Comprehensive Guide to Stihl FS 56 RC Parts Diagram

Maintaining your gardening equipment is essential for ensuring its longevity and optimal performance. Knowing the different elements that make up your trimming device can significantly enhance your ability to troubleshoot and repair any issues that may arise. This section delves into the intricate details of these components, providing a comprehensive overview that will serve as a valuable resource for users.

Each element within your tool plays a crucial role in its overall functionality. From the cutting mechanisms to the power delivery systems, understanding how these parts interact can empower you to carry out effective maintenance and repairs. Familiarity with these components not only facilitates better care but also enhances your confidence in handling your equipment.

In the following sections, we will explore the various segments of your trimming apparatus, highlighting their functions and importance. This knowledge will enable you to make informed decisions regarding replacements and repairs, ultimately extending the life of your device and improving your gardening experience.

Understanding the Stihl FS 56 RC

This section aims to explore the intricacies of a popular grass trimmer model, emphasizing its functionality and components. By examining its features, users can gain a clearer perspective on how to optimize its performance and maintenance.

Key features include:

- Powerful engine for efficient cutting

- Lightweight design for easy maneuverability

- Ergonomic handle for comfort during extended use

To ensure longevity and effectiveness, regular maintenance is crucial. Important maintenance tasks involve:

- Cleaning the air filter regularly

- Checking and replacing the cutting line as needed

- Inspecting the fuel system for leaks

By delving into these aspects, users can maximize their experience and enhance the life of their equipment.

Importance of Parts Diagrams

Understanding the layout and components of any machinery is crucial for effective maintenance and repairs. Visual representations not only simplify the identification of elements but also enhance the overall efficiency of service tasks. When users are familiar with how parts fit together, they can troubleshoot issues more effectively and make informed decisions during repairs.

Enhancing Maintenance Efficiency

Utilizing visual aids streamlines the process of upkeep. Users can quickly locate the required components, which saves time and reduces frustration. This clarity is essential for both novice and experienced technicians, ensuring that tasks are completed swiftly and accurately.

Facilitating Accurate Repairs

Clear illustrations foster a deeper understanding of how each component interacts within the system. This knowledge is vital for diagnosing problems and implementing precise solutions, ultimately extending the lifespan of the equipment. By delving into these visuals, users gain confidence in their repair abilities.

Common Issues with FS 56 RC

The FS 56 RC model, like any outdoor power tool, can encounter various challenges that may affect its performance. Understanding these issues can help users troubleshoot effectively and maintain optimal functionality. Regular maintenance and awareness of potential problems are key to ensuring longevity and efficiency.

One common concern is fuel-related problems. Stale or contaminated fuel can lead to starting difficulties and poor engine performance. It is essential to use fresh, high-quality fuel and to check the fuel lines for any signs of wear or blockage.

Another frequent issue is related to the cutting mechanism. Dull or damaged blades can result in inefficient cutting and may strain the engine. Regularly inspecting and replacing the blades when necessary will enhance cutting performance and reduce wear on the engine.

Additionally, users may experience difficulties with the ignition system. Issues such as a faulty spark plug can prevent the engine from starting or cause erratic performance. Regular inspection and replacement of the spark plug can help maintain consistent operation.

Finally, overheating can be a significant problem, often caused by prolonged use or insufficient airflow. Ensuring that the ventilation areas are clear and taking breaks during operation can help mitigate this risk.

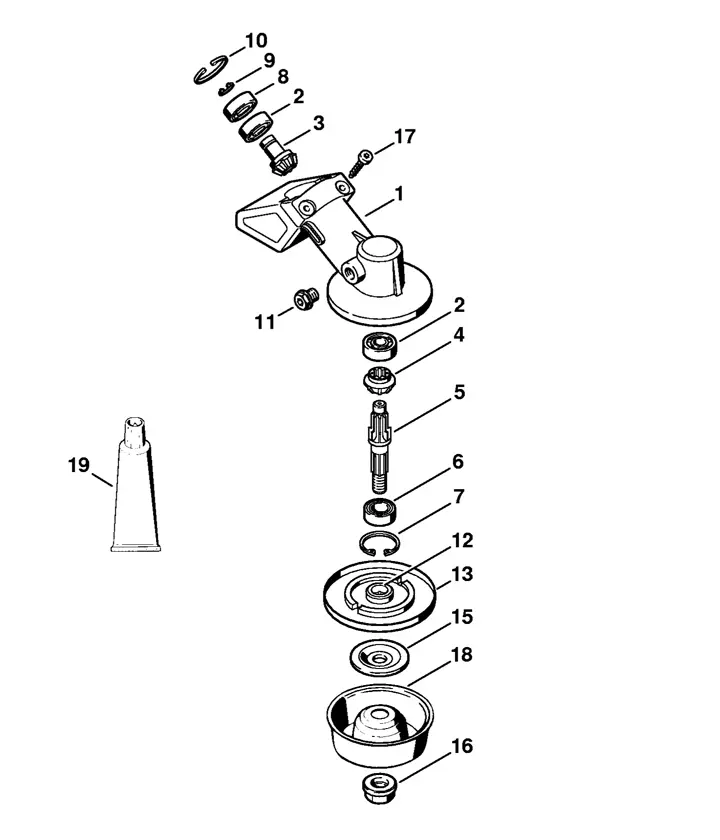

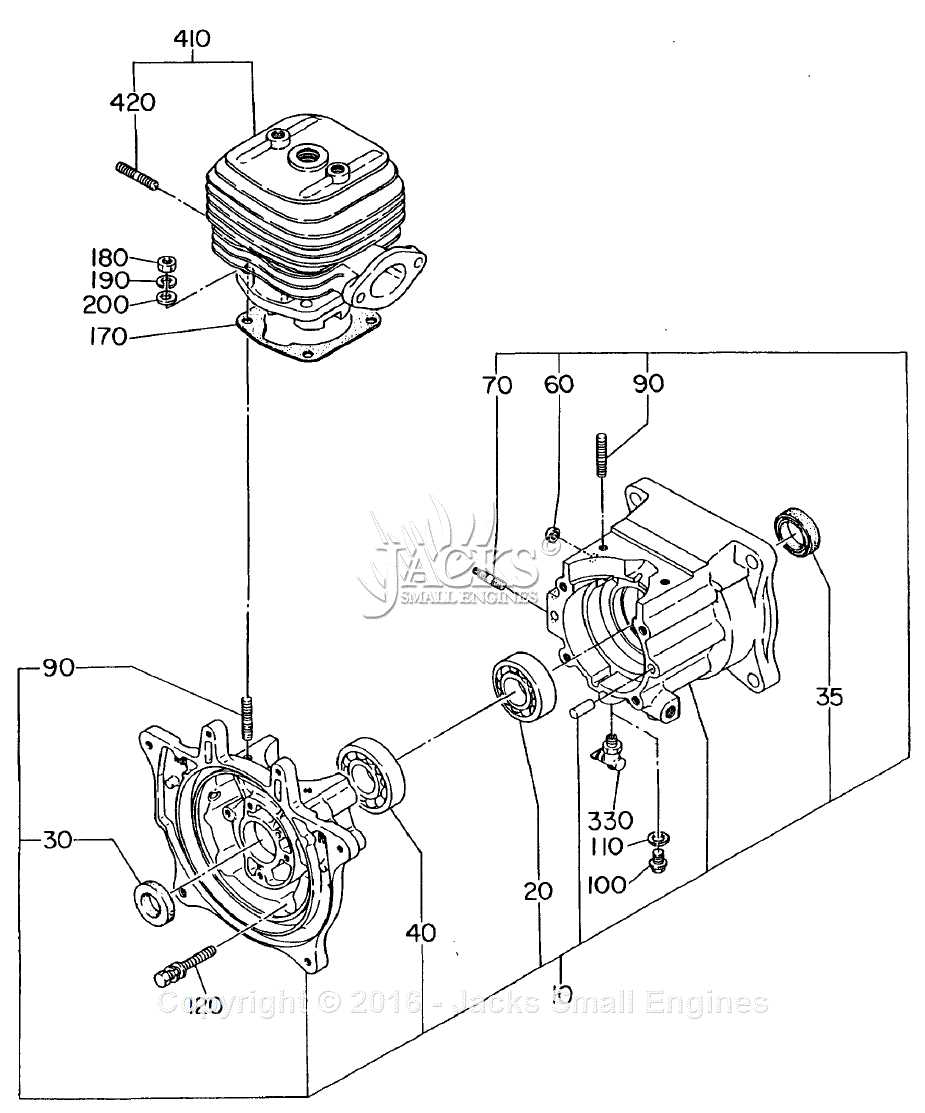

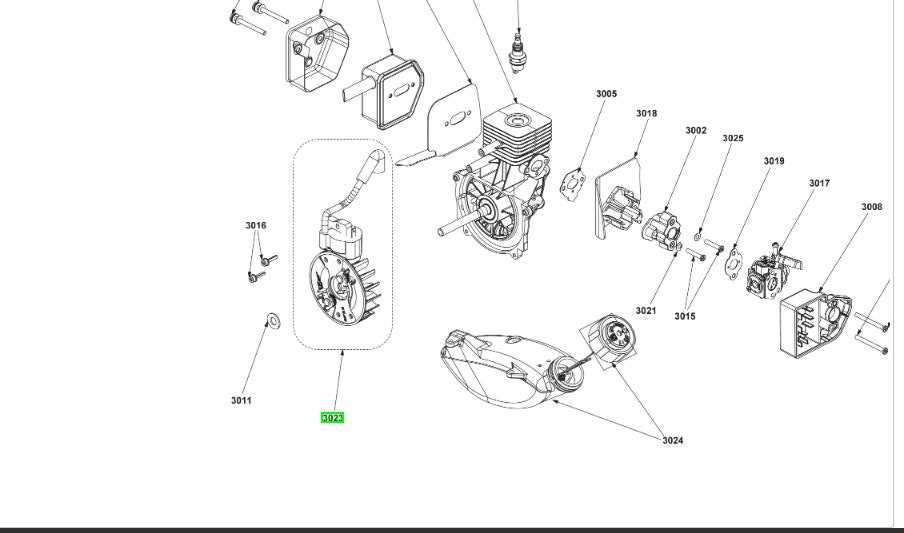

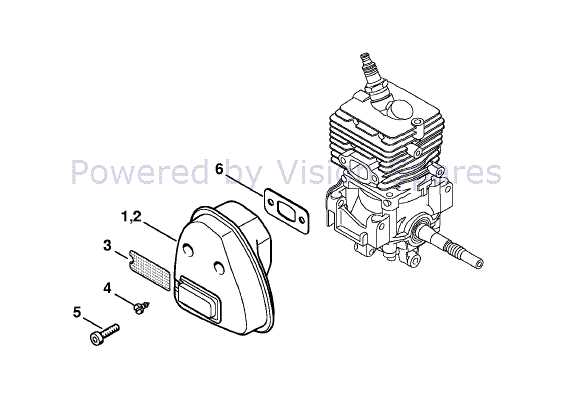

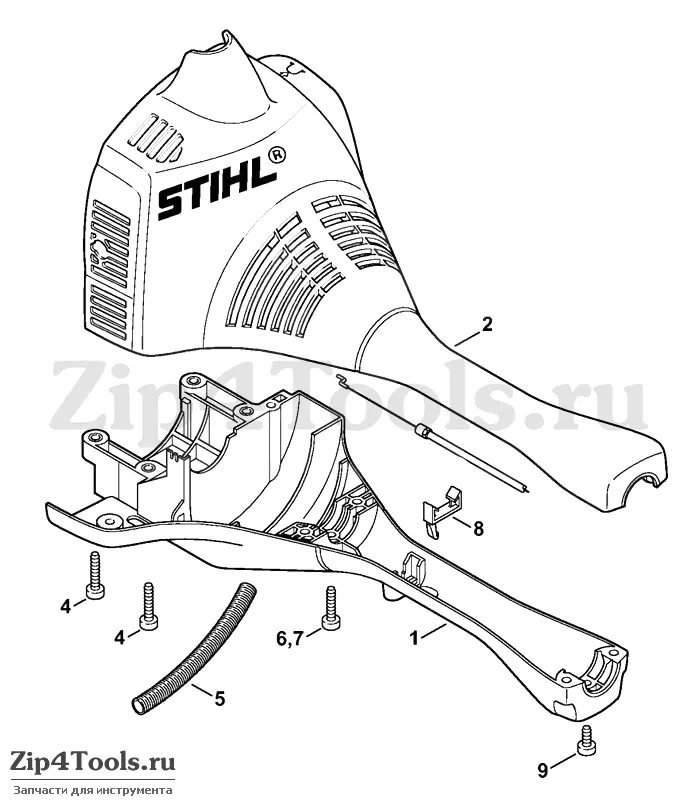

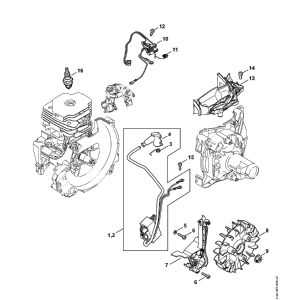

Identifying Key Components

Understanding the essential elements of a tool is crucial for effective operation and maintenance. By recognizing each significant part, users can enhance their familiarity and ensure optimal performance over time.

Major Elements Overview

This section highlights the primary components that contribute to the functionality of the equipment. A grasp of these parts will aid in troubleshooting and general upkeep.

| Component | Description |

|---|---|

| Engine | Drives the device, providing power for operation. |

| Cutting Head | Utilizes a line or blade to perform cutting tasks. |

| Handle | Facilitates control and maneuverability during use. |

| Throttle | Regulates engine speed and cutting power. |

Importance of Each Component

Each element plays a pivotal role in the overall functionality, making it essential to recognize their significance. Familiarity with these parts not only aids in effective usage but also promotes longevity of the device.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. By following a few essential practices, you can enhance its functionality and prevent potential issues. This proactive approach not only maximizes performance but also extends the life of your device.

Regular Cleaning

Frequent cleaning is crucial to remove debris and dirt that can hinder operation. After each use, inspect and wipe down surfaces, focusing on air filters and cutting elements. Keeping these areas clear allows for better airflow and optimal cutting efficiency.

Routine Inspections

Conducting regular checks on all components helps identify wear and tear early. Look for signs of damage or looseness, particularly in moving parts. Replacing worn items promptly prevents further complications and ensures smooth performance.

Where to Find Replacement Parts

Finding suitable components for your equipment can be essential for maintaining its performance and longevity. Whether you’re a professional or a hobbyist, knowing where to source quality replacements is key.

Online Resources

- Official Manufacturer Websites

- Online Retailers (e.g., Amazon, eBay)

- Specialized Tool Shops

Local Options

- Authorized Dealers

- Hardware Stores

- Repair Shops

Exploring these avenues can help you delve into a wide selection of options, ensuring you find the ultimate replacements for your needs.

Assembly and Disassembly Instructions

This section provides essential guidance for the efficient assembly and disassembly of your equipment, ensuring that all components are correctly fitted and secured. Following these steps will help maintain optimal performance and longevity of your device.

Tools Required

Before beginning, gather the necessary tools to facilitate the process. This will ensure a smooth experience and prevent any damage to the components.

| Tool | Purpose |

|---|---|

| Screwdriver | To tighten and loosen screws |

| Wrench | For securing nuts and bolts |

| Pliers | To grip and manipulate parts |

Step-by-Step Guide

Start by carefully removing any covers to access the internal components. Proceed by detaching each part in reverse order of assembly. For reassembly, ensure that all components fit snugly and follow the manufacturer’s specifications to guarantee proper functionality.

Comparison with Other Stihl Models

In examining various models within the same product line, it becomes evident that differences in performance, design, and functionality can greatly influence user experience. This section highlights how a specific model stands against its counterparts, providing insights into what makes each option unique.

Performance Overview

When evaluating efficiency, power output, and ease of use, different models can cater to varying needs. Some are designed for heavy-duty tasks, while others are tailored for light, residential use. The comparison below illustrates key specifications that differentiate them:

| Model | Engine Power (cc) | Weight (lbs) | Cutting Width (inches) |

|---|---|---|---|

| Model A | 25.4 | 10.5 | 16 |

| Model B | 30.0 | 11.2 | 18 |

| Model C | 27.2 | 10.8 | 17 |

User Experience and Features

The user interface and additional features can significantly impact usability. For instance, some models come equipped with advanced vibration reduction systems, enhancing comfort during prolonged use. Others may include ergonomic handles or easy-start mechanisms that facilitate operation. Understanding these distinctions allows users to choose a model that best fits their preferences and working conditions.

Safety Precautions for Use

Ensuring safety while operating equipment is crucial for both the user and those nearby. Adhering to recommended guidelines minimizes risks and enhances overall efficiency.

- Always wear appropriate personal protective gear, including gloves, goggles, and sturdy footwear.

- Inspect the equipment before use, checking for any signs of wear or damage.

- Maintain a safe distance from bystanders and pets during operation.

Follow these additional precautions to ensure a secure experience:

- Read the operating instructions thoroughly before starting.

- Use the device only in suitable weather conditions to avoid accidents.

- Ensure the working area is clear of obstacles and hazards.

By implementing these practices, users can create a safer environment and achieve optimal performance.

Enhancing Durability with Upgrades

Upgrading components can significantly improve the longevity and performance of outdoor equipment. By incorporating high-quality enhancements, users can ensure their machines withstand rigorous tasks and harsh conditions, leading to better reliability over time.

| Upgrade Type | Benefit |

|---|---|

| Heavy-Duty Trimmer Line | Increased resistance to wear and breakage |

| Reinforced Cutting Head | Improved durability under intense usage |

| High-Quality Fuel Filter | Enhanced engine protection and efficiency |

| Advanced Anti-Vibration System | Reduced operator fatigue and improved control |