Understanding the 5HP Briggs and Stratton Parts Diagram for Optimal Engine Maintenance

When it comes to maintaining and optimizing mechanical equipment, having a clear overview of the essential elements is crucial. Proper knowledge of how various components connect and interact with each other can make troubleshooting easier and more efficient. This section focuses on providing a detailed explanation of the main elements involved, helping you better understand how everything fits together.

Recognizing essential elements is an important first step in any maintenance or repair work. By familiarizing yourself with each component’s function, you can significantly enhance the performance and longevity of your machinery. This guide is designed to walk you through the most critical aspects, allowing you to approach any repairs or upgrades with confidence.

Understanding the layout and configuration of different elements will also aid in proper assembly and disassembly. Having a clear mental picture of where everything belongs ensures a smoother process and minimizes the risk of errors. Whether you’re addressing a minor issue or conducting routine maintenance, this resource will serve as a helpful reference for ensuring your equipment operates at peak efficiency.

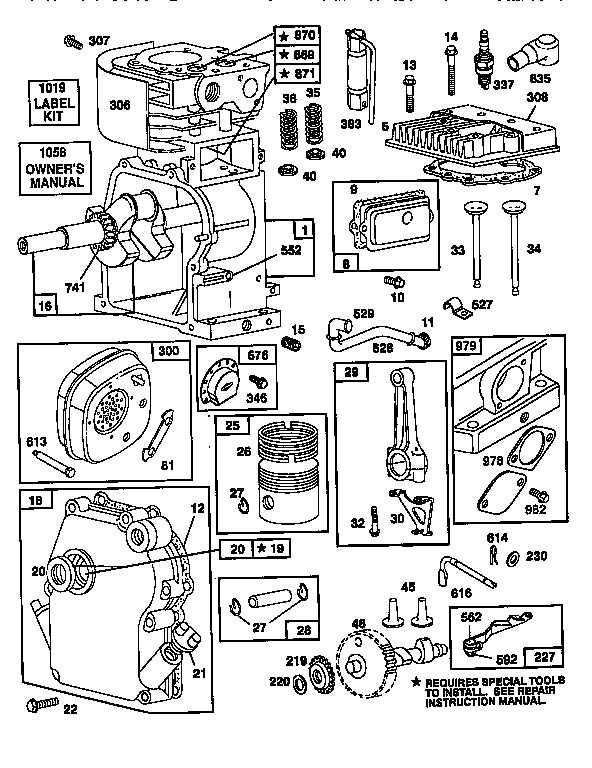

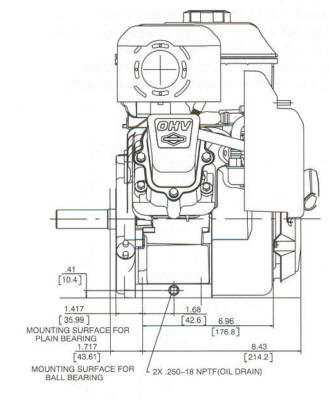

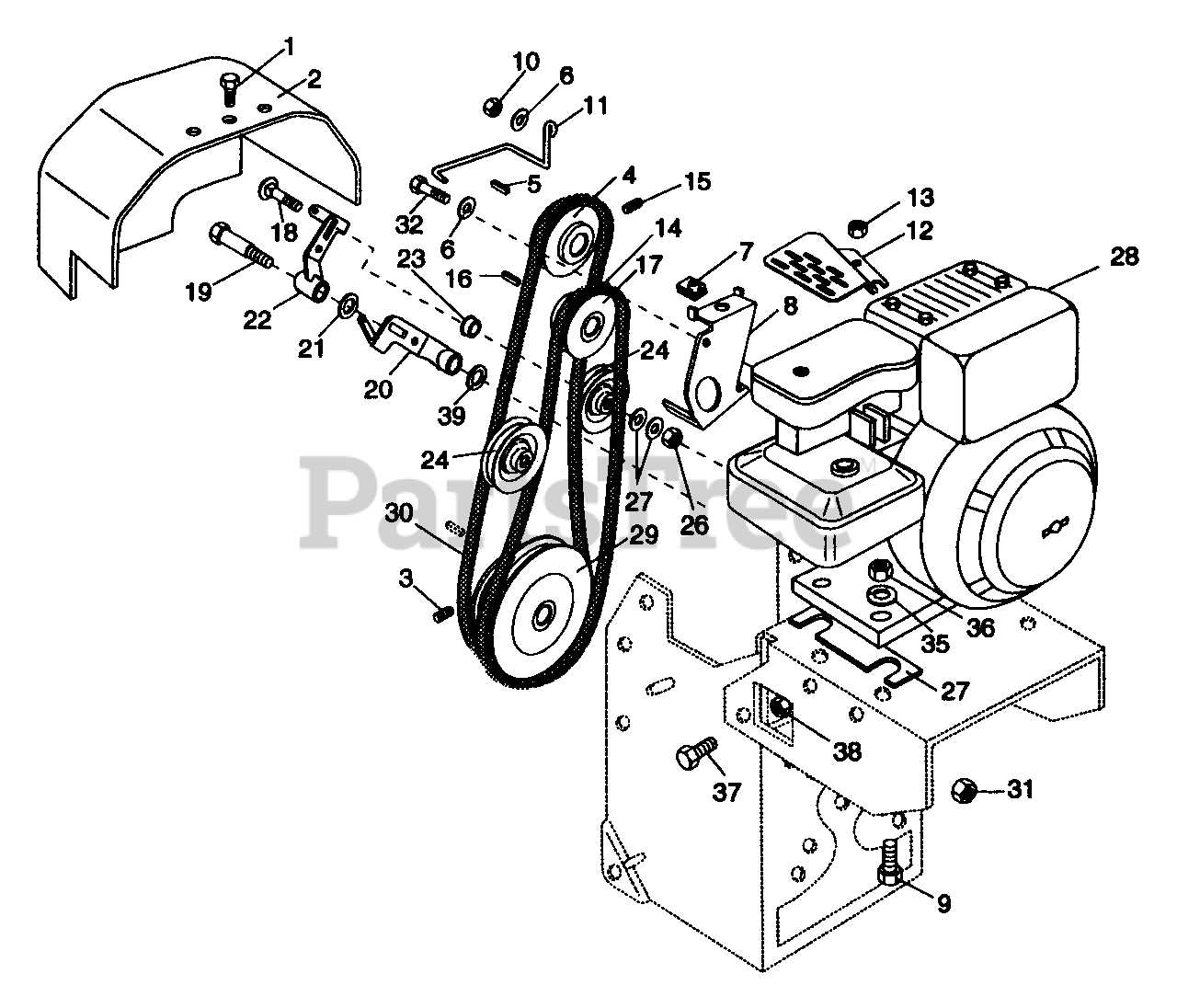

Understanding the 5HP Briggs and Stratton Engine Layout

The structure of a small motor often reveals the complexity behind its simple design. By examining the key sections and their functions, one can gain insight into how the system operates, ensuring smooth performance and longevity. Understanding the placement of critical elements helps identify potential issues and simplifies maintenance procedures.

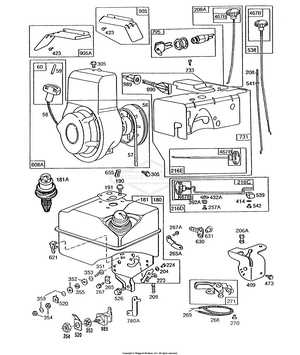

- Fuel System: The engine’s fuel delivery components are crucial for maintaining proper combustion. Key sections like the fuel tank, carburetor, and connecting lines ensure a consistent fuel flow.

- Ignition Components: The ignition system, including spark plug connections and wiring, is responsible for generating the spark that powers the motor. It’s vital to keep these parts in good condition for efficient operation.

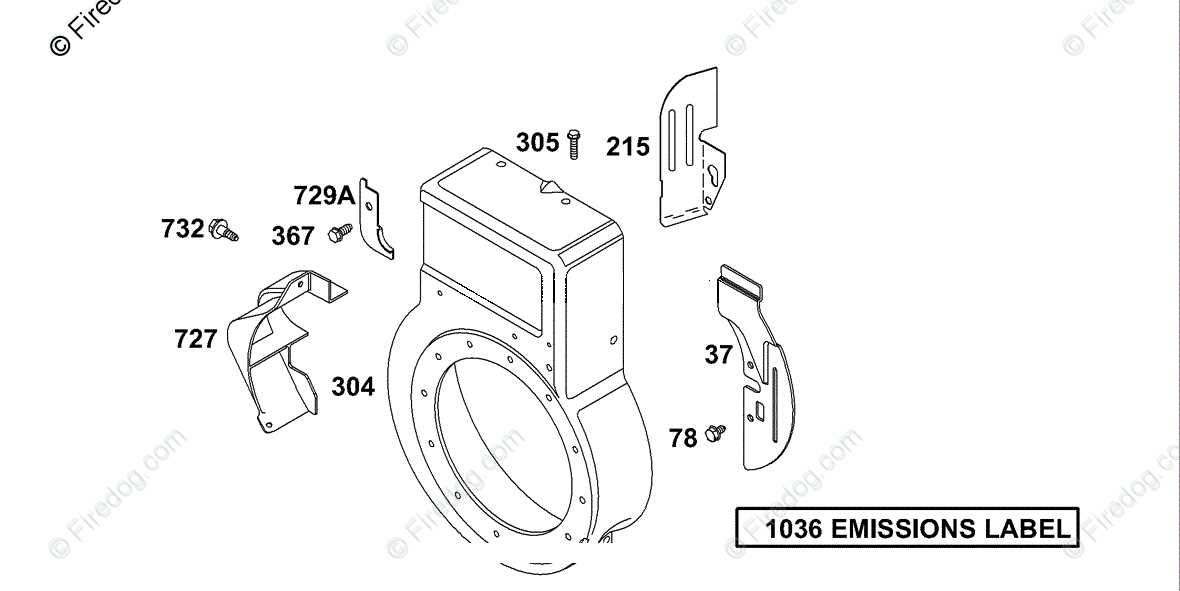

- Cooling Mechanism: The motor relies on air circulation to prevent overheating. Understanding the fan system and air passages is essential for optimal cooling and avoiding heat damage.

- Exhaust System: The exhaust route is designed to expel gases efficiently. Components like the muffler help reduce noise while guiding emissions away from sensitive parts.

- Transmission Elements: The gear system trans

Key Components of the 5HP Engine

This section focuses on the fundamental mechanical elements that drive the engine’s operation. These key units work together, ensuring smooth functionality and overall efficiency. Understanding each element’s role helps in maintaining optimal performance and identifying any areas needing attention.

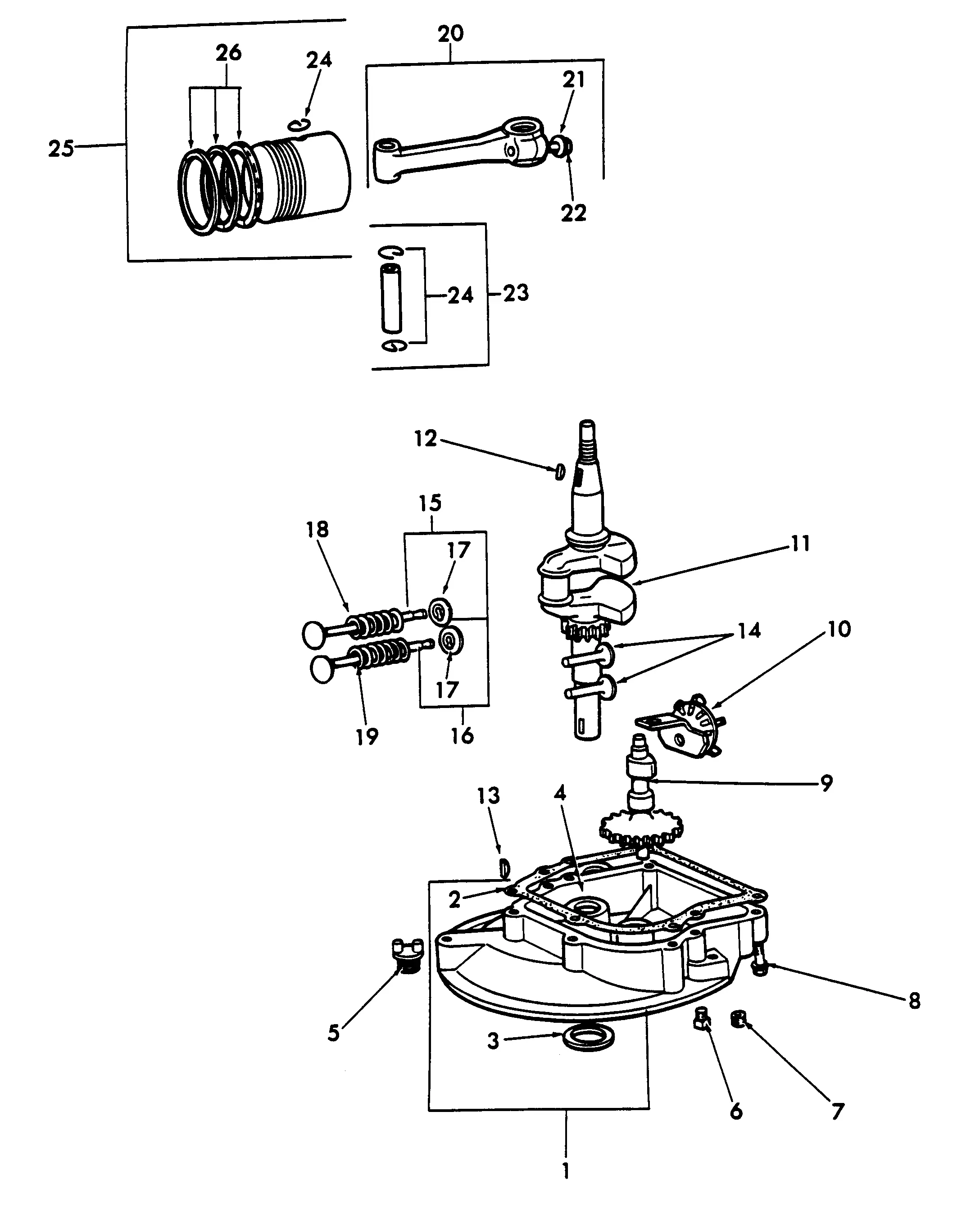

Engine Block

The engine block serves as the core structure, housing essential parts that work together to generate power. It supports the movement of various components while maintaining stability under pressure. This unit must be kept in good condition to ensure the smooth running of the entire system.

Fuel and Air System

The fuel and air system is critical for delivering the right mixture into the combustion chamber. It consists of components responsible for proper flow and regulation, ensuring that the engine runs efficiently. Each part within this system plays a vital role in energy conversion.

Component Function Cylinder Head Provides a sealed environment for combustion, allowing the transfer of power to the moving parts. Carburetor Mixes fuel with air in the correct ratio to optimize combustion efficiency. Piston Transfers energy from the combustion process to the crankshaft, How the Fuel System is Configured

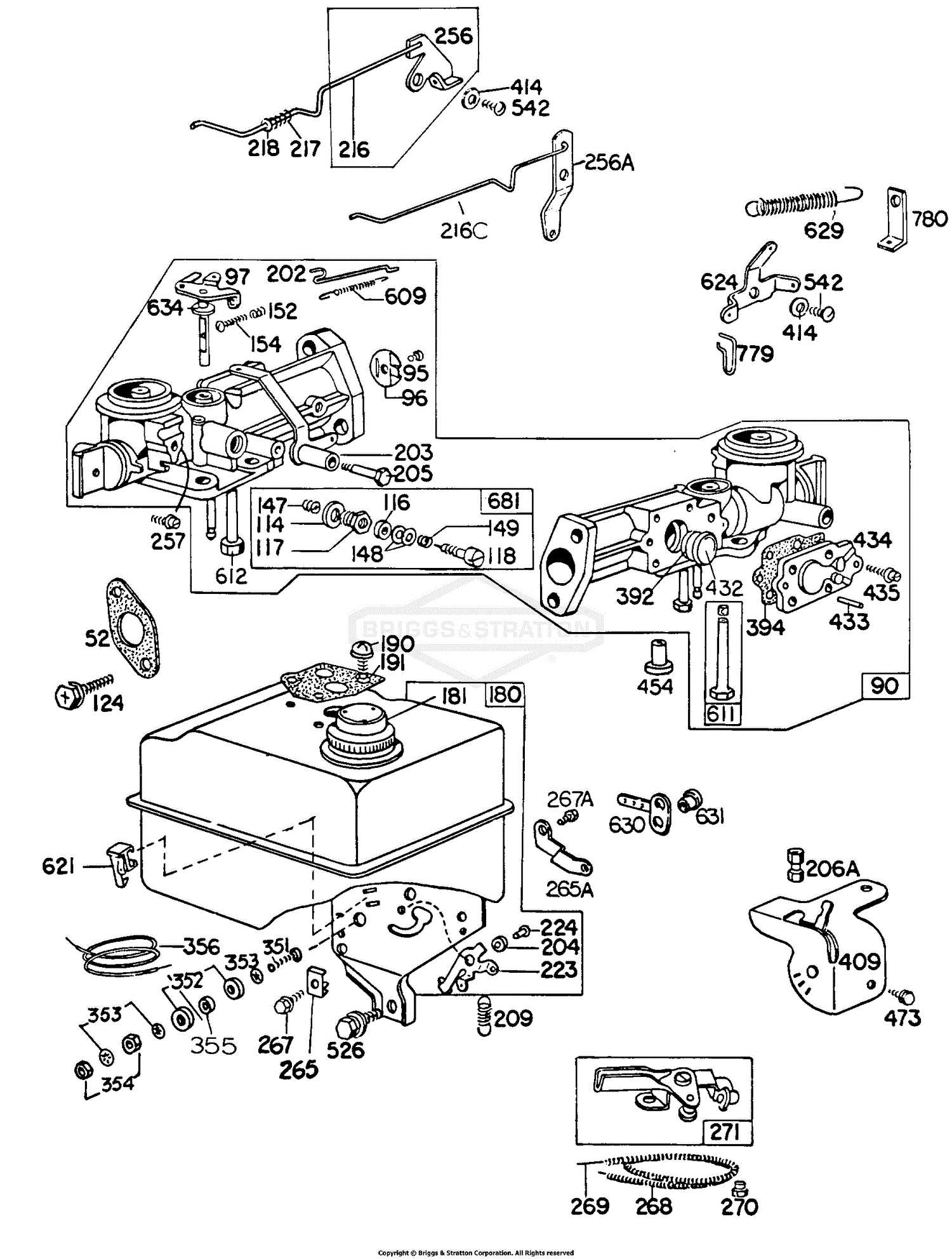

The setup of the fuel mechanism plays a crucial role in ensuring the proper functioning of an engine. It ensures the consistent delivery of fuel, optimizing performance by balancing the flow with air intake. Understanding how this system operates is essential for troubleshooting and maintaining efficient operation.

Main Components of the Fuel Setup

- Fuel tank: Stores the gasoline needed for operation, designed with specific features to prevent contamination and ensure safe storage.

- Fuel line: A conduit that transports fuel from the tank to the carburetor, made from durable materials to withstand pressure and potential wear.

- Carburetor: A key component that mixes air and fuel in the right proportions before the combustion process, ensuring efficient engine operation.

- Fuel filter: Removes impurities from the gasoline, protecting the engine’s sensitive parts from damage caused by debris.

Fuel Delivery Process

- The fuel is drawn from the storage tank via the fuel line.

- Ignition System Parts Overview

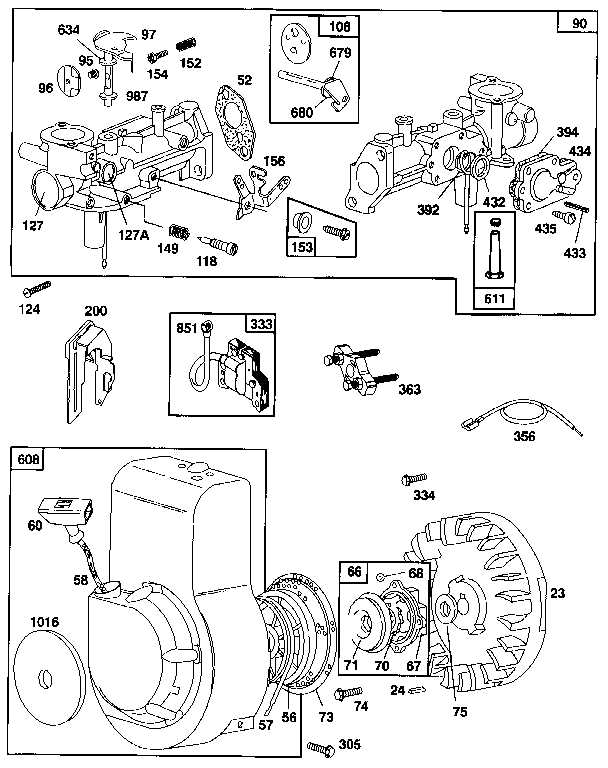

The ignition mechanism plays a crucial role in ensuring a smooth start and efficient operation of small engines. Understanding the components involved helps in identifying issues and maintaining the engine’s performance. This section covers the key elements that make up the system and how they contribute to its function.

Primary Components

- Ignition Coil: A core element that converts electrical energy to the high voltage required to create a spark in the spark plug.

- Spark Plug: Responsible for igniting the air-fuel mixture in the engine’s cylinder.

- Flywheel: Helps generate the magnetic field that activates the ignition coil during engine rotation.

Supporting Elements

- Kill Switch: Used to stop the engine by interrupting the electrical flow to the ignition system.

- Wiring: Connects various parts of the ignition system to ensure proper flow of electricity.

- Magneto: Generates electric current using the motion of the flywheel.

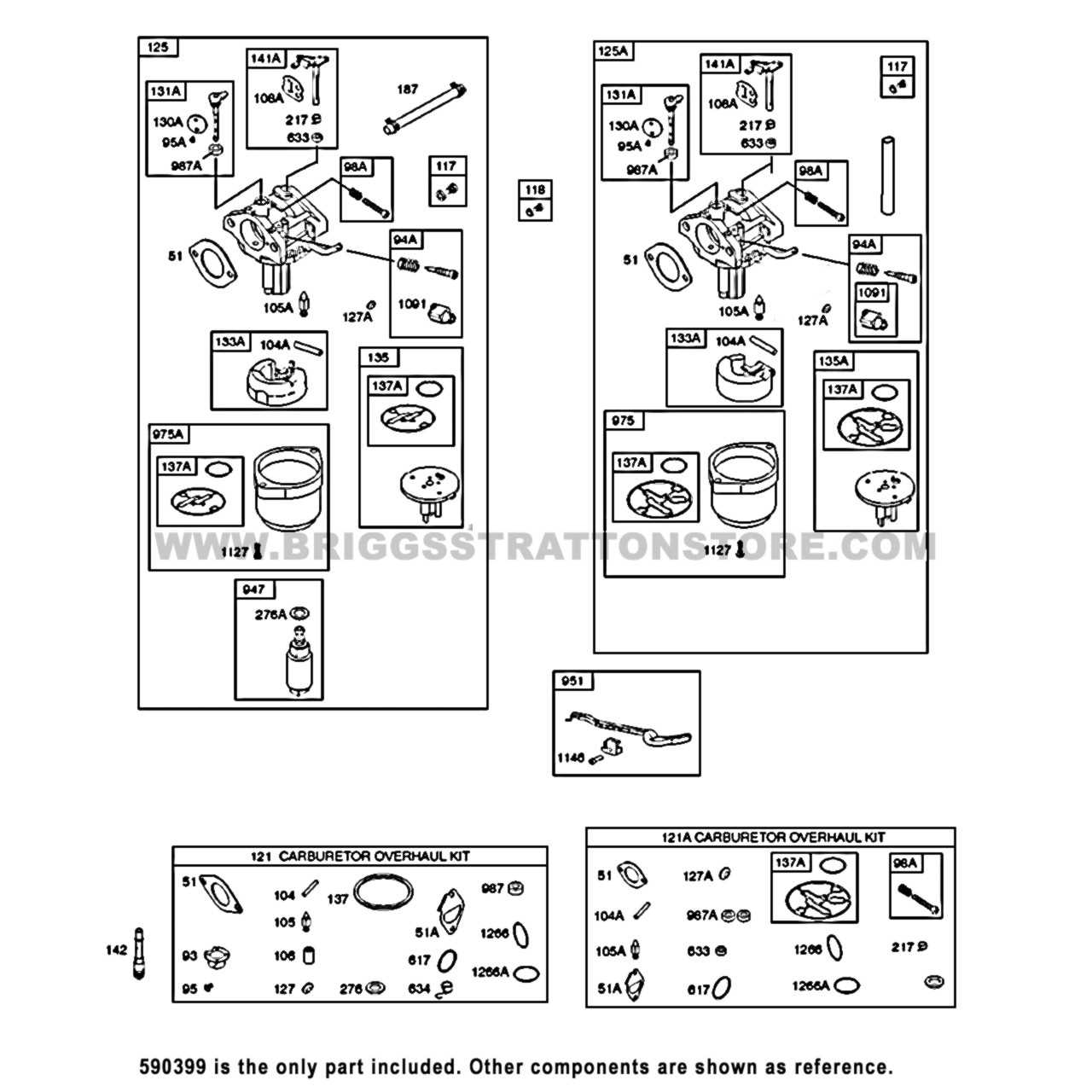

Exploring the Carburetor Mechanism

The carburetor plays a critical role in regulating the air and fuel mixture needed for proper engine function. Understanding its key components and how they interact can help you maintain optimal performance. This section will provide an overview of how this essential part works and what to look for when inspecting or servicing it.

Key Components of the Carburetor

- Fuel Inlet: Where the fuel enters the carburetor, preparing to mix with air.

- Throttle Valve: Controls the airflow into the engine, affecting speed and performance.

- Choke Valve: Adjusts air intake during cold starts, ensuring proper ignition.

- Float Chamber: Maintains a steady level of fuel within the carburetor.

How the Mechanism Operates

- Air flows through the intake, where it mixes with fuel drawn from the chamber.

- The throttle adjusts the amount of this mixture

Oil and Lubrication Parts Guide

Proper maintenance of lubrication components is crucial for ensuring the longevity and smooth operation of your engine. Understanding the key elements involved in oil circulation and lubrication can help prevent wear and extend the life of your machinery. This section will provide an overview of the most essential components, helping you to identify and maintain them effectively.

Component Description Maintenance Tips Oil Filter Ensures that contaminants are removed from the oil before it circulates through the engine. Replace regularly to avoid clogging and ensure efficient filtration. Oil Pump Responsible for circulating oil through the engine to keep moving parts well-lubricated. Check for proper functioning to prevent oil starvation and overheating. Dipstick Used to measure the level and condition of the engine’s oil. Regularly inspect oil levels and top up as necessary to maintain optimal performance. Gaskets and Seals Understanding the Air Filter Setup

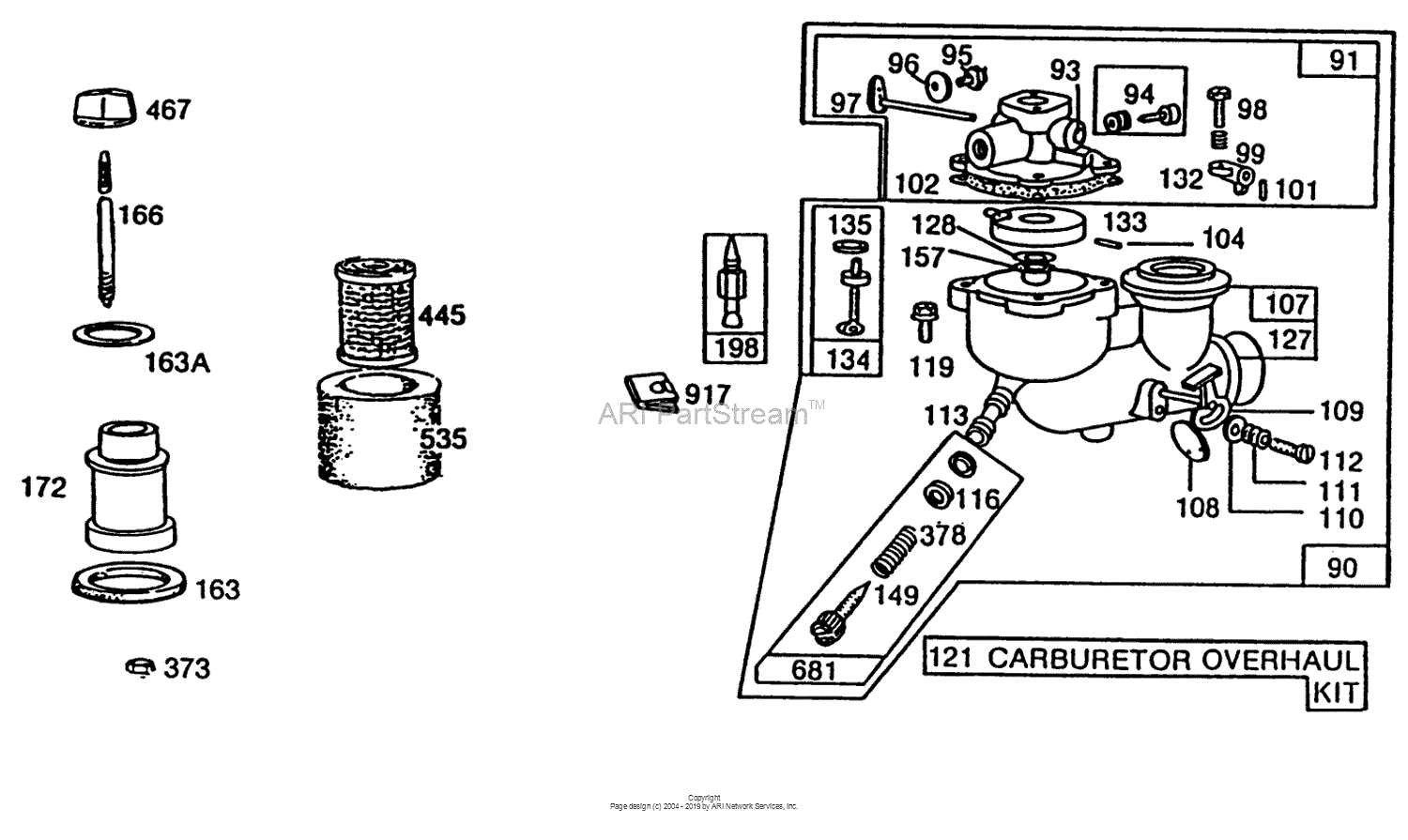

The air filtration system is a critical component in maintaining engine performance and longevity. It serves to prevent dust, debris, and other contaminants from entering the combustion chamber, ensuring smooth operation. A well-functioning filter setup contributes significantly to the overall efficiency of the engine, promoting clean air intake for optimal fuel combustion.

The filter assembly typically consists of a housing, a filter element, and often a pre-cleaner. The housing is designed to secure the filter in place while protecting it from external elements. Inside the housing, the filter element traps particles, ensuring that only clean air reaches the engine. Some setups may also include an additional pre-cleaner, which helps to remove larger particles before they reach the main filter.

Maintenance of this setup is crucial for keeping the engine in top condition. Regular cleaning or replacing the filter element ensures that air flow remains unobstructed, allowing the engine to perform at its best. Failure to maintain the air filtration system can lead to engine inefficiency, increased fuel consumption, and potentially severe damage over time.

Exhaust System Components Breakdown

The exhaust system plays a crucial role in ensuring that harmful gases are safely expelled from the engine. It consists of various elements that work together to direct exhaust fumes out of the engine compartment. Understanding these components helps in maintenance and optimization of engine performance.

Key Components of the Exhaust System

The exhaust system generally includes a few essential parts such as the manifold, pipes, and muffler. The manifold collects exhaust gases from the engine’s cylinders, guiding them through the pipes towards the muffler. The muffler, in turn, reduces the noise produced by the engine, ensuring smoother operation.

Maintenance and Replacement Considerations

Proper care of the exhaust system is vital to avoid engine damage. Over time, parts like the muffler and pipes may corrode or get damaged due to exposure to heat and gases. Regular inspection ensures that these components are functioning optimally, preventing performance issues and costly repairs.

Maintenance Tips for Engine Parts

Proper upkeep of the components within a small engine is essential for its longevity and optimal performance. Regular attention to key elements can prevent breakdowns and extend the life of your machine. Maintaining these elements ensures smooth operation, reduces the need for repairs, and enhances efficiency.

Regular Cleaning: Keep engine components free from dirt, dust, and debris. These can clog air filters and affect airflow, leading to overheating or inefficient operation. Ensure that the cooling fins, air intake, and exhaust areas remain clear. Cleaning should be done periodically to maintain air circulation and prevent overheating.

Inspect and Replace Filters: Air and fuel filters should be inspected regularly for damage or clogging. A clogged air filter restricts airflow, which can lead to engine strain. Clean or replace filters as needed, following the manufacturer’s recommendations, to ensure a clean fuel supply and proper engine breathing.

Oil Maintenance: Changing the engine oil at the recommended intervals helps maintain lubrication and reduces friction between moving parts. Always use the correct type of oil and check oil levels frequently to avoid damage. A well-lubricated engine runs more smoothly and prevents unnecessary wear on internal components.

Check Spark Plug Condition: A worn or fouled spark plug can cause misfiring, poor fuel efficiency, or difficulty starting the engine. Inspect the spark plug for wear and carbon buildup, cleaning or replacing it when necessary. A properly functioning spark plug ensures reliable ignition and smooth engine operation.

Monitor Fuel Quality: Stale or contaminated fuel can cause poor engine performance or even damage over time. Drain old fuel if the engine has been unused for an extended period. Always use fresh, high-quality fuel and consider adding a fuel stabilizer if the machine will not be used for several months.

Regular Inspections: Always check the engine for any loose bolts, nuts, or damaged components that could affect performance. Tighten or replace any parts that appear worn or loose to avoid potential mechanical failures during use.

Common Issues with 5HP Engine Parts

Small engines are subject to various complications over time, often due to wear and tear, improper maintenance, or faulty components. These challenges can significantly impact performance, leading to issues such as reduced power, difficulty starting, or overheating. Identifying and addressing these common issues can ensure the longevity and efficiency of the engine.

One of the most frequent problems encountered is the failure of the ignition system. Worn-out spark plugs, faulty coils, or dirty contacts can prevent proper ignition. Another issue arises with fuel delivery, where clogged carburetors or fuel lines may disrupt the engine’s ability to run smoothly. Additionally, air intake blockages can lead to improper air-fuel mixture, affecting combustion and engine power.

Issue Possible Cause Solution Engine won’t start Faulty spark plug or ignition coil Replace spark plug or ignition coil Loss of power Clogged carburetor or air filter Clean or replace carburetor and air filter Overheating Blocked cooling fins or low oil level Clear fins and check oil level Excessive smoke Incorrect oil or worn piston rings Use correct oil and replace piston rings Replacing Worn-Out Engine Components

Over time, engine elements can experience wear due to continuous use, leading to reduced performance or malfunctions. Identifying and replacing these components is crucial for maintaining optimal functionality. Regular inspection helps detect parts that may need replacement before they cause further damage, ensuring the smooth operation of the engine.

Common signs of wear include unusual noises, diminished power, or irregular operation. If you notice these symptoms, it’s essential to inspect key parts such as the fuel system, ignition components, and internal mechanisms for any signs of deterioration.

When replacing parts, choose high-quality replacements that match the specifications of the engine. Proper installation ensures longevity and prevents potential issues down the line. Regular maintenance is the key to keeping your engine running efficiently for an extended period.