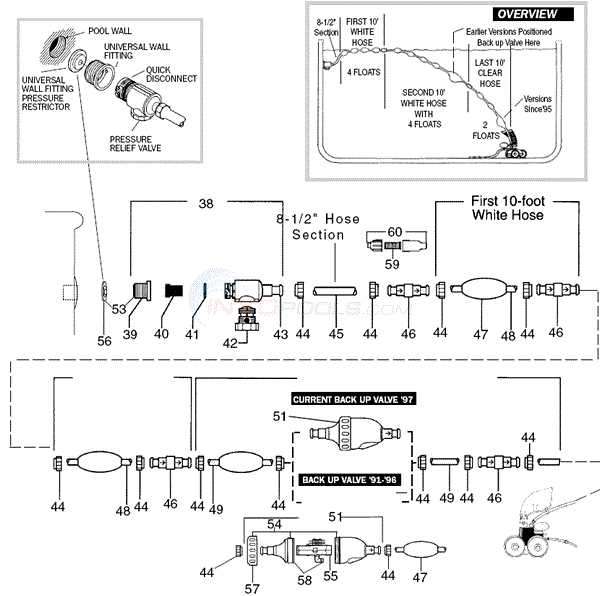

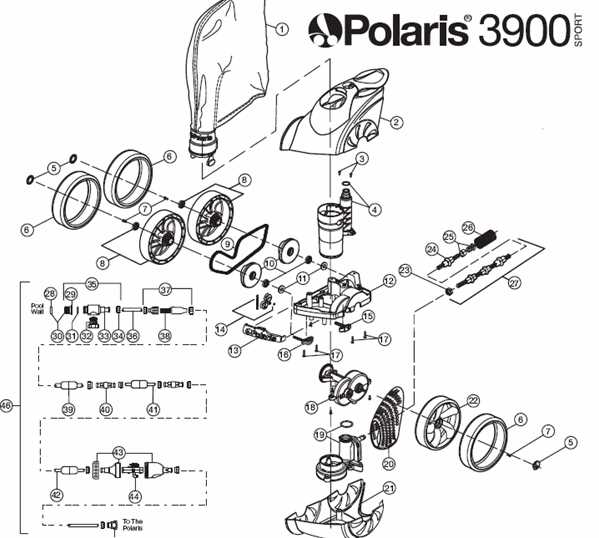

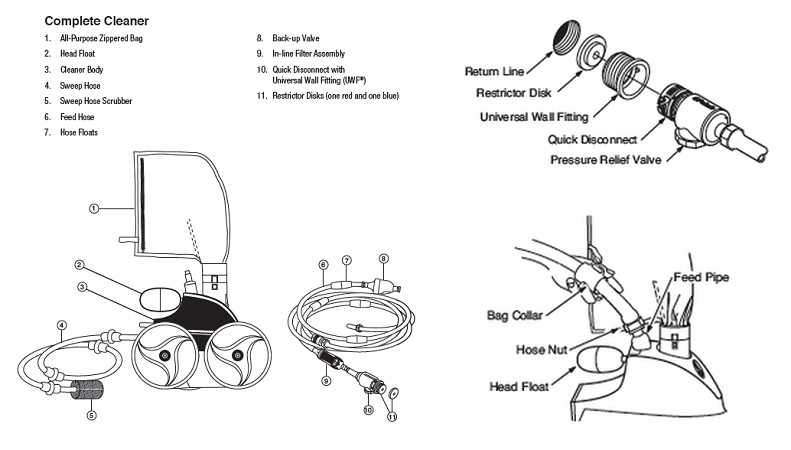

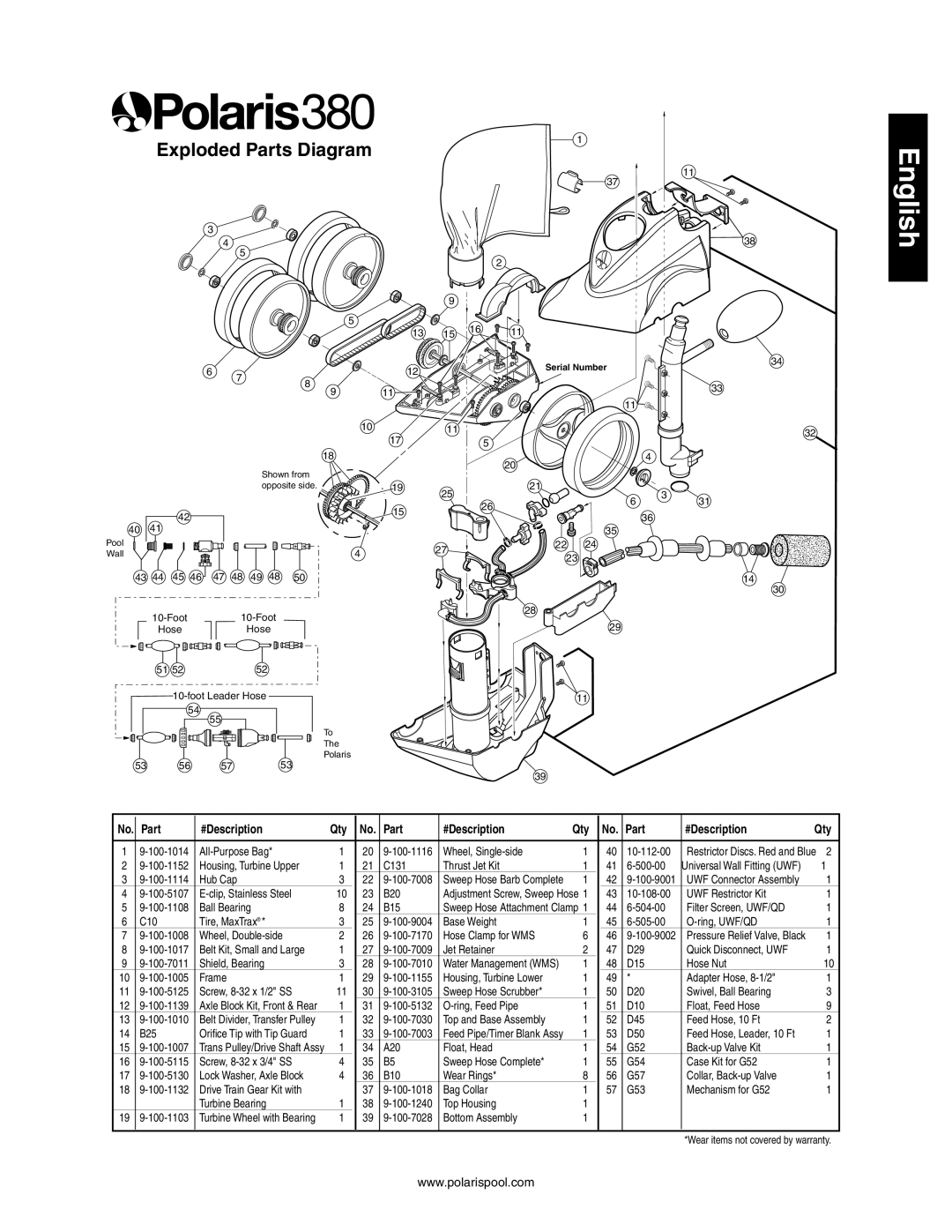

Polaris 380 Parts Diagram Overview

Understanding the various elements that make up a specific model is crucial for effective maintenance and repair. By examining the intricacies of these components, one can ensure optimal performance and longevity. This section aims to provide a clear visual representation of the intricate assembly, allowing users to identify and locate individual pieces with ease.

Whether you’re a seasoned technician or a novice enthusiast, having access to a comprehensive illustration can significantly streamline the troubleshooting process. The graphical layout serves as a valuable reference, helping to clarify the relationships between different segments and their respective functions within the entire system.

With this detailed overview, users can gain insight into the construction and assembly of the unit, facilitating informed decisions when it comes to repairs or replacements. Such knowledge empowers individuals to tackle maintenance tasks confidently, ultimately enhancing the overall efficiency of their equipment.

This section aims to explore the essential elements that contribute to the overall functionality of a specific model in the recreational vehicle industry. Understanding these components is crucial for maintenance and repair, ensuring optimal performance and longevity.

The primary elements of this model include:

- Engine System

- Transmission Mechanism

- Steering Assembly

- Cooling System

- Electrical Components

Each of these parts plays a vital role in the operation of the vehicle. An in-depth look at each system will help users identify issues and perform necessary repairs effectively.

Key Components Overview

- Engine System: The powerhouse that drives the vehicle, responsible for generating the necessary energy for movement.

- Transmission Mechanism: This component transfers power from the engine to the wheels, affecting speed and torque.

- Steering Assembly: Allows for navigation and control, ensuring the vehicle responds accurately to the driver’s inputs.

- Cooling System: Maintains optimal operating temperatures for the engine, preventing overheating during use.

- Electrical Components: Supports various functions, from ignition to lighting, critical for safety and functionality.

Understanding these systems and their interconnections is key to effective troubleshooting and repair. By familiarizing oneself with these components, users can enhance their technical knowledge and ensure their vehicles operate at peak efficiency.

Essential Parts Overview

This section provides a comprehensive look at the vital components required for the optimal functioning of a specific type of recreational vehicle. Understanding these elements is crucial for maintenance and performance enhancement, ensuring longevity and reliability.

Key Components

Each component plays a significant role in the overall system. Recognizing the function and interconnection of these elements can aid in troubleshooting and repairs. Here are some of the primary components commonly found in this type of vehicle:

| Component | Description |

|---|---|

| Engine | The heart of the vehicle, providing the necessary power for operation. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, enabling movement. |

| Suspension | Absorbs shocks and provides stability, enhancing ride comfort. |

| Steering System | Allows for maneuverability and control of the vehicle’s direction. |

| Braking System | Critical for safety, enabling the operator to slow down or stop the vehicle. |

Importance of Regular Maintenance

Regular upkeep of these essential components is vital for ensuring peak performance and safety. Addressing wear and tear promptly can prevent more significant issues and extend the lifespan of the vehicle.

Exploring the Engine Layout

Understanding the configuration of an engine is crucial for effective maintenance and performance optimization. A well-structured engine layout facilitates the efficient operation of various components, ensuring reliability and longevity. This section delves into the essential elements that make up the overall engine architecture.

- Power Unit: The central component responsible for converting fuel into mechanical energy.

- Cylinders: These are the chambers where the fuel-air mixture is combusted, driving the engine’s pistons.

- Pistons: Moving within the cylinders, pistons translate the force of combustion into rotational energy.

- Crankshaft: This element converts the linear motion of the pistons into rotational motion, which ultimately powers the vehicle.

- Valvetrain: A system that controls the timing and operation of the intake and exhaust valves, ensuring optimal airflow into and out of the cylinders.

- Cooling System: Essential for regulating the engine temperature and preventing overheating, thereby maintaining performance efficiency.

Each of these components plays a vital role in the engine’s functionality, and understanding their arrangement can significantly enhance troubleshooting and repair efforts. By familiarizing oneself with the layout, one can better appreciate the intricate mechanics of engine operation.

Detailed Electrical System Breakdown

The electrical system in recreational vehicles plays a crucial role in ensuring optimal performance and functionality. Understanding its components and their interconnections can enhance maintenance and troubleshooting processes. This section aims to provide a comprehensive overview of the essential elements within this intricate network.

At the core of the electrical framework is the battery, which serves as the primary power source. It supplies energy to various systems, including the ignition and lighting. Adjacent to the battery is the starter motor, responsible for initiating the engine’s operation. This component requires a significant amount of power, underscoring the importance of having a reliable battery.

Another vital element is the wiring harness, which acts as the nervous system, transmitting electrical signals between various components. This harness ensures that the current flows seamlessly, enabling functions such as the dashboard indicators and electronic controls. Regular inspection of the wiring is essential to prevent issues caused by wear and tear.

Furthermore, the fuses and relays are integral to protecting the system from overloads and ensuring that electrical circuits operate efficiently. In the event of a malfunction, these components help isolate the problem, making diagnostics easier. Understanding their locations and functions can significantly aid in troubleshooting.

In summary, the electrical system is a complex interplay of various components, each contributing to the overall functionality of the vehicle. Regular maintenance and a solid understanding of these elements can enhance both performance and longevity.

Analyzing the Steering Mechanism

The steering mechanism is a crucial component that facilitates the directional control of various vehicles. Understanding its design and functionality is essential for ensuring optimal performance and safety. This section delves into the intricacies of the steering system, exploring how different elements work together to provide smooth and responsive navigation.

| Component | Description | Function |

|---|---|---|

| Steering Wheel | The primary interface for the driver, allowing for direct input in vehicle direction. | Transmits driver input to the steering system. |

| Steering Column | A shaft connecting the steering wheel to the gear mechanism. | Facilitates the transfer of motion from the wheel to the steering gears. |

| Gear Mechanism | Comprises gears that amplify the movement of the steering wheel. | Converts rotational input into lateral movement of the vehicle. |

| Linkage System | Network of rods and joints that connects the gear mechanism to the wheels. | Transmits movement to the wheels, enabling directional changes. |

| Steering Knuckles | Components that house the wheel hub and allow for pivoting. | Facilitate the turning of the wheels in response to steering input. |

In summary, the steering mechanism’s efficiency hinges on the seamless interaction of its components. Each part plays a vital role in translating the driver’s intentions into precise movements, which are essential for effective vehicle maneuvering.

Insights into Suspension Assembly

The suspension assembly plays a crucial role in enhancing the overall performance and comfort of vehicles designed for off-road adventures. This component system is engineered to absorb shocks and vibrations, providing a smoother ride even in challenging terrains. Understanding the intricacies of the suspension system is essential for maintaining optimal handling and stability.

Key Components of the Suspension System

At the heart of the suspension assembly are several key components that work in harmony. These include the shock absorbers, springs, and control arms. Shock absorbers are designed to dampen the impact of rough surfaces, while springs support the vehicle’s weight and ensure stability. Control arms connect the suspension to the vehicle frame, allowing for controlled movement and flexibility.

Maintenance Tips for Longevity

To prolong the lifespan of the suspension system, regular inspections and maintenance are recommended. Checking for signs of wear and tear, such as leaks or unusual noises, can help identify issues early. Additionally, keeping the suspension components clean and properly lubricated can significantly enhance their performance and durability.

Key Features of the Hull

The design of the hull plays a crucial role in determining the overall performance and stability of watercraft. It is essential to understand the characteristics that contribute to a vessel’s efficiency on the water. A well-constructed hull enhances maneuverability, buoyancy, and durability, making it a vital component for any aquatic vehicle.

Hydrodynamic Shape: The hull’s shape is engineered to reduce drag, allowing for smoother navigation through water. A streamlined form aids in increasing speed while conserving energy, which is beneficial for long-distance travel.

Material Composition: The materials used in hull construction significantly impact its strength and weight. Lightweight yet sturdy materials are preferred to ensure resilience against the elements while enhancing overall agility on the water.

Stability Features: Stability is a key aspect of hull design, as it ensures a safe and comfortable experience for passengers. Various features, such as a wider base and strategic weight distribution, contribute to a vessel’s steadiness during operation.

Maintenance Considerations: The hull’s design also influences maintenance requirements. Smooth surfaces are easier to clean and less prone to accumulating debris, reducing the effort needed to maintain optimal performance.

Overall, understanding these key features helps in appreciating the intricate design and engineering that goes into creating a functional and reliable watercraft hull.

Maintaining the Exhaust System

The exhaust system is crucial for optimal performance and efficiency in any vehicle. Proper upkeep ensures that emissions are managed effectively while enhancing overall functionality. Regular inspection and maintenance can prevent costly repairs and extend the lifespan of the components involved.

To maintain the exhaust system effectively, consider the following practices:

- Regular Inspections: Check for any signs of wear or damage, including cracks, rust, or loose fittings.

- Cleaning: Remove any debris or buildup from the exhaust pipes and muffler to ensure unobstructed flow.

- Gasket and Seal Checks: Inspect gaskets and seals for leaks, as these can lead to inefficient exhaust management.

Furthermore, adhering to a maintenance schedule can help identify potential issues before they escalate. Be sure to consult the manufacturer’s recommendations for specific intervals and procedures related to the exhaust system’s upkeep.

Commonly Replaced Components

When maintaining a recreational vehicle, several components frequently require attention due to wear and tear over time. Understanding which elements are often replaced can help owners ensure optimal performance and longevity of their machines. This section outlines the most commonly swapped parts that enthusiasts typically encounter during routine maintenance.

Key Elements for Replacement

Among the critical components that often need replacement are seals, gaskets, and filters. These parts are essential for maintaining the vehicle’s integrity and ensuring smooth operation. Seals are particularly vital in preventing leaks, while filters ensure that fluids remain clean and uncontaminated. Regularly checking and replacing these elements can prevent more significant issues down the line.

Additional Considerations

In addition to seals and filters, other items such as belts and hoses are also frequently replaced. Belt degradation can lead to performance issues, while hoses can develop cracks over time, risking fluid leaks. Regular inspections can help identify wear on these components, allowing for timely replacements and reducing the likelihood of unexpected breakdowns.

Installation Tips for Parts

When it comes to assembling components for your machinery, following a few key strategies can ensure a seamless and efficient process. Understanding the layout and functionality of each element is essential, as it allows for proper alignment and enhances the overall performance of the equipment.

Preparation Steps

Before starting the installation, gather all necessary tools and components. Ensure that you have a clean workspace to avoid any mix-ups. It’s advisable to review the manual or guides related to the specific assembly process, as this will provide insights into any special requirements or precautions.

Installation Process

Begin by securely fixing the first component in place, ensuring that it aligns perfectly with the designated areas. Gradually add other pieces, verifying that each fits correctly before proceeding. Use the recommended fasteners and tighten them to the specified torque. Always double-check connections and fittings to prevent any issues during operation.

Repair Techniques for Polaris 380

Maintaining and restoring aquatic vehicles involves understanding various methods to address common issues. This section explores effective approaches to repair and enhance the performance of your unit, ensuring it operates smoothly and efficiently.

Common Issues and Solutions

- Leak Repairs: Check for leaks regularly. Use sealants designed for aquatic environments to fix minor leaks. For significant leaks, consider replacing damaged components.

- Mechanical Failures: Regularly inspect moving parts for wear and tear. Lubricate necessary parts and replace worn components to avoid further damage.

- Electrical Troubles: Ensure all electrical connections are secure. Use a multimeter to diagnose electrical issues and replace faulty wiring or connectors as needed.

Preventive Maintenance Tips

- Conduct routine checks before and after usage to identify potential problems early.

- Store the unit in a dry, covered space to protect it from harsh weather conditions.

- Use high-quality maintenance products specifically designed for your vehicle type.

Aftermarket Parts vs. OEM

When it comes to maintaining or upgrading your vehicle, one critical decision involves choosing between original equipment manufacturer (OEM) components and aftermarket alternatives. Each option has its distinct advantages and considerations that can influence performance, cost, and overall satisfaction.

Understanding OEM Components

OEM components are manufactured by the original maker of the vehicle, ensuring that they meet the exact specifications set forth during production. This consistency often translates to higher reliability and compatibility. Customers who prioritize quality and a guarantee of fit typically lean towards OEM options, as these parts are designed specifically for the vehicle’s make and model.

Exploring Aftermarket Alternatives

Aftermarket alternatives provide a range of options from various manufacturers, which can lead to more competitive pricing and availability. While some aftermarket components may lack the precision of their OEM counterparts, many reputable brands offer high-quality products that can enhance performance. Consumers seeking customization or improved functionality may find that aftermarket parts suit their needs better than original components.

Benefits of Using Diagrams

Visual representations serve as powerful tools for enhancing understanding and communication. They break down complex information into manageable parts, making it easier for individuals to grasp intricate concepts and workflows. Whether for instructional purposes or to illustrate relationships, these visuals play a crucial role in facilitating effective learning and collaboration.

Improved Comprehension

Utilizing visual aids can significantly enhance comprehension by presenting information in a clear and organized manner. Viewers can quickly identify key components and their interactions, reducing the cognitive load associated with processing textual data. This clarity enables users to focus on the essential elements without being overwhelmed.

Enhanced Collaboration

When teams work together, visuals provide a common reference point that fosters collaboration. By sharing illustrations, group members can discuss specific elements and propose changes or solutions more efficiently. This collective approach encourages participation and ensures that all voices are heard, ultimately leading to better decision-making.