John Deere 2140 Component Layout Guide

The efficiency of modern agricultural machinery relies heavily on its intricate components and their interconnections. A thorough understanding of these elements is essential for anyone looking to maintain or repair their equipment effectively. This section delves into the various elements that comprise a specific model, illustrating their roles and interactions.

By exploring the arrangement and functionality of each component, operators can enhance the longevity and performance of their machinery. Knowing how each piece contributes to the overall system empowers users to make informed decisions during maintenance and repairs. This knowledge is invaluable for ensuring that agricultural operations run smoothly and effectively.

Understanding the vital elements of this agricultural equipment is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring that the machine performs optimally in various farming tasks. Familiarity with these parts aids in troubleshooting and repairs, enhancing the longevity and reliability of the equipment.

The following are key elements of the machine:

- Engine: The powerhouse that drives the entire system, providing the necessary energy for various operations.

- Transmission: Responsible for transferring power from the engine to the wheels, allowing for speed and torque adjustments.

- Hydraulic System: This system controls the lifting and lowering of attachments, enabling versatile functionality.

- Chassis: The frame that supports all components and provides stability during operation.

- Wheels: Essential for mobility, designed to navigate various terrains effectively.

- Control Panel: The interface that allows the operator to monitor and adjust settings for optimal performance.

Each of these components must be properly maintained to ensure the machine operates efficiently and safely. Regular inspections and timely replacements can prevent unexpected breakdowns and enhance overall productivity.

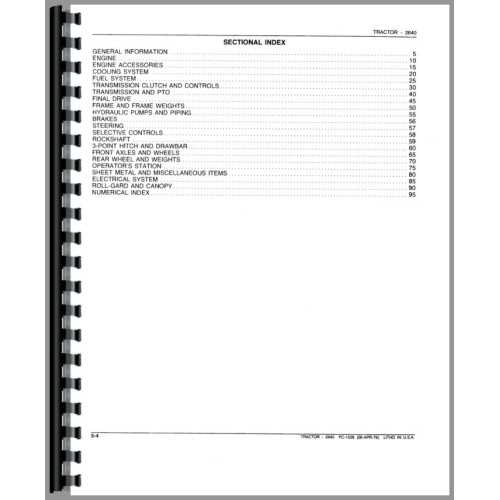

Understanding the Parts Layout

The arrangement of components within a machine plays a crucial role in its overall functionality and maintenance. A clear visualization of how these elements interact can significantly enhance the efficiency of repairs and upgrades. This section aims to provide insight into the organization of various segments and their respective roles in the system.

Key Elements of the Configuration

Each segment serves a specific purpose, contributing to the seamless operation of the machinery. Familiarizing oneself with these arrangements not only facilitates troubleshooting but also aids in identifying potential issues before they escalate. A well-structured overview can streamline maintenance tasks and ensure optimal performance.

Importance of a Structured Overview

Understanding how components are laid out fosters a deeper appreciation for the engineering behind the machinery. This knowledge empowers operators to make informed decisions when it comes to repairs and modifications, ultimately leading to increased longevity and reliability of the equipment.

Identifying Key Replacement Parts

Understanding the essential components of agricultural machinery is crucial for maintaining optimal performance and efficiency. When machinery breaks down or shows signs of wear, identifying the correct elements for replacement becomes a priority. This process not only ensures the longevity of the equipment but also enhances its operational capabilities.

Common Components to Consider

Several critical components often require replacement due to regular wear and tear. Among these are:

- Filters: Essential for keeping the engine clean and functioning smoothly.

- Belts: Vital for transferring power between moving parts.

- Seals: Important for preventing leaks and maintaining fluid levels.

Benefits of Using Quality Replacements

Opting for high-quality replacements can significantly impact performance. Utilizing premium components not only reduces the risk of future failures but also enhances efficiency and reliability. Investing in quality ensures that the machinery operates at its best, ultimately saving time and reducing operational costs.

Maintenance Tips for Longevity

Ensuring the extended life of machinery requires consistent care and attention. Regular upkeep not only enhances performance but also minimizes the risk of unexpected failures. By following a systematic approach to maintenance, operators can effectively prolong the operational lifespan of their equipment.

Routine Inspections

Conducting periodic evaluations is essential for identifying potential issues before they escalate. Consider the following steps:

- Examine all fluid levels regularly, including engine oil, hydraulic fluid, and coolant.

- Check belts and hoses for signs of wear or damage.

- Inspect tires for proper inflation and tread condition.

Scheduled Servicing

Establishing a servicing schedule can greatly benefit machinery reliability. Key recommendations include:

- Follow the manufacturer’s guidelines for oil changes and filter replacements.

- Keep an organized log of all maintenance activities to track service history.

- Utilize genuine components during repairs to ensure compatibility and performance.

Common Issues and Solutions

This section addresses prevalent challenges encountered with agricultural machinery and offers practical solutions for each. Understanding these common problems can assist operators in maintaining optimal performance and ensuring longevity in their equipment.

Frequent Mechanical Failures

Mechanical malfunctions often arise due to wear and tear or inadequate maintenance. Regular inspection and timely repairs can mitigate these issues significantly. Here are some common failures and their remedies:

| Issue | Solution |

|---|---|

| Overheating Engine | Check coolant levels and inspect the radiator for blockages. |

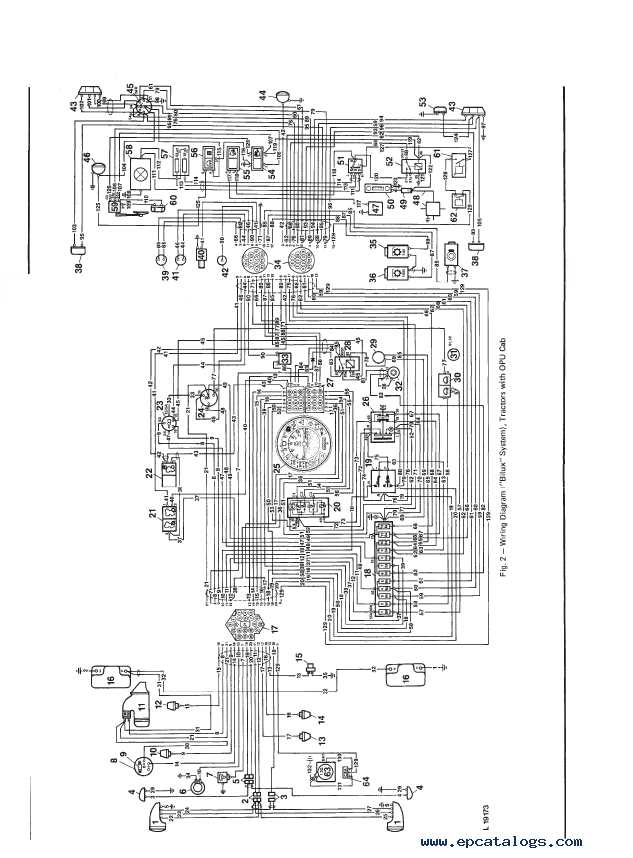

| Electrical Failures | Inspect wiring and connections for corrosion or damage. |

| Poor Fuel Efficiency | Ensure fuel filters are clean and replace as needed. |

Operational Challenges

In addition to mechanical issues, operators may face challenges in handling and using the equipment effectively. Training and practice can enhance operational proficiency, leading to better results. Consider the following common operational difficulties:

| Challenge | Recommended Action |

|---|---|

| Difficulty in Maneuvering | Practice in open spaces to improve handling skills. |

| Inconsistent Performance | Regularly calibrate settings based on field conditions. |

| Unresponsive Controls | Check control linkages for wear and ensure proper lubrication. |

Ordering Parts Online Effectively

Acquiring components via the internet can significantly streamline maintenance and repair tasks. By leveraging online resources, individuals can access a broader selection and potentially lower prices. Understanding the essentials of efficient online purchasing will enhance the overall experience, ensuring that the right items arrive promptly and meet the necessary specifications.

To navigate the online ordering process successfully, follow these steps:

| Step | Description |

|---|---|

| 1 | Identify the specific components needed for your machinery. |

| 2 | Research reputable online suppliers that specialize in your equipment type. |

| 3 | Check for customer reviews and ratings to ensure reliability. |

| 4 | Compare prices and availability across multiple websites. |

| 5 | Add selected items to your cart and verify the details. |

| 6 | Proceed to checkout, ensuring accurate shipping information. |

| 7 | Finalize the purchase and keep a record of the order confirmation. |

By adhering to these guidelines, you can enhance your online ordering efficiency and ensure that your machinery remains in optimal condition.

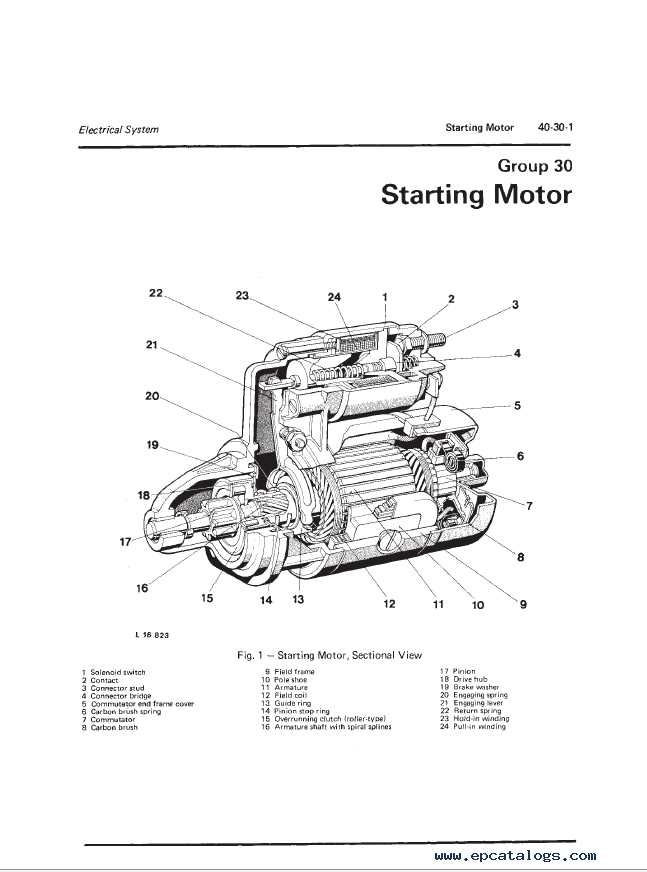

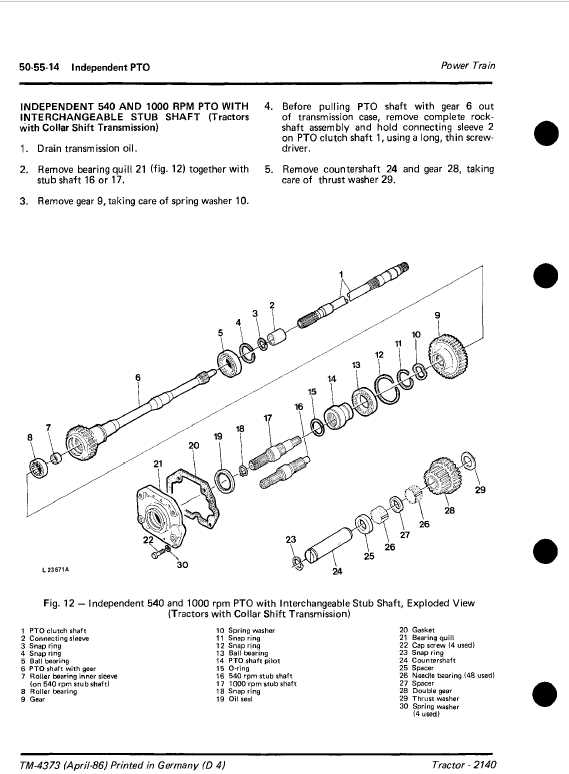

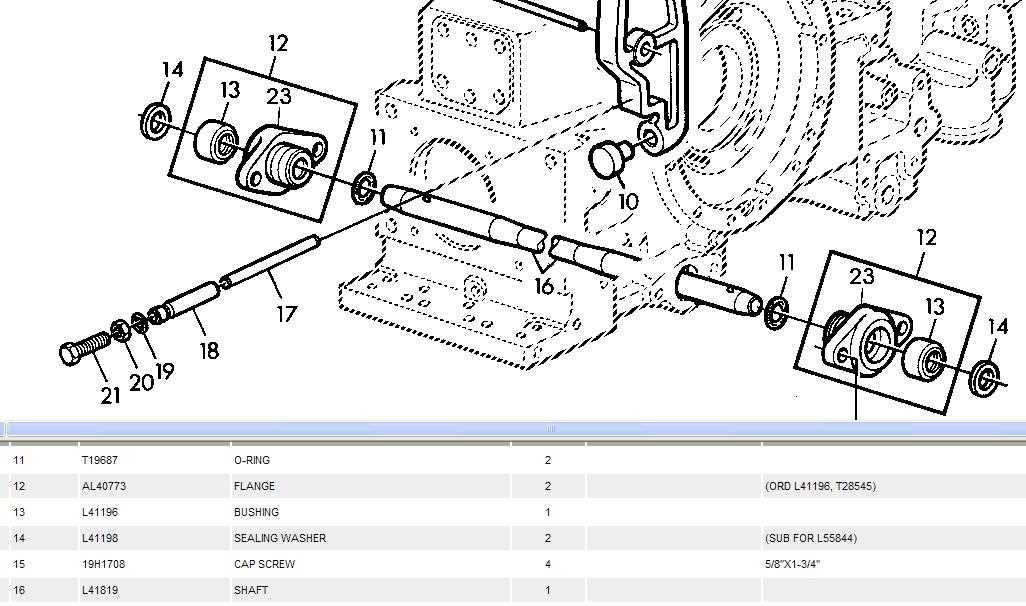

Visual Aids for Assembly Guidance

Effective assembly of machinery often relies on comprehensive visual resources that simplify complex processes. These materials serve as crucial tools, enhancing understanding and ensuring accuracy during the construction or repair phases. By providing clear illustrations and annotations, users can navigate through intricate steps with confidence and ease.

Types of Visual Resources

Various types of visual aids are available to assist users in their assembly tasks. Illustrated manuals feature detailed drawings that highlight specific components and their arrangements. Step-by-step guides often combine images with concise instructions, making it easier to follow the necessary procedures. Additionally, videos can offer dynamic demonstrations, showcasing real-time assembly techniques.

Benefits of Using Visual Aids

Incorporating visual aids into the assembly process significantly reduces the likelihood of errors and misunderstandings. Users benefit from enhanced clarity, which allows them to quickly identify parts and their functions. Furthermore, visual resources can improve efficiency, as they streamline the workflow and minimize downtime associated with incorrect assemblies.

Importance of Genuine Parts

Utilizing authentic components is crucial for maintaining the efficiency and longevity of machinery. High-quality materials ensure optimal performance, which can significantly impact productivity and operational costs. When genuine items are used, users can be confident that their equipment operates as intended, minimizing the risk of unexpected failures.

Benefits of Authentic Components

Choosing original items brings numerous advantages. First and foremost, these components are designed specifically for the machinery, ensuring a perfect fit and compatibility. Additionally, they often come with warranties, providing peace of mind to the owner. By opting for genuine materials, one can enhance the durability and reliability of their equipment, leading to reduced maintenance costs in the long run.

Risks of Imitation Parts

On the contrary, using imitation or substandard components can lead to several issues. These alternatives may not meet the required specifications, resulting in poor performance and potential damage to the machinery. The long-term effects of such choices can include increased downtime and higher repair expenses. Therefore, investing in genuine items is not just a choice but a necessity for anyone seeking to preserve their investment.

Comparing Aftermarket Options

When considering alternatives for machinery components, it’s essential to evaluate the various choices available in the market. Numerous suppliers offer a wide range of replacements that can effectively serve the same functions as original equipment. These substitutes often promise competitive pricing, enhanced durability, or improved performance, appealing to both budget-conscious consumers and those seeking to upgrade their equipment.

Quality is a critical factor when assessing aftermarket selections. While some alternatives may provide cost savings, others might compromise on longevity or functionality. It is advisable to research the reputation of manufacturers and to seek out reviews from other users to ensure that the chosen replacements meet the necessary standards.

Additionally, compatibility with existing machinery is paramount. Not all substitutes fit seamlessly into specific models; thus, verifying that the replacement items align with the machine’s specifications is crucial. This attention to detail helps avoid potential installation issues and operational inefficiencies.

Finally, consider the warranty and support offered with aftermarket products. Many suppliers provide guarantees on their items, which can add peace of mind. Understanding the terms and conditions of these warranties can aid in making a more informed decision, ultimately enhancing the reliability of the machinery in the long run.

Tools Needed for Repairs

Effective maintenance and repair of agricultural machinery require a range of specialized instruments. Utilizing the right equipment not only ensures efficiency but also enhances safety during the repair process. Below are essential tools that are commonly needed for various repair tasks.

Basic Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle nose and regular)

- Socket set

- Hammer

Specialized Equipment

- Torque wrench

- Grease gun

- Oil filter wrench

- Measuring tape

- Electrical multimeter

Having these tools readily available will significantly facilitate the repair process, making it easier to diagnose issues and implement effective solutions.

Tips for DIY Repairs

Engaging in self-repair projects can be both rewarding and economical. By understanding the essentials of your machinery, you can effectively troubleshoot and resolve various issues. This section offers practical advice for individuals looking to undertake repairs without professional assistance.

1. Gather Necessary Tools: Before starting any repair, ensure you have the right tools at hand. This may include wrenches, screwdrivers, and pliers. Having everything organized will save time and increase efficiency.

2. Refer to Reliable Sources: Utilizing trustworthy manuals or online resources is crucial. They provide valuable information regarding components and assembly procedures, ensuring you have a clear understanding of the repair process.

3. Take Safety Precautions: Always prioritize safety. Wear protective gear and follow safety guidelines to avoid accidents while working on machinery.

4. Document Your Work: Keeping a record of your repairs can be beneficial. Take notes and photos throughout the process, making it easier to remember steps and identify any future issues.

5. Don’t Rush: Patience is key in DIY repairs. Take your time to thoroughly examine each component, ensuring all parts are functioning correctly before reassembling.

By following these tips, you can enhance your repair skills and maintain your machinery more effectively, leading to a longer lifespan and better performance.

Connecting with Local Dealers

Establishing a connection with nearby distributors can significantly enhance your experience in acquiring equipment components. Local dealers often provide valuable insights and personalized assistance that can streamline your procurement process. Their familiarity with the local market allows them to offer tailored solutions that suit your specific needs.

The Benefits of Local Partnerships

Working closely with local vendors presents numerous advantages. These professionals not only have access to a broad inventory but also possess extensive knowledge about the machinery and its requirements. This relationship fosters quick responses to inquiries, ensuring that you receive timely support when needed.

How to Find Reliable Dealers

Identifying trustworthy distributors involves some research. Consider exploring online reviews, seeking recommendations from fellow operators, and visiting local trade shows. Building a rapport with these professionals can lead to beneficial long-term partnerships that enhance your operational efficiency.

| Dealer Name | Location | Contact Information |

|---|---|---|

| Example Dealer 1 | City A | (123) 456-7890 |

| Example Dealer 2 | City B | (098) 765-4321 |

| Example Dealer 3 | City C | (555) 123-4567 |