Comprehensive Guide to Stihl MS 251 Parts Diagram

The intricacies of a chainsaw’s inner workings play a crucial role in its performance and longevity. By examining the individual elements that make up this powerful tool, users can enhance their maintenance skills and ensure optimal functionality.

Identifying each segment allows for better troubleshooting and repairs. Familiarity with these components not only aids in effective servicing but also deepens the user’s appreciation of the engineering behind the machine.

Ultimately, delving into the specifics of each piece empowers owners to make informed decisions, promoting both safety and efficiency in their woodcutting endeavors. This exploration provides a roadmap to mastering the essential parts that drive your equipment.

Understanding the Stihl MS 251

When exploring the features of a popular chainsaw model, it’s essential to grasp its design, functionality, and the various components that contribute to its efficiency. This tool is engineered for both casual users and professionals, offering a blend of power and precision.

Key Features: This machine is known for its lightweight construction and ergonomic design, making it easy to handle during extended use. Its powerful engine provides reliable performance, ensuring that tasks are completed swiftly.

Components Overview: Each element of the chainsaw plays a vital role in its operation. From the cutting mechanism to the fuel system, understanding these parts can enhance maintenance and improve overall longevity.

Key Features of Stihl MS 251

This powerful cutting tool is designed for efficiency and versatility, making it a top choice for both professionals and enthusiasts. Its robust construction ensures durability, while innovative technology enhances performance and ease of use.

Engine Performance: The heart of this machine boasts a high-output engine that delivers excellent cutting power, allowing users to tackle a variety of tasks with ease.

Lightweight Design: Its compact form factor ensures that users can maneuver it effortlessly, reducing fatigue during extended use.

Fuel Efficiency: Advanced engineering results in lower fuel consumption without compromising performance, making it an eco-friendly option.

Easy Maintenance: Designed with user convenience in mind, this model features accessible components that simplify routine maintenance and upkeep.

Safety Features: Equipped with a chain brake and other protective measures, it prioritizes user safety while operating.

Overall, this cutting tool combines power, efficiency, and safety, making it an ultimate choice for various cutting tasks.

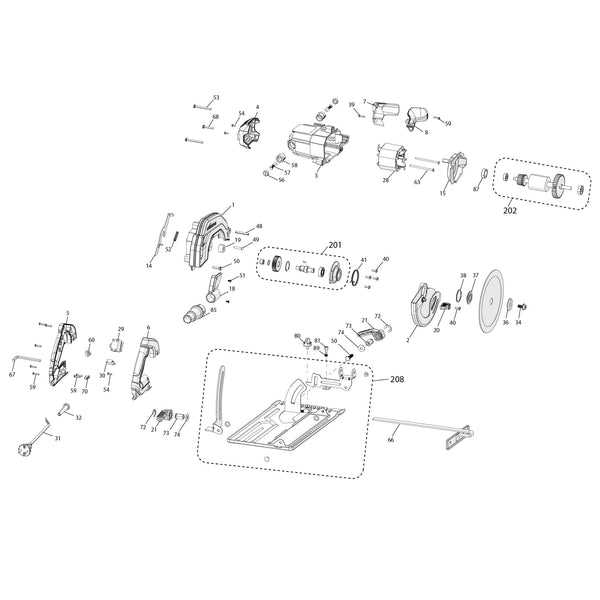

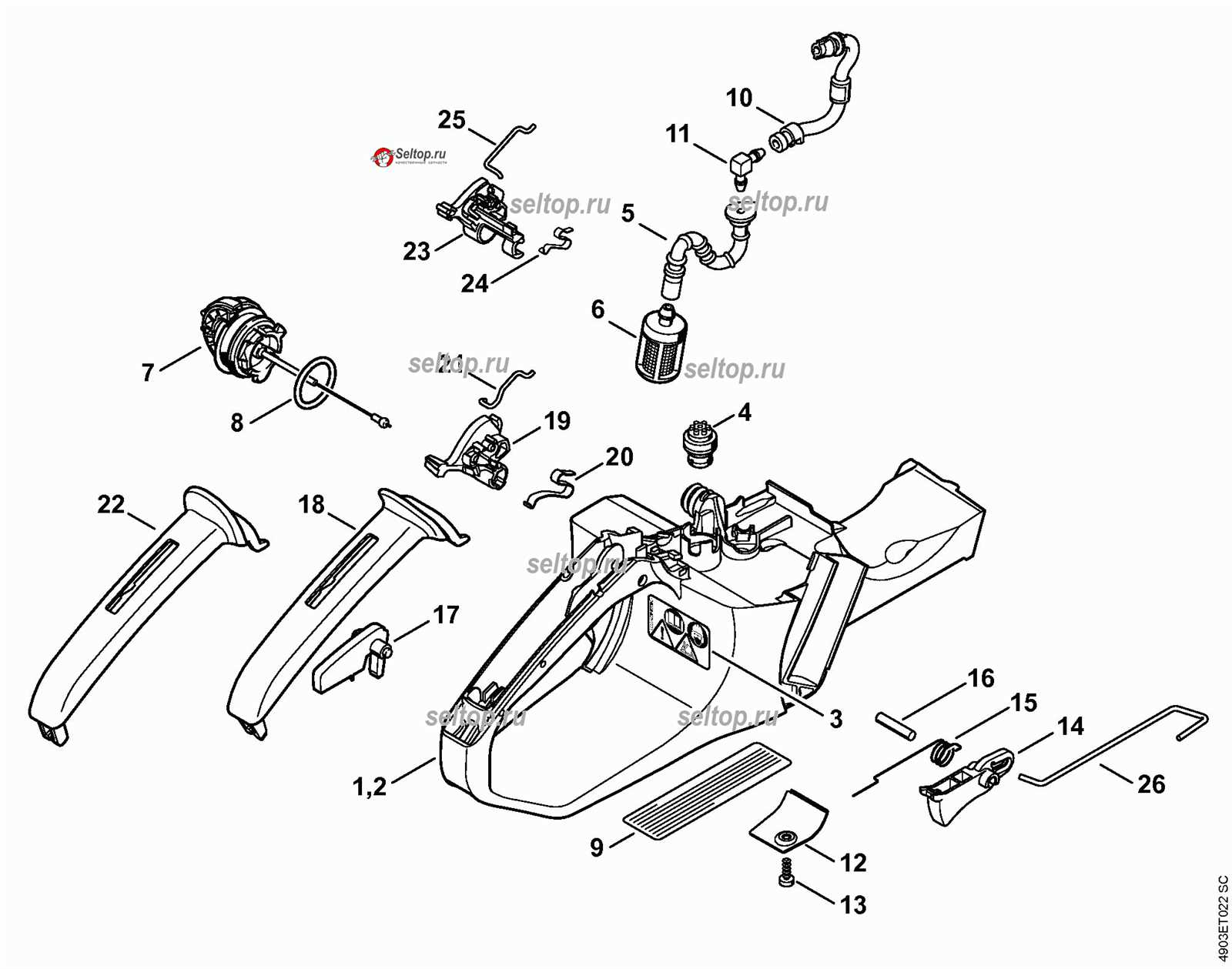

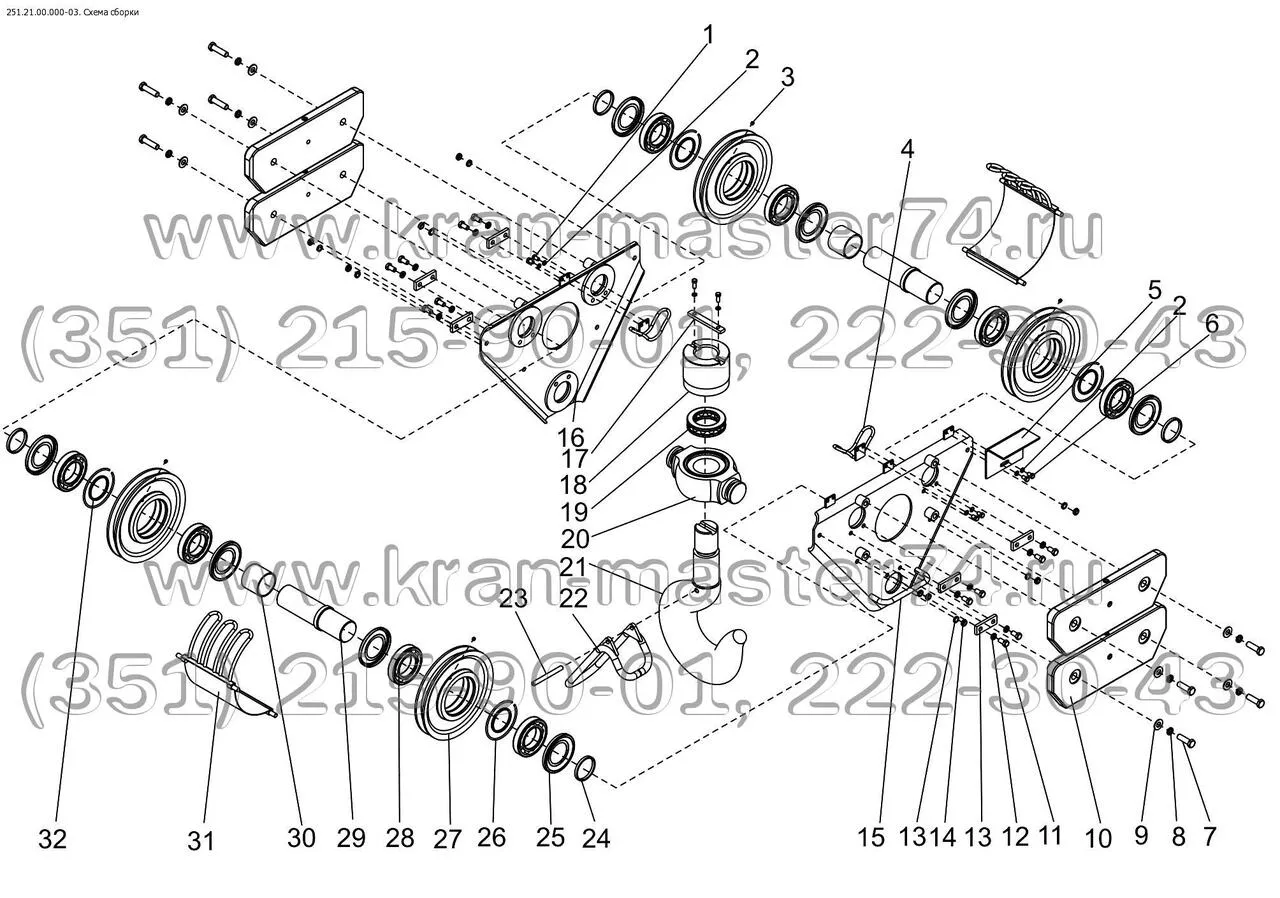

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations of these elements serve as essential tools for both professionals and hobbyists alike. They provide clarity, allowing users to identify specific pieces and their relationships within the whole system.

Enhanced Clarity: These illustrations simplify complex assemblies, making it easier to comprehend how each part functions and interacts. This clarity reduces the likelihood of errors during repairs, as individuals can pinpoint exact locations and functions without confusion.

Streamlined Repairs: With a comprehensive visual guide, the process of troubleshooting becomes more efficient. Users can quickly locate issues, ensuring that repairs are conducted swiftly and accurately. This not only saves time but also minimizes potential damage that could occur from misdiagnosis.

Improved Communication: When working in teams, having a common reference point enhances collaboration. These visual aids allow team members to discuss components and processes more effectively, fostering a shared understanding of tasks at hand.

Education and Training: For newcomers, these illustrations serve as invaluable learning resources. They provide a foundational understanding of how equipment operates, which is essential for developing practical skills in maintenance and repair.

In conclusion, visual representations of machinery components play a vital role in ensuring effective management, repair, and understanding of equipment, ultimately leading to better performance and longevity.

Common Issues and Solutions

Maintaining outdoor power equipment can sometimes be challenging. Users may encounter a range of difficulties that affect performance and reliability. Understanding these common problems and their solutions can greatly enhance the lifespan and efficiency of your machinery.

1. Difficulty Starting

If your equipment struggles to start, it could be due to fuel issues, such as stale gasoline or improper fuel mixture. Ensure that you use fresh fuel and the correct ratio of oil to gasoline. Additionally, check the spark plug for wear or damage, and replace it if necessary.

2. Poor Performance

Experiencing a loss of power while operating can be frustrating. This may stem from a clogged air filter or muffler. Regularly inspect and clean these components to maintain optimal airflow. If the problem persists, consider checking the fuel lines for blockages.

3. Excessive Vibration

Excessive vibrations during use can indicate loose or damaged parts. Inspect the cutting mechanism and ensure all fasteners are tightened. Additionally, worn-out or unbalanced blades can contribute to this issue, so regular maintenance is essential.

4. Oil Leaks

Leaks can lead to decreased performance and environmental concerns. Check all seals and gaskets for integrity. If a leak is detected, replacing the affected components is necessary to prevent further issues.

5. Overheating

Overheating may occur due to inadequate cooling or excessive workload. Ensure that cooling fins are free from debris and that the machine is not operated continuously beyond its capacity. Allowing the unit to rest can also help manage temperature.

By addressing these common concerns with appropriate solutions, users can ensure their outdoor equipment remains in good working order, enhancing both productivity and safety.

Identifying MS 251 Components

Understanding the various elements of a chainsaw is essential for effective maintenance and operation. Each component plays a crucial role in the overall functionality, ensuring safety and efficiency during use. This section aims to provide a clear overview of key parts and their significance.

Main Elements Overview

Familiarity with the primary components helps users recognize the importance of each part in the performance of the machine. Below is a concise table listing essential elements and their functions.

| Component | Function |

|---|---|

| Engine | Drives the cutting chain and powers the tool. |

| Guide Bar | Supports the chain and aids in precise cutting. |

| Chain | Engages with the guide bar to cut through wood. |

| Fuel Tank | Holds the fuel necessary for engine operation. |

| Air Filter | Prevents debris from entering the engine, ensuring optimal performance. |

Importance of Component Knowledge

Recognizing these elements not only enhances user confidence but also aids in troubleshooting and repairs. A comprehensive understanding of each part’s function contributes to the ultimate longevity and effectiveness of the tool.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention to detail. By following a structured maintenance routine, you can significantly extend the lifespan of your tools while enhancing their efficiency. This section outlines key practices that will help maintain your equipment in peak condition.

Regular Cleaning

Accumulation of dirt and debris can lead to premature wear and hinder functionality. Make it a habit to clean your tools after each use. Focus on the following areas:

| Component | Cleaning Method |

|---|---|

| Air Filter | Remove and gently wash with soap and water; ensure it’s completely dry before reinstalling. |

| Chain | Wipe down with a cloth and apply appropriate lubricant. |

| Fuel System | Inspect and clean fuel lines; replace filters as needed. |

Routine Inspections

Conducting regular inspections can help identify potential issues before they escalate. Check the following components:

- Blades for sharpness and damage

- Fasteners for tightness

- Fuel and oil levels to ensure proper operation

By adhering to these maintenance tips, you can promote the longevity of your tools and ensure they continue to operate efficiently for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. Various resources are available that cater to both professionals and hobbyists, ensuring you can maintain optimal performance. Whether you prefer shopping online or visiting local retailers, understanding your options is essential for a successful repair.

Here are some of the best places to consider when searching for quality replacements:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers provide genuine components and expert advice, ensuring compatibility and reliability. |

| Online Marketplaces | Websites like eBay or Amazon offer a vast selection, often with user reviews to guide your choice. |

| Local Hardware Stores | Neighborhood shops may carry a limited selection but can be convenient for quick repairs. |

| Specialty Repair Shops | These establishments focus on specific equipment and may provide high-quality alternatives. |

| Manufacturer’s Website | Directly purchasing from the manufacturer guarantees authenticity and may offer additional resources for installation. |

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations simplify complex machinery, allowing users to identify and locate individual pieces quickly. Mastering the interpretation of these visuals enhances your ability to troubleshoot and source the necessary elements for your equipment.

Key Elements to Identify

- Labels: Pay attention to part names and numbers associated with each element.

- Connections: Observe how different components interact and fit together.

- Sections: Notice how diagrams are often divided into sections, each highlighting specific areas.

Steps to Effectively Interpret

- Familiarize yourself with the overall layout before diving into details.

- Cross-reference labels with a corresponding list for clarification.

- Look for legends that explain symbols or color codes used.

Benefits of Genuine Stihl Parts

Using authentic components in your outdoor equipment ensures optimal performance and longevity. These high-quality replacements are engineered specifically for your machine, providing unmatched reliability and efficiency.

Durability is a key advantage, as original elements are crafted to withstand rigorous use, reducing the likelihood of premature failure. Additionally, they often come with a warranty, offering peace of mind and protecting your investment.

Furthermore, utilizing genuine replacements helps maintain the manufacturer’s performance standards. This guarantees that your device operates at its best, minimizing the risk of breakdowns and costly repairs in the long run.

Finally, authentic components are designed for easy installation, making maintenance straightforward and enhancing your overall experience with the equipment.

Tools Needed for Repairs

When it comes to performing maintenance on your equipment, having the right tools is essential for ensuring efficiency and accuracy. The appropriate instruments not only streamline the process but also enhance safety and effectiveness during repairs.

Essential Tools

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for different screw types.

- Pliers: For gripping and manipulating small components.

- Torque wrench: To apply precise torque settings to fasteners.

- Safety gear: Goggles and gloves to protect yourself during repairs.

Additional Accessories

- Cleaning supplies: Brushes and solvents to maintain cleanliness.

- Lubricants: Essential for smooth operation of moving parts.

- Replacement parts: Always keep common components on hand for quick fixes.

Expert Recommendations for Users

When maintaining outdoor power equipment, understanding its components is crucial for ensuring optimal performance and longevity. Expert insights can guide users in choosing the right replacement parts and performing routine maintenance, thereby enhancing the efficiency of their tools.

Routine Maintenance Practices

Regular upkeep is essential. Users should establish a maintenance schedule that includes cleaning air filters, checking spark plugs, and ensuring proper lubrication. These practices not only prolong the life of the equipment but also prevent potential breakdowns that could lead to costly repairs.

Choosing Quality Components

When it comes to replacements, investing in high-quality components is advisable. Genuine parts offer compatibility and reliability, ensuring that the equipment operates as intended. Additionally, users should consider consulting with professionals or referring to manuals to verify compatibility before making a purchase. Prioritizing quality over cost can save time and money in the long run.