Understanding the Yth24v48 Parts Diagram for Efficient Maintenance

In the world of machinery, comprehending the various elements that contribute to functionality is essential. Each part plays a vital role in ensuring optimal performance and reliability. A thorough exploration of these elements can lead to better maintenance practices and enhance overall efficiency.

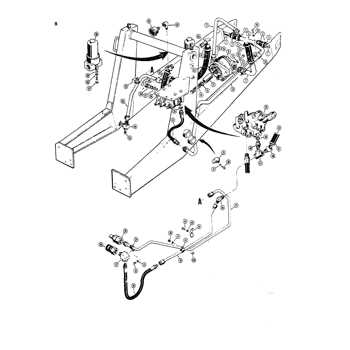

Illustrating the layout of these components is crucial for both novice and experienced users. By examining the arrangement and interconnections, one can identify potential issues and facilitate smoother repairs. This knowledge empowers individuals to tackle challenges with confidence.

Ultimately, gaining insight into the configuration of these essential parts will deepen your understanding of the machine’s operation. This foundational knowledge serves as a stepping stone for more advanced technical skills, fostering a greater appreciation for the intricacies of machinery.

Understanding Yth24v48 Parts Diagram

Gaining insight into the components and their arrangement of a specific machine can significantly enhance its maintenance and operation. This knowledge allows users to effectively identify, troubleshoot, and replace parts when necessary. Familiarity with the layout facilitates better communication with service professionals and aids in the overall understanding of the equipment’s functionality.

Key Components Overview

Each piece within the system serves a unique purpose, contributing to the overall efficiency and performance. Recognizing these elements can help in diagnosing issues or planning for upgrades.

Importance of Clarity

A clear representation of the components is vital for both novice and experienced users. This clarity assists in ensuring that each part is understood in its context, making it easier to follow through with repairs or modifications.

| Component | Description | Function |

|---|---|---|

| Engine | Power unit | Drives the machinery |

| Transmission | Power transfer system | Shifts power to the wheels |

| Chassis | Frame structure | Supports and houses components |

| Electrical System | Wiring and control units | Controls operation and functionality |

Components Overview of Yth24v48

This section provides a comprehensive look at the essential elements that make up the machinery in question. Understanding these components is crucial for efficient operation, maintenance, and troubleshooting. Each element plays a specific role, contributing to the overall functionality and performance of the equipment.

Key Elements

The following table outlines the primary components, along with their functions and significance within the system:

| Component Name | Function | Importance |

|---|---|---|

| Engine | Generates power for operation | Core component ensuring functionality |

| Transmission | Transfers power to the wheels | Essential for movement and speed control |

| Hydraulic System | Facilitates lifting and lowering | Crucial for operational versatility |

| Chassis | Provides structural integrity | Foundation for all other components |

| Control Panel | Interface for user interaction | Vital for monitoring and adjustments |

Maintenance Considerations

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding within various fields. These illustrations serve as essential tools for conveying complex information in a clear and concise manner, enabling users to grasp intricate systems or components with ease.

Accurate illustrations facilitate several key benefits:

- Enhanced Clarity: Well-crafted visuals provide a clearer perspective on structures and functionalities, reducing the likelihood of misunderstandings.

- Improved Efficiency: Access to precise representations allows individuals to complete tasks more quickly and accurately, minimizing the risk of errors.

- Facilitated Learning: Detailed visuals support educational endeavors, making it easier for learners to engage with and comprehend material.

- Effective Problem Solving: Clear representations aid in diagnosing issues and identifying solutions, allowing for timely interventions.

In various industries, having reliable illustrations is not merely advantageous but essential. They underpin the entire process, from design and assembly to maintenance and troubleshooting. As such, investing time and resources into creating and utilizing high-quality representations pays dividends in operational effectiveness and user satisfaction.

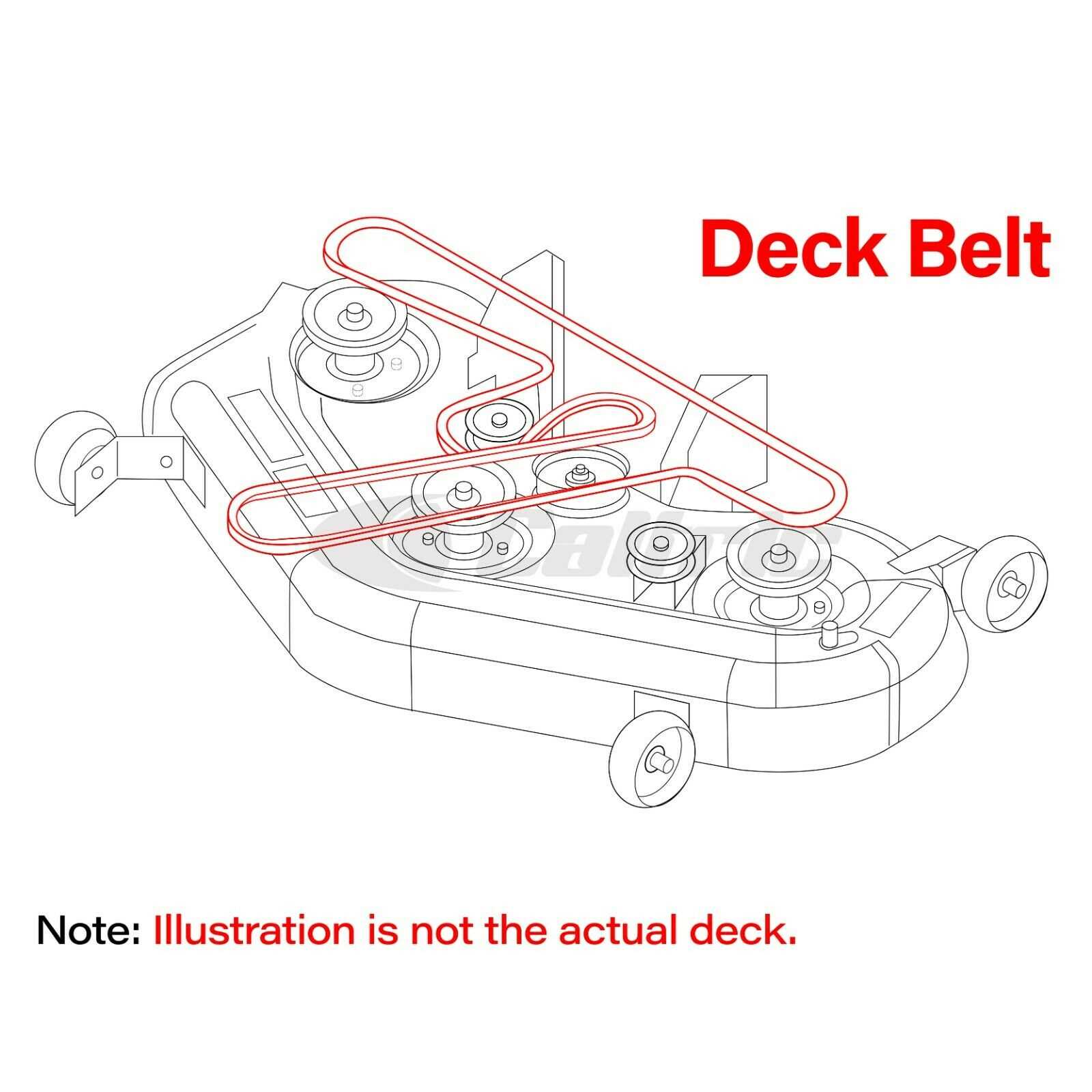

Common Issues with Yth24v48 Parts

Understanding the frequent challenges associated with specific components is essential for maintaining optimal functionality. Many users encounter various malfunctions that can lead to inefficiencies or even complete breakdowns. By identifying these common concerns, one can take proactive measures to mitigate potential problems.

Frequent Challenges

- Wear and Tear: Over time, certain elements may degrade due to regular use, resulting in diminished performance.

- Improper Installation: Incorrectly fitted components can lead to operational failures, often causing further damage.

- Contamination: Dust and debris can accumulate, impacting the efficiency of moving parts and electrical connections.

Signs of Trouble

- Unusual Noises: Grinding or rattling sounds may indicate that certain components are not functioning as intended.

- Leaking Fluids: Any visible leakage can signify a failure in seals or connections, requiring immediate attention.

- Inconsistent Performance: Fluctuations in power or response times often point to underlying issues that need to be addressed.

By being aware of these common difficulties, users can better prepare themselves to troubleshoot and maintain their machinery effectively.

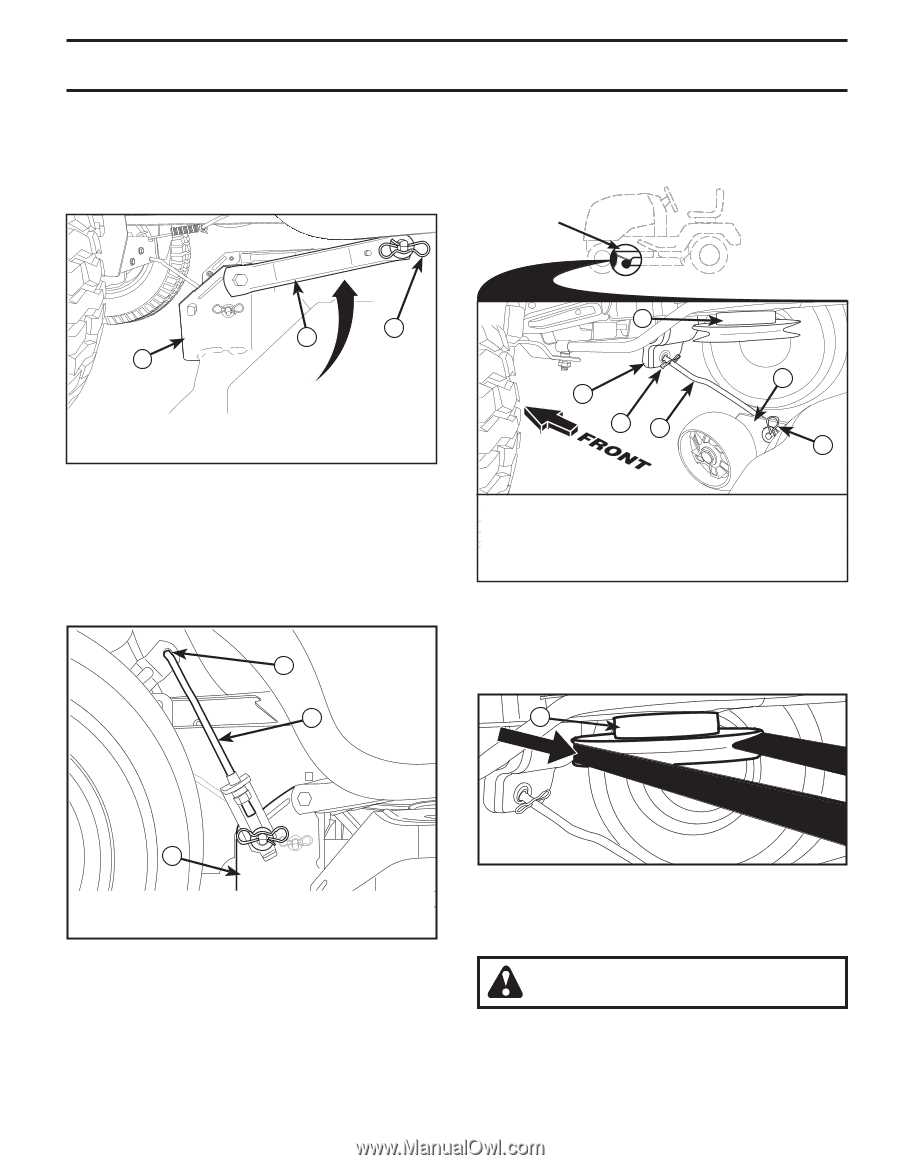

Step-by-Step Assembly Guide

This section provides a comprehensive guide for assembling your equipment with precision and ease. By following these clear instructions, you will ensure that each component fits perfectly, resulting in optimal performance. Whether you are a novice or an experienced assembler, this guide will assist you in every step of the process.

Required Tools and Materials

Before you begin, gather the necessary tools and components. Having everything at hand will streamline the assembly process and prevent interruptions.

| Tool/Material | Purpose |

|---|---|

| Screwdriver | To secure screws in place |

| Wrench | For tightening bolts |

| Lubricant | To ensure smooth operation |

| Cleaning Cloth | To wipe down components |

Assembly Steps

Follow these steps to complete your assembly:

- Start by laying out all components on a flat surface for easy access.

- Refer to the assembly instructions to identify each piece and its designated location.

- Begin with the base structure, ensuring all connections are secure.

- Continue with the installation of additional components, checking compatibility as you proceed.

- Once all parts are connected, review your work and tighten any loose connections.

By adhering to these guidelines, you can confidently assemble your equipment, leading to successful operation and longevity of the product.

Tools Needed for Maintenance

Proper upkeep of machinery requires a selection of essential instruments that ensure efficiency and longevity. These tools facilitate troubleshooting, repairs, and routine servicing, allowing for seamless operation and reduced downtime.

First and foremost, a comprehensive toolkit should include wrenches, screwdrivers, and pliers. These fundamental implements are vital for tightening or loosening various components. Additionally, a reliable multimeter is crucial for electrical diagnostics, while a torque wrench guarantees that fasteners are secured to the correct specifications.

For cleaning and lubrication, having brushes, rags, and appropriate oils on hand is indispensable. Moreover, safety equipment such as gloves and goggles cannot be overlooked, as they protect users during maintenance tasks. Investing in quality tools not only enhances performance but also contributes to a safer working environment.

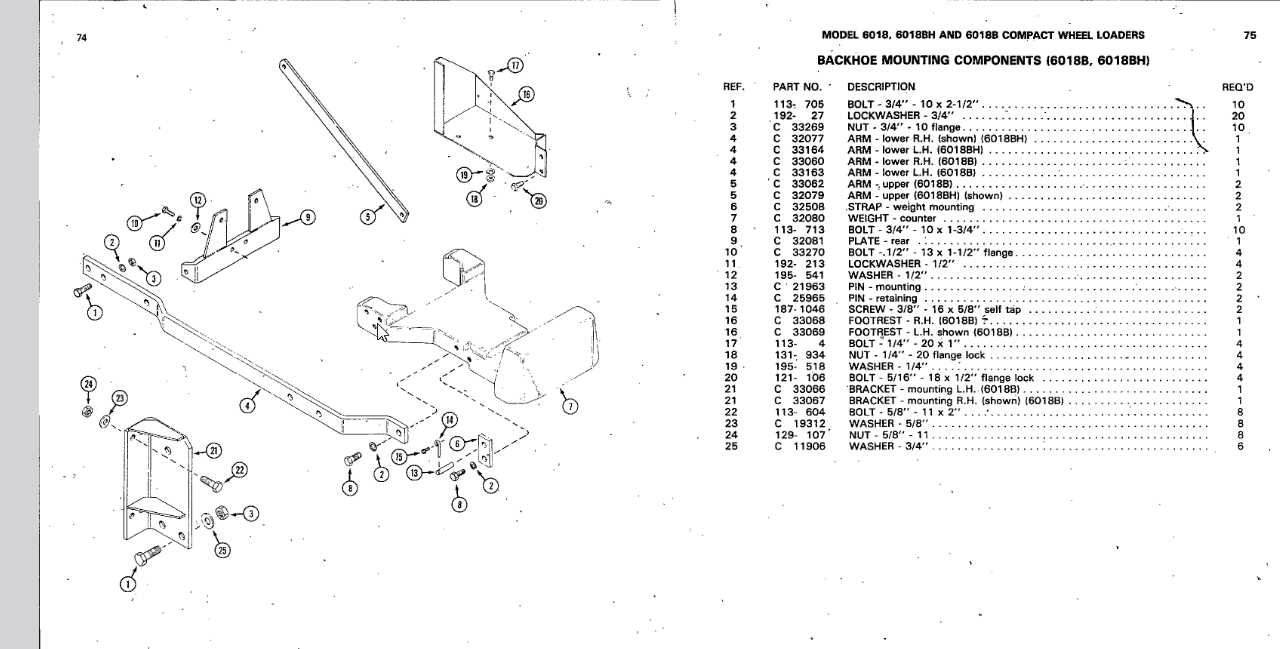

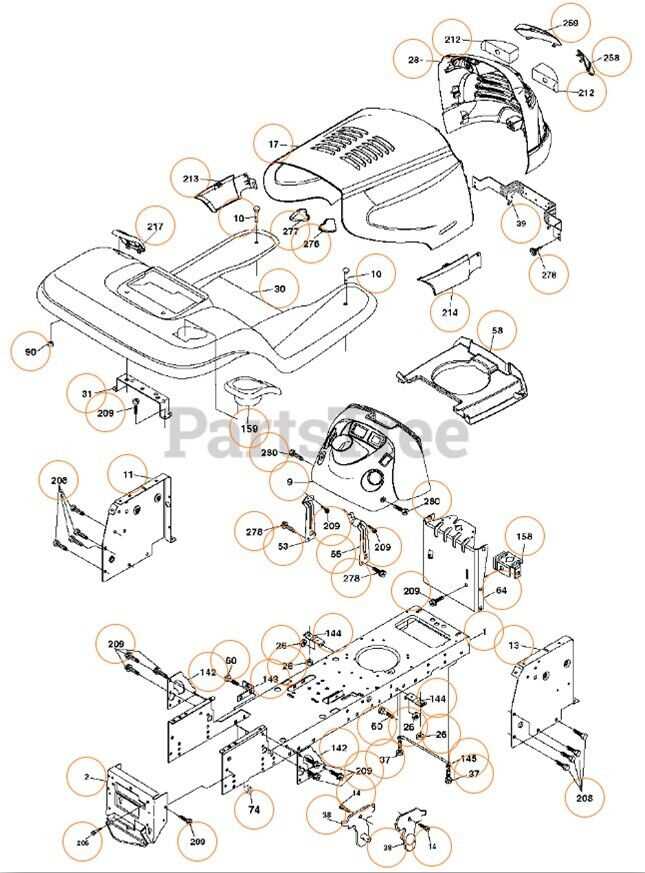

Identifying Parts in Diagrams

Understanding the components within technical illustrations is crucial for effective communication and problem-solving. These visual representations serve as a guide, helping users navigate complex systems by breaking them down into recognizable elements. By mastering the ability to interpret these visuals, individuals can enhance their comprehension and application of the underlying concepts.

Key Strategies for Recognition

One effective approach to recognizing elements is to familiarize oneself with common symbols and conventions used in technical illustrations. Each representation typically follows specific standards, allowing for quick identification and association with real-world items. Additionally, paying attention to labels and annotations can provide essential context that aids in understanding the relationships between various components.

Practical Application of Knowledge

When working with illustrations, hands-on practice can significantly improve one’s ability to identify and interpret the various elements. Engaging with real-world examples or simulations can reinforce learning and provide a clearer picture of how these representations apply in practical scenarios. This experiential knowledge not only boosts confidence but also enhances efficiency in addressing technical challenges.

Where to Find Replacement Parts

Finding suitable components for machinery can often be a challenge, but there are numerous avenues to explore. Whether you need a specific item or a more generic alternative, various resources can help you locate exactly what you’re looking for.

Online Retailers

- Specialty websites: Many online platforms specialize in equipment parts, offering a wide range of options tailored to specific models.

- General marketplaces: Websites like eBay and Amazon can also be useful for sourcing both new and used items.

- Manufacturer’s site: Visiting the official website of the equipment’s manufacturer often yields the most reliable options, including direct purchasing.

Local Suppliers

- Hardware stores: Many local hardware shops carry essential components or can order them for you.

- Authorized dealers: Partnering with authorized distributors ensures access to genuine items that meet quality standards.

- Salvage yards: For those seeking budget-friendly alternatives, salvage yards may have used components in good condition.

Tips for Effective Troubleshooting

When faced with mechanical issues, a systematic approach can make a significant difference in identifying and resolving problems efficiently. Effective troubleshooting not only saves time but also minimizes frustration, allowing for a smoother repair process. Adopting a structured method can enhance your ability to pinpoint the source of the trouble and implement appropriate solutions.

1. Gather Information

Begin by collecting as much relevant data as possible. This includes noting any symptoms, unusual sounds, or changes in performance. Understanding the context in which the problem occurs is crucial. Speaking with others who may have encountered similar issues can also provide valuable insights.

2. Follow a Step-by-Step Approach

Adopt a logical sequence when diagnosing the issue. Start with the simplest solutions before moving to more complex ones. Checking basic connections, power sources, and operational parameters can often reveal the root cause without extensive disassembly. Document your findings at each step to track your progress and avoid redundant efforts.

Maintaining Yth24v48 Performance

Ensuring optimal functionality of machinery requires regular attention and care. This involves monitoring various components and performing routine checks to identify any potential issues early. A proactive approach helps maintain efficiency and extends the lifespan of equipment.

Routine Maintenance Checklist

To keep your machinery running smoothly, follow this essential checklist:

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use recommended oil type. |

| Filter Inspection | Every 25 hours | Replace if clogged. |

| Battery Check | Monthly | Ensure proper charge level. |

| Tire Pressure | Weekly | Maintain recommended PSI. |

Common Performance Issues

Awareness of potential problems is key to preventing breakdowns. Common issues include overheating, reduced power, and unusual noises. Addressing these concerns promptly can lead to significant improvements in overall performance.

Upgrading Components for Efficiency

Enhancing the efficiency of machinery often requires a thoughtful approach to component improvement. By focusing on specific elements that contribute to overall performance, users can achieve significant gains in productivity and functionality. This section explores effective strategies for upgrading various elements to optimize operational efficiency.

When considering enhancements, it is essential to evaluate the following areas:

- Material Quality: Upgrading to higher-grade materials can lead to improved durability and reduced wear over time.

- Technology Integration: Incorporating advanced technology can streamline processes and reduce energy consumption.

- Precision Engineering: Implementing components with tighter tolerances can enhance performance and reliability.

- Modular Designs: Opting for interchangeable parts can simplify maintenance and reduce downtime.

Prioritizing these upgrades not only boosts efficiency but also extends the lifespan of the system. Careful consideration of each component’s role in the overall framework allows for targeted improvements that yield the best results.

- Assess current performance metrics to identify areas for enhancement.

- Research and select upgraded options that align with operational goals.

- Implement changes gradually to monitor effects on overall efficiency.

- Regularly review and adjust strategies based on performance feedback.

By focusing on these key strategies, operators can create a more efficient system that meets evolving demands and optimizes resource use.

Real User Experiences and Insights

This section delves into the genuine feedback and perspectives of users who have engaged with the system. By exploring their experiences, we can uncover valuable lessons and practical tips that enhance understanding and improve usability. User insights play a crucial role in identifying both strengths and weaknesses, guiding future improvements.

User Testimonials

- Many users have praised the intuitive interface, making navigation straightforward even for beginners.

- Several individuals noted the effectiveness of the support community, which offers quick resolutions to common issues.

- Users highlighted the robustness of the materials, emphasizing their durability during extended use.

Common Challenges

- Some users reported difficulties with compatibility when integrating additional tools.

- Occasional discrepancies in documentation led to confusion regarding installation procedures.

- A few individuals mentioned the learning curve associated with advanced features.

Overall, the shared experiences reflect a blend of positive feedback and constructive criticism, serving as a roadmap for future enhancements and user satisfaction.