Comprehensive Stihl 015L Parts Diagram Guide

Understanding the internal configuration of mechanical systems is crucial for maintaining and repairing equipment efficiently. Each device, no matter how complex, is built from essential elements that work in harmony to deliver optimal performance. By exploring the layout of these crucial elements, users can gain insight into how to approach repairs and ensure long-term durability.

In this guide, we delve into the specific arrangement of various components that make up a well-known tool in its category. The focus will be on how each element connects, interacts, and functions within the system, allowing enthusiasts and professionals alike to perform routine maintenance or troubleshoot issues with greater confidence.

For those who are familiar with repair work, this resource will offer detailed guidance, providing a clear view of the most important sections and their role in the overall operation. Whether you’re looking to understand the core structure or locate specific areas for adjustments, this guide will serve as a valuable tool.

Overview of the Stihl 015L Components

This section provides an introduction to the essential mechanical elements that ensure the functionality of a well-known model of chainsaw. Understanding the primary components and how they interact is crucial for maintaining optimal performance and extending the equipment’s lifespan.

Key Mechanical Elements

The internal structure consists of several interconnected parts that work in unison to drive the tool. These include a durable engine, designed for reliable power output, and a cutting mechanism engineered for precise operation. The design of each component plays a vital role in ensuring efficient performance during operation.

Maintenance and Performance

Regular upkeep of these elements is essential to prevent wear and ensure smooth functioning. The engine, for instance, requires periodic checks to maintain its power and reliability, while the cutting mechanism must be kept sharp to ensure accuracy. Each part contributes to the overall durability and efficiency of the tool, making routine maintenance a priority for any user.

Understanding the Engine Layout

The internal combustion system of this tool is designed with efficiency and ease of maintenance in mind. Its structure, consisting of several key components, allows for reliable performance and straightforward upkeep. In this section, we’ll explore the main elements and their arrangement within the engine, ensuring optimal function during operation.

- Cylinder Assembly: This section forms the heart of the machine, where fuel combustion generates the power needed for the tool’s function.

- Crankshaft Mechanism: Connected to the cylinder, the crankshaft transforms the linear motion of the piston into rotational energy, driving the rest of the system.

- Carburetor Unit: Responsible for mixing air and fuel in the correct proportions, this component ensures that the engine runs smoothly under various conditions.

- Ignition System: This crucial part initiates the combustion process by creating a spark that ignites the fuel mixture within the cylinder.

- Cooling Components: A combination of fins and airflow systems works to regulate the temperature, preventing overheating during extended use.

- Exhaust Port: As combustion occurs, this outlet allows the engine to expel gases, ensuring continuous operation and maintaining efficiency.

Each of these components plays a vital role in ensuring the reliable and effective operation of the machine. A proper understanding of their layout helps in troubleshooting and maintaining long-term performance.

Examining the Fuel System of the 015L Model

The fuel system plays a crucial role in ensuring the proper operation of small engines, delivering the necessary fuel-air mixture for optimal combustion. In this section, we will explore the various components involved in this system, focusing on how they interact to provide a smooth and efficient operation. Understanding each part and its function is essential for diagnosing and resolving performance issues.

The following table provides an overview of the key elements and their respective roles in the system:

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Carburetor | Mixes fuel and air in the proper ratio for combustion. | ||||||||

| Fuel Tank | Stores the liquid fuel required for engine operation. | ||||||||

| Fuel Filter | Removes impurities from the fuel before it enters the carburetor. | ||||||||

| Fuel Line | Transports fuel from the tank to the carburetor. | ||||||||

| Primer Bulb | Helps prime the carburetor with fuel before starting the engine. |

| Component | Function |

|---|---|

| Ignition Coil | Converts low voltage from the power source into the high voltage needed for the spark plug. |

| Spark Plug | Delivers the spark required to ignite the air-fuel mixture in the combustion chamber. |

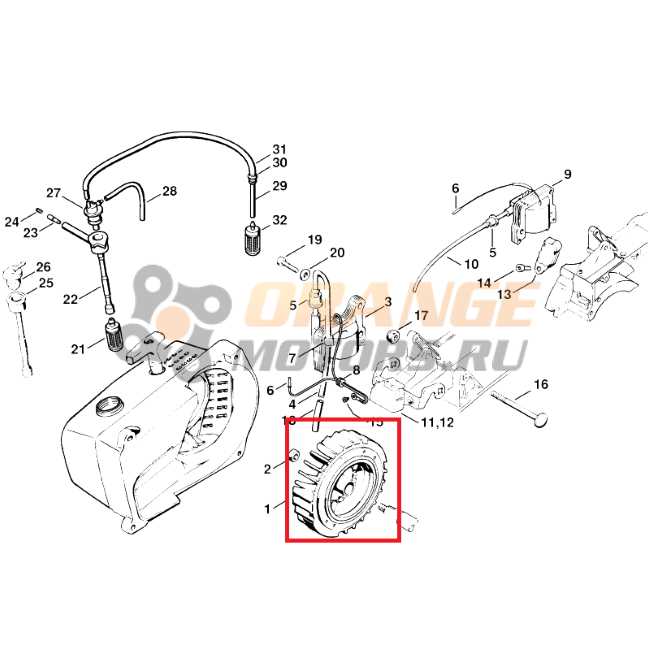

| Flywheel | Maintains momentum in the engine and helps generate the electrical current for the ignition system. |

Maintaining the Ignition System

Regular maintenance of these components is essential for reliable operation. Periodically checking the condition of the coil, cleaning the spark plug, and inspecting the flywheel can prevent ignition issues and prolong the lifespan of your equipment. Keeping the ignition assembly in

Chain Mechanism and Adjustments for Stihl 015L

The cutting system plays a crucial role in ensuring effective operation and safety. Proper maintenance and periodic adjustments of this component can significantly enhance performance and extend its longevity. Understanding how the mechanism works and knowing the correct procedures for adjustments are essential for optimal results.

Understanding the Chain Tension

Maintaining correct tension is critical to both safety and efficiency. Too much slack in the cutting link can lead to decreased accuracy and potential safety hazards, while overtightening could cause unnecessary wear. The tension should always be set just right to allow smooth movement without binding.

Steps to Adjust the Chain

Begin by locating the adjustment screw on the side of the unit. Loosen the securing elements slightly, allowing for minor movements of the cutting link. Turn the adjustment screw in small increments, checking the tension after each turn. The goal is to achieve a balance where the link rests firmly on the guide without being too tight or too loose.

Once the desired tension is achieved, securely tighten the securing elements and ensure all components are aligned properly for smooth operation.

Analyzing the Air Filter and Intake Assembly

The air filtration and intake system play a crucial role in the performance and efficiency of small engines. This assembly is designed to ensure that the engine receives clean air, which is vital for optimal combustion and overall functionality. A well-maintained intake system helps in preventing contaminants from entering the engine, thereby enhancing its lifespan and operational capabilities.

Importance of the Air Filter

The air filter serves as the first line of defense against dust, debris, and other pollutants that could compromise engine performance. Regular inspection and replacement of the air filter are essential practices to maintain the engine’s efficiency. A clogged or dirty filter restricts airflow, leading to reduced power output and increased fuel consumption.

Components of the Intake Assembly

The intake assembly consists of several critical components, including the air filter housing, intake manifold, and various gaskets. Understanding the functionality of each part is essential for effective maintenance. Proper sealing and alignment of these components prevent air leaks and ensure that the engine operates at its best, providing smooth performance and reliability.

Exploring the Carburetor Setup of the 015L

The carburetor plays a vital role in the efficient operation of any small engine, ensuring the correct fuel-to-air ratio for optimal performance. In this section, we will delve into the specifics of the carburetor arrangement found in a well-known model. Understanding its components and functionality can significantly enhance maintenance practices and troubleshooting efforts.

Key Components and Their Functions

At the heart of the fuel delivery system is the carburetor, which comprises several essential components. The float chamber regulates the fuel level, while the throttle plate controls the air intake, allowing for precise adjustments based on engine demand. Additionally, the mixture screw fine-tunes the fuel-air ratio, impacting acceleration and power output. Familiarity with these elements is crucial for effective maintenance and repair.

Maintenance Tips for Optimal Performance

Regular upkeep of the carburetor is essential for maintaining engine efficiency. Cleaning the jets and passages prevents fuel blockage, ensuring smooth operation. It’s advisable to check and replace gaskets and O-rings as needed to prevent leaks. Furthermore, adjustments to the mixture screw should be performed cautiously, as they directly influence engine performance and emissions. By adhering to these maintenance practices, users can extend the lifespan and reliability of their equipment.

Insights into the Oil Pump Assembly

The oil pump assembly is a crucial component in maintaining the optimal performance of small engines. Its primary function is to ensure a consistent supply of lubricant to various moving parts, reducing friction and wear. Understanding the intricacies of this assembly can enhance maintenance practices and improve engine longevity.

Key Components of the Oil Pump Assembly

- Oil Pump Body: The main housing that contains all the essential parts.

- Rotor: A rotating element that helps move oil through the system.

- Drive Shaft: Connects the pump to the engine, providing the necessary motion.

- Filter: Prevents contaminants from entering the lubrication system.

- Check Valve: Ensures that oil flows in the correct direction, preventing backflow.

Importance of Regular Maintenance

To ensure the efficient operation of the oil pump assembly, regular maintenance is essential. Neglecting this component can lead to several issues, including:

- Inadequate lubrication, resulting in increased wear.

- Overheating due to insufficient oil flow.

- Potential engine failure from oil starvation.

By regularly inspecting and servicing the oil pump assembly, users can significantly extend the life of their engines and enhance overall performance.

Detailed View of the Clutch and Drive System

The clutch and drive mechanism plays a critical role in the overall functionality of outdoor power tools. This system facilitates the transfer of energy from the engine to the cutting attachment, ensuring efficient operation during use. Understanding the components and their interactions can enhance maintenance practices and improve the tool’s performance.

The main elements of the clutch and drive system include:

- Clutch Assembly: This component engages and disengages the power transfer to the cutting tool. It typically consists of various parts, such as springs and shoes, that work together to regulate the connection based on engine speed.

- Drive Shaft: The drive shaft transmits rotational force from the engine to the cutting attachment. Its durability is vital for maintaining efficient energy transfer.

- Flywheel: The flywheel stabilizes the engine’s operation and assists in maintaining momentum, contributing to smoother engagement of the clutch system.

- Gears: Gears may be utilized to adjust the speed and torque delivered to the cutting tool, enhancing its effectiveness in various applications.

Maintaining these components is essential for optimal performance. Regular inspections can prevent wear and tear, ensuring a reliable operation over time. Key maintenance tips include:

- Check the clutch for signs of wear, such as cracks or overheating.

- Inspect the drive shaft for any bends or damage.

- Ensure that the flywheel is securely attached and free from debris.

- Lubricate gears as necessary to minimize friction and wear.

By understanding the intricacies of the clutch and drive system, operators can make informed decisions regarding maintenance and troubleshooting, ultimately prolonging the lifespan of their equipment.

Replacing the Recoil Starter Mechanism

When the recoil starter mechanism fails, it can hinder the functionality of your tool, making it difficult to start the engine. This section will guide you through the process of replacing this essential component, ensuring that your device operates smoothly and efficiently once again.

Begin by ensuring the engine is turned off and cool to the touch. Gather the necessary tools, including a screwdriver and a replacement starter assembly. Carefully remove any screws securing the starter cover, then lift it away to expose the mechanism.

Next, detach the old starter by loosening the retaining screws and disconnecting any attached components. Take care to observe the arrangement of parts, as this will assist during reinstallation. Once the old starter is removed, position the new mechanism in place, aligning it correctly with the mounting holes.

Secure the new starter with screws, ensuring they are tightened adequately to prevent movement during operation. Afterward, reattach the starter cover, making sure it fits snugly. Finally, perform a test start to confirm that the replacement was successful and the engine starts without issues.

Brake and Safety Mechanisms on the Stihl 015L

Effective braking and safety systems are essential components in any cutting tool, ensuring the operator’s security during use. These features are designed to minimize the risk of accidents while maximizing efficiency. The integration of advanced technology provides both ease of use and a reliable experience, promoting confidence in operation.

Brake System Functionality

The braking mechanism serves as a crucial element in halting the chain’s movement when needed. When engaged, this system immediately reduces the risk of injury by stopping the chain within a fraction of a second. This rapid response is vital for maintaining control over the equipment, particularly during unexpected situations.

Safety Features for Operator Protection

In addition to braking systems, various safety features enhance the overall protection of the user. These include mechanisms that prevent accidental starts and ensure secure handling during operation. By adhering to strict safety standards, these features contribute significantly to a safer working environment, allowing for greater focus on the task at hand.

Maintenance Tips for the Muffler and Exhaust System

Proper upkeep of the exhaust components is crucial for optimal performance and longevity of your engine. Regular checks and cleaning can prevent blockages and ensure that the system operates efficiently, reducing harmful emissions and enhancing power output. This section outlines essential practices to maintain these vital parts effectively.

Regular Inspection

- Check for any visible cracks or damage to the muffler and exhaust pipes.

- Inspect the mounting brackets and connections for signs of wear or corrosion.

- Listen for unusual noises during operation, which may indicate issues within the exhaust system.

Cleaning Procedures

- Use a soft brush to remove any soot or debris from the muffler outlet and exhaust ports.

- Periodically flush the exhaust system with a suitable cleaner to eliminate buildup.

- Ensure that all gaskets and seals are intact to prevent leaks, replacing any that show signs of deterioration.

By following these maintenance tips, you can help ensure the exhaust system remains in excellent condition, promoting efficient engine function and extending the lifespan of your machinery.

Cleaning and Servicing the Spark Plug Unit

Proper maintenance of the ignition component is essential for optimal engine performance. Regular cleaning and servicing ensure that the spark plug operates efficiently, providing reliable ignition and enhancing the overall functionality of the machine.

To begin, remove the spark plug from the engine using the appropriate socket wrench. Inspect the spark plug for any signs of wear, such as corrosion, carbon buildup, or damaged electrodes. If the spark plug appears dirty, clean it using a wire brush or a specialized cleaning tool designed for this purpose.

After cleaning, check the gap between the electrodes with a feeler gauge. Adjust the gap if necessary, following the manufacturer’s specifications. A properly gapped spark plug is crucial for effective ignition. Once satisfied with the condition and gap, reinstall the spark plug, ensuring it is tightened securely but not overly tight, as this could damage the threads in the engine.

Finally, periodically inspect the spark plug as part of regular maintenance to ensure optimal engine performance. Address any issues immediately to prevent further complications and maintain the longevity of the equipment.