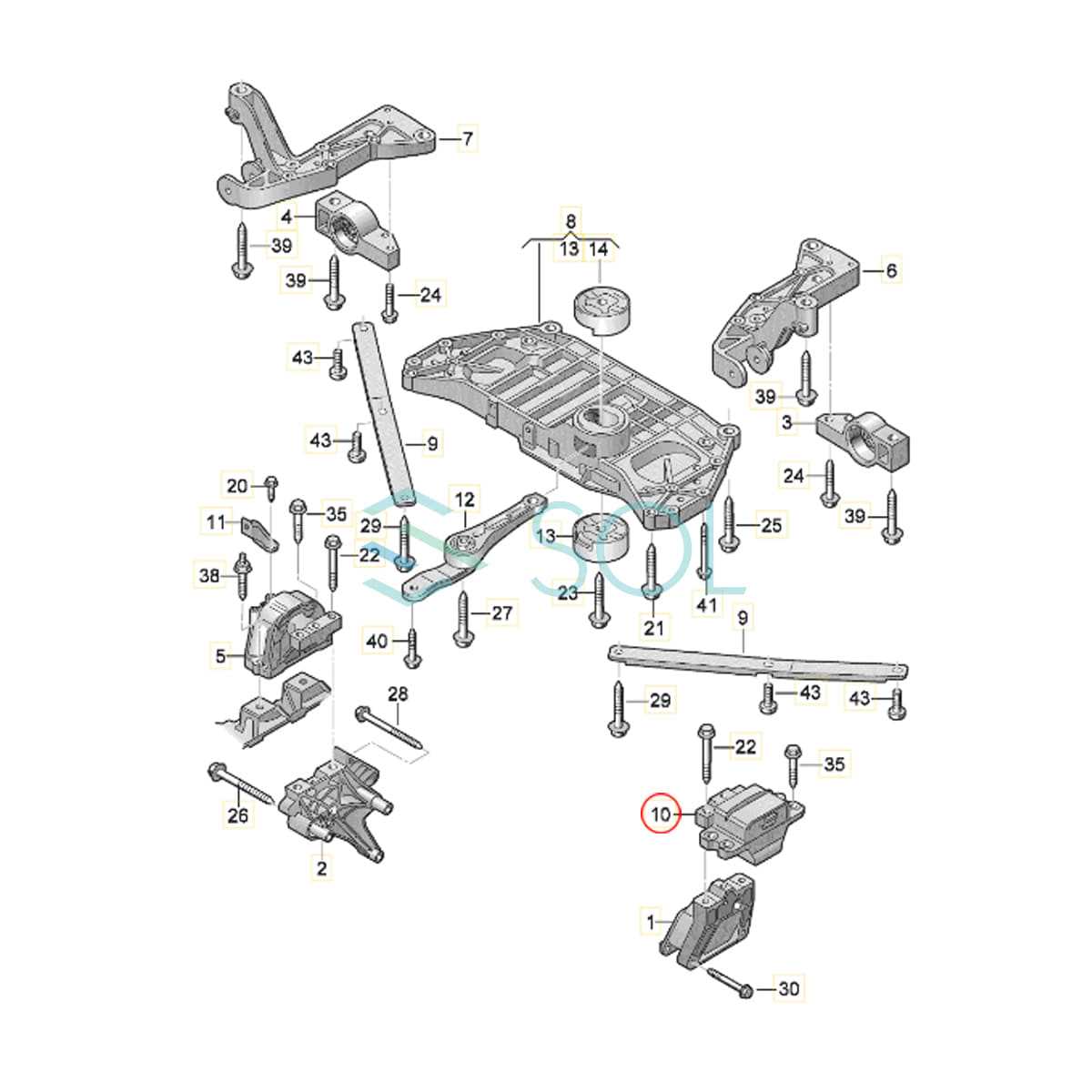

Role of the Engine Block

The core component of any power unit serves as a critical foundation for the entire assembly. Its design not only supports various elements but also ensures optimal functionality and longevity of the system.

Structural Integrity

A robust framework is essential for housing moving parts and maintaining alignment under intense pressure. This strength allows the unit to withstand vibrations and thermal expansion during operation.

Heat Management

Effective thermal regulation is vital for performance. The structure aids in dissipating heat, preventing overheating, and ensuring that the system operates efficiently over extended periods. Proper cooling contributes significantly to durability and reliability.

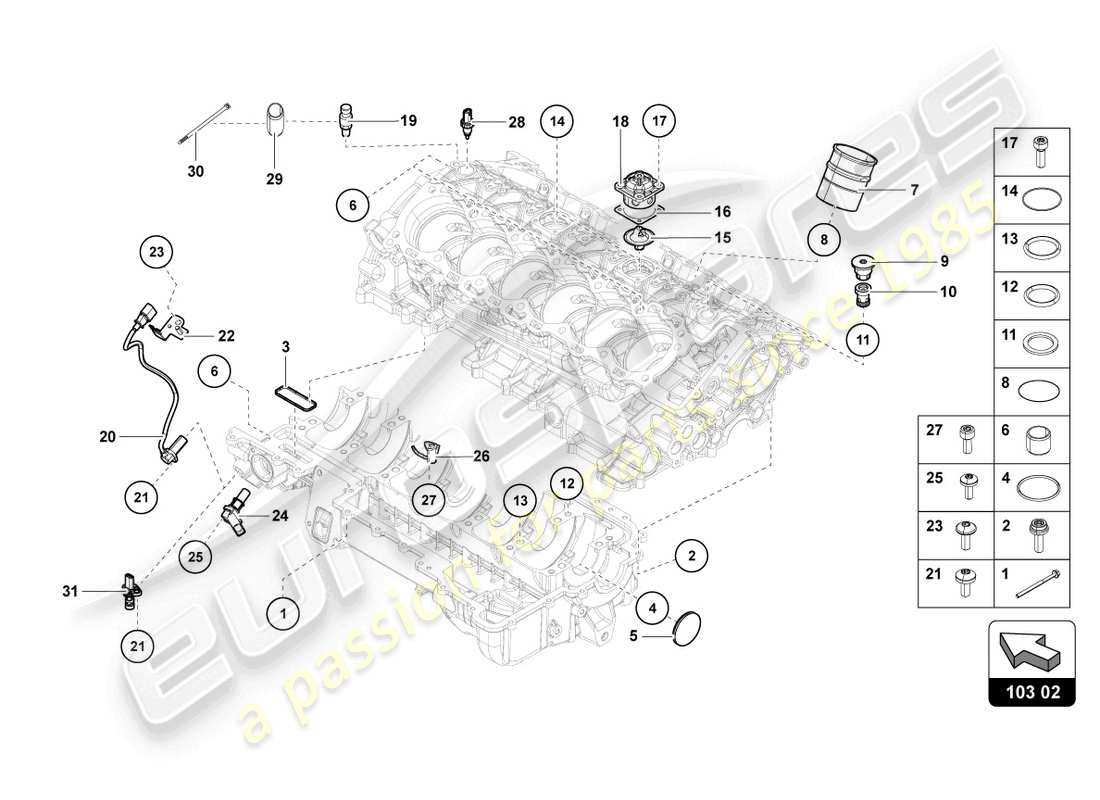

Importance of Cylinder Head Design

The configuration of the upper section of a combustion unit plays a crucial role in optimizing performance and efficiency. It directly influences the flow of gases, heat dissipation, and overall functionality, making its design a pivotal aspect of mechanical engineering.

Impact on Performance

A well-engineered upper section enhances airflow and improves combustion, leading to greater power output. This design can significantly affect acceleration and responsiveness, providing the ultimate driving experience.

Heat Management

Effective thermal regulation is essential for durability and reliability. A thoughtfully designed upper section facilitates better heat distribution, reducing the risk of overheating and extending the lifespan of the entire system.

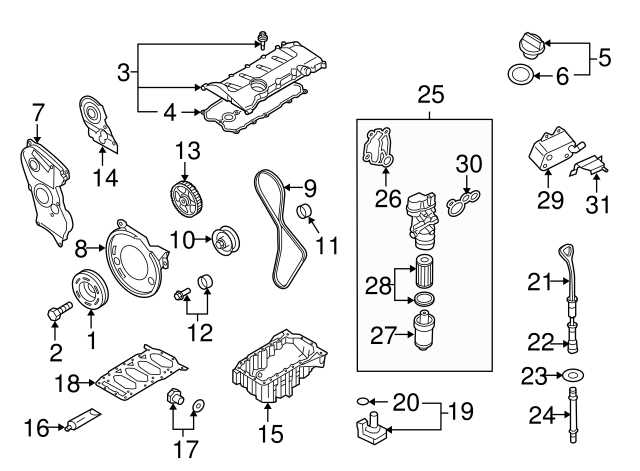

Function of Piston and Rings

The core components within a combustion chamber play a vital role in converting fuel into mechanical energy. Their efficient operation ensures optimal performance and longevity of the overall system.

Piston Role

The piston acts as a movable barrier, compressing the air-fuel mixture during the intake stroke and transferring the force generated from combustion to the crankshaft. This transformation is essential for driving the vehicle forward.

Rings Functionality

Rings encircle the piston, serving multiple purposes. They maintain compression by preventing gases from escaping during the power stroke and assist in regulating oil consumption, ensuring a smooth operation. Proper sealing is crucial for enhancing efficiency and minimizing emissions.

Timing Mechanisms in Audi Engines

The precision of motion within an internal combustion system is crucial for optimal performance and efficiency. Timing mechanisms play a pivotal role in coordinating the movements of various components, ensuring that each part operates in harmony. Understanding these systems helps in appreciating the engineering excellence behind high-performance vehicles.

Types of Timing Systems

There are primarily two types of timing systems utilized: belt-driven and chain-driven. Belt-driven mechanisms often offer reduced weight and noise, making them a popular choice for many modern applications. However, chain-driven systems are known for their durability and longevity, frequently preferred in high-stress environments. Each type has its own advantages and maintenance considerations that influence their usage.

Functionality and Importance

The primary function of timing systems is to synchronize the opening and closing of valves with the movement of the pistons. This synchronization is vital for ensuring that fuel intake and exhaust expulsion occur at the right moments. A precise timing mechanism not only enhances power output but also contributes to fuel efficiency and lower emissions. Regular inspection and timely replacement of these components can prevent significant mechanical failures, ensuring the longevity of the entire system.

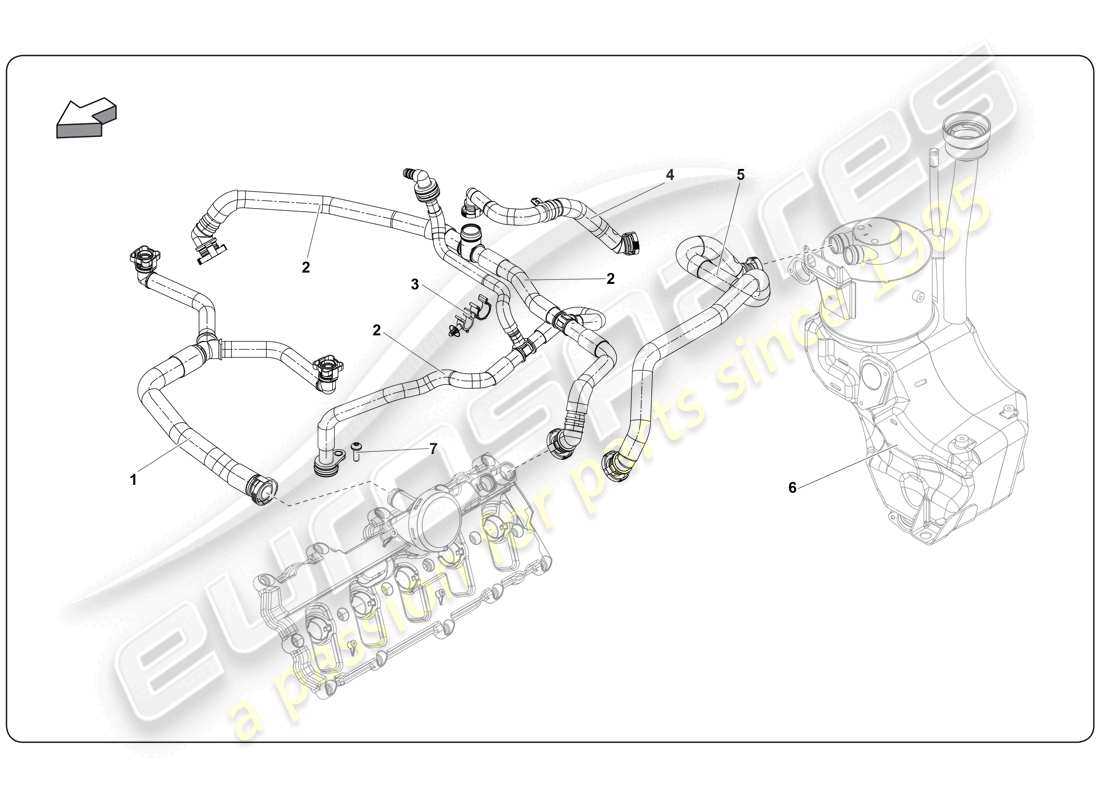

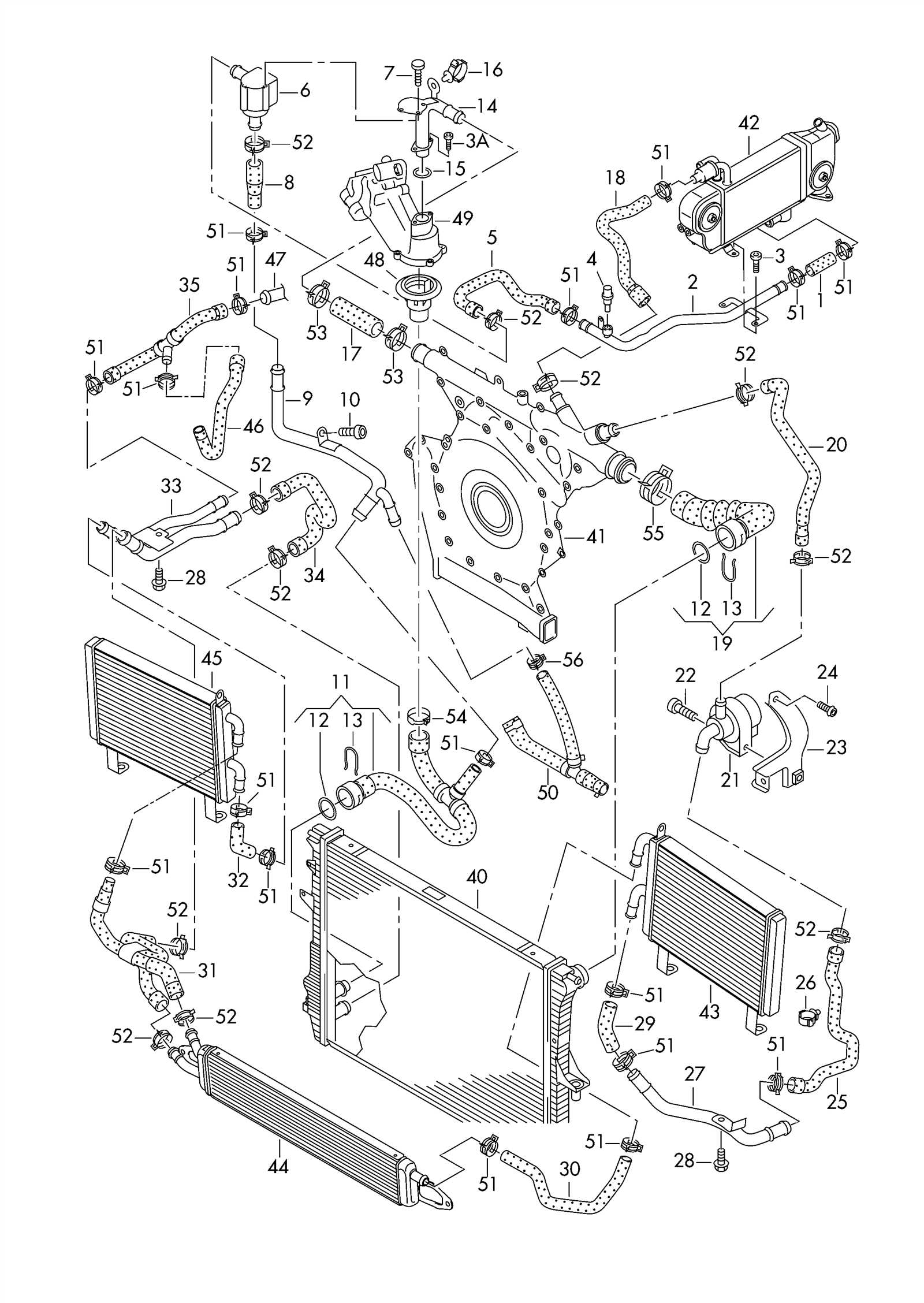

Cooling Systems and Their Significance

Effective temperature regulation is crucial for the optimal performance and longevity of mechanical systems. These systems prevent overheating and maintain the appropriate operating conditions, ensuring that various components function smoothly without degradation.

Key functions of cooling mechanisms include:

- Maintaining optimal temperature levels

- Preventing thermal expansion and warping of components

- Enhancing overall efficiency and performance

- Reducing wear and tear on vital mechanisms

- Promoting safety by avoiding overheating hazards

Various types of cooling systems are employed, each tailored to specific requirements and environments. Some common types include:

- Liquid Cooling

- Air Cooling

- Evaporative Cooling

- Thermoelectric Cooling

Understanding the importance of these systems is essential for effective maintenance and optimal functionality, contributing to the reliability and efficiency of the entire mechanism.

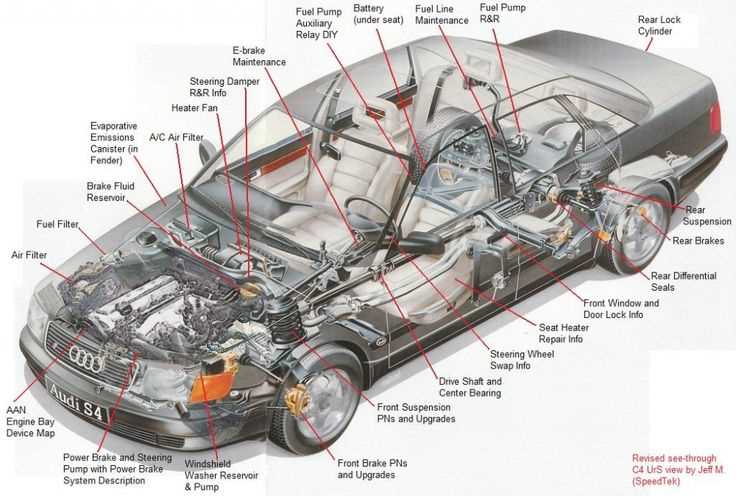

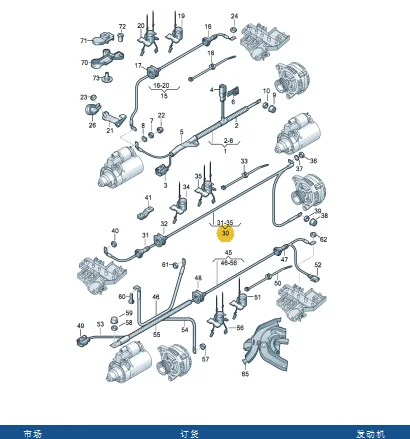

Fuel Delivery Systems Overview

Fuel delivery systems play a crucial role in ensuring optimal performance and efficiency in various vehicles. These systems are designed to transport fuel from the tank to the combustion chamber, where it mixes with air for effective combustion. A well-functioning fuel delivery system is essential for maximizing power output and minimizing emissions.

Key Components

Several integral components work together within the fuel delivery system:

- Fuel Tank: Stores the fuel until it is needed.

- Fuel Pump: Moves the fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel to protect other components.

- Fuel Injectors: Deliver precise amounts of fuel into the combustion chamber.

- Pressure Regulator: Maintains consistent fuel pressure throughout the system.

Types of Fuel Delivery Systems

There are two primary types of fuel delivery systems commonly used:

- Carbureted Systems: Utilize a carburetor to mix air and fuel before it enters the combustion chamber. These systems are generally simpler and were more common in older vehicles.

- Fuel Injected Systems: Use electronic injectors to precisely control the amount of fuel delivered to the engine. This modern system offers better efficiency and performance.

Understanding these components and types is essential for diagnosing issues and ensuring the longevity of the fuel delivery system in any vehicle.

Exhaust Components and Their Function

The system responsible for directing and treating gases released from the combustion process plays a crucial role in vehicle performance and environmental impact. Each element within this framework is designed to optimize efficiency, reduce emissions, and enhance overall operation.

Key Elements of the Exhaust System

Among the vital components, the catalytic converter stands out, transforming harmful emissions into less harmful substances. Another significant element is the muffler, which minimizes noise, ensuring a smoother auditory experience while driving.

Importance of Proper Functioning

Ensuring that these components operate effectively not only contributes to better performance but also aligns with environmental standards. Regular maintenance and timely replacement of these parts are essential for achieving the ultimate efficiency and compliance.

Maintenance Tips for Audi Engines

Regular upkeep is essential for the longevity and performance of any vehicle’s power unit. By adhering to specific practices, you can ensure that the machinery operates smoothly and efficiently, minimizing the risk of unexpected failures and maximizing its lifespan. Here are some key suggestions to maintain optimal functionality.

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Reduces friction, prevents wear |

| Coolant Check | Every 6 months | Prevents overheating, protects components |

| Air Filter Replacement | Every 15,000 miles | Enhances airflow, improves efficiency |

| Spark Plug Inspection | Every 30,000 miles | Ensures optimal combustion, enhances performance |

| Fuel System Cleaning | Every 20,000 miles | Improves fuel efficiency, reduces emissions |

Implementing these maintenance practices will significantly contribute to the reliability and performance of your vehicle’s heart. Staying proactive about care can help avoid costly repairs and ensure a smoother driving experience.