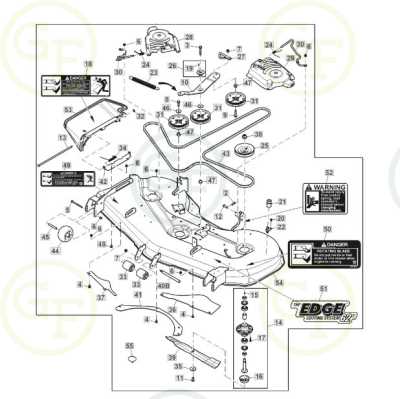

Comprehensive Parts Diagram for John Deere D170 Mower Deck

In the realm of lawn maintenance, the efficiency of your machinery plays a crucial role in achieving a pristine outdoor space. Familiarity with the various elements that constitute these essential tools enhances both their functionality and longevity. This section delves into the intricacies of a particular model, shedding light on its construction and the interrelation of its individual components.

Having a comprehensive grasp of how each segment operates is vital for effective upkeep and repair. Whether you’re a seasoned professional or a weekend warrior, understanding these mechanical parts can save time and resources. A detailed overview allows users to pinpoint potential issues and facilitate smoother operations, ultimately leading to a more efficient mowing experience.

Additionally, for those looking to perform maintenance or upgrades, visual references serve as invaluable aids. By examining the layout and connections of the various segments, users can gain insights into the assembly and disassembly processes. This knowledge empowers lawn enthusiasts to take control of their equipment, ensuring optimal performance and extending the lifespan of their investment.

Understanding John Deere D170 Mower Deck

Maintaining a lawn care machine requires familiarity with its essential components. One key area of focus is the cutting mechanism, which plays a vital role in achieving a well-manicured lawn. This section aims to elucidate the crucial elements involved in the operation and maintenance of this essential gardening equipment.

Understanding the configuration and functionality of the cutting assembly can greatly enhance performance and longevity. Here are some important aspects to consider:

- Design: The layout of the cutting assembly significantly impacts efficiency. A well-structured configuration allows for better grass management.

- Materials: The choice of materials used in the construction influences durability and resilience, ensuring a longer lifespan even under tough conditions.

- Adjustability: Many machines offer height adjustment features, allowing operators to tailor the cutting height according to specific lawn conditions.

- Maintenance: Regular upkeep, such as sharpening blades and checking for wear, is crucial for optimal performance.

- Compatibility: Knowing which components are compatible ensures that replacements and upgrades are easily obtainable, enhancing the overall functionality.

By familiarizing oneself with these aspects, users can ensure their equipment remains efficient and effective throughout its operational life. Proper understanding not only aids in maintenance but also empowers operators to make informed decisions about modifications and repairs.

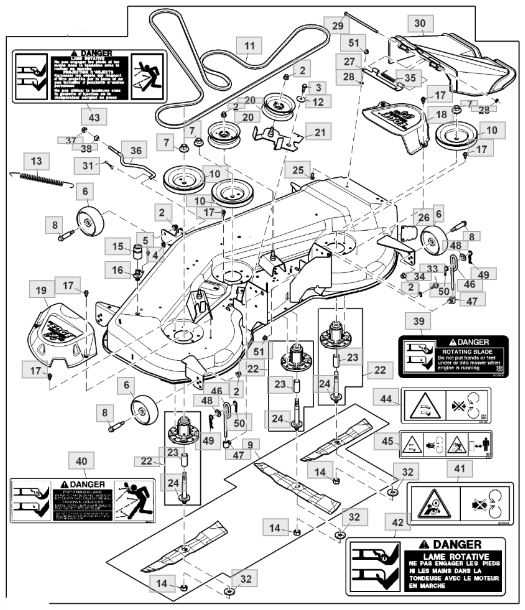

Components of the D170 Mower Deck

The assembly responsible for cutting grass efficiently consists of various essential elements that work in harmony to achieve optimal performance. Understanding these constituents is crucial for maintenance and repairs, ensuring that the equipment remains in peak operational condition. Each component plays a significant role in the overall functionality, contributing to the effectiveness and longevity of the entire system.

Cutting Blades

At the forefront of the assembly are the cutting blades, designed to deliver a precise and clean cut. These sharp, rotating implements are essential for achieving the desired lawn height. Regular inspection and sharpening are necessary to maintain their efficiency, as dull blades can lead to uneven cutting and potential damage to the grass.

Spindle Assembly

The spindle assembly serves as the support structure for the cutting blades, allowing them to rotate smoothly during operation. This component houses the bearings and helps maintain proper alignment, reducing friction and wear. Regular lubrication and inspection are vital to ensure that the spindle operates efficiently, preventing overheating and prolonging its lifespan.

Importance of Mower Deck Maintenance

Regular upkeep of lawn care equipment is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to reduced efficiency, higher operational costs, and ultimately, the need for early replacements. Proper maintenance practices not only enhance functionality but also promote safety during use.

Key reasons for prioritizing maintenance include:

- Enhanced Performance: A well-maintained system operates more smoothly and effectively, leading to better results in lawn management.

- Increased Longevity: Routine care can significantly extend the lifespan of equipment, delaying the need for costly replacements.

- Cost Efficiency: Regular inspections and repairs can prevent major issues, saving money on extensive repairs in the long run.

- Safety: Ensuring all components are functioning correctly reduces the risk of accidents, protecting the operator and bystanders.

- Environmental Impact: Efficient machinery consumes less fuel and reduces emissions, contributing to more sustainable lawn care practices.

In conclusion, implementing a comprehensive maintenance routine is vital for achieving the best results from your lawn care equipment. Prioritizing these practices not only benefits the machinery but also ensures a safe and efficient working environment.

Identifying Common Parts for Replacement

Understanding the key components of lawn equipment is essential for maintaining optimal performance. Knowing which elements are subject to wear and tear can help ensure a well-kept machine. Regular inspection and timely replacement of these items can significantly extend the lifespan of your equipment.

When evaluating the essential components, consider the following common items that often require attention:

- Blades: The cutting edges are crucial for efficient grass trimming. Dull or damaged blades can affect performance.

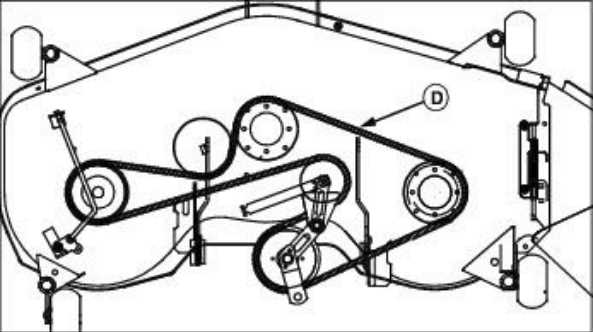

- Belt: This component drives the blades and can wear out over time, leading to decreased efficiency.

- Spindle Assembly: This part supports the blades and is vital for smooth operation. Look for signs of wear or damage.

- Wheels: The wheels facilitate movement and can become worn or misaligned, affecting maneuverability.

- Deck Shell: The outer casing protects internal components. Cracks or corrosion can compromise its integrity.

Regular maintenance and awareness of these crucial components will enhance the functionality of your equipment. When identifying items for replacement, always consult the manual for specifications and compatibility.

Step-by-Step Assembly Instructions

Assembling outdoor machinery requires attention to detail and a clear understanding of each component’s role. This guide outlines the process of putting together essential elements, ensuring optimal functionality and longevity of your equipment.

Follow the steps below to complete the assembly efficiently:

| Step | Description | Tools Required |

|---|---|---|

| 1 | Begin by laying out all components on a flat surface to ensure everything is accounted for. | N/A |

| 2 | Attach the primary frame using the provided bolts, ensuring they are securely fastened. | Wrench |

| 3 | Install the secondary components in their designated positions, referring to the included guide for specific placements. | Screwdriver |

| 4 | Connect the belts according to the schematic, ensuring they are aligned correctly to avoid any operational issues. | Wrench |

| 5 | Final checks should be performed on all connections and fastenings to ensure everything is secure and ready for use. | N/A |

By adhering to these instructions, you will ensure that your machinery operates smoothly and efficiently, providing you with reliable performance throughout its use.

Tools Needed for Deck Repairs

Maintaining the functionality of outdoor equipment requires a set of essential instruments that facilitate efficient repairs. Whether addressing minor adjustments or major overhauls, having the right tools on hand can significantly streamline the process. This section will outline the necessary items that should be part of any repair toolkit to ensure optimal performance.

Basic Hand Tools

To start, a collection of fundamental hand tools is indispensable. These typically include a variety of wrenches, screwdrivers, and pliers. A socket set will also prove invaluable for reaching difficult areas. Additionally, a rubber mallet can help dislodge stubborn components without causing damage.

Specialized Equipment

Beyond basic hand tools, specialized equipment may be necessary for more intricate tasks. A torque wrench ensures that fasteners are tightened to the correct specifications, preventing any issues related to over or under-tightening. Furthermore, a mechanic’s creeper can provide comfort and ease of movement while working beneath the machinery, making the entire process more efficient.

How to Troubleshoot Mower Issues

Dealing with cutting equipment can sometimes be frustrating, especially when unexpected problems arise. Identifying the root cause of malfunctions is essential for effective resolution. This section outlines common issues encountered during operation and provides practical steps to diagnose and rectify them.

Begin by considering the following areas:

- Power Supply: Ensure that the power source is functioning properly. Check connections, switches, and fuses for any signs of damage or wear.

- Cutting Performance: Inspect the cutting mechanism for any blockages or wear. Dull blades can lead to uneven cutting, while debris buildup can impede operation.

- Movement and Steering: If the equipment is difficult to maneuver, examine the wheels, tires, and drive components. Look for signs of wear or misalignment.

- Noise and Vibration: Unusual sounds or excessive vibration may indicate loose parts or failing components. Check bolts, bearings, and other attachments for stability.

Follow these steps for a systematic approach to identifying issues:

- Conduct a visual inspection of the entire unit, looking for obvious signs of damage or wear.

- Refer to the user manual for specific troubleshooting guidelines relevant to your model.

- Test each component individually to isolate the issue. This can include running the unit without load or adjusting settings to see if performance improves.

- If problems persist, consider consulting a professional technician for further assistance.

By following these guidelines, operators can efficiently troubleshoot issues and ensure optimal performance of their cutting equipment.

Ordering Parts for the D170 Model

When it comes to maintaining your machine, obtaining the right components is essential for ensuring its longevity and efficiency. Whether you’re replacing a worn-out item or upgrading for improved performance, knowing how to navigate the ordering process can save time and effort. This section provides a guide on how to successfully procure the necessary items for your equipment.

Steps to Order Components

To streamline your purchasing experience, follow these steps:

- Identify the specific component you need by consulting your user manual or online resources.

- Check with authorized dealers or reliable online retailers that specialize in machinery supplies.

- Gather necessary information such as part numbers, descriptions, and compatibility details.

- Place your order and ensure you receive a confirmation for tracking your shipment.

Recommended Retailers

Below is a table of some reputable suppliers where you can find quality components:

| Supplier Name | Website | Contact Number |

|---|---|---|

| Authorized Dealer 1 | www.authorizeddealer1.com | (123) 456-7890 |

| Parts Supplier A | www.partssupplierA.com | (234) 567-8901 |

| Online Store B | www.onlinestoreB.com | (345) 678-9012 |

Differences Between Mower Deck Versions

The variations among cutting platforms can significantly influence performance and user experience. Understanding these distinctions is crucial for selecting the right model for specific lawn care needs. Factors such as size, blade configuration, and material composition play a vital role in determining the efficiency and durability of the equipment.

One of the most notable differences lies in the size of the cutting assemblies. Larger platforms typically allow for quicker coverage of expansive areas, while smaller versions offer increased maneuverability in tight spaces. The choice of size can directly impact both time spent on maintenance and the quality of the finished cut.

Another essential aspect is the blade configuration. Some models feature a multi-blade system designed to enhance cutting efficiency and ensure a finer finish. In contrast, simpler configurations may prioritize ease of maintenance and lower operational costs. Users should consider their specific mowing conditions and desired outcomes when evaluating these options.

Moreover, the materials used in construction vary between models, affecting their longevity and resistance to wear. Heavy-duty steel platforms may provide enhanced durability, while lighter options can offer improved fuel efficiency and ease of handling. It is essential to weigh these material choices against the intended use to find the optimal balance between strength and efficiency.

Ultimately, understanding the differences in these systems enables users to make informed decisions, ensuring they select the best option tailored to their individual landscaping requirements.

DIY Repair Tips for Homeowners

Performing repairs on outdoor equipment can be a rewarding experience for homeowners. With a little knowledge and the right tools, you can save money and gain valuable skills. This section provides essential advice to help you tackle common maintenance tasks effectively and confidently.

1. Understand Your Equipment: Before starting any repair, familiarize yourself with the machine’s components and how they function together. This understanding will help you identify issues and determine the necessary steps for resolution.

2. Gather the Right Tools: Ensure you have all the required tools at hand. Commonly needed tools include wrenches, screwdrivers, pliers, and a socket set. Having the right equipment can make your repair process smoother and more efficient.

3. Consult the Manual: Always refer to the equipment’s manual for specific repair instructions and safety precautions. Manuals often provide helpful diagrams and troubleshooting tips that can guide you through the repair process.

4. Safety First: Prioritize safety by wearing appropriate protective gear, such as gloves and goggles. Additionally, make sure the machine is powered off and disconnected from any power source before starting repairs.

5. Take Notes and Photos: Document the disassembly process by taking notes and photos. This can be invaluable when reassembling parts, ensuring that everything goes back together correctly.

6. Start Small: If you’re new to repairs, begin with minor issues to build your confidence. Once you gain experience, you can tackle more complex problems with ease.

7. Don’t Hesitate to Ask for Help: If you encounter a challenging repair, don’t hesitate to seek assistance from friends, family, or online forums. Many communities exist where you can find support and advice from fellow enthusiasts.

By following these tips, you can approach repairs with confidence, ensuring your equipment runs efficiently for years to come.

Resources for Further Assistance

When seeking guidance on equipment maintenance and repairs, various resources can provide valuable information and support. These materials can help users better understand their machinery, troubleshoot issues, and acquire the necessary components for optimal performance. Below are several options to consider for comprehensive assistance.

Online Communities

- Forums: Joining specialized forums can connect you with other enthusiasts and professionals who share insights and experiences.

- Social Media Groups: Platforms like Facebook or Reddit often have dedicated groups where members discuss maintenance tips and share solutions.

- Video Tutorials: Websites such as YouTube offer countless instructional videos that cover various repair and maintenance tasks.

Official Resources

- Manufacturer’s Website: The official website often provides manuals, troubleshooting guides, and updates on new products.

- Customer Support: Contacting customer service can yield direct assistance and specific guidance for your equipment issues.

- Authorized Dealers: Visiting or calling authorized dealers can provide access to knowledgeable staff and genuine components.