Understanding the Stihl MS 310 Chainsaw Parts Diagram

For enthusiasts and professionals alike, maintaining and understanding the intricacies of a powerful cutting instrument is essential for optimal performance. A comprehensive examination of its components can enhance longevity and efficiency, ensuring you get the most out of your investment. This guide aims to unravel the complexities involved in the assembly and functionality of such equipment.

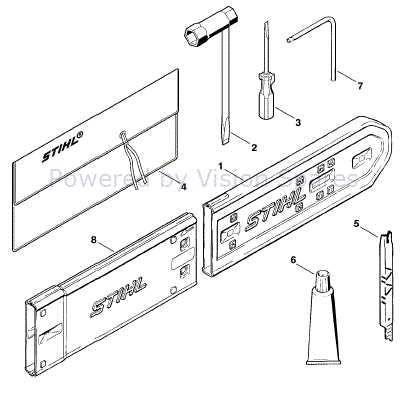

Detailed illustrations serve as valuable resources, offering clarity on the arrangement and interaction of various elements. By exploring these visual aids, users can identify specific parts, understand their roles, and facilitate easier troubleshooting. This approach not only empowers operators but also promotes safer practices when handling and servicing their tools.

Whether you are a seasoned operator or a novice, having access to a well-structured reference can significantly simplify the maintenance process. By familiarizing yourself with the layout and relationships among different components, you can ensure that your tool remains in peak condition, ready to tackle any task at hand.

Understanding the Stihl MS 310 Design

The design of this power tool exemplifies a harmonious blend of functionality and ergonomics, aiming to provide users with optimal performance and comfort during operation. By carefully considering each component, the engineers have created a reliable and efficient machine suitable for a variety of tasks.

Power and Efficiency: The engine design plays a crucial role in delivering impressive power while maintaining fuel efficiency. The configuration allows for rapid acceleration, enabling users to tackle demanding jobs without excessive strain on the motor.

Durability and Materials: Constructed from high-quality materials, this tool is built to withstand harsh conditions. The choice of components ensures longevity, allowing it to endure the rigors of frequent use in challenging environments.

User-Friendly Features: Attention to detail in the layout of controls enhances the user experience. Features such as an accessible start mechanism and well-positioned handles contribute to a seamless operation, reducing fatigue and increasing productivity.

In summary, the thoughtful engineering behind this tool not only maximizes performance but also prioritizes user comfort and durability, making it an invaluable asset for both professionals and enthusiasts.

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the functionality and efficiency of the equipment. This section explores the primary parts that contribute to the overall performance, highlighting their functions and interrelations.

| Component | Function |

|---|---|

| Engine | Powers the unit, providing the necessary energy for cutting. |

| Guide Bar | Directs the chain and supports the cutting process. |

| Chain | Equipped with sharp teeth to effectively slice through wood. |

| Fuel System | Supplies the engine with the necessary fuel mixture for operation. |

| Oiling Mechanism | Ensures proper lubrication of the chain and bar, reducing friction. |

| Handle | Provides a grip for the operator, ensuring control and safety during use. |

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repairs. These visual guides offer a detailed look at components, helping users identify parts and comprehend their functions within a machine. By mastering the art of interpreting these illustrations, you can streamline your repair processes and ensure optimal performance.

Key Elements of Assembly Illustrations

- Labels: Each component is typically labeled with a number or code, linking it to a reference list.

- Sections: Diagrams are often divided into sections, highlighting specific assemblies or areas of focus.

- Orientation: Pay attention to the orientation of parts, as it can affect assembly and functionality.

- Legend: A legend may explain symbols and markings used throughout the illustration.

Steps to Interpret the Visual Guide

- Start by identifying the main assembly you are working on.

- Locate the reference numbers corresponding to the parts you need.

- Check the legend for any unfamiliar symbols or abbreviations.

- Follow the layout to understand how components fit together.

- Use the information to gather the necessary items for repairs or replacements.

Common Issues with MS 310 Parts

When dealing with machinery, certain components often present challenges that can hinder performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and prolonging the lifespan of the equipment. From wear and tear to compatibility issues, a variety of factors can contribute to malfunctions.

Wear and Tear

Over time, certain elements may experience significant degradation due to prolonged usage. This can manifest as decreased power, difficulty in operation, or even complete failure of specific components. Regular inspection and timely replacement are crucial to prevent extensive damage and ensure smooth operation.

Compatibility and Installation Issues

Incorrect installation or using incompatible components can lead to a range of problems, including improper function and increased risk of breakdown. It’s vital to verify that all elements are suited for the specific model, as deviations can compromise performance and safety.

Replacement Parts for Optimal Performance

Ensuring the highest efficiency of your cutting tool involves the timely replacement of worn or damaged components. Quality replacements play a crucial role in maintaining functionality and extending the lifespan of your equipment. Understanding which elements need attention can enhance your overall experience and effectiveness in various tasks.

When considering replacements, focus on the following critical components:

- Bar and Chain: Essential for cutting performance; regular inspection is key.

- Air Filter: Keeps the engine clean; replace it to maintain optimal airflow.

- Spark Plug: Vital for ignition; a worn plug can lead to starting issues.

- Fuel Filter: Ensures clean fuel supply; replace it periodically to avoid engine problems.

- Oiler System: Keeps the chain lubricated; check for blockages or leaks.

Using high-quality replacements will not only enhance performance but also contribute to safety during operation. Investing in reliable components can prevent costly repairs and improve the longevity of your equipment.

For best results, refer to manufacturer recommendations when selecting new components, ensuring compatibility and performance standards are met. Regular maintenance and timely replacements can make a significant difference in the effectiveness of your tools.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your cutting tool requires regular attention and care. By implementing a few essential practices, you can significantly extend the lifespan of your equipment while enhancing its performance.

Regular Cleaning: After each use, it’s vital to clean the machine thoroughly. Remove any debris, sawdust, or residues that may accumulate in various components. This prevents clogging and reduces wear, contributing to smoother operation.

Proper Lubrication: Consistent lubrication of moving parts is crucial. Use high-quality oil designed for your specific model to ensure optimal functionality. This not only minimizes friction but also protects against rust and corrosion.

Routine Inspections: Periodically check for wear and tear. Look for any signs of damage, such as cracks or loose components. Early detection of issues can prevent more significant problems down the line, saving time and money.

Sharpening Blades: Keeping the cutting edges sharp is essential for efficiency. Dull blades require more power and can strain the motor. Regularly sharpen or replace blades as needed to maintain optimal cutting performance.

Fuel Quality: Always use high-quality fuel mixed at the correct ratio. Poor-quality fuel can lead to engine problems and decreased performance. Additionally, consider using fuel stabilizers if you store the equipment for extended periods.

Storage Conditions: Proper storage is critical for longevity. Keep the tool in a dry, temperature-controlled environment, and use protective covers to shield it from dust and moisture.

By following these straightforward maintenance tips, you can ensure that your equipment remains reliable and effective for years to come.

Identifying Genuine Stihl Components

Ensuring the authenticity of components is crucial for optimal performance and safety. Recognizing genuine items can significantly impact the longevity and reliability of your equipment. With numerous alternatives on the market, distinguishing between authentic and counterfeit products requires careful attention to detail.

Key Features of Authentic Items

Original components typically showcase superior craftsmanship. Look for precise fit and finish, as well as quality materials that enhance durability. Additionally, legitimate items often come with clear markings or serial numbers that indicate their authenticity. Verify these details against official sources to ensure you’re purchasing genuine products.

Where to Purchase Genuine Components

Acquiring authentic items is essential for maintaining the integrity of your equipment. Always source your purchases from authorized dealers or reputable retailers. Online marketplaces can pose risks, so exercise caution and confirm the seller’s credibility. Investing in genuine components not only enhances performance but also provides peace of mind during operation.

Repair Techniques for Common Failures

Maintaining and troubleshooting power tools can significantly extend their lifespan and enhance performance. Understanding typical issues that may arise allows users to implement effective repair techniques. This section provides a guide to address frequent malfunctions, ensuring that you can quickly return to work without unnecessary delays.

Identifying Common Issues

- Engine won’t start

- Overheating

- Excessive vibration

- Fuel leakage

Recognizing the symptoms of these problems is the first step toward resolution. Each issue often has specific causes, which can usually be diagnosed through careful inspection.

Repair Techniques

- Engine Won’t Start:

- Check fuel levels and quality.

- Inspect the spark plug for wear or damage.

- Ensure the air filter is clean.

- Overheating:

- Verify that the cooling fins are free of debris.

- Examine the oil levels and change if necessary.

- Ensure proper airflow around the engine.

- Excessive Vibration:

- Inspect the cutting attachment for damage.

- Check for loose screws or bolts.

- Ensure that the tool is properly balanced.

- Fuel Leakage:

- Examine all fuel lines for cracks or breaks.

- Check the fuel tank for leaks.

- Replace any damaged gaskets or seals.

By following these techniques, you can effectively address common problems and maintain the functionality of your equipment. Regular inspections and preventative measures are key to avoiding larger repairs in the future.

Tools Needed for Disassembly

To successfully dismantle your equipment, it’s essential to have the right set of instruments at your disposal. Proper tools not only facilitate the process but also ensure that components remain intact and can be reassembled without issues. Below is a list of necessary implements that will aid you in this task.

1. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are crucial for removing screws that hold parts together. Ensure you have the appropriate sizes to prevent stripping.

2. Wrenches: A set of wrenches is needed for loosening nuts and bolts. Both adjustable and fixed options are beneficial, as they can accommodate different sizes.

3. Pliers: Needle-nose pliers can assist in grasping and pulling small components, while standard pliers are useful for gripping larger parts. They are essential for precision tasks.

4. Socket Set: A socket set will provide the versatility needed for various fastening applications. Select a ratchet and sockets that match the sizes of your hardware.

5. Safety Gear: Don’t forget to wear safety goggles and gloves to protect yourself during the disassembly process. Safety should always be a priority.

Equipped with these tools, you will be well-prepared to undertake the disassembly of your machinery effectively and efficiently.

Where to Buy MS 310 Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. Whether you need replacements for worn-out items or upgrades to improve efficiency, knowing where to source these essentials is crucial. Below are some reliable options to consider when searching for the necessary materials.

Online Retailers

Shopping online offers convenience and often a wider selection. Here are some popular online platforms:

- Amazon: Known for a vast inventory and user reviews.

- eBay: Great for both new and used components, often at competitive prices.

- Specialized Websites: Various retailers focus on equipment supplies, providing a range of specific items.

Local Stores

Visiting a physical store can provide immediate access to what you need. Consider these options:

- Home Improvement Stores: Large chains typically carry a selection of tools and accessories.

- Authorized Dealers: Specific retailers may offer brand-specific components and expert advice.

- Small Hardware Stores: Local shops often stock basic items and can order specific ones for you.