Dewalt Blower Parts Diagram Guide

Maintaining efficiency in your outdoor equipment is essential for optimal performance and longevity. Whether you’re tackling yard work or professional landscaping, a thorough comprehension of your device’s inner workings can make all the difference. Identifying and understanding the various elements within your tool can enhance both safety and functionality.

In this section, we will explore the intricate design and layout of your equipment. By examining each component, you can better appreciate how they work together to produce powerful results. Knowledge of these elements not only aids in troubleshooting but also empowers you to perform necessary maintenance and repairs.

Additionally, familiarizing yourself with the assembly and connections can save time and resources. With a clear visualization of the structure, you’ll be well-equipped to address any issues that may arise, ensuring your equipment remains a reliable ally in your tasks.

Dewalt Blower Parts Overview

This section provides a comprehensive insight into the various components of a powerful outdoor cleaning tool. Understanding the essential elements that contribute to its functionality is crucial for effective maintenance and repair. Each part plays a significant role in ensuring optimal performance and longevity.

Key Components

The primary elements include the motor, housing, and nozzle, each designed to work harmoniously. The motor generates the necessary power, while the housing protects internal mechanisms. The nozzle directs airflow, enhancing efficiency in clearing debris.

Maintenance Tips

Understanding Blower Components

To fully appreciate how air-moving tools function, it’s essential to delve into their fundamental elements. Each component plays a significant role in ensuring optimal performance, contributing to efficiency and reliability. Recognizing these integral pieces can aid in troubleshooting and maintenance, enhancing the user experience.

Key Elements of Air-Moving Equipment

At the core of these devices is the motor, which provides the necessary power to generate airflow. Coupled with a fan assembly, it creates the force that moves air through the outlet. Additionally, the casing not only protects the internal mechanisms but also aids in directing airflow efficiently.

Importance of Accessories

Accessories such as nozzles and filters are crucial for adapting the equipment to various tasks. Nozzles can concentrate the airflow for targeted applications, while filters help maintain performance by trapping debris and preventing clogs. Regular inspection and replacement of these components can significantly extend the lifespan of the tool.

Common Issues with Blower Parts

When working with outdoor equipment, users often encounter various challenges that can impact performance. Understanding these common issues can help in diagnosing problems and ensuring smooth operation. From mechanical failures to minor malfunctions, addressing these concerns promptly can extend the lifespan of the device.

Frequent Mechanical Failures

One of the most prevalent issues involves mechanical breakdowns. Components may wear out due to constant use, leading to inefficiencies. Loose connections or damaged elements can cause unexpected interruptions, necessitating careful inspection and timely replacement to maintain optimal functionality.

Clogging and Blockages

Another common challenge is the accumulation of debris, which can obstruct airflow and reduce efficiency. Regular cleaning is essential to prevent clogs in the system. Neglecting this aspect can result in overheating and decreased performance, ultimately impacting the overall effectiveness of the equipment.

How to Identify Part Numbers

Understanding how to locate and recognize component identifiers is essential for anyone looking to maintain or repair equipment. Accurate identification ensures that the correct elements are sourced, minimizing downtime and enhancing functionality.

Steps to Identify Component Identifiers

- Consult the User Manual: Most equipment comes with a manual that includes a comprehensive list of component identifiers and descriptions.

- Check Online Resources: Manufacturer websites often provide searchable databases where you can find detailed information about various components.

- Utilize Retailer Catalogs: Many online retailers offer parts catalogs that can help in cross-referencing and identifying the necessary identifiers.

Tips for Accurate Identification

- Look for Model Numbers: Ensure you have the correct model number of your equipment, as part identifiers can vary by model.

- Examine Existing Components: If possible, physically inspect the component for any visible numbers or markings that could assist in identification.

- Join Online Forums: Engaging with communities can provide insights and help in obtaining the correct identifiers from experienced users.

Benefits of Genuine Dewalt Parts

Utilizing authentic components ensures optimal performance and longevity of your equipment. These original elements are designed to meet strict quality standards, providing users with a reliable experience.

Key advantages of choosing original components include:

- Enhanced durability: Authentic parts are crafted from high-quality materials, ensuring they withstand wear and tear.

- Perfect compatibility: Original components fit seamlessly, minimizing the risk of malfunctions or damage.

- Improved efficiency: Genuine parts work together harmoniously, allowing the machinery to operate at peak performance.

- Warranty protection: Using authentic components often helps maintain warranty coverage, offering peace of mind.

- Better resale value: Equipment maintained with original parts typically retains higher resale value.

In conclusion, opting for genuine components is a wise investment for anyone looking to maximize the performance and lifespan of their machinery.

Where to Buy Replacement Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. Numerous sources are available for acquiring high-quality items, ensuring you can maintain and repair your tools effectively.

Online Retailers

The internet offers a wide array of options for purchasing necessary components. Here are some popular online platforms:

- Amazon

- eBay

- Specialized tool websites

- Manufacturer’s official site

Local Stores

If you prefer shopping in person, several brick-and-mortar locations can provide what you need:

- Home improvement centers

- Hardware stores

- Specialty tool shops

- Automotive supply stores

Whether you choose online or in-store shopping, make sure to verify the compatibility and quality of the components before making a purchase. This ensures your equipment will function optimally for years to come.

Step-by-Step Repair Guide

This section provides a comprehensive guide to help you restore your equipment to optimal condition. By following these structured steps, you can efficiently troubleshoot and resolve common issues, ensuring your tool performs reliably for years to come.

Gather Necessary Tools

Before starting any repair work, it’s essential to have the right tools at hand. Collect items such as screwdrivers, wrenches, and replacement components. Having everything organized will streamline the process and minimize downtime.

Follow Repair Steps

Begin by disconnecting the power source to ensure safety. Then, carefully disassemble the unit, noting the order of components. Replace any faulty items, and reassemble the equipment in reverse order. Finally, perform a test run to confirm everything is functioning properly.

Tip: Keep a detailed record of the steps you take and any parts replaced. This can be invaluable for future maintenance and repairs.

Maintenance Tips for Dewalt Blowers

Proper upkeep of your equipment is essential to ensure longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs. Here are some key practices to consider for keeping your device in top condition.

- Regular Cleaning: After each use, remove debris and dirt from the exterior. Use a soft brush or cloth to clean the surfaces.

- Check the Filters: Inspect and clean the air intake filters regularly. Clogged filters can hinder airflow and reduce performance.

- Inspect the Battery: For battery-operated models, ensure the battery is charged and check for any signs of damage or wear.

- Lubrication: Apply lubricant to moving parts as recommended by the manufacturer to prevent wear and tear.

- Inspect Cables and Connections: Regularly check for frayed wires or loose connections that could affect functionality.

Following these guidelines will help maintain the efficiency of your device, ensuring it serves you well for years to come. Always refer to the manufacturer’s instructions for specific maintenance procedures and schedules.

Tools Needed for Repairs

When it comes to performing maintenance or fixing equipment, having the right tools on hand is essential. A well-equipped toolkit not only streamlines the repair process but also ensures that tasks are completed efficiently and safely. Below is a guide to the essential instruments that can aid in your repair endeavors.

Essential Tools

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are crucial for removing and tightening screws.

- Wrenches: Adjustable and socket wrenches help in loosening or securing nuts and bolts.

- Pliers: Needle-nose and slip-joint pliers can be invaluable for gripping and twisting.

- Hex Keys: Often required for components that utilize hex screws.

- Multimeter: This tool is essential for checking electrical connections and diagnosing issues.

Additional Equipment

- Safety Gear: Always wear protective eyewear and gloves to safeguard against potential hazards.

- Work Surface: A stable and organized workspace helps prevent accidents and misplacements.

- Lubricants: Keep mechanical parts functioning smoothly with the appropriate oils and greases.

- Flashlight: Good illumination can help in inspecting hard-to-see areas.

- Storage Containers: Organize small parts and tools to avoid losing important items during repairs.

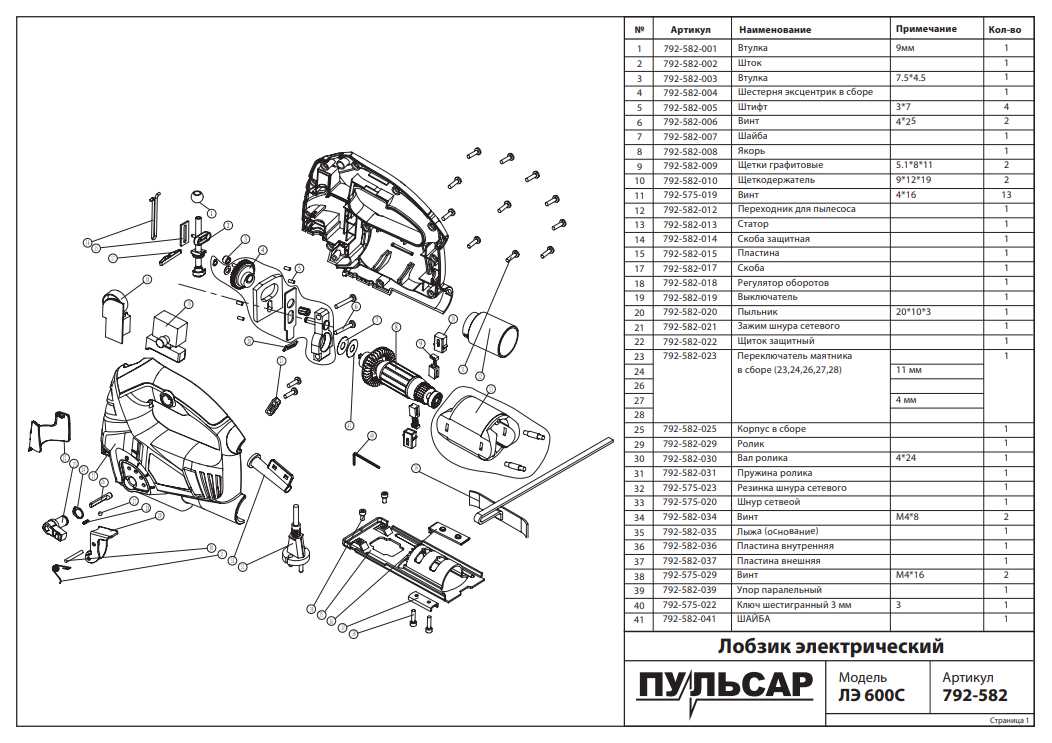

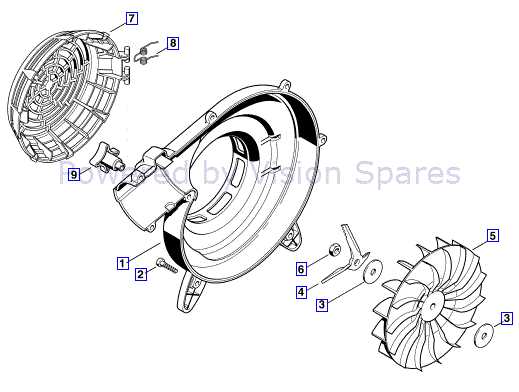

Assembly Diagram Explanation

This section delves into the intricate visual representation that serves as a guide for assembling various components of the tool. Understanding this illustration is crucial for ensuring that all elements fit together correctly and function efficiently.

By examining the layout, users can identify each piece and its corresponding placement within the entire system. This clarity aids in troubleshooting and maintenance, making it easier to replace or repair specific sections.

Key features to focus on include:

- Labeling: Each component is often marked with a reference number or letter, linking it to a list of descriptions.

- Orientation: The diagram usually provides a clear indication of how parts should be oriented during assembly.

- Sequence: It may outline the order in which components should be assembled, minimizing the risk of mistakes.

To maximize the utility of the visual representation, consider the following steps:

- Carefully compare the actual components with the illustration to ensure accuracy.

- Follow the assembly sequence as depicted to avoid complications.

- Refer to any accompanying documentation for additional context or troubleshooting tips.

By fully grasping the assembly representation, users can enhance their understanding and skills, leading to more efficient and effective use of the tool.

Safety Precautions During Repair

Ensuring safety while performing maintenance on equipment is crucial for both the technician and the machinery. Proper precautions help prevent accidents and prolong the lifespan of tools. Adhering to safety protocols minimizes risks associated with electrical components and moving parts.

- Always disconnect the device from the power source before starting any repair work.

- Use appropriate personal protective equipment (PPE), including gloves, goggles, and dust masks.

- Keep your workspace organized and free from clutter to avoid tripping hazards.

- Familiarize yourself with the manufacturer’s instructions and guidelines prior to beginning repairs.

In addition to these basic precautions, consider the following safety measures:

- Inspect all tools and equipment for damage before use.

- Ensure that your hands are dry when handling electrical components.

- Work in a well-ventilated area to avoid inhaling fumes or dust.

- Have a first aid kit readily available in case of emergencies.

By following these safety measures, you can protect yourself and ensure a smooth repair process, leading to better results and enhanced safety overall.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and troubleshooting for your outdoor equipment. Understanding the intricacies of your tools can enhance their performance and longevity.

-

What should I do if my device won’t start?

- Check the power source to ensure it’s connected.

- Inspect the battery for charge or replacement needs.

- Examine any switches for proper functionality.

-

How can I improve the efficiency of my equipment?

- Regularly clean the air intake and exhaust areas.

- Replace worn-out components promptly.

- Use the right settings for your specific tasks.

-

Where can I find replacement components?

- Authorized retailers often stock official replacements.

- Online marketplaces may have various options.

- Consult the manufacturer’s website for direct purchases.

-

How often should I perform maintenance?

- It’s recommended to conduct routine checks before and after use.

- Full maintenance should occur every few months, depending on usage.

- Refer to the user manual for specific guidelines.

Customer Reviews of Dewalt Parts

This section explores the feedback from users regarding components related to their tools. Understanding customer experiences can provide valuable insights into quality, performance, and durability.

Many users share their thoughts on the effectiveness and reliability of various components. Here are some common themes found in the reviews:

- Quality: Most customers appreciate the sturdy construction and longevity of the items.

- Ease of Replacement: Many reviews highlight the straightforward process of swapping out worn or damaged pieces.

- Performance: Users frequently mention noticeable improvements in efficiency after replacing certain components.

- Customer Service: Positive interactions with support teams are often noted, enhancing overall satisfaction.

Below are some specific user ratings and comments:

-

Rating: 5 stars

“These replacements have made my tool feel brand new! Highly recommend.”

-

Rating: 4 stars

“Great product, but shipping took longer than expected.”

-

Rating: 3 stars

“Decent quality, but I wish there were more detailed instructions.”

Overall, feedback emphasizes a high level of satisfaction, particularly regarding the performance and reliability of the items in question. This information can guide potential buyers in making informed decisions.