2011 Ford F250 Front Axle Parts Overview

In the realm of automotive maintenance, comprehending the intricate elements of the suspension system is essential for ensuring optimal performance and safety. A detailed exploration of these components reveals their critical roles in the overall functionality of heavy-duty vehicles, especially in terms of load-bearing capacity and stability on diverse terrains.

The anatomy of suspension systems can be complex, yet it is vital for any vehicle owner or enthusiast to familiarize themselves with these mechanical structures. Recognizing how each piece interacts within the system can aid in diagnosing issues and facilitating effective repairs. A clear representation of these components allows for a better grasp of their arrangement and function.

Through careful examination of various elements, one can appreciate the engineering behind these systems. Identifying specific components and understanding their relationships enhances knowledge and promotes proactive maintenance, ultimately extending the lifespan of the vehicle and improving driving experience.

Understanding the 2011 Ford F250 Axle

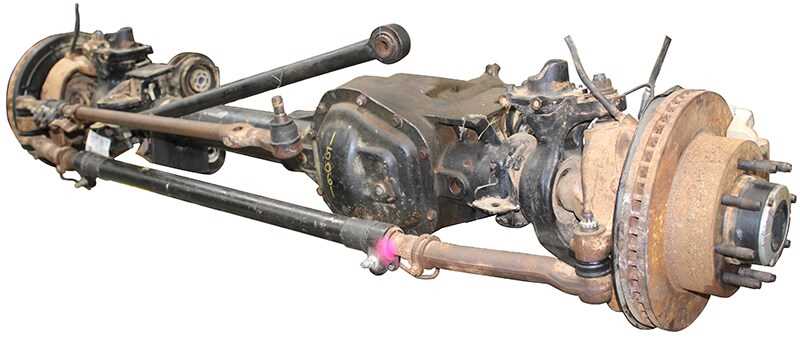

The component in question plays a crucial role in the overall performance and stability of heavy-duty vehicles. It facilitates the transfer of power from the transmission to the wheels, ensuring efficient movement across various terrains. Grasping its structure and function is essential for both maintenance and enhancement of vehicle capabilities.

At its core, this assembly consists of several key elements that work in unison. Each piece contributes to the system’s robustness and resilience under demanding conditions. Regular inspection and timely replacement of worn components can significantly impact the vehicle’s longevity and reliability.

Key components include bearings, shafts, and differentials, each serving a specific purpose. For instance, bearings allow for smooth rotation, while shafts transmit torque effectively. Understanding these roles aids in diagnosing issues and performing necessary repairs.

Overall, familiarity with this assembly empowers vehicle owners and mechanics alike, ensuring optimal performance and safety on the road.

Components of the Front Axle Assembly

The assembly responsible for steering and supporting the vehicle’s weight is crucial for optimal performance and stability. Understanding the various elements involved helps in maintenance and enhances overall driving safety.

- Housing: This durable outer shell encases internal components, providing protection and structural integrity.

- Hub: Serves as the central point for wheel attachment, allowing for rotation and movement.

- Spindles: These shafts connect the hubs to the steering mechanism, enabling directional control.

- Bearings: Critical for smooth rotation, these components reduce friction between moving parts.

- CV Joints: Allow for flexibility and movement while transferring torque to the wheels.

Each of these elements plays a vital role in ensuring the vehicle functions efficiently, contributing to overall handling and maneuverability.

- Regular inspection of components is essential to identify wear and tear.

- Lubrication is important for maintaining the lifespan of bearings and joints.

- Replacing worn parts promptly helps avoid more significant issues down the line.

Common Issues with Front Axles

The assembly responsible for connecting the wheels to the vehicle is crucial for optimal performance and safety. Various problems can arise over time, leading to potential hazards and decreased driving efficiency. Understanding these common issues is essential for maintaining a reliable driving experience.

Worn Bearings

Bearings are vital components that support the rotating parts. When they wear out, they can cause excessive play and noise, leading to further damage in the assembly. Regular inspections can help identify wear early.

Leaking Seals

Seals are designed to keep lubricants in and contaminants out. When these seals fail, it can lead to lubricant loss and contamination, which compromises the entire assembly’s functionality. Addressing leaks promptly can prevent more severe damage.

| Issue | Symptoms | Solutions |

|---|---|---|

| Worn Bearings | Noisy operation, uneven tire wear | Replace bearings, perform regular checks |

| Leaking Seals | Fluid spots under the vehicle, noise | Replace seals, monitor fluid levels |

| Misalignment | Steering issues, uneven tire wear | Realign components, check suspension |

| Cracked Components | Vibration, noise, handling problems | Inspect for cracks, replace damaged parts |

Importance of Regular Maintenance

Routine upkeep is essential for ensuring the longevity and reliability of any vehicle. Neglecting this vital aspect can lead to severe issues, increased repair costs, and compromised safety on the road. A well-maintained vehicle not only performs better but also retains its value over time, making it a wise investment for any owner.

Enhanced Performance

Regular inspections and timely replacements of critical components contribute significantly to optimal functionality. Ensuring that every part operates efficiently minimizes the risk of unexpected breakdowns. This proactive approach helps in identifying potential problems before they escalate, resulting in a smoother driving experience.

Safety Considerations

Prioritizing maintenance directly impacts the safety of the driver and passengers. Well-maintained systems, such as braking and steering, are crucial for preventing accidents. Routine checks can reveal wear and tear that might otherwise go unnoticed, allowing for necessary repairs that enhance overall safety.

Tools Needed for Axle Inspection

Inspecting the rotational component of your vehicle is crucial for maintaining performance and safety. Having the right tools at your disposal makes this task more efficient and effective. Below are essential instruments that can aid in the thorough examination of these mechanical parts.

Basic Hand Tools

Start with fundamental hand tools that are necessary for disassembly and inspection. A wrench set is vital for loosening and tightening various bolts. Additionally, a screwdriver set will help you navigate different types of fasteners. A rubber mallet is useful for gently persuading components that may be stuck, while a torque wrench ensures that all fittings are securely fastened to the manufacturer’s specifications.

Specialized Inspection Equipment

Incorporating specialized equipment can elevate the quality of your inspection. A digital caliper allows for precise measurement of critical dimensions, ensuring that all parts meet necessary standards. A magnifying glass can assist in identifying wear and damage that may not be visible to the naked eye. Lastly, utilizing a fluid leak detector will help spot any potential issues with seals and gaskets, further ensuring that everything is in optimal condition.

Identifying Axle Wear and Damage

Recognizing signs of deterioration and harm in the suspension system is crucial for maintaining vehicle safety and performance. Over time, components may experience stress and fatigue, leading to potential issues that can affect handling and stability. Being aware of the indicators of wear can help in taking timely action to prevent further damage.

Visual Inspection: Start with a thorough visual examination of the suspension components. Look for cracks, rust, or any unusual discoloration on surfaces, which may indicate corrosion or structural failure. Pay attention to any leaks from seals, as these can signal that lubrication is compromised.

Noise and Vibration: Unusual sounds during operation, such as clunking or grinding, can be early warning signs of underlying issues. Additionally, excessive vibrations while driving may suggest imbalance or misalignment, necessitating further investigation.

Movement and Play: Check for any excessive movement in the suspension parts. Use your hands to feel for play in joints and connections. If components can be easily moved or shifted, this could indicate significant wear that requires immediate attention.

Performance Issues: Noticeable changes in handling characteristics, such as pulling to one side or a decrease in ride quality, are often linked to deteriorating components. These performance issues can serve as key indicators of potential damage within the system.

By regularly assessing these aspects, vehicle owners can ensure that any issues are promptly addressed, ultimately extending the lifespan of the suspension system and enhancing overall safety on the road.

Replacing Front Axle Parts: A Guide

Maintaining your vehicle’s stability and performance often involves addressing key components that support the weight and ensure smooth handling. This guide will walk you through the essential steps for swapping out these crucial elements, helping to enhance your driving experience and prolong the life of your machine.

Identifying Components

Before beginning the replacement process, it’s important to familiarize yourself with the various elements involved. Each component plays a vital role in overall functionality, and understanding their positions and interconnections will simplify your task.

| Component | Description |

|---|---|

| Bearings | Support rotational movement and reduce friction. |

| U-joints | Allow for flexibility in the drivetrain while transmitting power. |

| Spindles | Serve as the pivot point for steering and suspension. |

| Hubs | Connect the wheel assembly to the vehicle and facilitate movement. |

Replacement Steps

To successfully replace the necessary components, follow these steps carefully. Begin by lifting the vehicle securely and removing the wheels. Next, disconnect the relevant assemblies, ensuring you keep track of any fasteners for reinstallation. Install the new elements in the reverse order of removal, making sure everything is torqued to manufacturer specifications.

Upgrades for Enhanced Axle Performance

Improving the efficiency and strength of your vehicle’s suspension system can significantly impact its overall handling and durability. Upgrades in this area often focus on enhancing stability, increasing load capacity, and ensuring better traction. By selecting the right components, drivers can achieve a more robust performance, whether for off-road adventures or heavy-duty tasks.

One popular modification involves replacing standard components with heavy-duty alternatives. Upgraded bearings and seals can reduce wear and tear, allowing for smoother operation and longer lifespan. Additionally, utilizing stronger materials in joints and connections enhances the resilience of the system against harsh conditions.

Another effective enhancement is the installation of upgraded differentials. These components can improve power distribution to the wheels, enhancing traction and control, especially in challenging terrains. Performance differentials can provide better locking mechanisms, allowing for improved grip when needed.

Finally, adjusting the suspension geometry with aftermarket kits can optimize the vehicle’s handling characteristics. These adjustments can help maintain alignment and stability, resulting in a smoother ride and better response to steering inputs. Overall, thoughtful enhancements can transform a standard setup into a high-performing system tailored to specific needs.

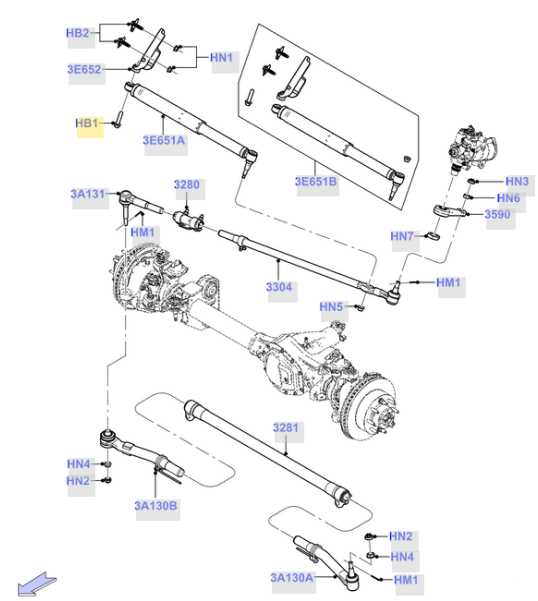

How to Read an Axle Diagram

Understanding the layout of a vehicle’s suspension system is crucial for maintenance and repairs. A well-structured visual representation can provide essential information about the components involved, their connections, and how they function together. This guide will help you interpret such illustrations effectively.

Familiarize Yourself with Symbols: Each diagram uses specific symbols and notations to represent various components. Take the time to learn what these symbols signify, as this will enable you to grasp the overall configuration quickly.

Identify Key Components: Focus on the main elements depicted in the illustration. Look for crucial parts such as the housing, gears, and bearings. Recognizing these components will allow you to understand their roles within the assembly.

Examine Connections: Pay attention to how parts are linked. Lines or arrows often indicate relationships or movements between components. Understanding these connections is vital for diagnosing issues or planning repairs.

Refer to Annotations: Many diagrams include notes or labels that provide additional details. These annotations can clarify complex sections or highlight specific features, making it easier to follow the schematic.

Utilize a Legend: If available, refer to a legend that explains the symbols and notations used in the illustration. This reference can enhance your comprehension and ensure you’re interpreting the information accurately.

By following these steps, you can become proficient in reading technical visuals related to vehicle mechanisms, empowering you to tackle repairs with confidence.

Differences Between Axle Types

Understanding the variations among different types of support structures is crucial for vehicle performance and handling. Each type has unique characteristics that influence factors such as durability, load capacity, and driving dynamics.

Here are the primary categories of these structures:

- Live Axles: These are commonly used in heavy-duty vehicles, providing enhanced strength and stability. They allow for better power distribution to the wheels.

- Dead Axles: Primarily found in non-driving wheels, these structures support the vehicle’s weight but do not provide power to the wheels.

- Independent Suspension Axles: This type allows each wheel to move independently, resulting in improved ride quality and handling, particularly on uneven surfaces.

When considering replacements or upgrades, it’s essential to weigh the pros and cons of each design:

- Performance: Different designs can significantly affect handling, especially in challenging terrains.

- Weight: Variations in weight can impact fuel efficiency and overall vehicle dynamics.

- Maintenance: Some designs require more frequent upkeep, affecting long-term costs.

Ultimately, selecting the right type depends on the intended use of the vehicle, driving conditions, and personal preferences.

Tips for DIY Axle Repairs

Engaging in do-it-yourself repairs can be both rewarding and challenging, especially when dealing with critical components of your vehicle’s drivetrain. Understanding the fundamentals and taking a methodical approach will enhance your chances of success and ensure a safer ride.

1. Gather Necessary Tools: Before starting your project, make sure you have all the required tools at hand. This typically includes wrenches, sockets, a torque wrench, and possibly a jack and jack stands for better accessibility.

2. Study the Repair Manual: Familiarize yourself with the specific procedures outlined in your vehicle’s repair manual. This resource is invaluable and provides step-by-step instructions, torque specifications, and safety precautions.

3. Work on a Level Surface: Always perform repairs on a flat, stable surface to prevent accidents. This ensures that your vehicle remains secure while you work, minimizing the risk of injury.

4. Label Components: As you disassemble parts, label them or take pictures to help remember their original configuration. This practice can save time and frustration during reassembly.

5. Be Mindful of Safety: Wear appropriate safety gear, such as gloves and goggles. It’s essential to protect yourself from debris and sharp edges when working on mechanical components.

6. Take Your Time: Rushing through repairs can lead to mistakes. Take your time to ensure each step is completed correctly, as thoroughness is key to a successful outcome.

7. Test Your Work: After completing the repair, carefully test your vehicle in a controlled environment before taking it on the road. Listen for any unusual sounds and check for leaks to confirm everything is functioning properly.

Finding Quality Replacement Parts

When it comes to maintaining the performance and safety of your vehicle, sourcing high-quality components is crucial. The right replacements not only ensure longevity but also enhance overall functionality. As vehicle systems can be complex, understanding where to find reliable alternatives is essential for any automotive enthusiast or everyday driver.

Researching Reliable Sources

Start by exploring reputable online retailers and local auto parts stores. Look for those that specialize in your specific vehicle model and year. User reviews and ratings can provide insight into the reliability of the components offered. Additionally, manufacturers’ websites often list certified dealers, ensuring that you receive genuine items that meet industry standards.

Evaluating Quality and Compatibility

When considering replacements, always check for compatibility with your vehicle. Verify specifications and compare them with your existing components. Opt for parts that come with warranties or guarantees, as this reflects the manufacturer’s confidence in their quality. Investing time in this process can save you from potential issues down the line.

Understanding Suspension System Interactions

The suspension system of a vehicle plays a crucial role in maintaining stability, comfort, and control. Its various components work together to absorb shocks, manage weight distribution, and enhance overall handling. Understanding how these elements interact can significantly improve driving experience and safety.

Key Components of the Suspension System

- Springs: These provide the primary cushioning effect, absorbing bumps and maintaining vehicle height.

- Dampers: Also known as shock absorbers, they control the oscillation of the springs, ensuring a smooth ride.

- Control Arms: These link the chassis to the wheel assembly, allowing for controlled movement during turns and bumps.

- Stabilizer Bars: These reduce body roll during cornering, enhancing stability.

Interactions Within the Suspension System

The synergy between these components is essential for optimal performance. When one part is affected, it can lead to a chain reaction that impacts the entire system:

- Spring and Damper Coordination: The balance between how much a spring compresses and how quickly a damper reacts is critical for comfort and control.

- Weight Transfer Management: Control arms and stabilizer bars work together to distribute weight effectively, preventing loss of traction during maneuvers.

- Alignment and Handling: Proper alignment of all components ensures even tire wear and maximizes grip on the road.

Recognizing these interactions allows for better maintenance and informed modifications, ultimately leading to improved vehicle performance.