Understanding the Parts Diagram of Hilti TE 7

The TE 7 is a versatile tool widely used in various construction and renovation tasks. Its design incorporates multiple elements that contribute to its functionality and performance. Gaining insight into the various sections of this equipment is essential for effective operation and maintenance.

Each segment plays a critical role in the overall mechanism, allowing users to achieve precise results. Familiarity with these components can enhance user experience and extend the longevity of the device. By understanding how each element interacts, operators can maximize the efficiency and reliability of this essential equipment.

In this article, we will explore the different sections of the TE 7, highlighting their significance and interrelations. Whether you are a seasoned professional or a newcomer to the field, comprehending these details will empower you to use the tool more effectively.

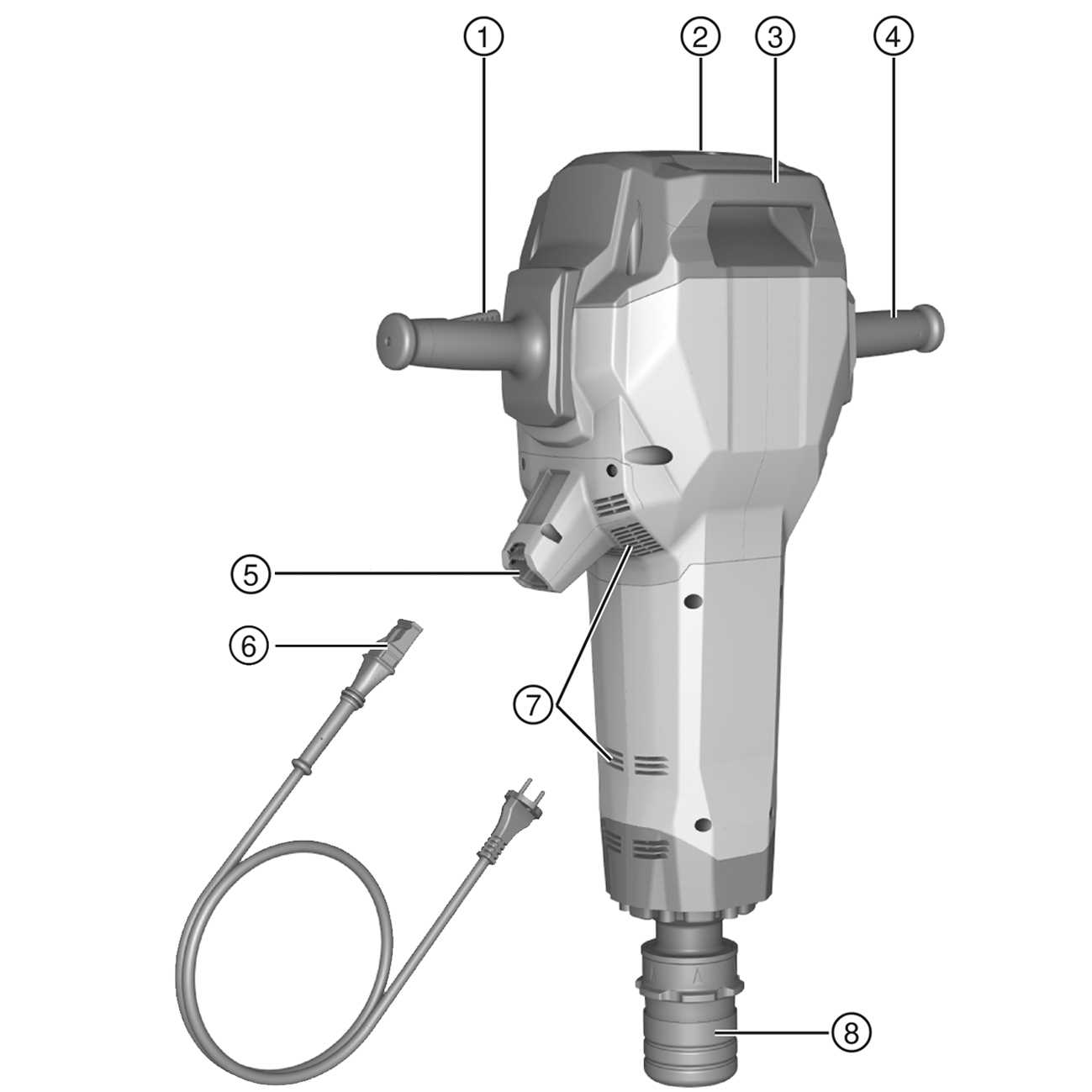

The following section presents a comprehensive overview of a specific tool utilized in construction and maintenance tasks. This powerful device is designed for efficient drilling and chiseling, making it an essential asset for professionals in various industries. Understanding its components is crucial for proper usage and maintenance.

The structure of this article is as follows:

| Heading Number | Heading Title |

|---|---|

| 1 | Introduction to the Tool |

| 2 | Key Features and Benefits |

| 3 | Technical Specifications |

| 4 | Understanding the Mechanism |

| 5 | Essential Components Breakdown |

| 6 | How to Operate the Device |

| 7 | Safety Precautions |

| 8 | Maintenance Tips |

| 9 | Common Issues and Solutions |

| 10 | Comparative Analysis with Similar Tools |

| 11 | User Testimonials |

| 12 | Conclusion and Recommendations |

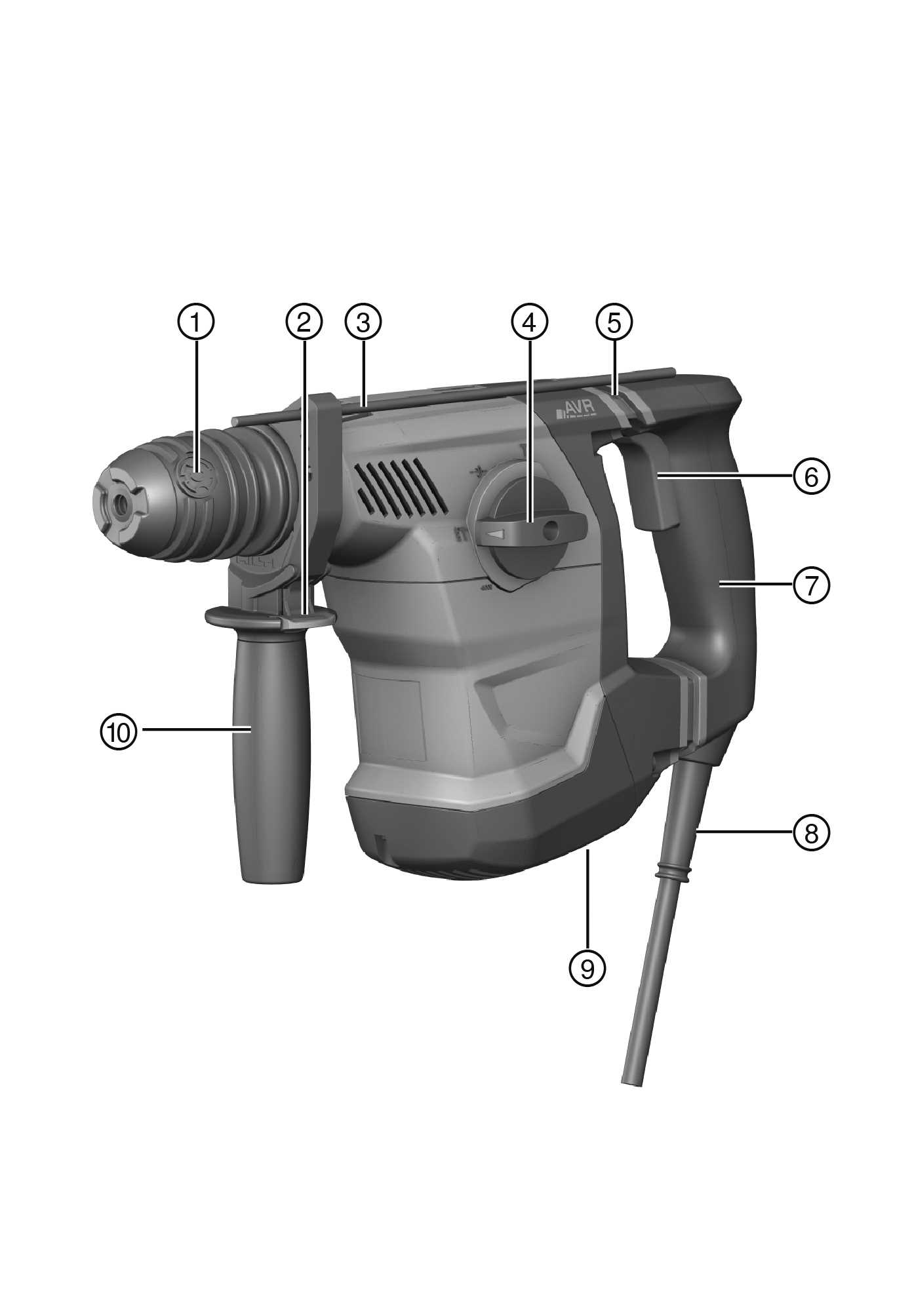

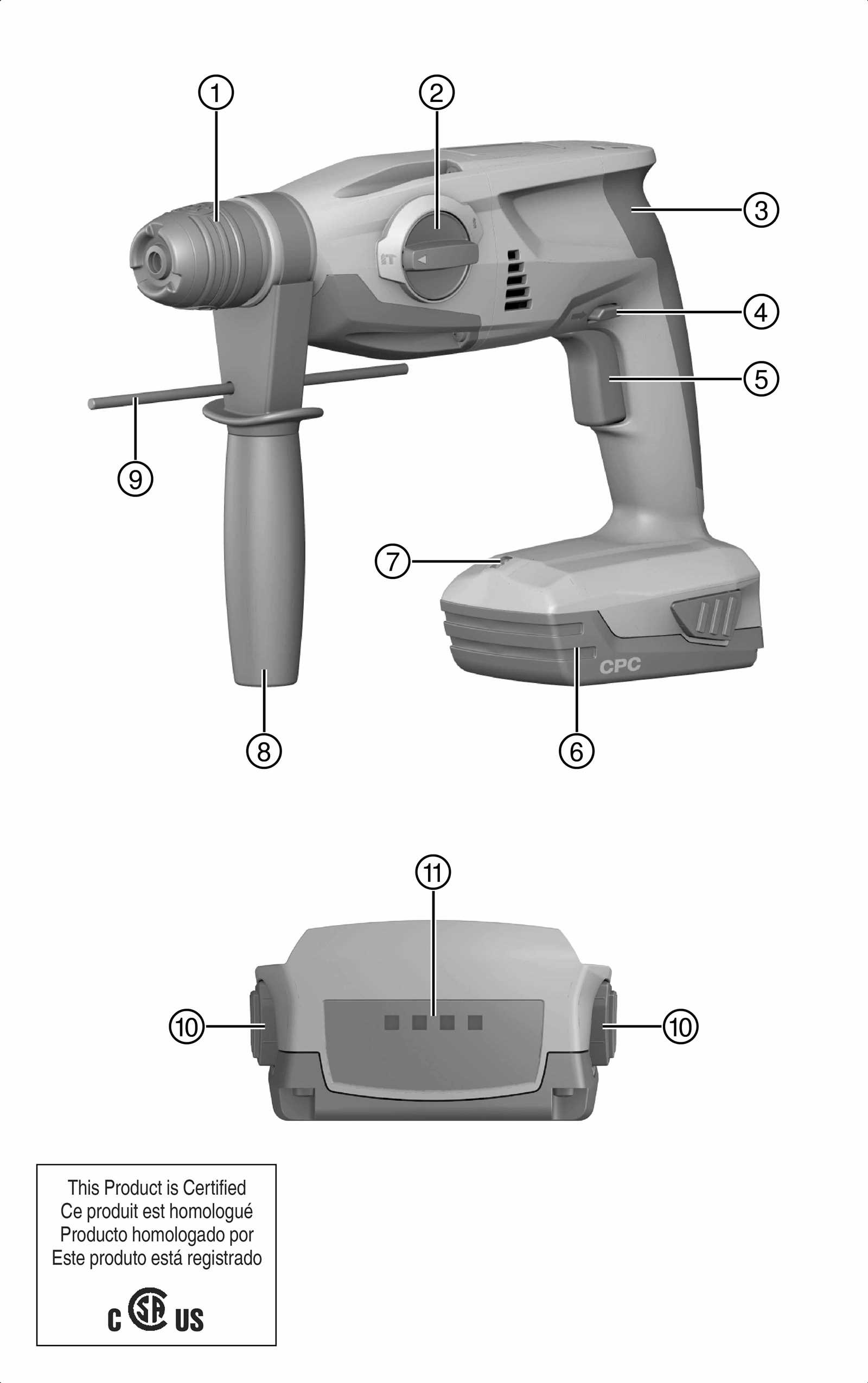

Key Components of the Tool

The functionality of any mechanical device relies heavily on its essential elements. Understanding these fundamental components is crucial for effective operation and maintenance. Each part contributes to the overall performance, ensuring the tool operates smoothly and efficiently.

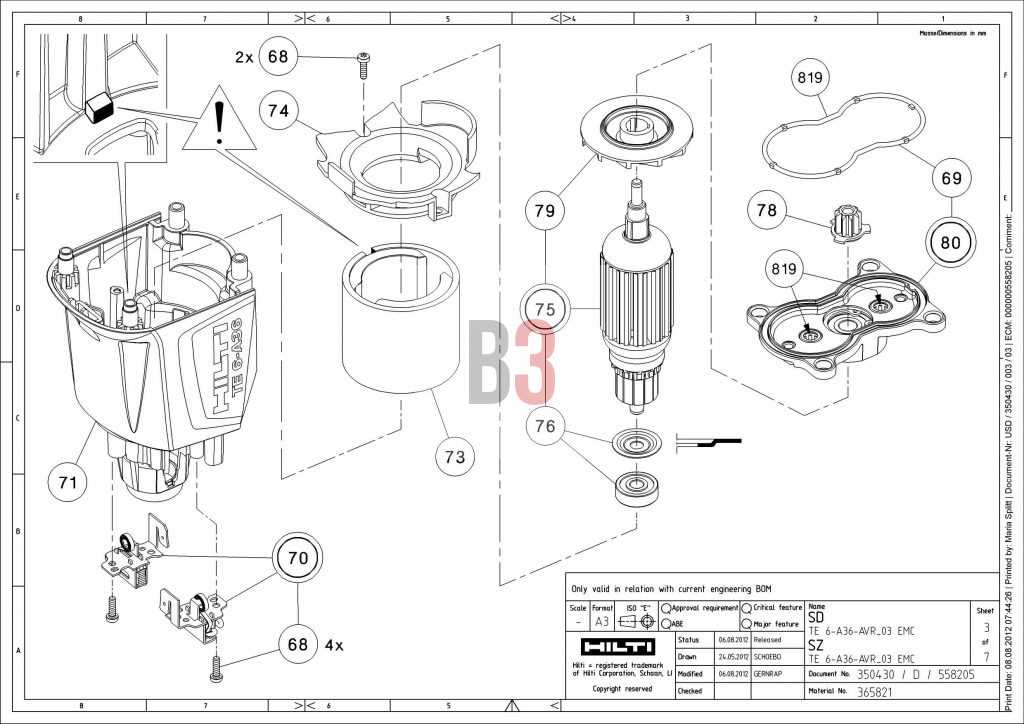

Motor Assembly

The motor assembly serves as the heart of the device, providing the necessary power to perform various tasks. This component is responsible for converting electrical energy into mechanical energy, enabling the tool to accomplish its intended functions. Regular checks and maintenance of the motor are vital for optimal performance.

Drilling Mechanism

The drilling mechanism is designed to create holes in various materials. This component often features adjustable settings to accommodate different drilling depths and speeds. Understanding how to adjust and use this mechanism effectively can significantly enhance the versatility of the tool.

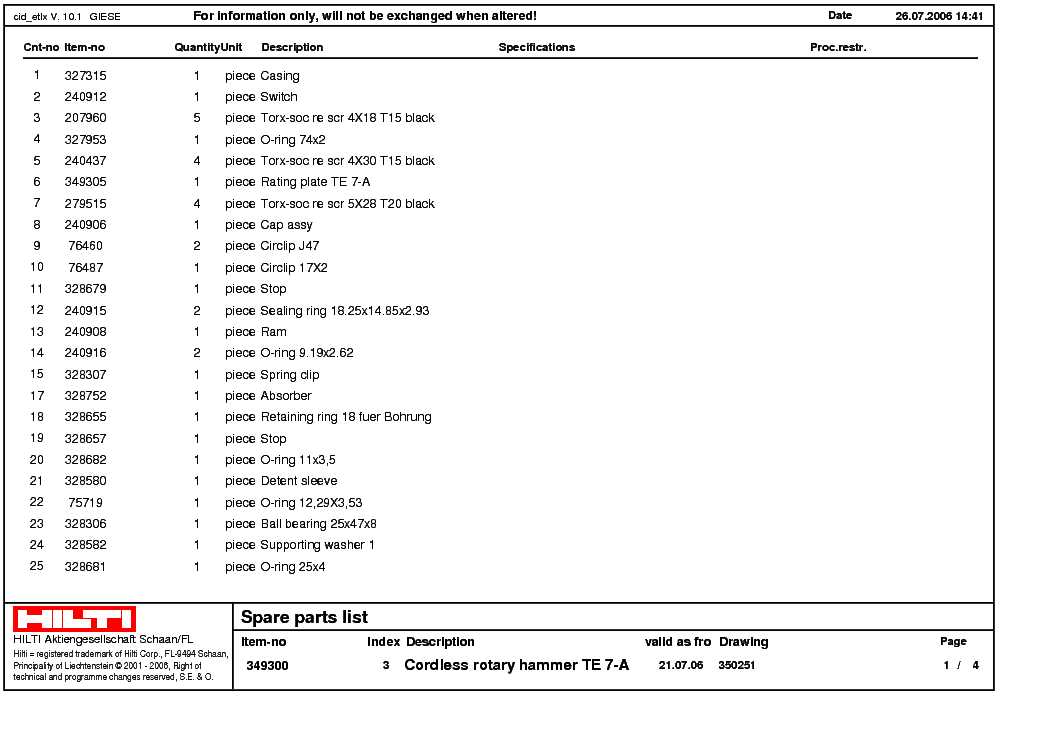

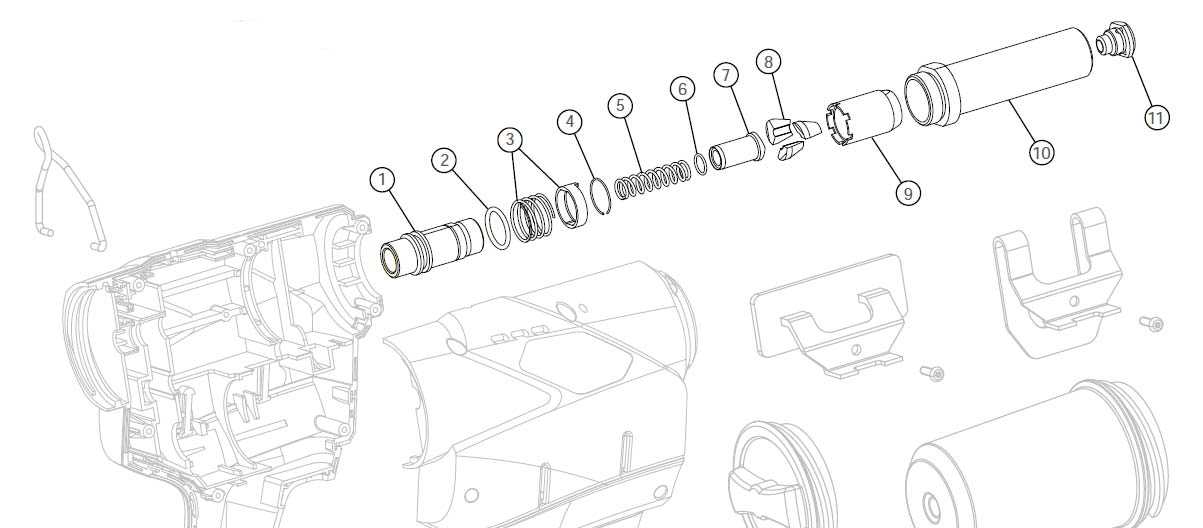

Understanding the Parts Diagram

The illustration of components plays a crucial role in comprehending the assembly and functionality of any equipment. By analyzing this visual representation, users can gain insights into how various elements interact and contribute to the overall performance of the tool.

It is essential to familiarize oneself with the different sections depicted in the illustration. Here are some key aspects to consider:

- Identification: Each segment is labeled to provide clarity on its specific function.

- Connection Points: Understanding how different parts link together helps in maintenance and repairs.

- Functionality: Recognizing the purpose of each element enhances operational efficiency.

In conclusion, a comprehensive understanding of the visual representation is vital for effective usage and care of the equipment. By studying the arrangement and relationships among components, users can improve their proficiency and troubleshooting skills.

Functionality of Each Component

This section provides an overview of the various elements that make up the tool, emphasizing their individual roles and how they contribute to overall performance. Understanding the functionality of these components is crucial for effective operation and maintenance.

The motor serves as the powerhouse of the equipment, driving the mechanisms necessary for operation. It transforms electrical energy into mechanical motion, enabling the tool to perform its intended tasks efficiently.

The gear system plays a vital role in regulating the speed and torque output. By adjusting the relationship between input and output, it allows for optimal performance across different applications.

The trigger acts as the control interface for the user. Engaging this component initiates the operation, providing a direct means to control the activation of the tool and ensuring precise handling during use.

The housing is essential for protecting internal components from dust and debris. It provides structural integrity while ensuring user safety by preventing accidental contact with moving parts.

The chuck is responsible for securing various attachments, ensuring that they remain firmly in place during operation. Its design facilitates quick and easy swapping of tools, enhancing versatility and efficiency.

The cooling system prevents overheating during prolonged use, maintaining optimal operating temperatures. This is crucial for sustaining performance and extending the lifespan of the tool.

By recognizing the significance of each element, users can better appreciate how these components work together to achieve efficient operation and effective results.

Maintenance Tips for Durability

Ensuring the longevity of your equipment requires consistent care and attention. By following simple maintenance practices, you can enhance performance and extend the lifespan of your tools. This section outlines essential guidelines that contribute to the overall durability of your machinery.

Regular Cleaning

Keeping your tools clean is vital for optimal functionality. Debris and dust can accumulate, leading to potential malfunctions. Make it a habit to wipe down the exterior surfaces and remove any residues after each use. Regularly inspect and clean the internal components as well, ensuring that no buildup interferes with operation.

Periodic Inspections

Conducting routine checks can help identify wear and tear before it becomes a significant issue. Look for signs of damage or wear on various parts and replace them promptly. This proactive approach can prevent unexpected breakdowns and costly repairs.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Cleaning | After each use | Use a soft cloth and appropriate cleaners. |

| Inspection | Monthly | Check for signs of wear and damage. |

| Lubrication | Every 3 months | Ensure moving parts are well-lubricated. |

| Calibration | Every 6 months | Verify precision and adjust settings as needed. |

Common Issues and Solutions

When operating power tools, users may encounter a variety of challenges that can affect performance and safety. Understanding these common problems and their remedies can help maintain efficiency and prolong the life of the equipment.

Frequent Problems

- Inconsistent power delivery

- Excessive vibration during operation

- Overheating of the device

- Difficulty in maintaining proper functionality

Effective Solutions

- Check the power source and connections to ensure stable energy flow.

- Inspect the tool for any loose components or wear that may cause vibrations.

- Allow the equipment to cool down during extended use to prevent overheating.

- Regularly clean and lubricate moving parts to ensure optimal performance.

By addressing these issues promptly, users can enhance the reliability and effectiveness of their tools, ensuring a safer working environment.

Comparing with Other Hilti Models

This section explores the distinctions and similarities between various models within the same brand, focusing on performance, design, and user experience. By analyzing different tools in the lineup, we can better understand how each one fits specific needs and preferences in the construction and engineering sectors.

Performance Evaluation

When evaluating the efficiency of different models, one can observe variations in power output and operational speed. Each tool is engineered to cater to specific tasks, making it crucial to select the right one based on the job requirements. This assessment highlights the strengths of each variant and guides users in making informed decisions.

Design Features

The ergonomic design and weight distribution play significant roles in user comfort and productivity. Comparing these aspects reveals how different versions have been tailored to enhance usability, which can ultimately influence the choice of equipment. The advanced technology incorporated into each model also contributes to its effectiveness in diverse environments.

Installation Guidelines for Components

Proper assembly and fitting of components are essential for achieving optimal performance and safety. This section provides a comprehensive overview of best practices to follow during the installation process, ensuring that all elements work together seamlessly.

Preparation Before Installation

Before beginning the assembly, it is crucial to prepare the workspace and gather all necessary tools. Verify that all components are available and undamaged. Familiarize yourself with the specifications and ensure that the area is clean and organized to facilitate an efficient installation.

Step-by-Step Assembly Process

Follow a systematic approach during the installation. Begin with the primary elements, ensuring they are securely fastened. Gradually add secondary components, double-checking each connection as you progress. Regularly consult the installation guidelines to ensure adherence to recommended procedures and maintain the integrity of the overall assembly.

Safety Precautions While Using

When operating power tools, it is essential to adhere to safety measures to prevent accidents and ensure a secure working environment. Proper precautions not only protect the user but also extend the life of the equipment and enhance overall efficiency.

Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and hearing protection. These items shield against potential hazards such as flying debris and excessive noise, which can cause injury over time.

Additionally, familiarize yourself with the equipment’s manual before usage. Understanding the tool’s features and recommended practices significantly reduces the risk of misuse and enhances safety. Always inspect the tool for any damage or wear before each use, as this can help identify issues that may lead to malfunctions.

Maintain a clean and organized workspace to minimize risks. Ensure that the area is free from obstacles and hazards that could cause slips or falls. Proper lighting is also crucial, as it allows for better visibility and awareness of surroundings.

Lastly, never bypass safety features or operate equipment while fatigued or under the influence of substances. Such actions can impair judgment and reaction times, leading to potentially dangerous situations. Prioritize safety to ensure a productive and secure working experience.

Accessories to Enhance Performance

To maximize the efficiency and functionality of power tools, utilizing the right accessories is essential. These supplementary components can significantly improve productivity, enabling users to complete tasks with greater ease and precision. Investing in quality enhancements not only extends the capabilities of the tool but also ensures a smoother workflow.

Types of Enhancements

Various enhancements are available that cater to different needs. These include specialized attachments designed for specific applications, durable cases for protection, and advanced bits that offer superior cutting or drilling performance. Selecting the appropriate accessories can transform a standard tool into a versatile asset.

Benefits of Quality Accessories

Utilizing high-quality enhancements provides numerous advantages. They often lead to improved accuracy, reduced wear and tear on the primary tool, and enhanced user comfort. Additionally, well-designed accessories can save time and effort, resulting in a more efficient working experience.

How to Identify Genuine Parts

Ensuring the authenticity of components is crucial for optimal performance and longevity of your equipment. This section outlines key factors to consider when verifying the legitimacy of your components, enabling you to make informed decisions.

Check for Manufacturer’s Markings

One of the simplest ways to ascertain authenticity is by examining the markings on the component. Genuine items typically feature specific logos or serial numbers that can be verified through the manufacturer’s database. Look for consistent font styles, spacing, and placement of these markings.

Evaluate Quality and Craftsmanship

Authentic items often showcase superior quality in materials and construction. Pay attention to details such as weight, finish, and overall feel. Counterfeit components may exhibit signs of poor craftsmanship, including uneven surfaces, rough edges, or inferior materials. A thorough inspection can reveal discrepancies that signal a lack of authenticity.

Customer Reviews and Feedback

This section presents insights and evaluations from users regarding their experiences with the tool. Feedback is essential for understanding its effectiveness and reliability in various applications. User opinions help potential buyers make informed decisions based on real-world usage and satisfaction levels.

Positive Experiences

- Many users praise its durability and robust construction, making it suitable for demanding tasks.

- The versatility of the tool is often highlighted, allowing it to perform various functions efficiently.

- Customers appreciate the ergonomic design, which enhances comfort during prolonged use.

Areas for Improvement

- Some feedback indicates that the weight may be a concern for users who require portability.

- A few users mention a learning curve associated with its advanced features.

- Occasional comments point out the need for more detailed instructions for first-time users.

Where to Buy Replacement Parts

When it comes to maintaining your equipment, finding reliable sources for acquiring necessary components is essential. Whether you need to replace worn-out items or upgrade to newer models, knowing where to shop can significantly streamline the process.

Authorized Retailers

Authorized distributors are often the most trustworthy options for obtaining components. They provide genuine products and can offer expert advice. Here are some benefits of purchasing from these suppliers:

- Quality assurance of the products.

- Access to warranty services.

- Professional assistance in selecting the right items.

Online Marketplaces

For convenience, many individuals turn to online platforms. These websites typically offer a wide range of options, often at competitive prices. Consider the following tips when shopping online:

- Check the seller’s reputation and reviews.

- Verify return policies before making a purchase.

- Compare prices across different sites to find the best deal.