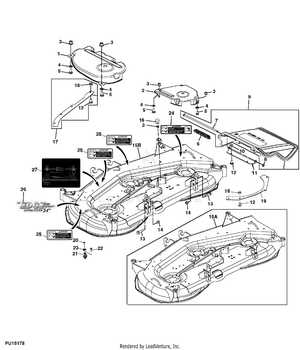

Understanding the 48c Mower Deck Parts Diagram

When it comes to maintaining your outdoor machinery, having a clear visual representation of its components can make a significant difference. A well-structured illustration helps users identify and comprehend the various elements that contribute to optimal performance. Whether you are troubleshooting an issue or performing routine maintenance, a comprehensive guide can enhance your understanding and efficiency.

Each segment plays a crucial role in the overall functionality of your machine. Recognizing the individual components not only aids in repairs but also empowers you to make informed decisions regarding upgrades and replacements. A detailed schematic allows enthusiasts and professionals alike to delve deeper into the mechanics, ensuring that every part operates harmoniously.

Furthermore, familiarizing yourself with the arrangement of these elements can save time and resources. By understanding how everything fits together, you can approach repairs with confidence and precision. This knowledge fosters a proactive attitude towards maintenance, ensuring your equipment remains in peak condition throughout its lifespan.

Understanding 48C Mower Deck Components

This section delves into the essential elements that contribute to the functionality of a lawn maintenance apparatus. Each component plays a crucial role in achieving efficient grass cutting and overall performance. Recognizing these elements helps users maintain their equipment effectively and ensure optimal operation.

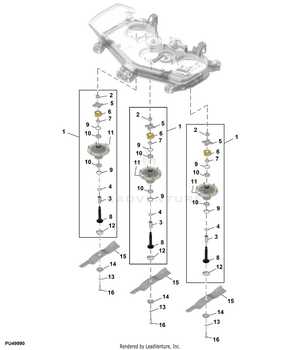

Blades are fundamental to the cutting process, designed to provide a clean and even finish. Understanding their configuration and maintenance is vital for achieving the best results. Regular sharpening and replacement are necessary to maintain performance and prevent damage.

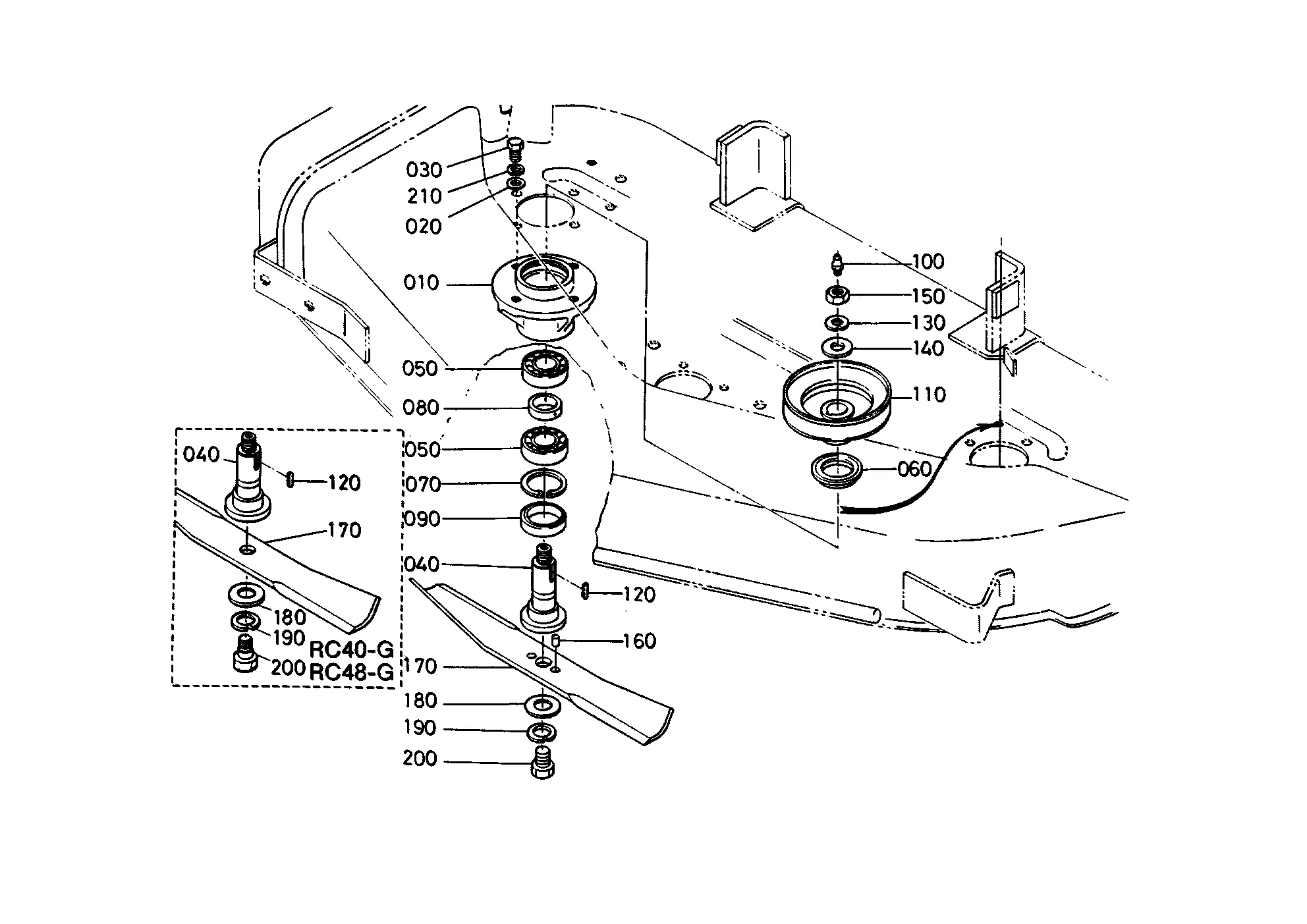

Spindles serve as the rotating mechanism that drives the blades. Their durability is crucial, as they must withstand significant wear and tear. Regular inspections can prevent costly repairs and ensure smooth operation.

Frame stability is essential for maintaining balance during operation. A sturdy structure not only supports other components but also enhances user safety. Regular checks for wear or damage can prolong the life of the entire assembly.

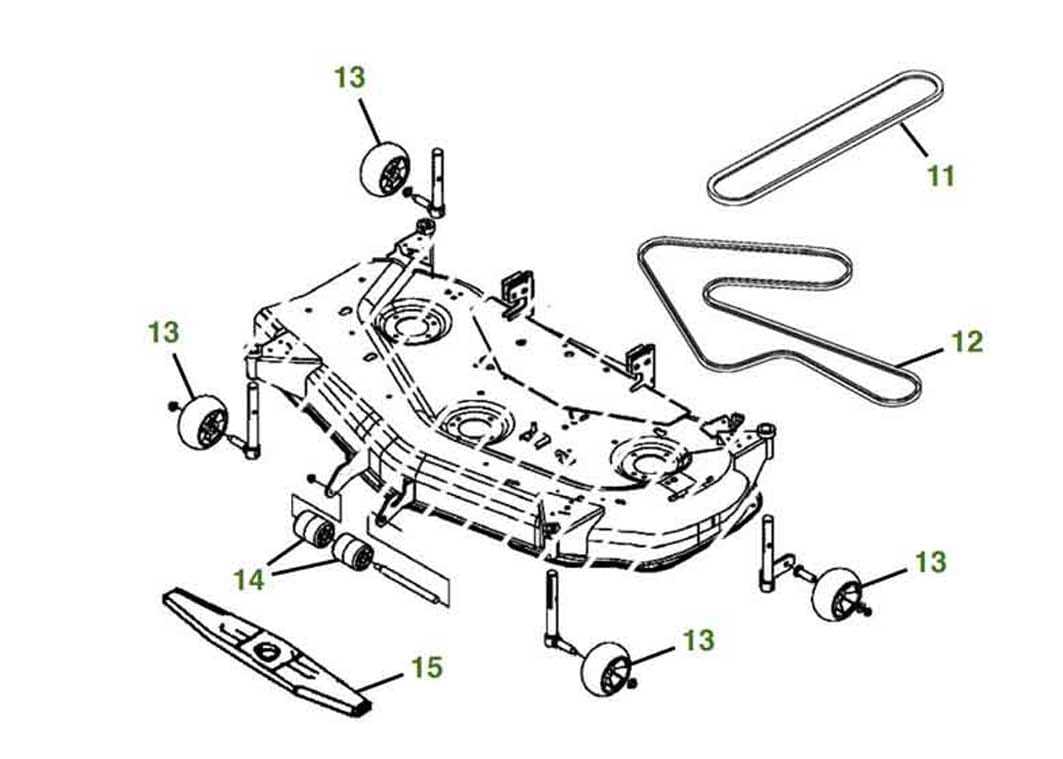

Belts transmit power from the engine to the blades. Ensuring proper tension and alignment can prevent slippage and improve efficiency. Routine maintenance of these components is critical to avoid interruptions during use.

Adjustable wheels provide versatility in height settings, allowing for tailored cutting lengths. Familiarizing oneself with their adjustment mechanism is essential for achieving the desired results across different grass types and conditions.

By comprehensively understanding these components, users can ensure their lawn maintenance equipment operates efficiently, leading to better results and longer service life.

Key Parts of the Mower Deck

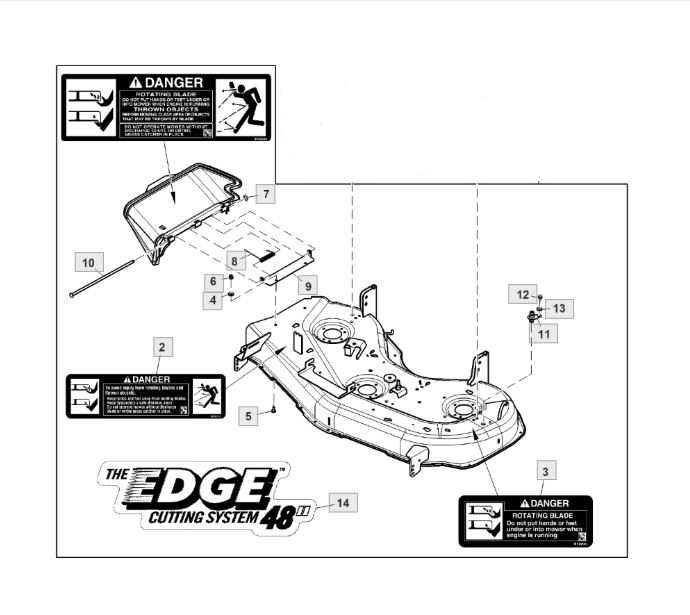

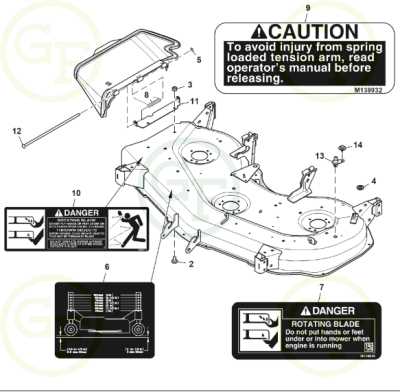

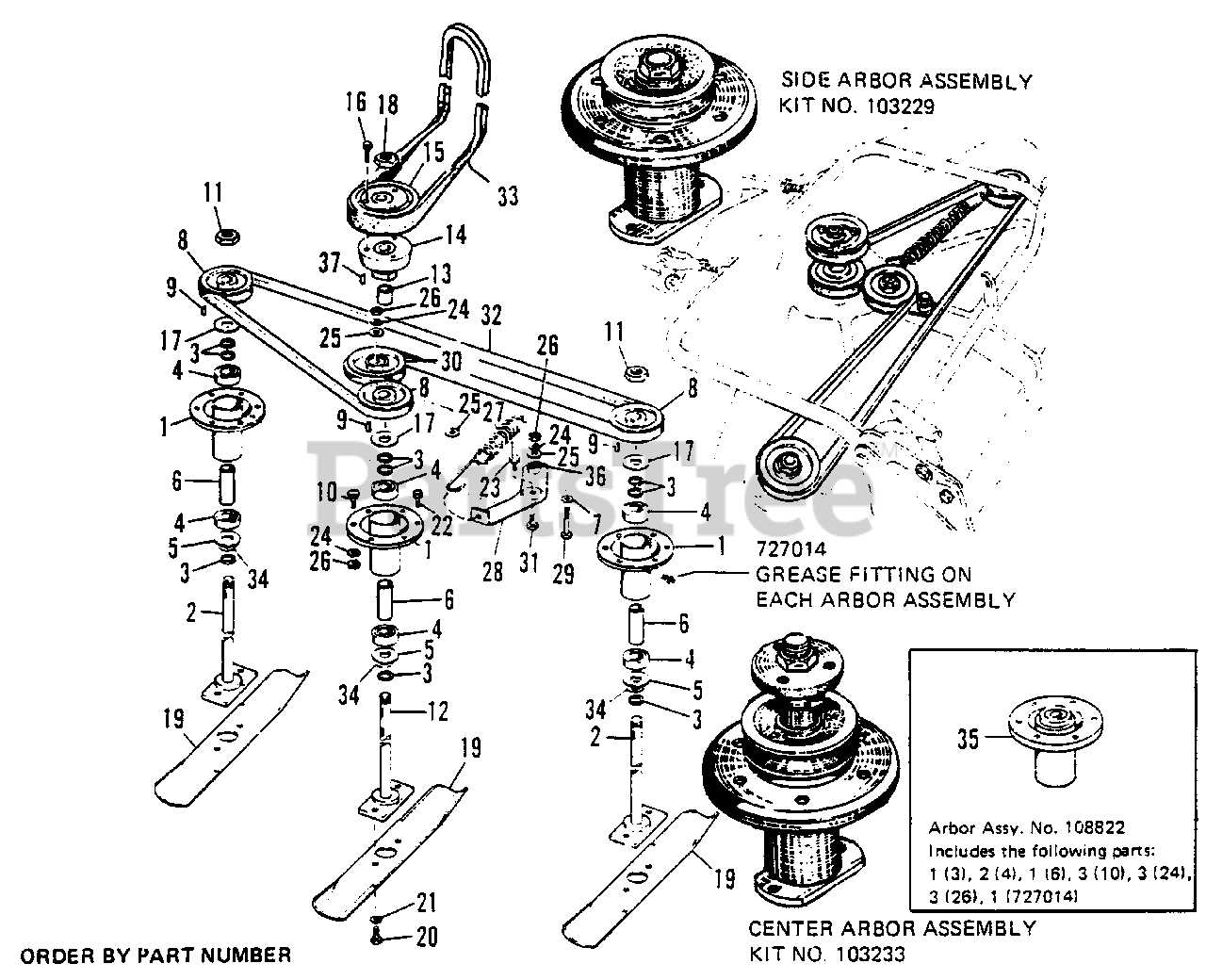

Understanding the essential components of a cutting mechanism is crucial for maintaining efficiency and performance. Each element plays a significant role in achieving a clean and even cut, ensuring optimal results during operation.

- Cutting Blades: These are the primary tools responsible for slicing through grass. Sharp, well-maintained blades contribute to a healthy lawn.

- Spindle Assembly: This unit houses the blades and enables them to rotate. Proper alignment and lubrication are vital for smooth functioning.

- Deck Housing: The structure that supports and protects the cutting elements. It also plays a role in directing grass clippings.

- Lift Mechanism: This system allows for adjusting the height of the cutting unit. It ensures versatility for different grass types and conditions.

- Support Wheels: These help in stabilizing the assembly during operation and can aid in maintaining consistent cutting height.

Each of these components interacts to create an effective cutting experience. Regular maintenance and checks can significantly enhance the longevity and performance of the entire mechanism.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in understanding complex machinery. They provide clear visual representations that help users identify components and their relationships, ensuring effective maintenance and repair.

Benefits of accurate illustrations include:

- Enhanced comprehension of assembly and disassembly processes.

- Reduction of errors during repairs, leading to increased safety.

- Streamlined communication among technicians and users.

Inaccurate representations can lead to:

- Confusion and misinterpretation of instructions.

- Increased downtime due to mistakes.

- Potential damage to equipment from improper handling.

Ultimately, reliable visual guides are essential for maintaining efficiency and longevity in machinery operations.

Common Issues with Mower Decks

Understanding typical challenges faced by grass-cutting equipment can enhance maintenance and prolong longevity. Various components may experience wear or malfunction, leading to suboptimal performance.

Frequent Problems

| Issue | Description |

|---|---|

| Uneven Cutting | This occurs when the blades are misaligned or worn, resulting in an inconsistent finish on the lawn. |

| Clogging | Debris accumulation can hinder performance, leading to poor efficiency and potential damage. |

Maintenance Tips

Regular inspection and cleaning are essential to avoid complications. Ensuring proper blade sharpness and alignment can significantly improve functionality and efficiency.

Identifying Wear and Tear Signs

Recognizing the signs of degradation is crucial for maintaining equipment functionality and longevity. Regular inspections can prevent minor issues from escalating into significant problems, ensuring optimal performance during use. Here are some key indicators to watch for.

Common Indicators

- Uneven Cuts: If the results are inconsistent, it may indicate dull blades or misalignment.

- Excessive Vibration: Unusual shaking can suggest worn components or imbalanced elements.

- Visible Damage: Cracks, dents, or rust can signal deterioration and require immediate attention.

- Noisy Operation: Increased sound levels might indicate friction or failing parts.

Maintenance Tips

- Regularly inspect and clean all moving parts.

- Sharpen or replace cutting tools as needed.

- Lubricate components to reduce wear and friction.

- Store equipment properly to avoid environmental damage.

By being vigilant and proactive, you can extend the lifespan of your machinery and maintain its efficiency, ensuring it performs at its best when needed.

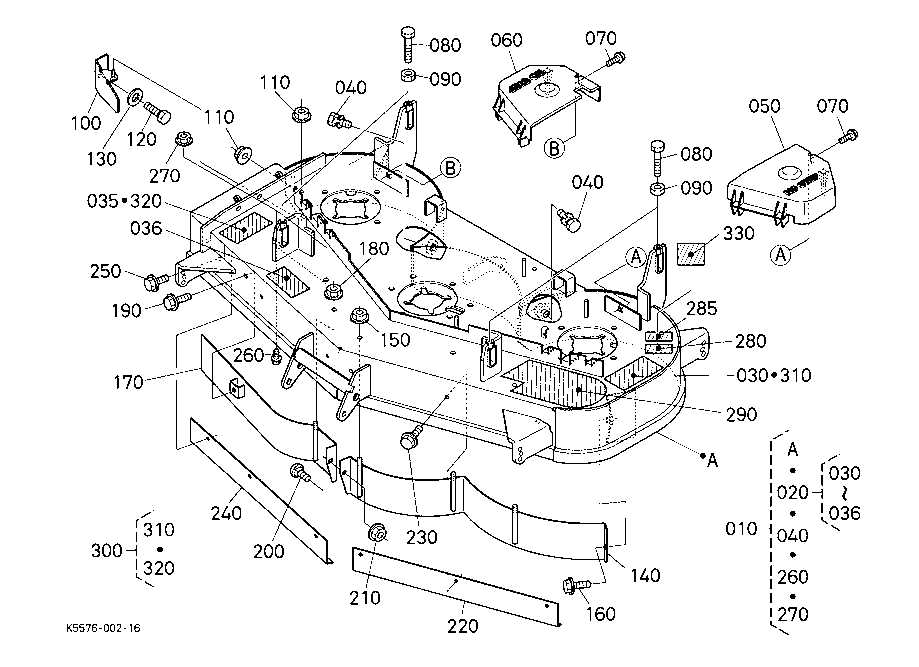

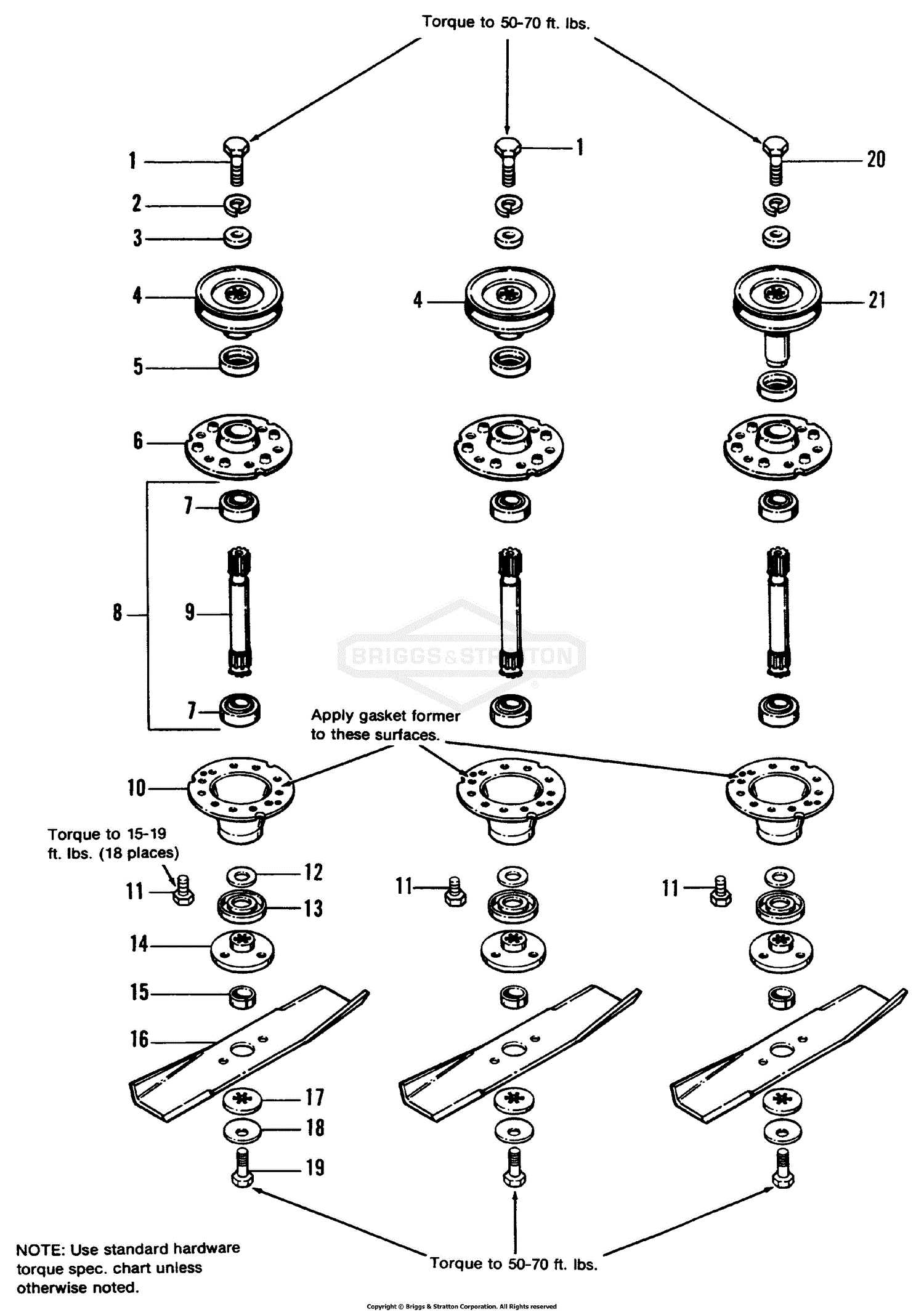

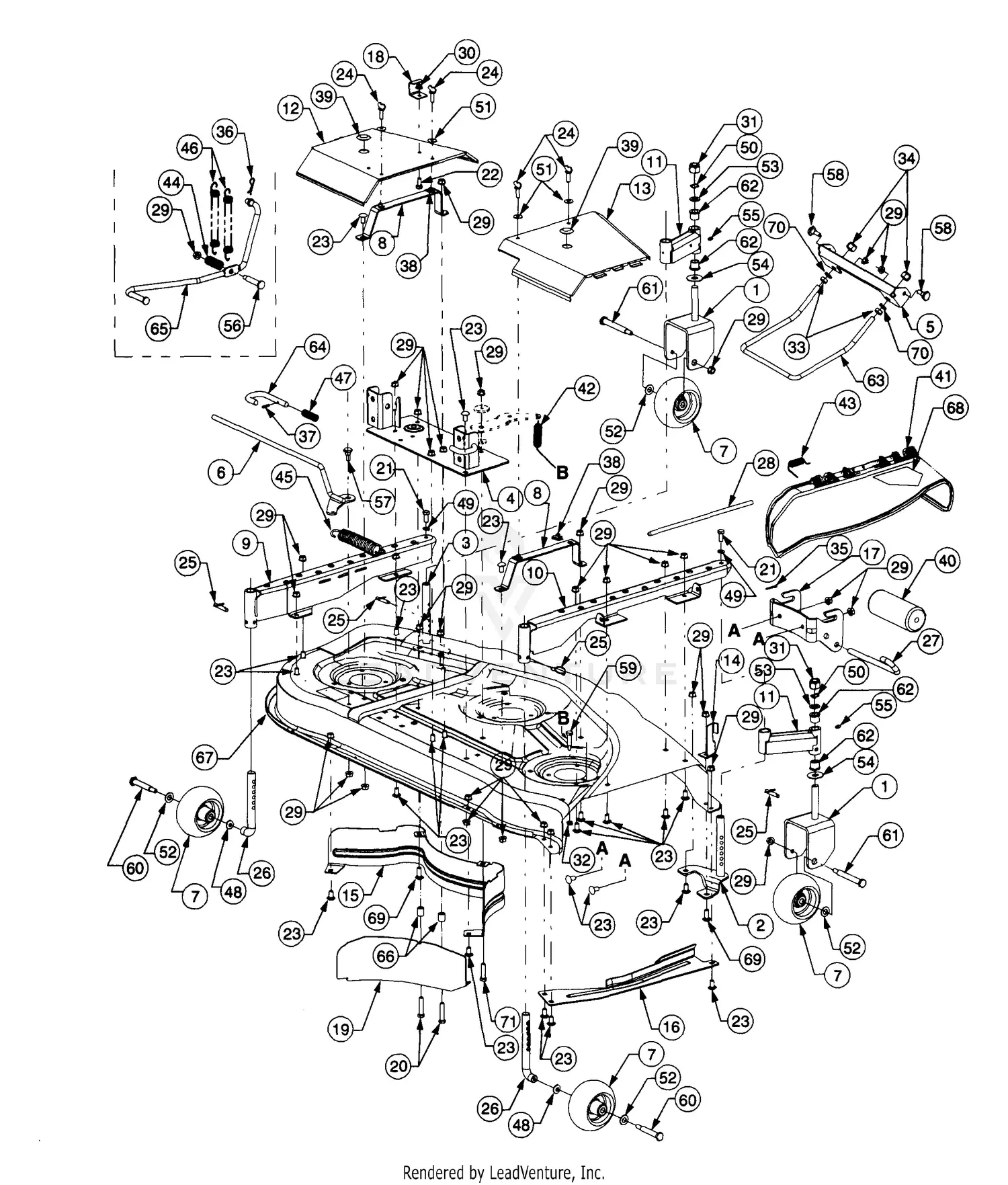

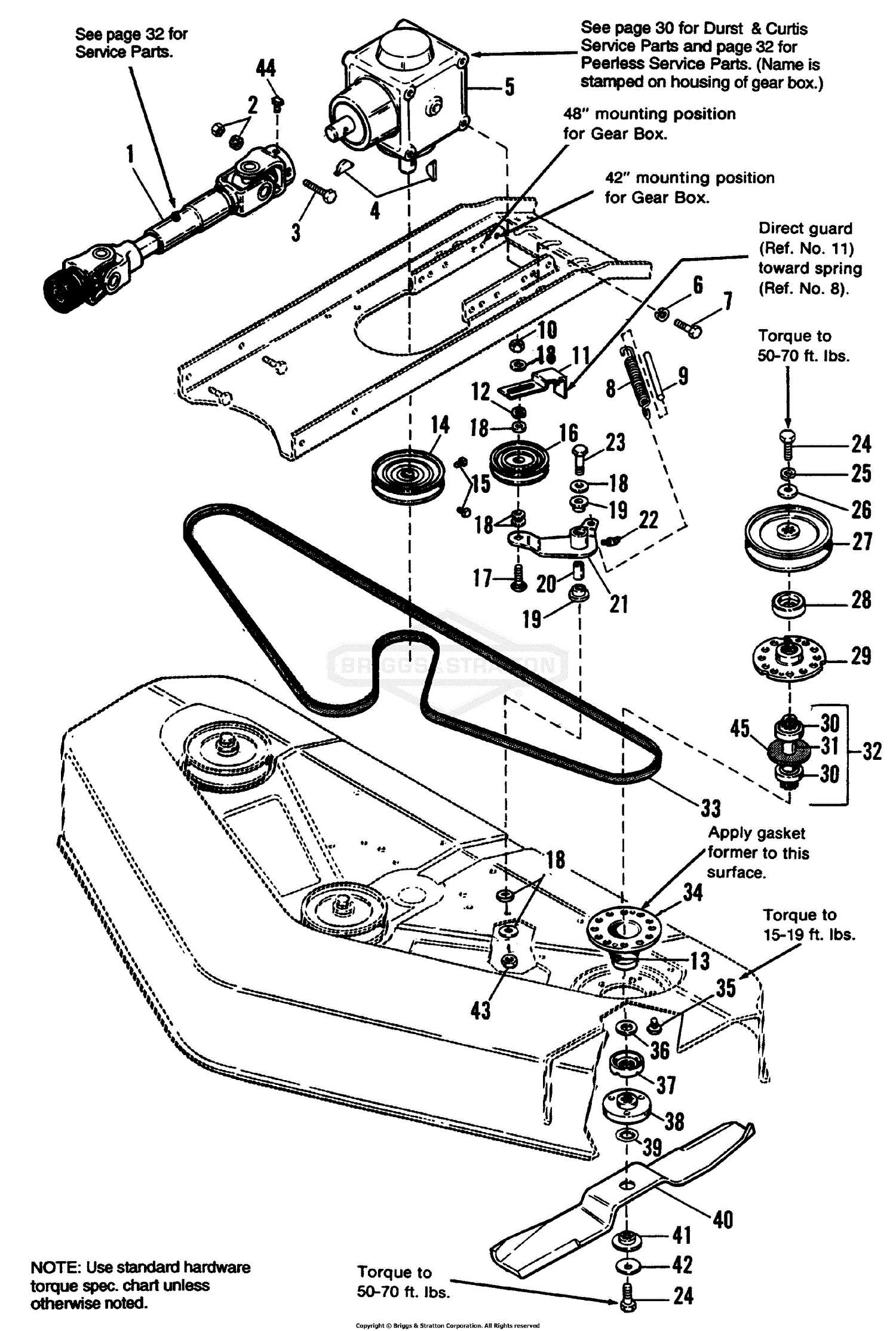

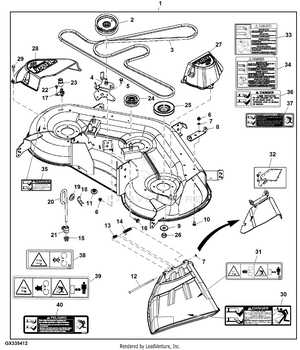

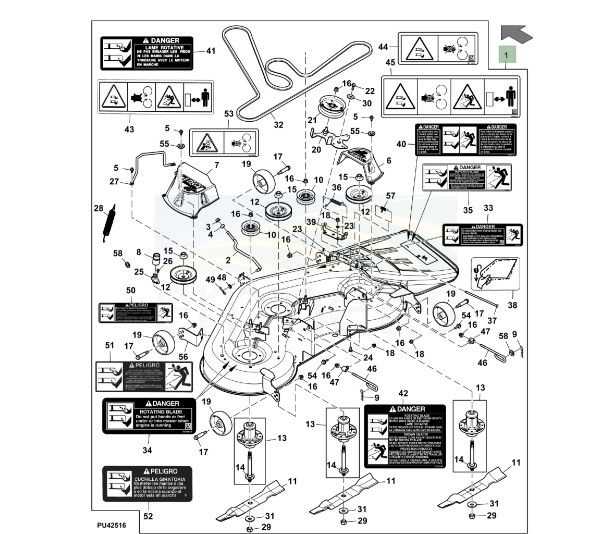

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repairs. These visual representations provide a clear layout of components, helping you identify individual elements and their functions within the overall structure. By familiarizing yourself with the symbols and numbering systems used, you can streamline your approach to troubleshooting and replacement tasks.

Key Elements of an Assembly Illustration

Typically, these visuals include various features that facilitate understanding:

| Feature | Description |

|---|---|

| Labels | Indicate specific components or groups, often accompanied by a reference number. |

| Lines | Connect parts, showing how they interact or fit together. |

| Symbols | Represent different types of components, such as fasteners, electrical connections, or fluid ports. |

| Notes | Provide additional instructions or specifications for assembly or disassembly. |

Interpreting the Information

To effectively use an assembly illustration, start by identifying the main components and their corresponding numbers. Cross-reference these with a parts list or catalog to find the exact items needed for your project. Pay attention to any special notes that may indicate installation methods or required tools. By carefully analyzing the information presented, you can ensure a smoother repair or replacement process.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right instruments is crucial. These tools not only facilitate smoother operations but also enhance safety and efficiency during repairs. A well-equipped toolkit can make a significant difference in the ease and success of any maintenance task.

| Tool | Purpose |

|---|---|

| Socket Wrench | To loosen or tighten fasteners with ease. |

| Screwdriver Set | For driving screws and securing components. |

| Pliers | To grip, twist, or cut wires and small parts. |

| Torque Wrench | To apply precise torque to fasteners. |

| Safety Goggles | To protect eyes during repair tasks. |

Step-by-Step Assembly Guide

This guide provides a clear, sequential approach to assembling essential components for a cutting tool. By following these instructions, you can ensure that all pieces fit together seamlessly, enhancing functionality and performance. Each step is designed to be straightforward, allowing both novices and experienced individuals to navigate the process with ease.

Gathering Required Tools and Components

Before starting the assembly, collect all necessary tools and components. Common tools include a wrench set, screwdriver, and pliers. Make sure you have all the items required for assembly laid out in an organized manner to streamline the process. Checking off each item as you gather it will help prevent missing any crucial elements.

Assembly Process

Begin by securing the main structure, ensuring it is stable and well-supported. Attach the first section by aligning it with the designated mounts and using screws to secure it firmly. Make sure to tighten all fasteners adequately to avoid any loose connections during operation. Continue this process with subsequent sections, referencing your gathered components to match them correctly. After all pieces are connected, perform a thorough inspection to ensure everything is assembled correctly and securely. Testing the unit before full operation is advisable to confirm proper assembly.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the life of your equipment. By implementing a few simple practices, you can ensure that it remains in optimal condition for years to come. This section highlights effective strategies to maintain your machine’s performance and reliability.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Check Oil Levels | Monthly | Use the manufacturer’s recommended oil for best results. |

| Inspect Blades | Every 10 hours of use | Sharpen or replace as needed to ensure efficient operation. |

| Clean Air Filter | Every season | Replace if damaged or excessively dirty to maintain airflow. |

| Check Belts and Cables | Every month | Look for signs of wear and replace as necessary. |

| Wash Exterior | After every use | Remove debris and prevent rusting by using mild soap and water. |

By adhering to these recommendations, you can significantly enhance the efficiency and lifespan of your machine, ensuring that it performs at its best whenever you need it.

Where to Find Replacement Parts

When searching for components to restore your equipment, it’s crucial to explore various sources to ensure you find high-quality alternatives. Whether you prefer online options or local retailers, a wide range of choices is available to meet your needs.

Online Retailers: Numerous websites specialize in selling equipment components. These platforms often provide detailed descriptions and user reviews, making it easier to select the right items.

Local Dealers: Visiting nearby suppliers can offer the advantage of immediate availability. Knowledgeable staff can assist you in identifying suitable replacements tailored to your specific model.

Forums and Community Groups: Engaging with fellow enthusiasts can lead to valuable recommendations for sourcing components. Online communities often share tips on where to find the best deals and trustworthy vendors.

Regardless of the route you choose, always ensure compatibility with your specific machinery to achieve optimal performance.

DIY vs. Professional Repairs

When it comes to fixing machinery, individuals often face the choice between tackling repairs themselves or seeking expert assistance. Each approach has its own advantages and considerations that can impact the outcome of the maintenance process.

- Cost: DIY repairs can save money, while professionals may charge for their expertise.

- Skill Level: Individuals with experience may find it rewarding to handle repairs, but those lacking skills might encounter difficulties.

- Time: DIY projects can be time-consuming, whereas professionals usually complete tasks more efficiently.

- Quality: Experts often provide a higher quality of work, ensuring longevity and performance.

Ultimately, the decision hinges on personal capability, available resources, and the complexity of the task at hand.

Safety Precautions During Maintenance

Ensuring safety during upkeep activities is essential to prevent accidents and injuries. By following specific guidelines, you can protect yourself and others while maintaining equipment.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Disconnect the power source before starting any maintenance tasks to avoid accidental activation.

- Work in a well-ventilated area to reduce the risk of inhaling harmful fumes or dust.

Additionally, it’s important to:

- Keep the work area clean and free from clutter to minimize trip hazards.

- Use the correct tools for the job to avoid injuries caused by improper handling.

- Follow the manufacturer’s instructions closely to ensure safe practices are maintained.

By adhering to these safety measures, you can create a secure environment during maintenance tasks.

Understanding Mower Deck Adjustments

Proper alignment and calibration of cutting equipment are essential for achieving optimal performance and maintaining a healthy lawn. Adjustments can greatly influence the quality of the cut, enhancing both the aesthetics and health of the turf. Recognizing the significance of these modifications will ensure efficient operation and longevity of your equipment.

Key factors in achieving accurate settings include blade height, tilt, and leveling. Each aspect plays a crucial role in determining how evenly the grass is trimmed and how well the machine functions. Below is a summary of the primary adjustments and their impact:

| Adjustment Type | Description | Impact on Performance |

|---|---|---|

| Blade Height | Setting the height at which the blades cut the grass. | Affects the overall appearance and health of the lawn. |

| Tilt Angle | Adjusting the angle of the blades to ensure an even cut. | Prevents uneven wear and promotes consistent trimming. |

| Leveling | Ensuring that the cutting apparatus is level from side to side and front to back. | Ensures uniform grass height across the area, avoiding scalping or missed patches. |

Maintaining regular adjustments will not only enhance the cutting efficiency but also extend the lifespan of the machinery, allowing for a better overall experience during operation.