John Deere 300 Garden Tractor Parts Diagram Overview

In the realm of outdoor machinery, comprehending the essential elements and their configurations is vital for maintenance and repair. An effective grasp of how each component interacts can greatly enhance the performance and longevity of your equipment. This knowledge not only aids in troubleshooting but also empowers operators to undertake repairs with confidence.

Every machine consists of a complex assembly of parts, each playing a critical role in its operation. Recognizing these elements and their specific placements allows users to identify potential issues quickly and ensure optimal functionality. With a clear representation of these components, individuals can navigate the intricacies of machinery more efficiently.

This exploration provides valuable insights into the structure and arrangement of the various elements, equipping users with the tools they need for effective upkeep. By delving into the configuration, one can foster a deeper understanding of the mechanics at play, ultimately leading to a more proficient and rewarding experience with their equipment.

Understanding John Deere 300 Models

This section delves into the various iterations of a well-known line of small machinery designed for landscaping and maintenance tasks. Each model has its unique features and capabilities, making them suitable for a range of applications, from simple yard upkeep to more complex gardening projects. By exploring these specific designs, users can gain insight into their operational strengths and how to maximize efficiency.

Key Features of the Series

The lineup is characterized by robust engines and versatile attachments, allowing for a seamless transition between tasks. Users appreciate the ease of operation and the adaptability of these machines, which can handle everything from mowing to snow removal. Understanding the engineering behind these models enables owners to select the right equipment for their needs.

Maintenance Considerations

Key Features of John Deere Tractors

Modern agricultural and utility machines are designed with durability and efficiency in mind, offering a wide range of capabilities to suit various tasks. These machines stand out for their robust performance, ease of use, and long-lasting build quality, making them reliable for both residential and commercial applications.

| Feature | Description |

|---|---|

| Powerful Engines | Equipped with high-performance engines, these machines deliver strong power output for demanding tasks, ensuring efficient operation in any condition. |

| Advanced Transmission | Featuring a smooth and efficient transmission system, they allow for seamless gear transitions, providing better control and comfort during work. |

| Ergonomic Design | The well-designed operator’s seat and control layout ensure maximum comfort and ease of use, reducing fatigue during extended periods of operation. |

| Versatile Attachments | These machines support a variety of attachments, increasing their flexibility for different tasks, from landscaping to heavy-duty operations. |

| Durability | Constructed with high-quality materials, they are built to withstand harsh conditions, ensuring longevity and reduced maintenance needs. |

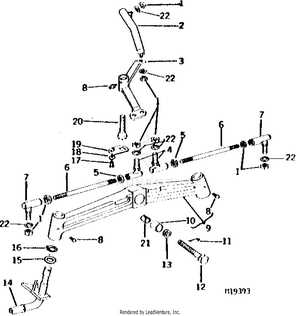

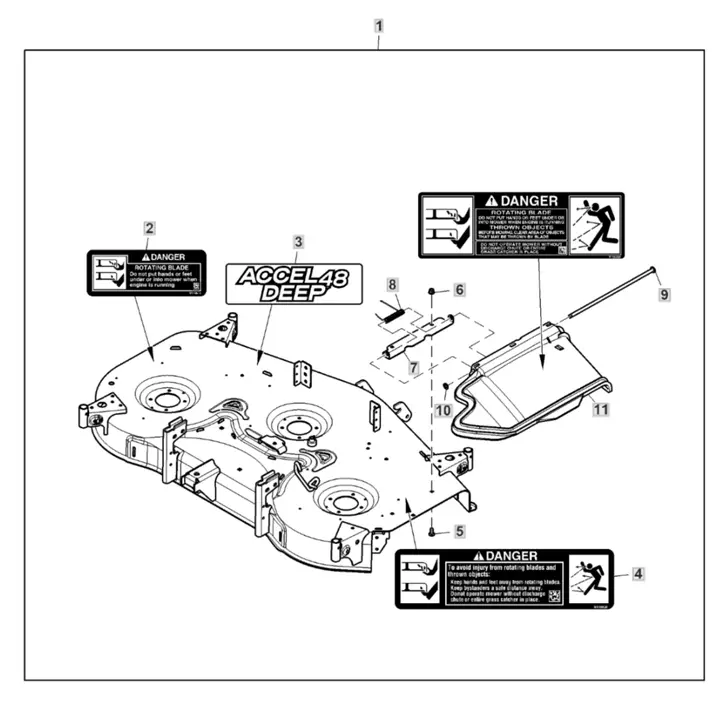

Importance of Parts Diagrams

Understanding the layout of individual components in a mechanical system is crucial for proper maintenance and repairs. A visual guide provides clarity on how different elements fit together, allowing users to quickly identify and address issues. Without such reference, even minor repairs can become complex and time-consuming.

Using detailed illustrations ensures that every connection is visible, helping avoid mistakes during assembly or disassembly. These guides also offer valuable insights into potential wear points, making preventative care more manageable. Whether for routine maintenance or significant repairs, having an accurate reference is indispensable.

In addition, a well-organized reference document enhances the efficiency of both professional technicians and DIY enthusiasts. By providing an easy-to-follow visual aid, these resources contribute to smoother operations and reduce the likelihood of errors during repairs.

Common Issues with Garden Tractors

Outdoor machines used for managing and maintaining larger areas often encounter various operational challenges over time. These problems can arise from regular use, wear and tear, or environmental factors, affecting both performance and reliability. Understanding these common concerns can help users maintain their equipment more effectively.

Engine-Related Problems

One of the frequent issues involves the engine not starting or running poorly. This can be due to several factors, such as a dirty air filter, fuel contamination, or spark plug issues. Routine inspection of these components can prevent significant downtime and ensure smooth operation.

- Clogged air filters causing poor airflow

- Fuel quality affecting combustion efficiency

- Spark plug fouling reducing ignition effectiveness

Transmission and Steering Issues

Another set of common problems relates to the transmission and steering systems. Poor response in these areas can lead to difficulty in maneuvering and can severely impact functionality. Addressing these issues promptly can extend the machine’s operational life.

- Transmission fluid leaks reducing performance

- Worn steering components causing instability

- Belts and pulleys becoming misaligned or

Where to Find Replacement Parts

When the need arises to repair or upgrade your equipment, sourcing the right components becomes essential. Identifying reliable sources ensures the longevity and efficiency of your machine. Whether you’re addressing a minor issue or seeking to maintain performance, knowing where to find suitable replacements is key to keeping everything running smoothly.

Online Retailers and Specialized Stores

A variety of online platforms offer a wide range of components for various machines, including older models. These retailers often provide detailed listings, allowing you to select exactly what you need. Additionally, specialized stores with experience in mechanical parts can offer valuable advice and guidance when selecting the correct item.

Local Dealers and Salvage Yards

For those who prefer in-person purchases, local dealers are a great option. They often stock commonly needed components and have access to catalogs for ordering more specific items. Alternatively, salvage yards can be a cost-effective option for sourcing older or hard-to-find components, often offering significant savings compared to new parts.

Benefits of Using Original Parts

When maintaining and repairing mechanical equipment, the choice of components plays a critical role in ensuring optimal performance. Utilizing authentic, factory-made components offers numerous advantages, making them a reliable option for long-term functionality and safety. Choosing these high-quality elements can significantly extend the lifespan of your machinery.

Enhanced Durability and Performance

Original components are engineered specifically for your machine, ensuring a perfect fit and seamless integration. This precision contributes to improved efficiency and reduced wear, leading to fewer breakdowns and better overall performance. Additionally, genuine parts undergo rigorous testing to meet industry standards, ensuring durability and reliability under various conditions.

Long-Term Cost Savings

While authentic components may initially seem more expensive, they help prevent frequent repairs and replacements. This leads to lower maintenance costs over time and contributes to smoother, uninterrupted operation. Investing in genuine parts can save significant expenses in the long run, reducing the need for future costly repairs.

Benefit Description Quality Assurance Tested and certified for optimal performance and reliability. Precise Fit Designed to fit perfectly without modification or adjustment. Warranty Protection Often covered under warranty, adding extra security for your investment. Step-by-Step Repair Guide

This section provides detailed instructions on how to troubleshoot and fix common mechanical issues. Whether you are dealing with minor adjustments or more complex tasks, following these steps will help you maintain the equipment in good working order. The process ensures that each component is checked and repaired effectively, reducing the chance of future breakdowns.

Start by gathering the necessary tools and identifying the issue. Each step should be performed carefully to avoid any additional damage. Here’s a table outlining the key areas to inspect during the repair process:

Component Common Issues Suggested Fixes Engine Difficulty starting, unusual noises Check fuel lines, clean carburetor, inspect spark plugs Transmission Poor shifting, slipping gears Inspect fluid levels, tighten belts, replace worn-out parts Electrical System Non-responsive controls, battery issues Test wiring, charge battery, replace fuses Blades Uneven cuts, vibration during operation Sharpen or replace blades, check blade alignment Tools Needed for Maintenance

Proper upkeep of your equipment requires the right tools to ensure smooth operation and longevity. Whether performing regular inspections or addressing occasional repairs, having the correct instruments on hand is essential for efficiency and accuracy. The selection of tools needed can vary depending on the specific components and tasks involved.

Common tools often include a set of wrenches, screwdrivers, and pliers for disassembly and reassembly. A torque wrench can be invaluable when precise tightening is required. Additionally, you may need specialized tools such as socket sets, oil filter wrenches, and a grease gun for lubrication. Keeping these items organized and readily available will streamline your maintenance routine.

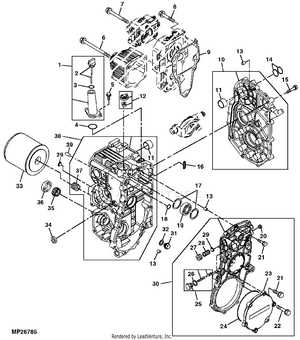

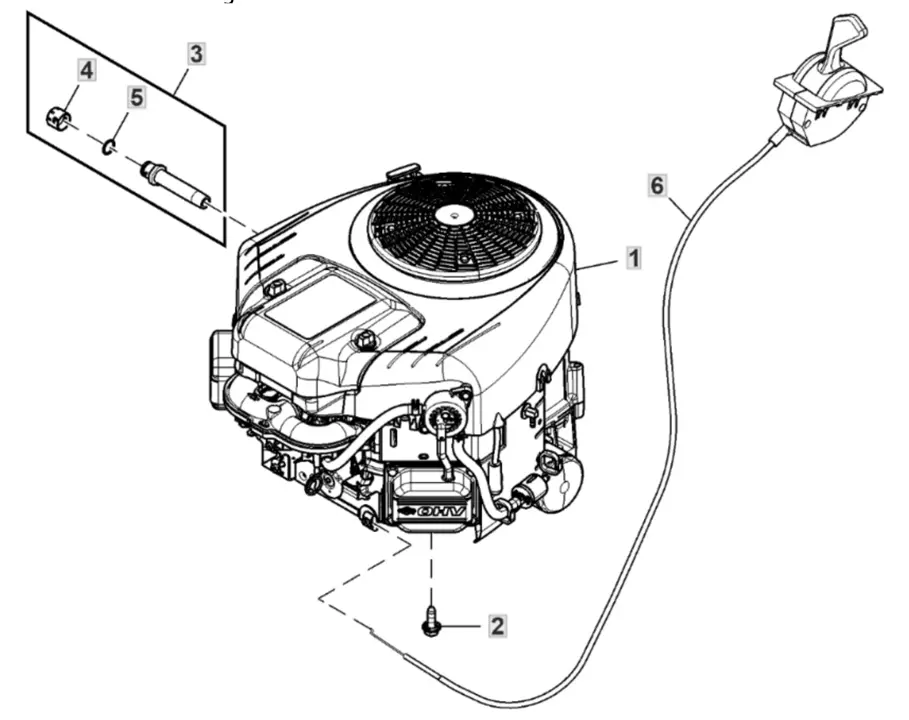

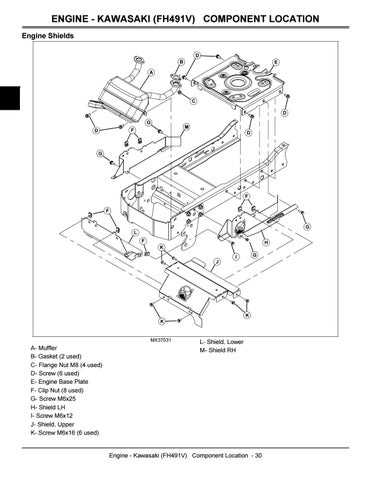

Understanding the Engine Components

The engine is a key element responsible for powering various machines and devices. It consists of several interconnected parts that work together to generate energy efficiently. Each component plays a vital role in ensuring smooth and reliable operation. A proper understanding of these elements can aid in identifying potential issues and maintaining performance.

Main Functional Elements

The engine is composed of essential elements, including the cylinder, pistons, and crankshaft. The cylinder is the core where fuel combustion occurs, and the pistons move within it, transforming energy into mechanical power. The crankshaft converts this motion into rotational force, which drives the machine’s various systems.

Supporting Systems

Beyond the core parts, several additional systems support engine functionality. These include the cooling system, which prevents overheating, and the lubrication system that reduces friction between moving components. Regular inspection of these systems is crucial to ensure that the engine operates efficiently over time.

Electrical System Overview

The electrical system in any mechanical equipment plays a crucial role in ensuring proper functionality. It integrates various components that work together to provide power, control, and safety. Understanding the layout and connection of these elements is essential for efficient maintenance and troubleshooting.

Main Components

The electrical system consists of several key parts that manage power distribution. These include the battery, which provides the initial source of energy, the alternator that charges the battery while the machine is in operation, and the wiring harness, which connects all electrical components. Additionally, fuses and relays help protect the system from electrical faults.

Key Connections

All vital connections within the electrical system must be in proper order for the equipment to function smoothly. This includes wiring between the power source, the ignition, and various switches and sensors. Regular inspection and testing of these connections can prevent potential failures and extend the lifespan of the equipment.

Component Function Battery Stores and supplies electrical energy Alternator Charges Safety Tips for Garden Tractor Use

When operating any machinery, it is crucial to prioritize safety to prevent accidents and injuries. Whether you’re maintaining your property or performing other tasks, taking appropriate precautions is essential for both the operator and those nearby. This section provides important guidelines to ensure a safe working environment while handling outdoor equipment.

Pre-Operation Checks

Before starting any machinery, it’s vital to conduct thorough inspections. Ensure that all components are in proper working order, including brakes, steering, and controls. Confirm that there are no visible leaks or damage, and always read and follow the instructions provided by the manufacturer. Being familiar with the operational manual can help prevent unexpected malfunctions.

Safe Operation Practices

While operating the machine, stay alert to your surroundings. Avoid operating on steep slopes, wet or uneven terrain to prevent tipping over. Keep bystanders and pets at a safe distance, and never allow children to operate the equipment. Always wear proper protective gear, including gloves, sturdy footwear,

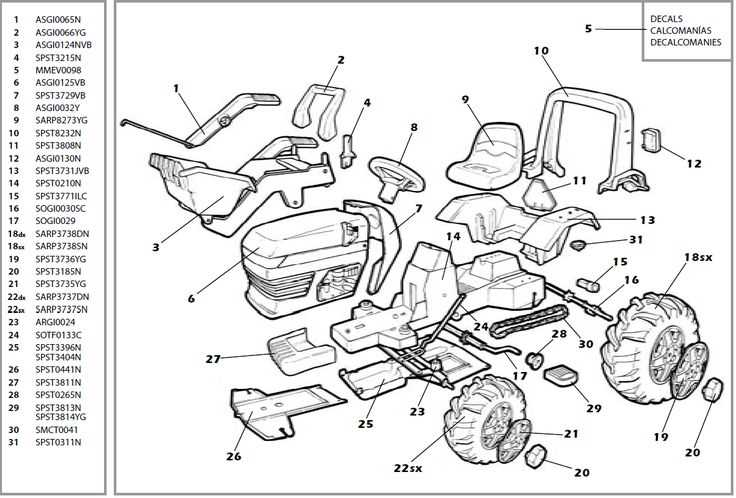

Upgrading Your John Deere Tractor

Improving your outdoor machine’s capabilities can be a rewarding experience. Whether you need enhanced power, better efficiency, or more advanced features, there are several ways to upgrade various components to meet your specific needs. With the right modifications, you can ensure your equipment runs more smoothly and serves you for years to come.

Choosing the Right Components

When looking to upgrade, it’s essential to focus on the areas that will make the most difference. Consider enhancing the engine for greater power, adding attachments for increased versatility, or investing in more durable wheels for better traction. Selecting high-quality components that match your machine’s requirements will maximize performance and extend its lifespan.

Installation and Maintenance Tips

Proper installation and regular maintenance are crucial for any upgrade. Follow the manufacturer’s instructions carefully to ensure safe and effective installation. Additionally, routine checks and cleaning after upgrades will help keep your machine running optimally and avoid potential issues down the line.

Customer Reviews and Experiences

Feedback from users provides valuable insights into the functionality and reliability of the machinery. Many owners share their personal experiences with different components and their performance, offering a clearer understanding of what to expect. These reviews often highlight aspects such as ease of use, durability, and the overall satisfaction of handling the equipment over time.

Users often note the convenience of operating the equipment for a variety of tasks, with many praising its smooth operation and comfort. A number of reviewers emphasize the longevity of specific elements, which have shown resilience under tough working conditions. On the other hand, some highlight the need for occasional maintenance or replacement of certain parts, offering advice on how to keep the machine in top shape for years to come.

Several individuals also share their stories about how the equipment has enhanced their productivity, making challenging tasks more manageable. These experiences provide new buyers with a sense of what they can expect, whether they are new to this type of machinery or experienced users looking for an upgrade.