Understanding the MTD Mower Deck Parts Diagram

When it comes to maintaining outdoor machinery, understanding the configuration and the crucial elements that ensure smooth operation is essential. The combination of several interconnected mechanical components plays a key role in achieving optimal performance. Recognizing how these elements work together allows for proper upkeep and enhances the longevity of the equipment.

Proper maintenance requires detailed knowledge of the core structure and the key features responsible for efficient functioning. By becoming familiar with each component, users can better identify potential issues and address problems before they escalate. This knowledge also helps in carrying out routine care more effectively, ensuring that the machine continues to perform as intended.

Additionally, having a clear visual understanding of how everything fits together can make the process of repairs and adjustments much easier. With the right information, managing wear and tear becomes a simpler task, leading to prolonged usability and minimized downtime.

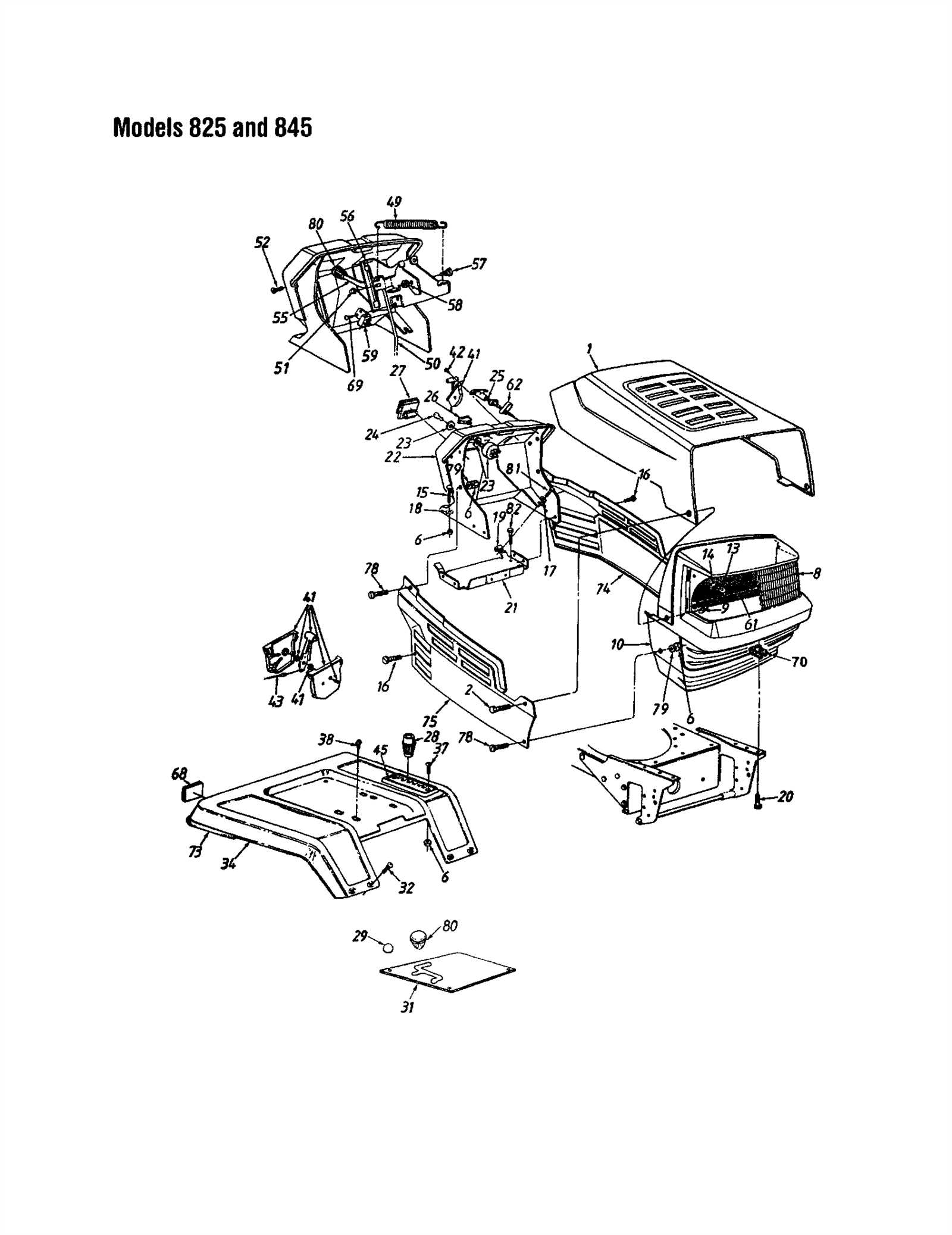

Understanding the Structure of Mower Decks

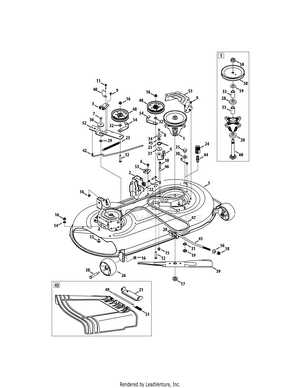

When examining the main section responsible for cutting, it’s essential to understand how different elements work together. Each component plays a crucial role in ensuring efficiency and proper functioning during the trimming process. The arrangement of these parts can vary, but their interaction remains the same in principle.

Below is a basic breakdown of the structure, highlighting key components and their interactions:

| Component | Function |

|---|---|

| Cutting Blades | Responsible for slicing through the grass evenly and consistently. |

| Spindles | These support the blades and allow them to rotate smoothly during operation. |

| Belt System | Connects the power source to the blades, ensuring they receive the energy to rotate. |

| Housing | Protects the internal components from debris and ensures a streamlined cutting process. |

Components of a Mower Cutting System

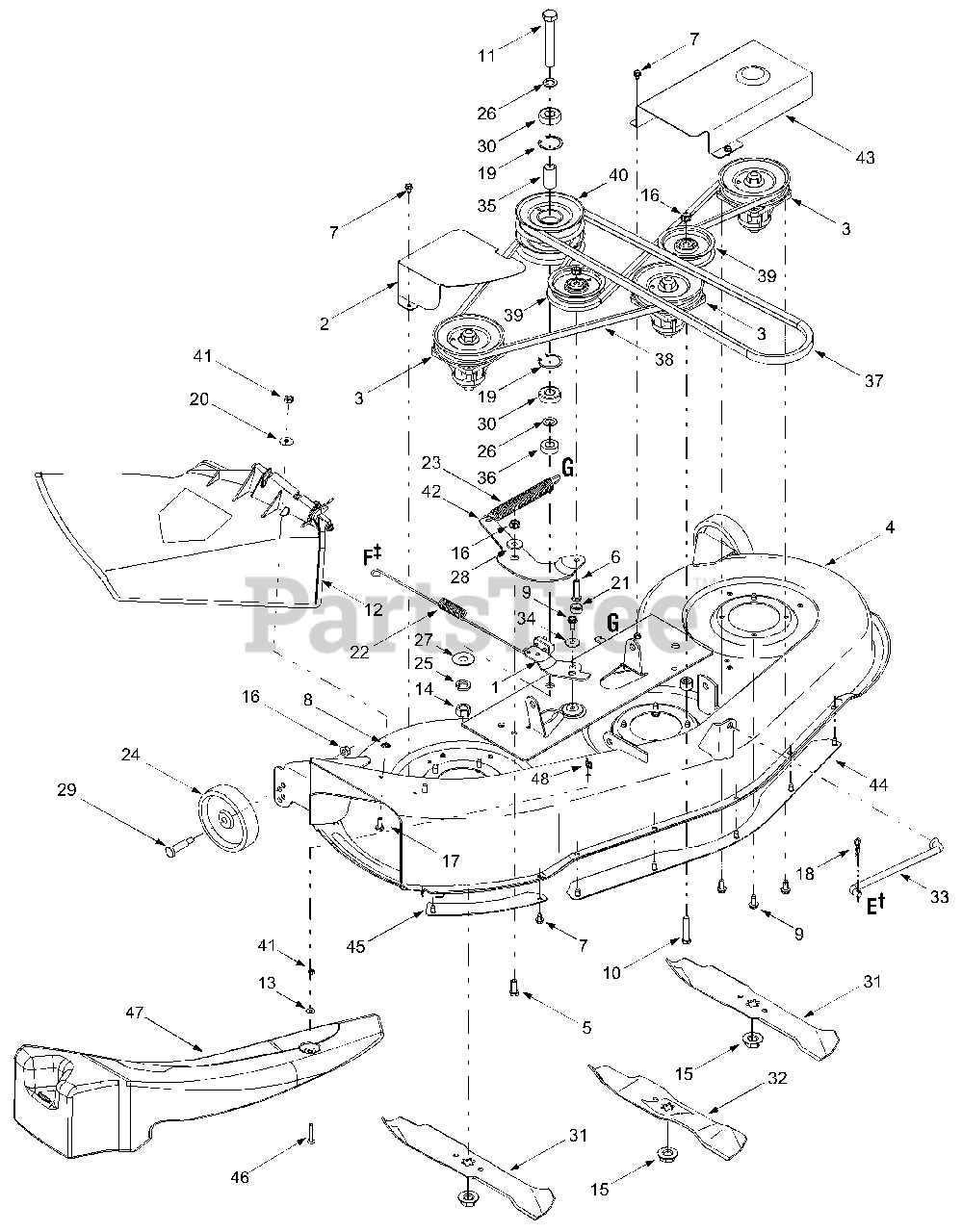

The cutting mechanism in a lawn care machine plays a vital role in maintaining the health and appearance of your yard. This system is composed of several interconnected elements that work together to achieve a precise trim, ensuring even results across various terrains. Understanding the structure and operation of these components can enhance both performance and longevity.

Blades and Their Function

Blades are one of the primary elements responsible for cutting grass. They rotate at high speeds, slicing through vegetation with accuracy. Different blade types, including mulching or bagging variations, offer specialized functions, providing flexibility based on the desired outcome.

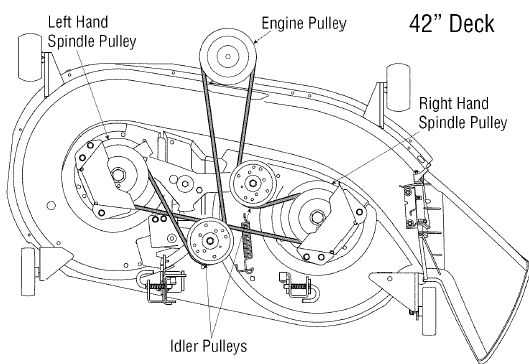

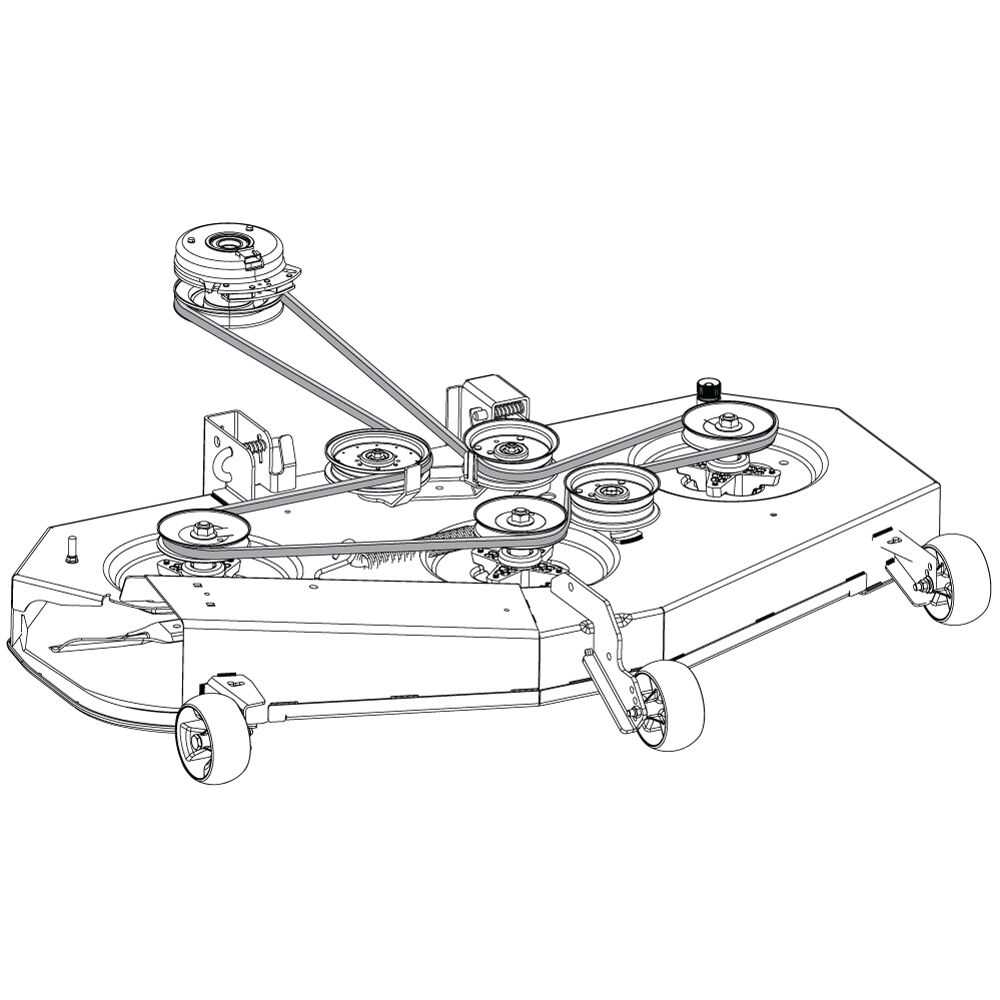

Belt and Pulley System

To drive the blades, a belt and pulley system transfers power from the engine to the cutting assembly. The belt must be properly aligned and maintained for smooth operation, while the pulleys ensure the rotational force is distributed evenly, preventing damage to the machine.

| Component | Description | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blades | Responsible for cutting grass with sharp edges, offering various types like mulching blades. | ||||||||||||||||||||||||||||||

| Belt | Transfers power from the engine to the cutting system, enabling

Blade Arrangement and Functions Explained

The layout and purpose of cutting blades are essential for achieving efficient operation and precise trimming. Understanding how different configurations affect performance can help in maintaining consistent results and prolonging equipment life. Understanding Blade PlacementBlades are positioned in specific arrangements to ensure optimal coverage and smooth cutting. The alignment plays a key role in reducing clumping and enhancing the even distribution of cut material. Proper setup of the blades also impacts the balance and overall efficiency of the machine. Primary Functions of Blades

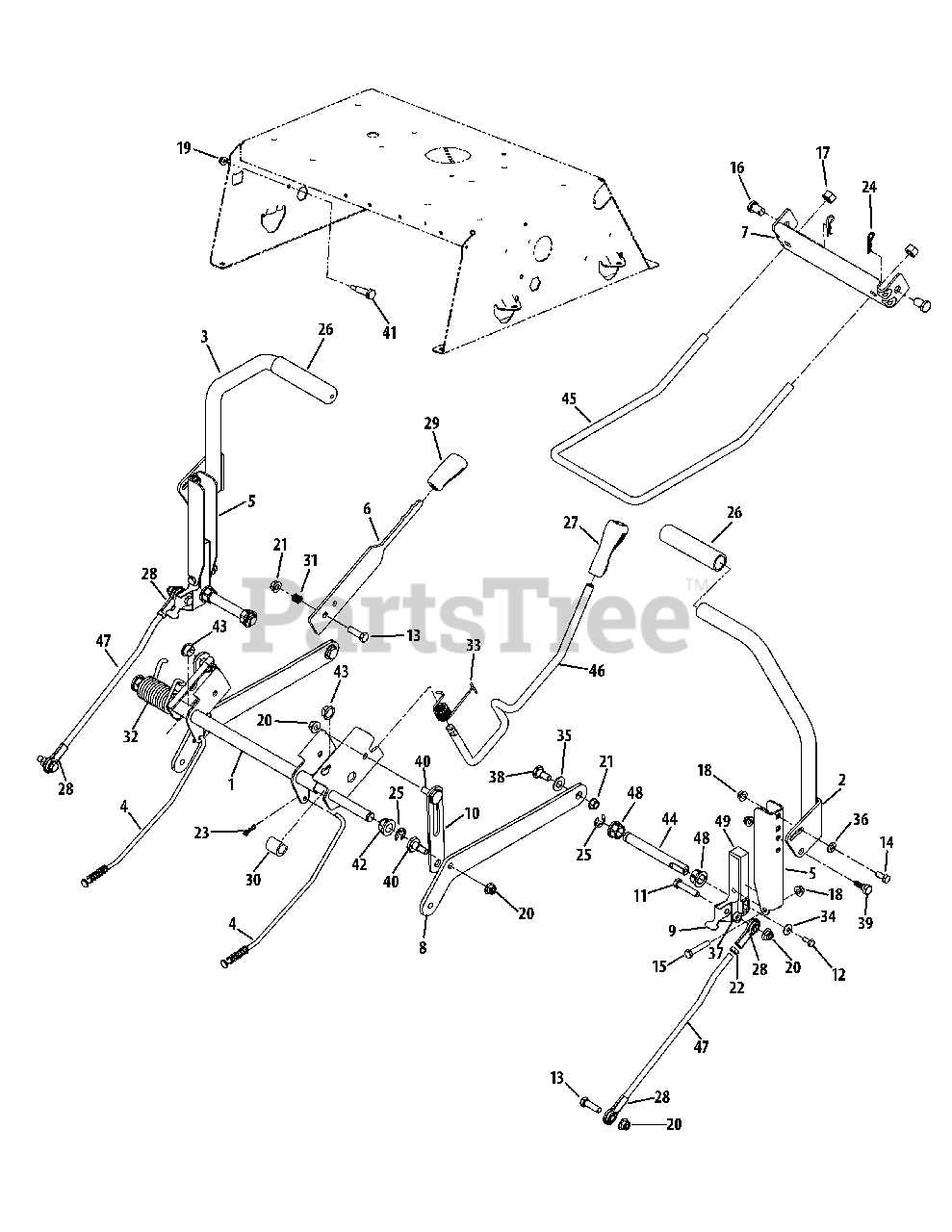

Role of Pulleys in Deck Operation

Pulleys play a key role in the operation of various outdoor machines, ensuring the smooth transfer of motion and power throughout the system. They are essential in creating an efficient rotation that drives the movement of cutting components and other vital mechanisms. Their main purpose is to guide and maintain tension in the belts, helping them rotate without slipping. Without properly functioning pulleys, the entire system could face operational challenges.

Understanding how these components contribute to the overall functionality is important for maintaining performance and extending the lifespan of the system. How Belts Drive the Mower Deck

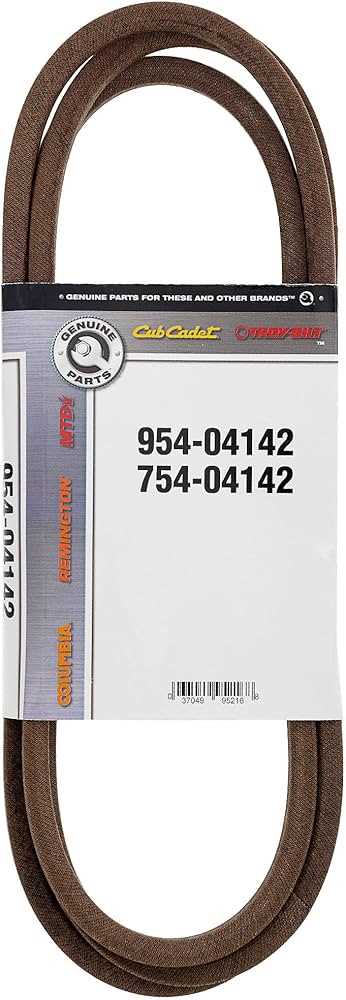

Belts play a crucial role in transferring power from the engine to the rotating blades, ensuring efficient operation. They act as the connection between the engine and cutting system, making sure the entire setup functions smoothly. The way these belts operate involves tension and precise alignment, allowing them to effectively transmit force. By maintaining the right amount of tension and positioning, they ensure the system works without interruptions, keeping everything in sync. Proper maintenance and timely replacement of these driving components are essential for avoiding malfunctions, as worn or damaged belts can lead to reduced efficiency or complete breakdown of the equipment’s cutting system. Spindle Assembly and Maintenance Tips

The spindle assembly plays a crucial role in the functionality of your cutting equipment. Understanding its structure and ensuring proper upkeep can enhance performance and extend the lifespan of your machinery. This section will guide you through essential maintenance practices and assembly insights to keep your device in top condition. Key Components of the Spindle AssemblyA spindle assembly typically consists of several key components that work together to ensure smooth operation. Familiarity with these parts is vital for effective maintenance and troubleshooting. The main elements include:

Maintenance Practices

Regular maintenance of the spindle assembly is essential for optimal performance. Here are some recommended practices:

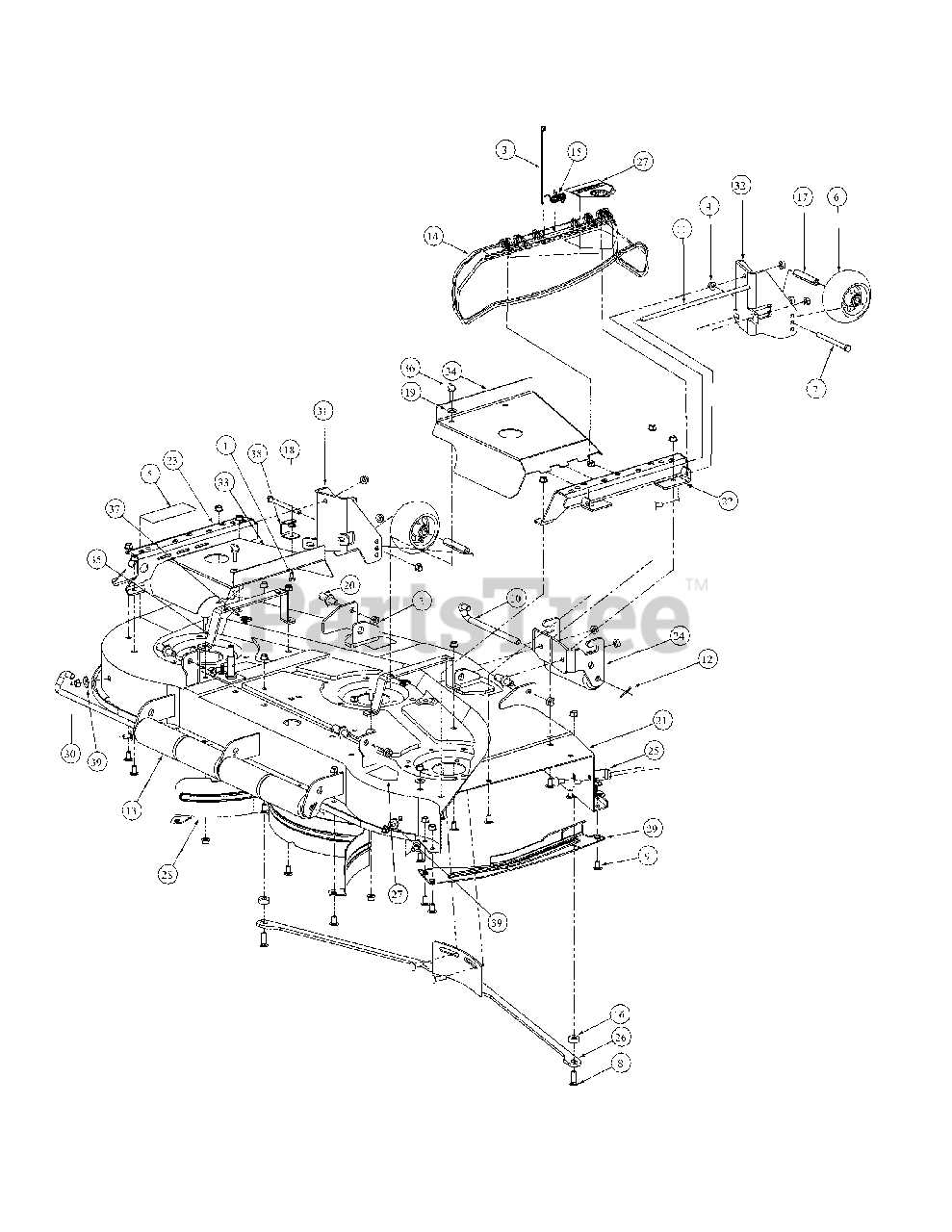

Importance of Deck Shell DurabilityThe resilience of a lawn care equipment’s exterior housing plays a crucial role in its overall performance and longevity. A robust shell not only protects the internal mechanisms from external elements but also contributes to the efficiency of the equipment during operation. Durability is essential for maintaining functionality over time. Equipment subjected to harsh conditions or heavy usage is more susceptible to wear and tear. A strong outer shell can withstand impacts, moisture, and debris, reducing the likelihood of damage that could hinder operation. Furthermore, an enduring exterior minimizes maintenance requirements. When the shell is built to last, it requires less frequent repairs or replacements, resulting in cost savings for the user. Investing in quality construction ensures that the equipment remains reliable and efficient, allowing for seamless operation. In conclusion, prioritizing the durability of the exterior housing not only enhances the performance of the machine but also extends its lifespan. This investment in quality pays off by ensuring reliable operation and reducing the need for frequent upkeep. How to Identify Wear on BladesRecognizing the signs of deterioration on cutting implements is essential for maintaining their efficiency and performance. Regular inspection can help ensure that the equipment operates effectively, providing a clean cut and optimal results. First, examine the cutting edges for any noticeable nicks or dents. These imperfections can affect the quality of the cut, leading to uneven results on the grass or foliage. Additionally, a dull edge may be less effective, requiring more effort to perform the same task. Another important factor is the thickness of the blades. Over time, wear can cause them to become thinner, compromising their strength and ability to cut through tougher materials. Measure the thickness at various points to assess overall wear. Furthermore, check for rust or corrosion, which can weaken the material and lead to further degradation. Any signs of rust should prompt immediate action, as it can significantly shorten the lifespan of the implements. Lastly, consider the overall shape of the blades. Any bending or warping can hinder performance and should be addressed. Keeping a close eye on these aspects will help maintain the efficiency of your cutting equipment. Adjusting the Deck Height for Precision

Achieving the ideal cutting height is essential for maintaining a healthy and visually appealing lawn. Proper adjustment ensures that your grass is cut evenly, promoting growth and preventing damage to the turf. Understanding the factors that influence height settings is crucial for optimal results. To begin the adjustment process, it is important to familiarize yourself with the specific settings available on your equipment. Each model may have different mechanisms for altering the height, often involving a simple lever or a set of pins. Regularly checking these settings can help achieve the desired length for your grass, whether it requires a shorter trim or a more extended cut. When making adjustments, consider the type of grass in your yard, as different species thrive at varying heights. For instance, cool-season grasses often benefit from being kept slightly taller than warm-season varieties. Additionally, seasonal changes may necessitate further modifications to maintain the health and appearance of your lawn. Inspecting Mower Deck Bearings Regularly

Regular examination of rotational components is crucial for maintaining optimal performance and prolonging the lifespan of your equipment. This process involves checking for any signs of wear, damage, or insufficient lubrication that could hinder functionality. By prioritizing these inspections, you can prevent unexpected breakdowns and ensure a smoother operation. Importance of Routine ChecksConducting periodic assessments allows you to identify potential issues early, reducing the risk of extensive repairs. Neglecting these checks can lead to significant downtime and costly replacements. A proactive approach promotes reliability and efficiency in your machinery. Steps for Effective Inspection

To carry out a thorough inspection, follow these steps:

Tips for Maintaining the Discharge ChuteProper care of the discharge chute is essential for optimal performance and longevity. Regular maintenance not only ensures effective grass dispersal but also prevents clogs and potential damage. Here are some practical tips to keep in mind.

Following these maintenance tips can significantly enhance the efficiency and lifespan of the discharge chute, ensuring that your equipment remains in excellent working condition. Protecting the Deck from Rust and Damage

Maintaining the condition of your outdoor equipment is crucial to ensure its longevity and performance. One of the primary concerns is to prevent deterioration caused by moisture and wear. Implementing preventive measures can significantly extend the life of the equipment and enhance its efficiency. Regular CleaningKeeping the surface clean is essential. After each use, remove any debris such as grass clippings, dirt, and leaves. This prevents moisture from accumulating and leading to corrosion. Use a brush and a garden hose to thoroughly wash the surface, ensuring all residue is eliminated. Protective Coatings

Applying protective treatments can safeguard the surface from rust. Consider using a high-quality sealant or rust-resistant paint. These coatings create a barrier against moisture and other damaging elements. Be sure to follow the manufacturer’s instructions for optimal results.

Upgrading Deck Parts for Better Performance

Enhancing the components of your lawn care equipment can significantly improve its efficiency and effectiveness. By focusing on specific upgrades, you can ensure a smoother operation and better results in maintaining your outdoor space. Consider the following enhancements to boost your machine’s functionality:

Each of these modifications can contribute to a noticeable improvement in performance, making your maintenance tasks more efficient and enjoyable. |