Understanding the Stihl HLA 86 Parts Diagram for Efficient Maintenance

In the world of outdoor equipment, knowing the intricate elements that make up your machinery is essential for optimal performance. A comprehensive understanding of each component not only enhances maintenance practices but also empowers users to troubleshoot effectively when issues arise. This knowledge can lead to extended lifespans for your devices and improved efficiency in their operation.

Every tool consists of various parts that work in harmony to achieve desired results. From the engine to the cutting mechanism, each segment plays a crucial role in overall functionality. By familiarizing yourself with the configuration and purpose of these elements, you can ensure that your device operates smoothly and meets your specific needs.

Whether you are a seasoned professional or a weekend enthusiast, having access to detailed illustrations and descriptions of these components can be invaluable. Such resources provide clarity on assembly and disassembly, making repairs more manageable. Furthermore, understanding the relationship between different parts can enhance your skills in troubleshooting and maintenance.

Understanding Stihl HLA 86 Components

In the realm of outdoor power tools, having a clear comprehension of the various elements that comprise a device can significantly enhance its operation and maintenance. Each component plays a pivotal role in the overall functionality and efficiency, ensuring that tasks are executed smoothly and effectively.

Key Elements of the Device

Here are the essential components that contribute to the performance of this outdoor tool:

- Engine: The powerhouse that drives the entire system, providing the necessary energy for operation.

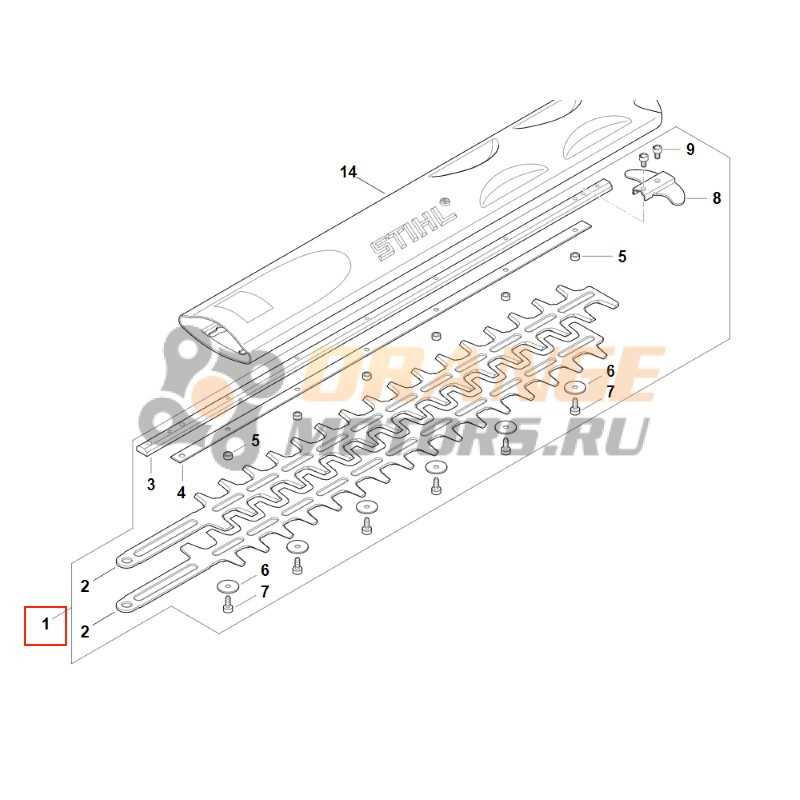

- Blades: The cutting edges designed for precision and efficiency, critical for achieving clean cuts.

- Handle: The ergonomic grip that ensures comfort and control during use.

- Battery: The energy source that powers the tool, enabling cordless convenience.

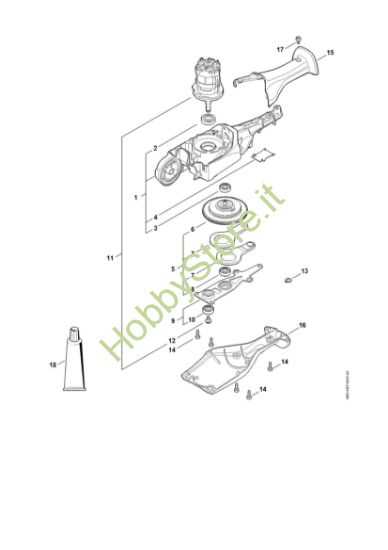

- Gearbox: A crucial element that regulates the speed and torque, optimizing performance for different tasks.

Maintenance Tips

Proper upkeep of these components is essential for longevity and optimal performance:

- Regularly inspect and clean the engine to prevent buildup and ensure efficiency.

- Sharpen or replace the blades as needed to maintain cutting precision.

- Check the handle for any wear or damage to ensure safety and comfort.

- Monitor battery health and charge levels to maximize usage time.

- Inspect the gearbox for any signs of wear or malfunction to prevent performance issues.

Overview of HLA 86 Parts

This section provides a comprehensive look at the various components of the trimming tool designed for efficiency and performance. Each element plays a crucial role in ensuring optimal operation, making it essential for users to understand their functions and interactions.

Key Components

The primary features of this device include the motor assembly, which drives the cutting mechanism, and the shaft that connects the motor to the working head. Additionally, the ergonomic handle enhances user comfort, while the control interface allows for easy adjustments during use.

Maintenance and Replacement

Importance of Using Genuine Parts

Utilizing authentic components in machinery and equipment is crucial for maintaining optimal performance and longevity. Genuine parts are specifically designed to fit seamlessly and function effectively within the system, ensuring safety and reliability during operation. Substituting with counterfeit or generic alternatives can lead to diminished performance, increased wear, and even potential hazards.

Benefits of Authentic Components

Choosing genuine replacements brings several advantages that enhance the overall efficiency of your equipment:

| Benefit | Description |

|---|---|

| Quality Assurance | Authentic components are manufactured to meet strict quality standards, ensuring durability and reliability. |

| Perfect Fit | Designed specifically for your machine, genuine parts guarantee a perfect fit, minimizing the risk of malfunction. |

| Enhanced Performance | Using original components helps maintain the machinery’s efficiency, optimizing its overall performance. |

| Warranty Protection | Utilizing authentic parts often helps preserve any existing warranties, providing peace of mind to the user. |

Long-Term Cost Savings

While genuine components may have a higher upfront cost, they often lead to significant savings over time. Reduced maintenance needs, fewer repairs, and prolonged lifespan of the equipment contribute to lower overall expenses. Investing in authentic parts is a proactive approach to ensuring your machinery operates smoothly and reliably for years to come.

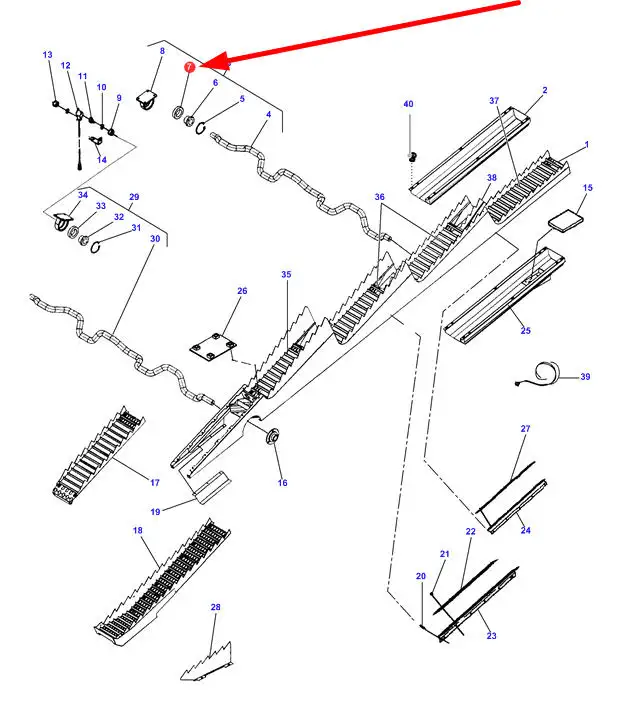

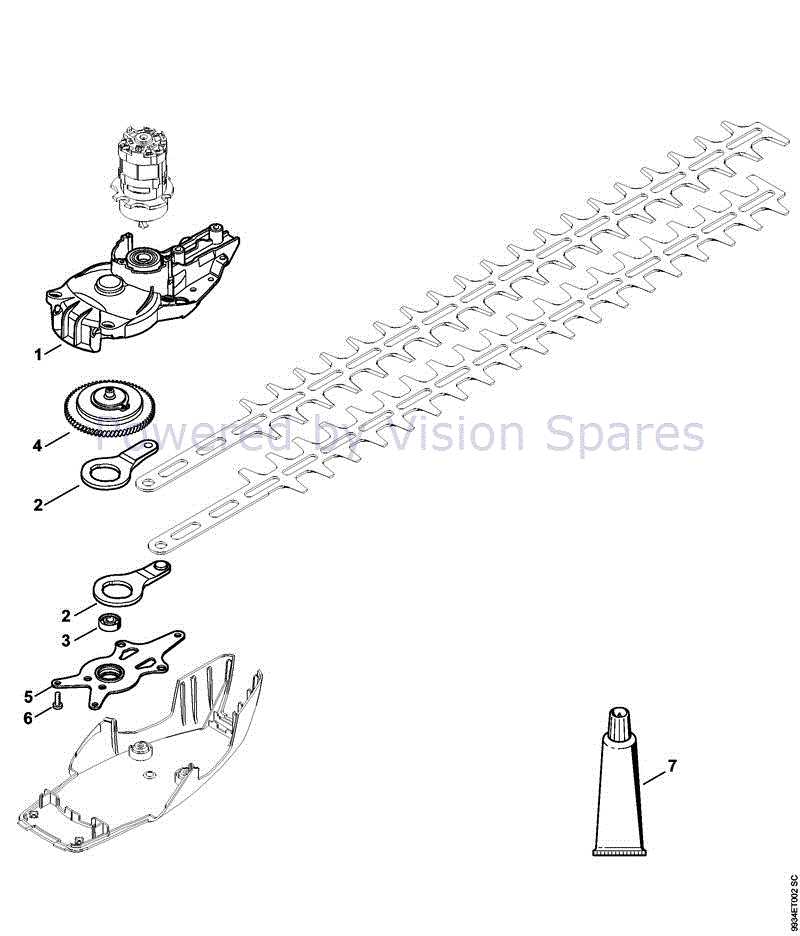

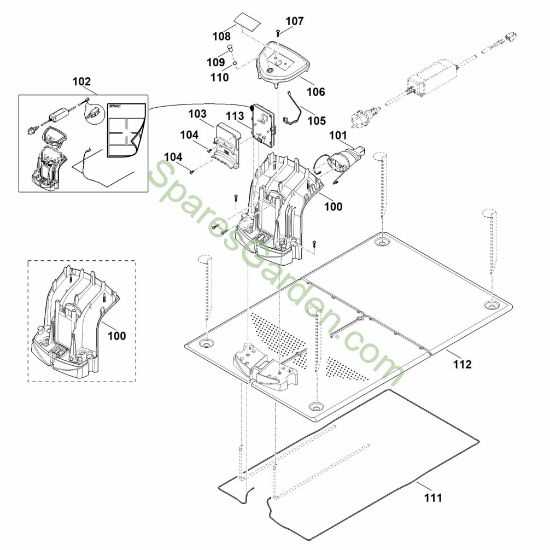

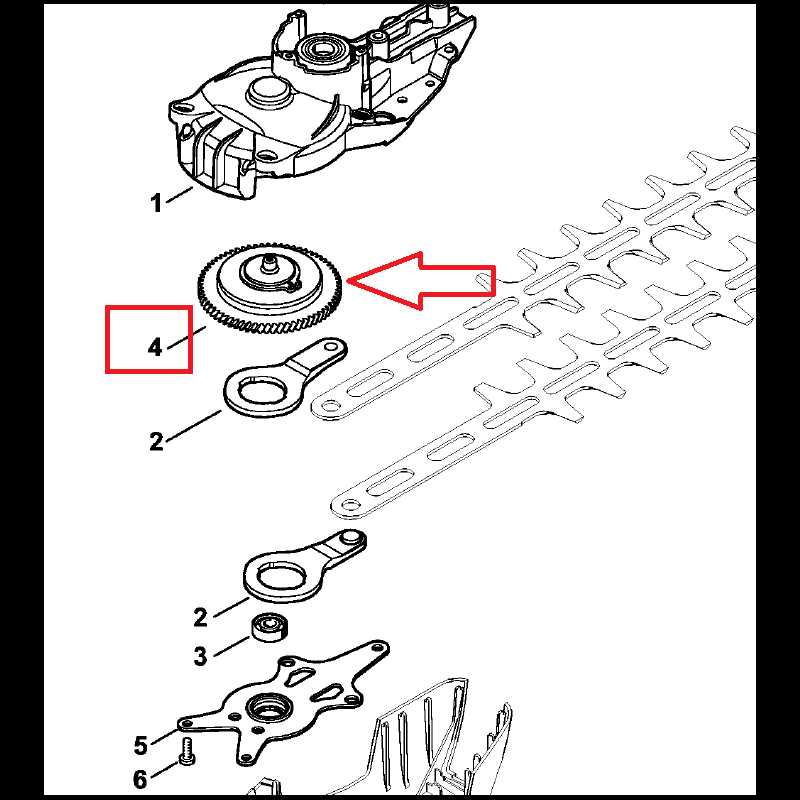

Identifying Key Diagrams for Repairs

Understanding the essential illustrations for maintenance tasks is crucial for ensuring efficient repairs. These visual aids provide a detailed look at the assembly and functionality of the equipment, helping users pinpoint issues and locate specific components quickly. With clear and accurate representations, users can enhance their repair skills and tackle problems with confidence.

Importance of Visual Aids

Visual representations serve as a roadmap, guiding individuals through the intricate details of machinery. By familiarizing oneself with these images, users can better grasp the layout and connections between different elements, which is vital for effective troubleshooting. This knowledge can significantly reduce downtime and improve overall performance.

Utilizing Illustrations for Efficient Maintenance

When performing repairs, referencing the correct visual aids can streamline the process. Identifying key components through these guides allows for a more organized approach to maintenance. Additionally, having a solid understanding of the parts involved can prevent errors and enhance the longevity of the equipment, ultimately saving time and resources in the long run.

Common Issues and Replacement Parts

In the realm of outdoor equipment maintenance, understanding frequent challenges and necessary components is essential for ensuring optimal performance. Users often encounter various malfunctions that can hinder the efficiency of their tools. Recognizing these common problems allows for timely interventions and effective solutions.

One prevalent issue involves the battery not holding a charge. This can lead to interruptions during use and can be caused by age, improper charging practices, or environmental factors. In such cases, replacing the battery is crucial for restoring functionality.

Another frequent concern is related to the cutting mechanism. Over time, blades may become dull or damaged, impacting cutting efficiency. Regular inspection and timely replacement of these components are vital for maintaining peak performance.

Additionally, the handle or trigger assembly may experience wear and tear due to prolonged use. This can affect control and safety during operation. Replacing these parts promptly ensures a safer user experience.

In summary, identifying and addressing these common issues with the appropriate components not only extends the life of the equipment but also enhances overall user satisfaction. Regular maintenance and understanding the signs of wear can prevent more significant problems down the line.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan and performance of your outdoor power equipment. Regular attention to maintenance tasks can prevent wear and tear, ensuring reliable operation when you need it most.

- Regular Cleaning: After each use, remove dirt and debris from the equipment. This prevents buildup that can hinder performance.

- Check and Replace Filters: Inspect air and fuel filters regularly. Clean or replace them as needed to ensure optimal airflow and fuel delivery.

- Inspect Blades: Keep blades sharp and free of damage. Dull or damaged blades can reduce efficiency and cause strain on the motor.

By incorporating these simple practices into your routine, you can significantly enhance the durability and effectiveness of your tools.

- Lubrication: Regularly apply lubricant to moving parts to minimize friction and wear.

- Battery Care: If your equipment is battery-operated, ensure the battery is charged and stored properly to extend its lifespan.

- Seasonal Storage: Prepare your equipment for seasonal changes. Store it in a dry place, and consider using protective covers to shield it from the elements.

Following these guidelines will not only extend the life of your equipment but also enhance its overall performance and reliability.

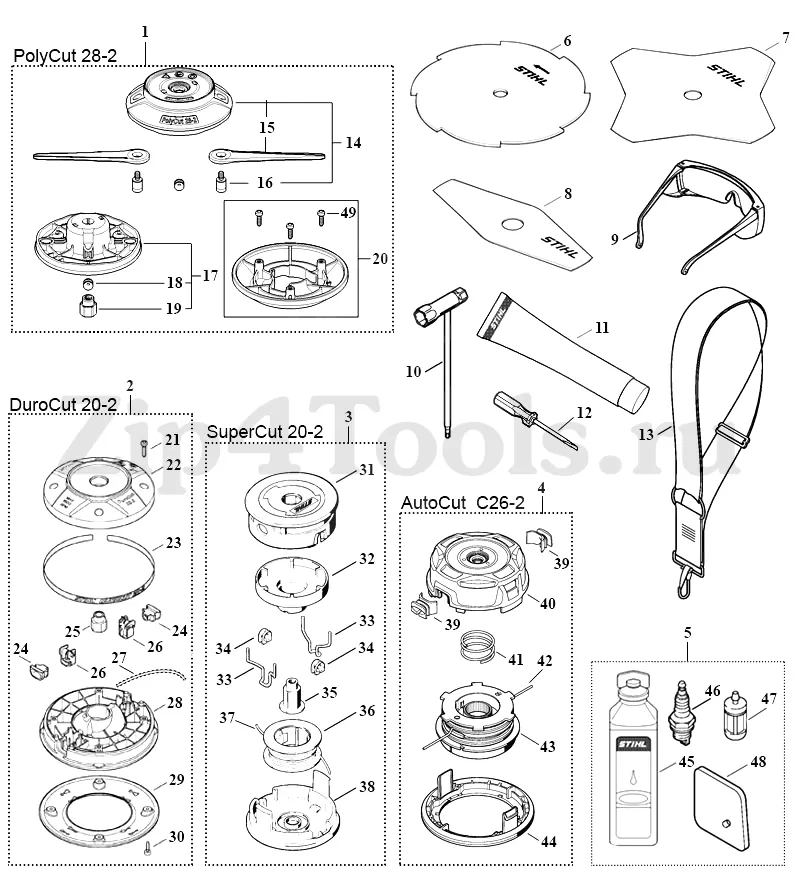

How to Interpret Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to maintain and repair equipment. These visuals provide a clear representation of components, their relationships, and how they fit together within the larger system. By familiarizing yourself with their structure, you can streamline the process of identifying and replacing worn or damaged elements.

When examining these visuals, consider the following key aspects:

- Numbering System: Each element is typically assigned a unique identifier, allowing for easy reference. Look for a corresponding list that provides details about each item.

- Component Grouping: Elements are often categorized into sections based on functionality. This grouping can help you understand how different parts interact.

- Orientation and Layout: Pay attention to the layout, as it reflects the actual assembly. Understanding orientation will aid in proper reassembly.

- Symbols and Icons: Familiarize yourself with any symbols that indicate specific types of components, such as fasteners or electrical elements. This knowledge will enhance your interpretation skills.

To effectively utilize these illustrations during maintenance, follow these steps:

- Identify the Problem: Clearly define the issue at hand to focus your search on relevant sections of the visual.

- Locate the Relevant Section: Use the indexing system to find the appropriate group related to your problem.

- Cross-reference Information: Match the visual elements with the parts list to ensure you have the correct components for replacement.

- Follow Assembly Instructions: If available, consult any accompanying instructions to aid in reassembly after replacing components.

By mastering these techniques, you will enhance your confidence and efficiency in working with technical schematics, ensuring successful repairs and maintenance of your equipment.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Understanding where to source these essential items is crucial for maintaining optimal functionality. Below are some effective avenues to explore when seeking replacements.

Authorized Retailers

One of the most reliable options is to visit authorized dealers. These retailers offer genuine components that meet quality standards and are designed specifically for your model. Here are some benefits of choosing authorized outlets:

- Guaranteed authenticity of components

- Access to expert advice and support

- Potential for warranty coverage

Online Marketplaces

The internet has transformed the way we shop, making it easier to find necessary items. Numerous online platforms provide a vast selection of components, often at competitive prices. Consider the following tips when using these resources:

- Check user reviews for reliability and quality.

- Verify return policies to ensure a smooth purchasing experience.

- Compare prices across different sites to find the best deal.

Tools Needed for Disassembly

When undertaking the task of disassembling your equipment, having the right tools is essential for ensuring a smooth and efficient process. The proper instruments not only facilitate the breakdown of components but also help prevent damage to delicate parts. Here’s a concise overview of the necessary tools you should gather before you begin.

Essential Tools

- Screwdrivers: Both flathead and Phillips screwdrivers in various sizes are crucial for removing screws.

- Wrenches: A set of adjustable wrenches or socket wrenches will help you tackle nuts and bolts.

- Pliers: Needle-nose pliers can be useful for gripping and manipulating small components.

- Hex Keys: Often required for hex screws, these come in various sizes and are essential for assembly and disassembly.

- Torque Wrench: This tool ensures that screws and bolts are tightened to the manufacturer’s specifications.

Additional Tools

- Wire Cutters: Useful for cutting through wires or cables that may be connected.

- Plastic Pry Tools: These prevent damage to the housing when prying apart components.

- Magnetic Tray: Ideal for keeping screws and small parts organized and preventing loss.

- Flashlight: A bright light source will help illuminate hard-to-see areas during the process.

Assembly Process Explained

The assembly process of gardening equipment is a crucial stage that ensures optimal performance and longevity. Understanding each step involved can enhance efficiency and prevent potential issues during operation. This guide will provide an overview of the essential components and their interconnections.

Preparation is Key: Before beginning the assembly, it’s important to gather all necessary tools and components. Ensuring that each piece is accounted for will streamline the entire process and reduce the likelihood of errors.

Step-by-Step Assembly: Start by identifying the main sections of the equipment, including the motor housing, cutting elements, and handle. Each part must be aligned properly to guarantee a secure fit. Follow the manufacturer’s instructions closely, as they often provide specific sequences that optimize functionality.

Final Checks: Once assembled, perform a thorough inspection of all connections and moving parts. Testing the equipment in a safe environment can reveal any adjustments needed for smooth operation. Ensuring everything is securely fastened and functional will extend the lifespan of your device.

By following these outlined steps, users can ensure their equipment is assembled correctly, ready for effective use in their gardening tasks.

Safety Precautions During Repairs

When undertaking maintenance or repair work on any equipment, prioritizing safety is essential. Proper precautions help prevent accidents and injuries, ensuring that both the individual performing the work and the surrounding environment remain secure. Adhering to safety measures not only promotes a safe workspace but also enhances the efficiency of the repair process.

Wear Appropriate Personal Protective Equipment

Before starting any repair, it is crucial to don suitable personal protective gear. This includes gloves to protect hands from sharp edges and hazardous materials, as well as goggles to shield the eyes from debris. Depending on the task, wearing ear protection and a dust mask may also be advisable to safeguard against noise and harmful particles.

Ensure a Clean and Organized Workspace

A tidy workspace significantly reduces the risk of accidents. Keep tools and components organized to prevent tripping hazards or misplacing essential items. Additionally, ensure that the area is well-lit and free of clutter, allowing for clear visibility and easy access to tools and equipment during the repair process.

Customer Support and Resources Available

In today’s fast-paced world, having access to reliable assistance and informative resources is essential for users seeking optimal performance from their tools. Whether you need guidance on maintenance, troubleshooting, or finding compatible accessories, a strong support system can enhance your overall experience. Various avenues exist to ensure that you receive the help you need in a timely and effective manner.

Comprehensive customer service options include dedicated hotlines, online chat support, and user forums where enthusiasts share their insights. Additionally, many manufacturers provide detailed manuals and instructional videos that cover a range of topics, from basic operations to advanced repairs. Access to these materials empowers users to maximize the efficiency and longevity of their equipment.

Moreover, warranty programs and service plans can offer peace of mind, ensuring that any necessary repairs or replacements are handled promptly. Staying informed about these resources not only helps you troubleshoot issues but also keeps your tools operating at their best.