Parts Diagram for Stihl FS200

Understanding the intricate elements of a garden tool is essential for anyone seeking to maintain or repair their equipment. This section will delve into the various components that make up a specific model, highlighting their functions and interrelationships. A thorough grasp of these parts can enhance efficiency and prolong the lifespan of the tool.

Illustrating the assembly of these devices not only aids in troubleshooting common issues but also fosters a deeper appreciation for their engineering. By examining each element, users can better comprehend how they contribute to the overall performance, ensuring effective operation during gardening tasks.

Whether you are an experienced landscaper or a novice gardener, having access to detailed illustrations of these components is invaluable. Such resources empower individuals to make informed decisions regarding maintenance and upgrades, ultimately enhancing the gardening experience.

This section aims to provide a comprehensive overview of the various components that make up a specific outdoor power equipment model. Understanding the arrangement and function of these elements is essential for effective maintenance and troubleshooting.

Key Components Overview

- Engine Assembly: The powerhouse of the device, responsible for driving performance.

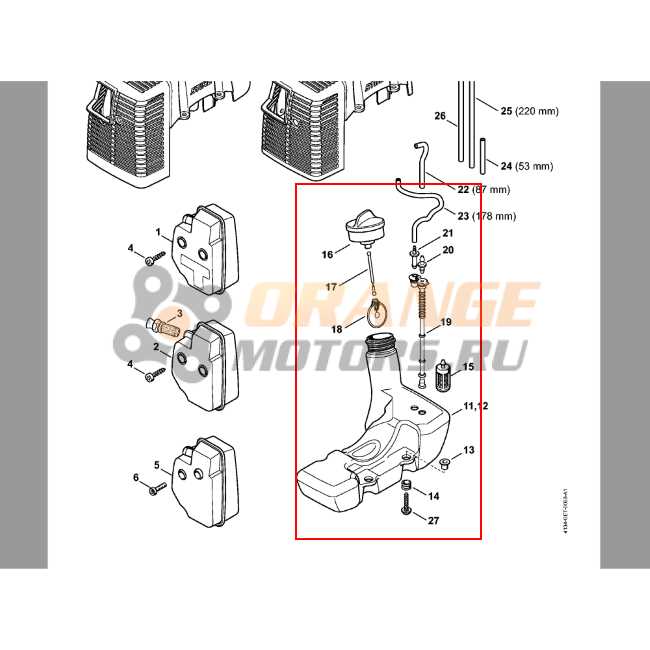

- Fuel System: Includes the tank, lines, and carburetor that facilitate the delivery of fuel to the engine.

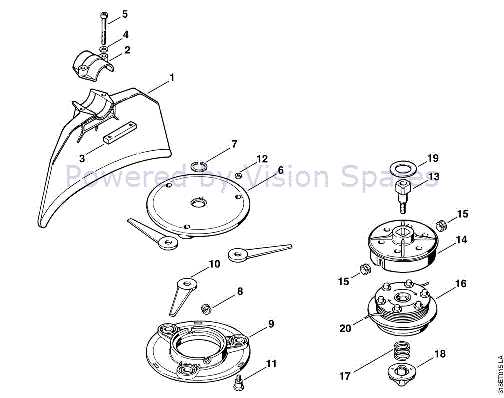

- Cutter Head: The mechanism that interacts with the vegetation, varying in design based on intended use.

- Handle and Control System: Offers user interaction with the equipment, ensuring safety and maneuverability.

Importance of Component Understanding

Having a clear understanding of each part’s role aids in efficient operation and prolongs the lifespan of the equipment. Regular checks and maintenance on these critical areas can prevent unexpected failures and enhance overall performance.

Overview of Stihl FS200 Model

This model represents a reliable tool designed for various landscaping tasks, making it a preferred choice for both professionals and homeowners. Its robust construction ensures durability while delivering efficient performance in demanding conditions.

Equipped with a powerful engine, this device offers an excellent balance of power and weight, allowing for easy maneuverability. Users can expect a seamless operation, whether trimming grass, tackling thick weeds, or maintaining larger outdoor areas.

Additionally, this tool features ergonomic handles that enhance user comfort during extended usage, minimizing fatigue. Maintenance is straightforward, with accessible components designed for easy servicing, ensuring longevity and consistent performance.

Overall, this model stands out in its category, providing exceptional functionality and user-friendly features, making it a valuable addition to any gardening toolkit.

Key Components of the Machine

The functionality of any machinery relies on its essential elements, which work in harmony to ensure optimal performance. Understanding these critical components is vital for anyone looking to maintain or operate equipment efficiently.

One of the primary parts is the engine, which provides the necessary power for operation. The engine’s design influences the machine’s overall efficiency and capability. Another significant element is the cutting mechanism, responsible for executing the intended tasks, whether it involves trimming, mowing, or clearing vegetation.

Additionally, the handle and grip contribute to user comfort and control, allowing for precision in handling. The fuel system is equally important, as it supplies energy to the engine and ensures seamless operation. Each component plays a vital role in the overall effectiveness of the machine, highlighting the need for regular maintenance and knowledge of how these parts function together.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate assembly of machinery. They provide an essential guide for users, allowing for easier identification of individual elements within complex systems. These illustrations not only enhance comprehension but also streamline the maintenance and repair processes.

Utilizing such visual aids can significantly reduce errors during reassembly. By clearly showcasing how each piece interacts, they facilitate a smoother workflow and minimize the risk of oversight. This clarity is especially beneficial for those who may not have extensive experience with the equipment, ensuring that even novice users can navigate repairs with confidence.

Moreover, these visual resources serve as valuable references when sourcing replacements. They help in accurately locating the necessary components, saving time and effort in the procurement process. By understanding the relationships between various elements, users can make informed decisions regarding upgrades or modifications, ultimately enhancing the functionality and longevity of the equipment.

Identifying Common Issues

Recognizing frequent problems in outdoor power equipment is crucial for maintaining optimal performance. Many users encounter various challenges that can affect the functionality and efficiency of their machines. Understanding these issues can help in addressing them promptly and effectively.

Here are some typical concerns that may arise:

- Engine Performance: Symptoms such as stalling or difficulty starting can indicate fuel delivery problems or ignition system failures.

- Cutting Efficiency: Dull or damaged blades can lead to subpar cutting performance, requiring inspection and replacement.

- Vibration and Noise: Excessive vibrations or unusual sounds may suggest loose components or wear and tear in moving parts.

Regular maintenance and timely troubleshooting can prolong the lifespan of your equipment. Keeping an eye out for these issues will ensure smoother operation and enhance overall user satisfaction.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of any outdoor power equipment. By adhering to a few fundamental practices, users can significantly enhance the performance and durability of their tools.

- Regular Cleaning: Keeping equipment clean prevents dirt and debris buildup, which can hinder functionality. Use a soft brush or cloth to wipe down surfaces after each use.

- Routine Inspections: Periodically check for any wear or damage. Look for loose screws, frayed wires, or cracked components that may require attention.

- Proper Storage: Store equipment in a dry and sheltered area to protect it from the elements. Consider using a cover to shield it from dust and moisture.

- Lubrication: Ensure that moving parts are well-lubricated to reduce friction and wear. Use the appropriate lubricant recommended by the manufacturer.

- Fuel Management: Use fresh fuel and ensure the fuel system is clean. Old or contaminated fuel can cause performance issues.

Implementing these maintenance tips can help users achieve optimal performance and longevity from their equipment, minimizing the need for repairs and replacements.

Replacement Parts Availability

Accessing suitable components for maintenance and repair is crucial for ensuring the longevity and efficient performance of equipment. The availability of replacement items plays a significant role in minimizing downtime and enhancing user satisfaction. Understanding where and how to procure these essential components can streamline the upkeep process.

Sources for Components

- Authorized Dealers: These outlets typically offer a comprehensive selection of original items, ensuring compatibility and quality.

- Online Retailers: Numerous e-commerce platforms provide a wide range of alternatives, often at competitive prices.

- Local Repair Shops: Local service centers may stock frequently needed components and can provide valuable advice on suitable substitutes.

Considerations When Purchasing

- Quality Assurance: Opt for items that meet or exceed the manufacturer’s specifications to ensure optimal performance.

- Warranty: Verify if the component comes with a warranty, which can provide peace of mind regarding durability.

- Compatibility: Ensure that the chosen part is compatible with the specific model to avoid operational issues.

Tools Required for Repairs

When it comes to maintaining outdoor power equipment, having the right tools on hand is essential for efficient and effective repairs. This section outlines the various implements that can facilitate the disassembly, troubleshooting, and reassembly of mechanical components, ensuring that your equipment functions optimally.

Essential Hand Tools

Basic hand tools are the backbone of any repair task. Commonly required items include screwdrivers, wrenches, and pliers. These tools allow for the removal of fasteners and the adjustment of parts. Additionally, a ratchet set can be invaluable for reaching tight spaces, while a torque wrench ensures that components are securely fastened to the manufacturer’s specifications.

Specialized Equipment

In addition to hand tools, certain specialized equipment may be necessary for more intricate repairs. Diagnostic tools can help identify issues with the engine or ignition system, while cleaning supplies, such as brushes and solvents, are crucial for maintaining optimal performance. A workbench or tool chest provides a stable workspace, allowing for organized and efficient repair processes.

Step-by-Step Assembly Instructions

Assembling machinery components requires careful attention to detail to ensure proper functionality. This guide provides clear steps to help you successfully put together your equipment, ensuring all parts fit seamlessly and operate effectively.

- Begin by gathering all necessary components. Ensure you have each item as specified in the assembly list.

- Inspect each component for any damage or defects before proceeding. Replace any faulty parts as needed.

- Start with the base unit. Secure it on a stable surface to facilitate easy assembly.

- Attach the main body components. Align them correctly and fasten them using the provided screws.

- Connect any internal wiring or mechanisms. Refer to the assembly reference for proper placement.

- Install any additional accessories or tools as specified in the instructions. Make sure they are tightly secured.

- Conduct a thorough check of all connections and fittings to ensure everything is in place.

- Once assembly is complete, perform a functionality test to confirm that the equipment operates correctly.

Following these steps diligently will lead to a successful assembly, resulting in a well-functioning machine ready for use.

Safety Precautions During Repairs

When undertaking maintenance or fixing machinery, prioritizing safety is essential to prevent accidents and injuries. Proper precautions ensure a secure working environment and protect both the individual and the equipment. Adhering to established safety measures minimizes risks associated with mechanical work.

- Wear Appropriate Gear: Always don protective eyewear, gloves, and sturdy footwear to shield yourself from debris and injuries.

- Work in a Well-Ventilated Area: Ensure adequate airflow to prevent inhalation of harmful fumes or dust generated during repairs.

- Disconnect Power Sources: Before beginning any work, disconnect power supplies or remove batteries to avoid accidental activation.

- Use Proper Tools: Utilize the correct tools for the job, ensuring they are in good condition to prevent slips and mishaps.

Implementing these safety measures significantly reduces the likelihood of accidents and ensures a smoother repair process. Taking the time to prepare properly not only enhances personal safety but also contributes to the longevity of the equipment being serviced.

- Read the Manual: Familiarize yourself with the manufacturer’s guidelines and safety recommendations before starting.

- Keep Work Area Organized: Maintain a clean and clutter-free workspace to avoid tripping hazards and facilitate efficient repairs.

- Have a First Aid Kit Nearby: Always have a basic first aid kit accessible to address minor injuries promptly.

Visual Guides for Component Locations

Understanding the arrangement of components in equipment is crucial for effective maintenance and troubleshooting. Visual aids serve as essential tools for users, enabling them to identify various parts quickly and efficiently. By utilizing illustrations or schematics, individuals can gain a clearer perspective on how different elements fit together and function within the machinery.

Detailed illustrations offer a comprehensive overview of the assembly, allowing users to pinpoint specific areas that may require attention. These guides enhance comprehension, particularly for those unfamiliar with the internal structure of the equipment. Furthermore, they assist in facilitating repairs or replacements by clearly indicating where each component is located.

Additionally, visual representations simplify the process of recognizing compatible parts, ensuring that users select the correct items for their repair needs. This not only saves time but also minimizes the risk of errors during maintenance activities. Ultimately, utilizing visual guides empowers users to engage more confidently with their machinery, leading to improved efficiency and longevity.

Understanding Part Numbers and Codes

In the realm of machinery and equipment, each component is assigned a unique identifier that serves various essential functions. These alphanumeric sequences not only facilitate inventory management but also ensure accurate ordering and replacement. Familiarizing oneself with these codes can significantly streamline maintenance and repair processes.

Significance of Identifier Systems

The identifier system plays a crucial role in distinguishing between various elements within a product line. Understanding how these codes are structured can help users quickly identify the right component they need, enhancing efficiency and reducing errors. Typically, a code may contain information regarding the type of component, its size, and even its compatibility with other elements.

Components of Part Numbers

Part identifiers usually consist of several segments that provide detailed insights into the item. Below is a simplified breakdown of what these segments may represent:

| Segment | Description |

|---|---|

| Prefix | Indicates the category or type of the item. |

| Main Number | Unique identifier for the specific component. |

| Suffix | Additional information such as size or version. |

By understanding these components, users can easily navigate catalogs and inventories, ensuring they acquire the correct items for their equipment.

Customer Support and Resources

Accessing quality assistance and resources is essential for users seeking to maintain or repair their equipment effectively. Various channels provide guidance and information to ensure optimal performance and longevity of your tools. Utilizing these resources can enhance your understanding and help you address any challenges that may arise during operation.

Online Help Centers

Many manufacturers offer comprehensive online platforms that feature troubleshooting guides, user manuals, and FAQs. These resources allow users to quickly find solutions to common issues, enabling them to handle maintenance tasks with confidence. Additionally, forums and community discussions can provide valuable insights and tips from experienced users.

Authorized Service Centers

For more complex repairs or replacements, visiting an authorized service center is recommended. These facilities employ trained professionals who can accurately diagnose problems and provide the necessary services. Furthermore, they often stock genuine components, ensuring that any repairs uphold the quality standards expected by users.